ValCOOL® General Catalog - Metalworking fluids

ValCOOL® General Catalog - Metalworking fluids

ValCOOL® General Catalog - Metalworking fluids

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

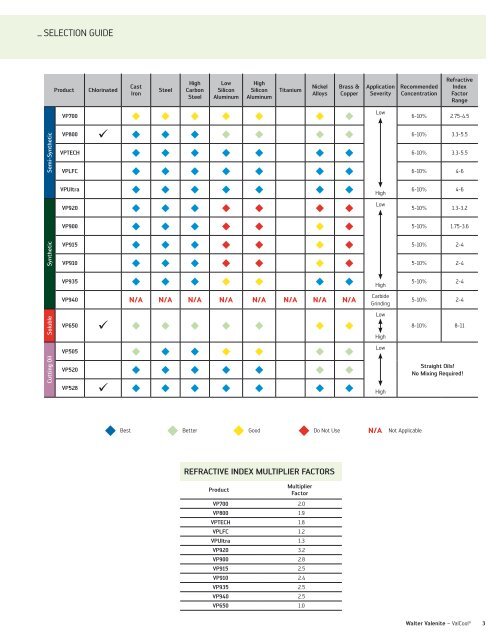

_ Selection GuideProductChlorinatedCastIronSteelHighCarbonSteelLowSiliconAluminumHighSiliconAluminumTitaniumNickelAlloysBrass &CopperApplicationSeverityRecommendedConcentrationRefractiveIndexFactorRangeVP700 u u u u u u uLow6-10% 2.75-4.5Semi-SyntheticVP800 u u u u u u u 6-10% 3.3-5.5VPTECH u u u u u u u 6-10% 3.3-5.5VPLFC u u u u u u u 6-10% 4-6VPUltra u u u u u u u High6-10% 4-6VP920 u u u u u u uLow5-10% 1.3-3.2VP900 u u u u u u u 5-10% 1.75-3.6SyntheticVP915 u u u u u u u 5-10% 2-4VP910 u u u u u u u 5-10% 2-4VP935 u u u u u u u High5-10% 2-4VP940 N/A N/A N/A N/A N/A N/A N/A N/ACarbideGrinding5-10% 2-4SolubleVP650 u u u u u u uLowHigh8-10% 8-11VP505 u u u u u u uLowCutting OilVP520 u u u u u u uStraight Oils!No Mixing Required!VP528 u u u u u u u Highu Best u Better u Good uDo Not Use N/A Not ApplicableRefractive Index Multiplier FactorsProductMultiplierFactorVP700 2.0VP800 1.9VPTECH 1.8VPLFC 1.2VPUltra 1.3VP920 3.2VP900 2.8VP915 2.5VP910 2.4VP935 2.5VP940 2.5VP650 1.0Walter Valenite – ValCool ® 3

_ PRODUCT OVERVIEWSemi-SyntheticThe lubricity of a soluble with the cooling and stability characteristics of a full synthetic.Product Description Characteristics BenefitLightDutyVP700• <strong>General</strong>-purpose for light to medium machining• Chlorine-free• Vapor phase inhibition• Most cost-effective semi-synthetic• Meets specific regulatory requirements• Less re-work, machine maintenance• Higher value at a lower costVP800• Heavy-duty chlorinated general purpose fluid• Superior lubrication package• Vapor phase inhibition• Increased tool life and improved surface finish• Less re-work and machine maintenanceVPTech• Heavy-duty non-chlorinated general purposefluid• Chlorine-free• Superior lubrication package• Meets specific regulatory requirements• Increased tool life and improved surface finishVPLFC• Heavy-duty non-chlorinated general purposefluid with low-foaming tendencies in allapplications• Chlorine-free• Low-foaming in all applications• Meets specific regulatory requirements• Increased tool life and improved surface finish• Low foaming fluid offers performance even inhigh pressure systemsHeavyDutyVPUltra• Heavy-duty non-chlorinated general purposefluid• Excellent bio-resistance• Excellent emulsion stability• Prolonged sump life• Increased tool life• Improved Surface finishValCOOL ® products not recommended for use with magnesium. Material safety data sheets available at www.walter-tools.com/us4

_ PRODUCT OVERVIEWSyntheticFormulated for high speed applications, our synthetics provide the highest level of cooling and stability.Product Description Characteristics BenefitLightDutyVP920• <strong>General</strong>-purpose synthetic for grinding and lightmachining• Most economical synthetic• Chlorine-free• Low-cost, high value• Meets specific regulatory requirementsVP900• <strong>General</strong>-purpose synthetic• Excellent corrosion package• Chlorine-free• Meets specific regulatory requirementsVP915• <strong>General</strong>-purpose synthetic• Moderate corrosion package• Chlorine-free• Protects machine and finished parts• Meets specific regulatory requirementsVP910• Heavy duty synthetic for machiningand grinding• Designed for a wide range of applications• Chlorine-free• Less inventory of <strong>fluids</strong>• Meets specific regulatory requirementsHeavyDutyVP935• Heavy-duty multi-purpose synthetic• Chlorine-free• Unique extreme pressure package• Meets specific regulatory requirements• Suitable for aerospace applicationsCarbideGrindingVP940• Heavy-duty multi-purpose synthetic• Chlorine-free• Special cobalt leaching inhibitors• Unique extreme pressure package• Meets specific regulatory requirements• Prevents cobalt leaching for carbide grinding• Suitable for aerospace applicationsValCOOL ® products not recommended for use with magnesium. Material safety data sheets available at www.walter-tools.com/us6

_ PRODUCT OVERVIEWSoluble OilProvides the highest level of lubrication and excellent rust control.Product Description Characteristics BenefitLightDuty• Premium heavy-duty chlorinated soluble oil• Contains a synthetic ester that enhances biostabilityand corrosion protection• Increased tool life, surface finish and sump lifeVP650HeavyDutyProduct Offering - United StatesSoluble OilPart Number Description/Container Material #VP650-005B 5 Gal VP650 Blue 5506862VP650-005U 5 Gal VP650 Undyed 5506863VP650-055B 55 Gal VP650 Blue 5506864VP650-055U 55 Gal VP650 Undyed 5506865VP650-220B 220 Gal VP650 Blue 5506866VP650-220U 220 Gal VP650 Undyed 5506867VP650-275B 275 Gal VP650 Blue 5506868VP650-275U 275 Gal VP650 Undyed 5506869Product Offering - Canada and MexicoSoluble OilPart Number Description/Container Material #VP650M019B 19 Litre VP650 Blue 5854173VP650M019U 19 Litre VP650 Undyed 5854174VP650M205B 205 Litre VP650 Blue 5854177VP650M205U 205 Litre VP650 Undyed 5854178VP650M820B 832 Litre VP650 Blue 6121372VP650M820U 832 Litre VP650 Undyed 6121373ValCOOL ® products not recommended for use with magnesium. Material safety data sheets available at www.walter-tools.com/us8

_ PRODUCT OVERVIEWCutting OilProduct Description CharacteristicsLightDutyVP505• Grinding and light machining oil• Clear, pale yellow color• Mild odor• Designed for grinding ferrous and non-ferrous materials• Chlorine-free• No active sulfur• Screw machine oil• Designed for screw machines, drilling, turning and other moderatelyaggressive machining applicationsVP520• May be used in medium duty machining and grinding• Will not discolor yellow metals• Low odor• No active sulfur• Clear, pale amber color• Can be used in all materials• Chlorine-free• Heavy duty machining oil• Can be used for gear hobbing, shaping, broaching and other moderatelyaggressive machining applicationsHeavyDutyVP528• Clear, brown color• Mild sulfur odor• Non-active sulfur• ChlorinatedProduct Offering - United StatesCutting OilPart Number Description/Container Material #VP505-005U VP505 / 5 Gal Undyed 5562906VP505-055U VP505 / 55 Gal Undyed 5562907VP505-220U VP505 / 220 Gal Undyed 5562908VP505-275U VP505 / 275 Gal Undyed 5562909VP520-005U VP520 / 5 Gal Undyed 5562950VP520-055U VP520 / 55 Gal Undyed 5562951VP520-220U VP520 / 220 Gal Undyed 5562952VP520-275U VP520 / 275 Gal Undyed 5562953VP528-005U VP528 / 5 Gal Undyed 5562954VP528-055U VP528 / 55 Gal Undyed 5562955VP528-220U VP528 / 220 Gal Undyed 5562956VP528-275U VP528 / 275 Gal Undyed 5562957Product Offering - Canada and MexicoCutting OilPart Number Description/Container Material #VP505M019U VP505 / 19 Litre Undyed 5854157VP505M205U VP505 / 205 Litre Undyed 5854158VP520M019U VP520 / 19 Litre Undyed 5854159VP520M205U VP520 / 205 Litre Undyed 5854161VP520M820U VP520 / 832 Litre Undyed 6119287VP522M019U VP522 / 19 Litre Undyed 5854162VP522M205U VP522 / 205 Litre Undyed 5854163VP528M019U VP528 / 19 Litre Undyed 5854164VP528M205U VP528 / 205 Litre Undyed 5854166VP528M820U VP528 / 1000 Litre Undyed 6121371Material safety data sheets available at www.walter-tools.com/us

_ PRODUCT OVERVIEWSpecialty FluidsProduct Description Directions Packaging & LiteratureVALTAPLiquid tapping compound• Contains extreme pressure lubricants, whichform a solid lubricant between the chip and thetool, eliminating chip welding and broken taps• Use in undiluted form. Apply directly to theworkpiece material before or during the tappingoperation• Caution: Avoid prolonged contactPackaging:• 5 gal. (19 liter) pails• 55 gal. (205 liter) drums• Case of (12) 16-oz. squirt bottles• Effective on both ferrous andnon-ferrous materials• May cause staining of some aluminum alloysProduct Offering - United StatesSpecialty FluidsPart Number Description/Container Material #VSFTAP-005B Valtap-Blue / 5 Gal. Pail 5507994VSFTAP-055B Valtap-Blue / 55 Gal. Drum 5478332VSFTAP-220B Valtap-Blue / 220 Gal. Bulk-Con 5478333VSFTAP-CASE12B Valtap-Blue / Case Of 12 Bottles 5507995Product Offering - Canada and MexicoSpecialty FluidsPart Number Description/Container Material #VSFTAP160Z VALTAP-Blue / 16 oz. Bottle 5854155VSFTAPMO19B VALTAP-Blue / 19 Litre Pail 5854156VSFTAPCASE12B VALTAP-Blue / Case of 12 Bottles 5507995“Truck-load” shipment of some of these ValCOOL ® products available on a quotation basis.10

_ PRODUCT OVERVIEWCleanersProduct Description Directions Packaging & LiteratureVAL-U-CLEAN ® VPAll-purpose alkaline cleaner• Contains a biocide that helps eliminate lingeringbacteria, especially during a machine toolclean-out, for a fresh cutting fluid charge• Includes a rust inhibitor to protect the machinetool from corrosion during the cleaning process• Use to clean the machine tool and sump for anew cutting fluid charge, or use as a generalpurpose shop cleaner• Use at a 2% – 5% dilution with water,depending on the severity of the cleaning joband cleaning timePackaging:• 5 gal. (19 liter) pails• 55 gal. (205 liter) drums<strong>General</strong>-purpose, nitrite free, alkaline,synthetic cleaner• Contains corrosion inhibiting ingredients toprotect machines and parts from rust duringcleaning process• Use at a 2% - 5% dilution with water, dependingon the severity of the cleaning job and cleaningtime• May stain some aluminumPackaging:• 5 gal. (19 liter) pails• 55 gal.(205 liter) drumsVAL-U-CLEAN ® K5• Suitable for use with all <strong>fluids</strong>• Recommended for cleaning individual machinesand central systems• Handles the toughest cleaning jobs, such asdecontaminating and removing insoluble soapsfrom dirty central systems in hard water areasProduct Offering - United StatesCleanersPart Number Description/Container Material #VCLVP-005U 5 Gal Machine Cleaner VP 5501877VCLVP-055U 55 Gal Machine Cleaner VP 5501878VCLK5-005U 5 Gal Machine Cleaner K5 5501872VCLK5-055U 55 Gal Machine Cleaner K5 5501873Product Offering - Canada and MexicoCleanersPart Number Description/Container Material #VCLVPM019U Machine Cleaner-Undyed / 19 Litre Pail 5854151VCLVPM205U Machine Cleaner-Undyed / 205 Litre Drum 5854152VCLK5M019U Machine Cleaner K5 30-Undyed / 19 Litre Pail 5854150ValCOOL ® products not recommended for use with magnesium. Material safety data sheets available at www.walter-tools.com/usWalter Valenite – ValCool ® 11

_ PRODUCT OVERVIEWAdditivesProduct Description Directions Packaging & LiteratureFOAMDEPRESSANT130Water conditioner• Prevents foam problems• Can be added to soft water (less than 100 ppm hardness) ineither individual machines or central system reservoirs.• Before using, run a water analysis to determine hardness.Recommended dilution is 1:2000 (0.05%) to 1:5000 (0.02%)• Excessive use may cause hard water scum, or may cause theemulsion to become unstable• Not recommended for use with ValCOOL ® synthetic <strong>fluids</strong>Packaging:• 5 gal. (19 liter) pails• 55 gal. (205 liter) drumsGROTAN ®Broad spectrum bactericide and fungicide• Eliminates existing mold and bacteria inmetalworking fliuds• Add directly to the clean side of the cutting fluid mix at a ratioof 10 oz. to every 50 gallons of cutting fluid mix. Coolant mustbe 8.5 ph or higher• Caution: Consult a Walter Valenite representative before usingPackaging:• 10 lb. (4.5 Kg) container or1 gal. (3.8 liter)• 45 lb. (20.25 Kg) pail or5 gal. (19 liter)• 500 lb. (225 Kg) drum or55 gal. (205 liter)VAL-U-ADD ®AF VPNon-silicone defoamer• Temporarily controls excessive foam inmachines• Add directly to the clean side of the cutting fluid mix at a ratioof 1 ounce per 200 gallons of cutting fluid mix• Caution: Consult a Walter Valenite representative before usingPackaging:• 5 gal. (19 liter) pails• 55 gal. (205 liter) drumsVAL-U-ADD ®PH VPpH adjuster• Used to raise the pH in ValCOOL ® cutting fluidmixes• Add directly to the clean side of the cutting fluid mix at a ratioof 1:1000 (.1%) to 1:2000 (0.05%)• Caution: Consult a Walter Valenite representative before usingPackaging:• 5 gal. (19 liter) pails• 55 gal. (205 liter) drumsVAL-U-ADD ®CO VPAdditve to replenish cobalt corrosioninhibitor levels• Exclusively for use with VP940• Add to ValCOOL ® VP-940 to prevent cobalt corrosion• Add to the clean side of the sump at a ratio of 13 oz. per 50gallonsPackaging:• 5 gal. (19 liter) pails• 55 gal. (205 liter) drumsADDITIVE17Lubricant enhancer• Designed to increase the lubricity of ValCOOL ®cutting fluid for exceptionally difficultapplications• Add directly to the clean side of the cutting fluid mix at a ratioof 8 oz. per 125 gallons of sump capacityPackaging:• 5 gal. (19 liter) pail• 55 gal (205 liter) drumsProduct Offering - United StatesAdditivesPart Number Description/Container Material #VADAFVP-005U 5 Gal Anti-Foam VP 5501527VADAFVP-055U 55 Gal Anti-Foam VP 5501528VADFD130VP-005U 5 Gal Foam Depress 130 VP 5501531VADFD130VP-055U 55 Gal Foam Depress 130 VP 5501532VADGT-001U Grotan ® Biocide / 10 Lb. Container 5501533VADGT-005U Grotan ® Biocide / 45 Lb. Pail 5501534VADPHVP-005U 5 Gal Ph Enhancer VP 5501536VADPHVP-055U 55 Gal Ph Enhancer VP 5501537VADCOVP-005U 5 Gal Cobalt Inhibitor 5501529VADCOVP-055U 55 Gal Cobalt Inhibitor 5501530VAD17-005U 5 Gal. Lube Additive 17 5501525Product Offering - Canada and MexicoAdditivesPart Number Description/Container Material #VADAFVPM19U Anti-Foam-Undyed / 19 Litre Pail 6236523VADAFVPM205U Anti-Foam-Undyed / 205 Litre Drum 6236524VADFD130VPM019U Foam Depressant 130-Undyed / 19 Litre Pail 5854019VADFD130VPM205U Foam Depressant 130-Undyed / 205 Litre Drum 6236525VADGTM004U Grotan ® Biocide-Undyed / 4.5kg Pail 6236526VADGTM020U Grotan ® Biocide-Undyed / 20kg Pail 6236527VADPHVPM019U Val-U-Add pH Adjusting-Undyed / 19 Litre Pail 6236528VADPHVPM205U Val-U-Add pH Adjusting-Undyed / 205 Litre Drum 6236529VADCO-VPM019U Cobalt Leaching Inhibitor/19 Litre Pail 6236581VADCO-VPM205U Cobalt Leaching Inhibitor/205 Litre Drum 6236582VAD17M019U Lube Additive / 19 Litre Pail 5854017“Truck-load” shipment of some of these ValCOOL ® products available on a quotation basis.12

_ TECHNICALTrouble ShootingProblem Causes Solutions See Details• Concentration too high • Adjust concentration* 1• Machine cleaner in sump • Check pH level 3• Allow machine to run, cleaner should dissipate* –Foaming• Mechanical (crack in hose, sump level too low, crackin pump, pump pressure too high) Restricted Intake• Check machinery and repair as required–• Soft water • Sample water, treat if necessary –• High tramp oil content• Skim off oil*• Check hydraulic lines for leaks, and repair as required4• Equipment design • Check system for point of agitation –Problem Causes Solutions See Details• Concentration too low• pH too low• Adjust concentration* 2• Adjust pH level 3Rusting• Poor mixing (soluble oil) • Add concentrate to water* 1• High tramp oil content• High bacteria count• Skim off oil* 4• Check hydraulic lines for leaks, and repair as required 4• Dump, clean and recharge system –Problem Causes Solutions See Details• Concentration too low • Adjust concentration* 1• Wrong product being used • Contact Walter Valenite at 800-945-554 for information –• Large amounts of biocide added to sump or system • Contact Walter Valenite at 800-945-554 for information –PoorTool Life• High tramp oil content • Skim off oil* 4• Check hydraulic lines for leaks, and repair as required 4• Air In coolant • Check for mechanical problems –• Incorrect application • Make sure coolant is directed at tool –Problem Causes Solutions See Details• Low concentration • Adjust concentration* 1• Low pH • Check pH then contact Walter Valenite representative for further instructions 3Odor• High tramp oil content • Skim off oil* 4• Check hydraulic lines for leaks, and repair as required 4• Contamination • Submit cutting fluid sample to a Walter Valenite representative –• Chips and swarf build-up • Thoroughly clean sump and machine, and fill with fresh fluid –*Refer to fluid maintenance Tips & Techniques on page 18-19.16

_ TECHNICALTrouble ShootingProblem Causes Solutions See Details• High concentration • Adjust concentration* 1 5• High pH • Check pH then contact Walter Valenite representative for further instructions 3 5• High tramp oil content • Skim off oil* 4 5SkinIrritation• Check hydraulic lines for leaks, and repair as required 4 5• Dirty shop cloths • Use only clean cloths –• Allergies • Have workers checked for allergies and contact physician if necessary –• Out-of-shop influences • Check pH then contact Walter Valenite representative for further instructions 3Problem Causes Solutions See Details• High concentration • Adjust concentration* 1• High tramp oil content • Skim off oil* 4Residuein Machine• Check hydraulic lines for leaks, and repair as required 4• Incorrect mixing • Submit cutting fluid sample to a Walter Valenite representative 1• High misting operations • Check ventilation system –• Adjust coolant nozzle(s) –*Refer to fluid maintenance Tips & Techniques on page 18-19.Solution Details Products to Use Part #1Efficiently mix coolant concentrates with water.• Always add concentrate to water, never the other way. Mix by hand,or with a slow speed mechanical agitator.• Accudose Mix Station for “charging” and “make-up” dilutionsPT-997PT-797PT-798PT1100• Check pH level• Coolant MixerPT-11002Check fluid concentration• Checking concentration is one of the most important maintenancefunctions.• Refractometer, a hand-held instrument to measure actual mixconcentration.PT-7953Check fluid mix pH• pH control is critical to maximizing fluid life and performance.Optimum pH range - 8.8 to 9.2.• Electronic pH Meter.• pH Test Strips to measure <strong>fluids</strong> in the 8.0 to 9.7 range.PT-796PT-8204Control tramp oil• Check and maintain your machines on a regular schedule• Use extreme care in lubricating or filling hydraulic systems• Sidewinder Skimmer for accesss to impaired sumps.• Smart Skimmer with integral gravity separator.• Belt Skimmers• Belt Skimmers Diverter only.• Standard Skimmer• PT-1042• PT-1043• PT-1044• PT-1045• PT-8215Control bacteria growth• Add oxygen to the sump to kill anaerobic bacteria• Keep sumps clean.Maintain proper cutting fluid concentration and pH• Remove tramp oil• Oxygenator• Refractometer• PT-1047• PT-795Walter Valenite – ValCool ® 17

_ TECHNICALFluid Maintenance Tips & TechniquesCare and Handling of ValCOOL ® ProductsAs with all cutting <strong>fluids</strong>, proper care and handling of ValCOOL ® products involvesseveral important factors, including storage, mixing, bacteria control, tramp oilcontrol, application to the cutting zone, and proper disposal. If you read and followthis list of care and handling recommendations, you will maximize the safety, lifeand usefulness of all your ValCOOL ® cutting <strong>fluids</strong>.Storage––Store in clean sealable drums, clearly marked, protected from frost or sunlight,and preferably indoors.––Have adequate ventilation and fire extinguishers in the storage area.––Clean up spills with inert, mineral absorbent materials.––Keep strong oxidizing agents out of the storage area.––Do not use sawdust or oily cotton waste for spill control.Water Hardness––Water hardness is a measure of the amount of inorganic salts (calcium andmagnesium) in the water.––Reacts with lubricants to produce soap scum.––Reacts with cutting <strong>fluids</strong> to break down the emulsion.––Water treatment methods are advisable.Water TypeWater Hardness ChartParts PerMillionGrains(1GR=17PPM)Soft 0-50 0-3Moderately Soft 50-100 3-6Slightly Hard 100-150 6-9Moderately Hard 150-200 9-12Hard 200-300 12-18Very Hard Over 300 Over 18Bacteria ControlBacteria feed on the fatty components, corrosion inhibitors and other componentsof the emulsion, which causes a chemical change that makes the emulsion moreacidic.Foul sulfide odors are produced in the low oxygen emulsions.To reduce bacteria growth, use an aerator, keep the sump clean, maintain properconcentration, remove surface or tramp oil, and add biocides.Mixing Water-Dilutable Concentrates––The oil concentrate must be added to the water. (Remember: OIL = Oil-In-Last)––Measure the water into a clean tank.––Measure the required volume of concentrate and gradually pour it into the water.––Keep mixing while pouring.––A slow speed mechanical agitation is preferred.––Use a suitable mixing unit or proportioner.Material safety data sheets available at www.walter-tools.com/us18

_ TECHNICALFluid Maintenance Tips & TechniquesControl of Tramp Oil––Employ regular checks and proper maintenance of machinery.––Use care when lubricating or filling up hydraulic systems.––Use of oil wheel and belt skimmers is advisable.Debris and Dirt––In machine tools, basic sieves and traps are usually sufficient, larger swarf separatesout by gravity.––Special systems may be required for cleaning grinding debris, dirt, and suspendedmaterials from high finish applications.Disposing of <strong>Metalworking</strong> Fluids––It is crucial to fully comply with federal, state and local regulations.––Methods used to treat waste <strong>fluids</strong> depend on the type of product.––In water dilutable coolants, the water (90-95% of volume) can be removed and theremaining solids are disposed.––Wastewater treatment is divided into three tiers:Primary, Secondary, and Tertiary stages• Primary: removing free oil (skimming) and suspended solids(filtration and settling)• Secondary: ultrafiltration (cross-flow to remove oil and solids), chemicaltreatment (most common way to split <strong>fluids</strong> - aluminum sulfate)• Tertiary (carbon filtration and reverse osmosis)Delivery to the Cutting Zone––Trouble spots to check include:• State of the cutting fluid• Flow rate• Accurate delivery to the cutting zone• Machining speed• Condition of the cutting tool• Sump size––Proper fluid flow is:2.5 - 3.0 gal. per min. per H.P.Material safety data sheets available at www.walter-tools.com/usWalter Valenite – ValCool ® 19

_ CLEAN-OUT PROCEDURECentral System and Individual Machine ReservoirsClean metalworking fluid performs better and lasts longer than dirty or contaminated fluid. When recharging an individualmachine or central system fluid tank, a proper clean-out of the tank is necessary. A thorough cleaning will allow the freshcharge of metalworking fluid to perform with maximum efficiency. If not removed, the metal swarf, oil, mold and bacteria willcause deterioration of the fresh mix. The following clean-out procedure should be used whenever possible.Preferred Clean-Out Procedure1. Drain the central system or individual tank completely.2. Remove all metal swarf and debris from sumps, return trenches, oil pans, and filtration units.3. Fill the machine with water and circulate through all lines and machines. Warm water is desirable, but is notabsolutely necessary.4. Add Val-U-Clean ® cleaner at 2-4% and circulate for 4 to 8 hours. As the cleaner circulates,clean all chip conveyers, screens, pans, and enclosed areas. DO NOT ADD BLEACH OR OTHER HOUSEHOLDCLEANERS. This will cause rusting and shorten the life of the coolant. If the coolant has a large amount ofbacterial growth, a biocide can be added to the cleaner and flushed through the system.5. It is suggested to steam clean areas where suspected accumulation of swarf and oil may not have beenremoved by the cleaner.6. After the cleaning is complete, drain the Val-U-Clean ® mix from the system.7. Refill with fresh water and circulate throughout the system or tank(s) to flush all traces of cleaner andswarf from the system. Drain all lines and sumps. If the rinse water is exceptionally dirty, rinse a secondtime8. Charge the system with fresh water.9. Add enough ValCOOL ® concentrate to reach the recommended concentration.10. Circulate through the system to insure proper mixing.Alternate Clean-out ProcedureWith Used Fluid- During ShutdownAfter production stops, add one gallon Val-U-Clean ® to each 50 gallons of dirty fluid in the machine reservoir or central system.Circulate the mixture for 4 hours or longer through all lines and machine tools. Drain, rinse, and recharge with a fresh ValCOOL ® mix.WARNING! Val-U-Clean ® is alkaline. Protective gloves and safety glasses should be worn by maintenance personnelduring this operation. Prolonged contact with the skin may cause irritation.20