Fiberfrax® Fraxfil™ and Fraxfil H™ - SIG Technical Insulation

Fiberfrax® Fraxfil™ and Fraxfil H™ - SIG Technical Insulation

Fiberfrax® Fraxfil™ and Fraxfil H™ - SIG Technical Insulation

- TAGS

- fraxfil

- technical

- insulation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

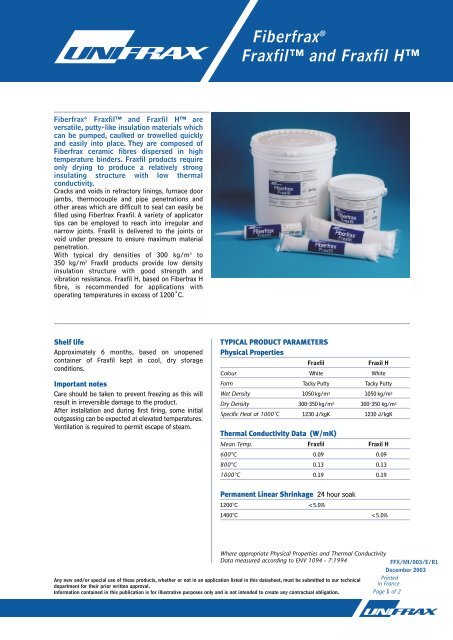

Fiberfrax ®<strong>Fraxfil</strong> <strong>and</strong> <strong>Fraxfil</strong> HTypical Applications• Hot or cold patch repair of boiler insulation• Hot or cold patch repair of refractoryback up insulation• Furnace door frames <strong>and</strong> jamb seals• <strong>Insulation</strong> of furnace penetrations(e.g. tubes, tube hangers <strong>and</strong> thermocouples)• Hot or cold repair of heat leaks around burner blocks<strong>and</strong> sight windows• Caulking of refractory cracks <strong>and</strong> expansion jointsAvailability<strong>Fraxfil</strong> <strong>and</strong> <strong>Fraxfil</strong> H products are available in 5 kg <strong>and</strong> 20 kgpails, in 300 g cartridges <strong>and</strong> in 600 g <strong>and</strong> 1500g sachets.Normally the 5 kg pail is used for trowelling, the 20 kg pailfor pumping <strong>and</strong> the 300 g cartridge for caulking. The 600g<strong>and</strong> the 1500 g sachets are supplied for use with either airor h<strong>and</strong> operated applicator tools.The material in the 20 kg pail is supplied pre-packed in aplastic bag for ease of transfer to a separate straight-sidedpail for use with the recommended pump unit. This isessential for a successful pumping operation.Installation & drying procedures<strong>Fraxfil</strong> can easily be installed by using the approvedequipment. Details of recommended pump units,applicator tools <strong>and</strong> caulking guns are available uponrequest from Unifrax local sales offices.When installed by pumping into ‘hot spot’ areas onboilers or furnace casings, a st<strong>and</strong>ard pipe connection isnormally used to which the pump unit is joined.Installation of the fitting is achieved by drilling the casing<strong>and</strong> welding or screwing the fitting into place. Subject tothe size of hot spot area to be filled, fittings positioned0.6 to 1.2m apart will ensure proper filling of the void.Always commence the pumping operation at the bottomlevel of the void.Typically, when pumping <strong>Fraxfil</strong> into blind areas or voidssuch as behind boiler <strong>and</strong> furnace refractory linings orinto refractory joints <strong>and</strong> cracks, it will air dry over aperiod of time. However, air drying is a slow processeven under ideal conditions.Since the dryingcycle is not critical, firingor heat up of the equipmentor furnace willremove the water quicklyfrom the <strong>Fraxfil</strong> material.Supplied by:H<strong>and</strong>ling InformationA Material Safety Data Sheet has been issued describingthe health, safety <strong>and</strong> environmental properties of thisproduct, identifying the potential hazards <strong>and</strong> givingadvice on h<strong>and</strong>ling precautions <strong>and</strong> emergencyprocedures. This must be consulted <strong>and</strong> fully understoodbefore h<strong>and</strong>ling, storage or use.Contact numbersWebsite: www.unifrax.comUnited KingdomTel:+44 (0) 1744 88 7600 Fax:+44 (0) 1744 88 9916FranceTel:+33 (0) 4 77 73 98 25 Fax:+33 (0) 4 77 73 39 91GermanyTel:+49 (0) 211 87 746 0 Fax:+49 (0) 211 87 746 115BelgiumItalySpainTel:+32 (0)2 761 23 12 Fax:+32 (0)2 761 23 13Tel:+39 02 96701808 Fax:+39 02 9625721Tel: +34 91 395 22 79 Fax:+34 91 395 21 24Information contained in this publication is for illustrative purposes only <strong>and</strong> is not intended to create any contractual obligation.Further information <strong>and</strong> advice on specific details of the products described should be obtained in writing from a Unifrax Corporation company (Unifrax Benelux, UnifraxEspaña, Unifrax France, Unifrax GmbH, Unifrax Italia, Unifrax Limited).Unifrax maintains a continuous programme of product development <strong>and</strong> reserves the right to change product specifications without prior notice.Therefore, it maintains at all times the responsibility of the customer to ensure that Unifrax materials are suitable for the particular purpose intended.Similarly, insofar as materials not manufactured nor supplied by Unifrax are used in conjunction with or instead of Unifrax materials, the customer shouldensure that all technical data <strong>and</strong> other information relating to such materials has been obtained from the manufacturer or supplier. Unifrax accepts noliability arising from the use of such materials.All sales made by a Unifrax Corporation company are subject to that company’s Terms <strong>and</strong> Conditions of Sale, copies of which are available on request.FFX/MI/003/E/R1December 2003Printedin FrancePage 2 of 2