Grease separator

Grease separator

Grease separator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

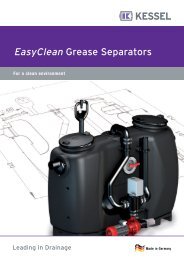

Euro-Norm grease <strong>separator</strong>s FROM KESSEL<strong>Grease</strong> SeparatorsPolyethylene grease <strong>separator</strong>s according to EuroNorm EN 1825Leading in drainage

Where grease is present...KESSEL is there!Reasons for installing grease separation sytemsOperations from small restaurants to large scale food processing plants disposing grease, oils and fats into public wastewater drainagesystems are becoming an increasing concern to industry, government and environmental agencies.Wastewater travels a long distance from its original source to the wastewater treatment facilities. During this time large amounts of grease andfood wastes build up on the interior drainage pipe walls.Avoiding a pipeblockagePrevention ofcorrosion and odourbuild-upNegative effects onwastewatertreatment facilitiesThe solution is here - The KESSEL Euro-SeparatorKESSEL’s design based on EN 1825-1 and state of the art manufacturing provide grease separation systems surpassing all needs ofthe industry. The <strong>separator</strong>s are available in a wide range of sizes and disposal methods to suit every business’ needs.For more information on KESSEL’s market leading Euro-Separators, please contact your KESSEL representative.www.kessel.de/exportOperational conditions<strong>Grease</strong> <strong>separator</strong>s should be installed in all locations where greases and oils from plant or animal origin are required to beremoved from the wastewater stream. This applies to commercial and industrial applications, for example:➟Butchers, meat and sausage factories➟➟➟➟➟➟➟➟Pre-prepared meal productionSlaughterhouses and meat preparation facilitiesSoap / stearin production plantsRestaurants and fast food shopsFish production facilitiesCooking oil refineries, butter /margarine productionFrying facilities /nut roasting factoriesCafeterias in commercial buildings,hospitals, universities, military basesand government agenciesPage 2

Content1 General Informationpages4-5page 6Selection Criteria and Product AdvantagesSeparator Function2 <strong>Grease</strong> Separatorsfor Interior Installationpages8-9pages 10 - 11pages 12 - 13<strong>Grease</strong> Separator Euro “E + S” PV<strong>Grease</strong> Separator Euro “E + S” M<strong>Grease</strong> Separator Euro “D + S-P1”pages 14 - 15 <strong>Grease</strong> Separator Euro “D + S”pages 16 - 17<strong>Grease</strong> Separator Euro “D”pages 18 -19 <strong>Grease</strong> Separator Euro “G” NS 2/4/7/10page 20 <strong>Grease</strong> Separator SE CNS NS 2-25page 21<strong>Grease</strong> Separator “Under sink”page 22 <strong>Grease</strong> Separator Euro “G” NS 0,25 / 0,5 / 1pages 23 - 26Accessories3 <strong>Grease</strong> Separatorsfor Underground Installationpages 28 - 29 <strong>Grease</strong> Separator Euro “G” NS 1/2/4page 30 <strong>Grease</strong> Separator Euro “G” NS 7-35page 31pages 32 - 33<strong>Grease</strong> Separator “G” roundAccessories4 Technical Informationpages34-38Size CalculationPage 3

Selection Criteria<strong>Grease</strong> Separator “E+S” PVFully automated operationOdour free disposal and cleaningMixing of <strong>separator</strong> contentswith Shredder-Mix-SystemOptimal cleaning with only a single pumpOptional remote control<strong>Grease</strong> Separator “E+S” MOdour free disposal and cleaningMixing of <strong>separator</strong> contentswith Shredder-Mix-SystemComplete cleaningof interior <strong>separator</strong> wallsDisposal through pre-installeddisposal pipe by pumpSimple On / Off controlManual change-over from mixingto disposal<strong>Grease</strong> Separator D+S / D+S-P1Odour free disposal and cleaningMixing of <strong>separator</strong> contentswith Shredder-Mix-SystemSimple controlsNo warm water connection necessaryDisposal through pre-installed disposal pipeFully automated operation exceptfor disposal (version D+S-P1)Product see page 8-9Product see page 10-11Products see pages 12-15Product AdvantagesKESSEL has been manufacturing draining systems made ofpolymer for a long time. “The certification confirms ourinnovative strength, the high level of quality of our productsand synthetic material as the material of the future.”The German Institute for Structural Engineering (DIBt) hasgranted site-inspection certification. This makes KESSEL thefirst manufacturer on the German market to be granted suchan inspection certificate.“The polyethylene material creates significant advantagesfor planners, decision makers and processing workers,such as long-term watertightness and fracture resistance,the relatively low weight, short installation times and lastbut not least an attractive price.”Resistant to aggressive fatty acidsThe polyethylene material used guarantees a long service life sincethere is no early damage to the material e.g. through corrosion.Compact design, low weightMinimum dimensions mean easy installatione.g. via narrow stairs into cramped cellarrooms where there is little installationspace.Simple and fast installationThanks to the low weight and straightforward KESSEL fasteningtechnology, the KESSEL round-design grease <strong>separator</strong> system caneasily be dismantled to minimum component size, allowing it tobe set up in rooms with only very narrow access.KESSEL extends the warranty period for tanksand upper sections beyond thestatutory requirement to 20 years.This covers the watertightness,usability and static safety ofthese components.WarrantyPolyethylene20YearsOdour-proofThe single-piece grease <strong>separator</strong> tank made of polyethylene isboth gas and waterproof. The covers are sealed tight with a sealingring and fast-action clamp.Page 4

Separator function based on EN 1825Product informationThe KESSEL Euro <strong>separator</strong> based on Euro-Norm EN 1825 (as seen inthe illustration below) consists of a grease separation chamber with anintegrated sludge trap located at the bottom. Following the <strong>separator</strong>is a sampling chamber.Wastewater containing oils and grease is guided into the <strong>separator</strong> bya pacifying pipe which allows the wastewater to be slowly and evenlydistributed into the <strong>separator</strong> preventing fast flowing wastewater fromdisturbing the separation process inside the chamber. The separationof the light material (grease and fats) and the heavier material (sludge)from the wastewater is all accomplished by the force of gravity.Heavily emulsified greases and oils may not be completely separablewith the gravity method.What can enter the <strong>separator</strong> ?7Only wastewater containing organic greases and oils, which arerequired to be separated from the water, should be allowed into thesepara-tor. Under no circumstances should sewage, rainwater orwastewater containing mineral oils (hydrocarbon based) be allowed toenter the <strong>separator</strong>.Examples of what should be connected to a <strong>separator</strong>:floor drains with odor traps, drainage channels, sinks, dishwashingmachines and cooking vats.Sludge separation chamberThe sludge <strong>separator</strong> serves to collect sludge/sediment which sinks tothe bottom of the chamber due to its density being greater than that ofthe density of water.<strong>Grease</strong> separation chamberIn the grease separation chamber, organic greases and oils (being lessdense than water) separate from the wastewater and rise to the surfaceof the chamber. As more wastewater enters the chamber, the layerof separated greases and oils builds from the top down until thegrease separation chamber is full and the entire chamber is emptied. Inlet Ventilation pipe Refill equipment Separation chamber Inspection window Outlet Sampling chamberPage 6

<strong>Grease</strong> <strong>separator</strong>sfor interior installationWPolyethylene Warrantyt20Years

<strong>Grease</strong> <strong>separator</strong> Euro “E+S” PV according to EN 1825-1NS 2/4/7/10 with program-controlled disposal unit and Shredder-Mix-Systemfor free standing installation in frost free areasIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> Euro “E+S” PV NS ...with program-controlled disposal system,Shredder-Mix-System, according to EN 1825,made of polymerFor free standing installation in frost free areas, with integratedsludge trap, domed covers made of polymer, with snapclosures and sealed odour-tight, inspection window, with disposalsystem PV (program-controlled and fully automated)System KESSEL with switching distribution and actuator, withjet nozzle and conical nozzle for mixing and rinsing, withexterior submersible pump (IP 68), with integrated maceratorand closure valve, controls in flow direction left or right asdesired (Protection IP 68, 400 V, 50 Hz, with 2.6 kW > 25m 3 /h at 0.7 bar middle pumping height and/or 4.0 kW > 30m 3 /h at 1.0 bar middle pumping height), with control cabinet,program-controlled and fully automated, manual operation,with two solenoid valves 1 inch, with inlet for rinsing andfilling according to DIN 1988, disposal flange Ø 65,PN 10 according to DIN 2501, Storz-B-Coupling 2 1 /2 inchfor disposal trucks.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PP, AS or HT accordingto DIN 19560.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: ........................Weight: ...... kg Certification no. Z-54.1-474Delivery: System completely assembled.On-site welding available on request.Art. # 93 004.00 / P1Version in flow direction rightInstallation sitefor free standing installationin frost free areas* other sizes and custom-made <strong>separator</strong>savailable on requestDimensioned illustrationNominal size* Weight approx.Article #NS 2NS 4NS 7NS 10150 kg165 kg200 kg225 kgPump left93 002.50 / P193 004.50 / P193 007.50 / P193 010.50 / P1Pump right93 002.00 / P193 004.00 / P193 007.00 / P193 010.00 / P1Pump size2.6 kW2.6 kW2.6 kW4.0 kWl420h2h1h3Ø = Outer diameterab1 = Installation dimensionsbb1Nominal sizeNS 2NS 4NS 7NS 10Ø110110160160a1030150016002430Access openingl1250181018502700x b670730990990b11000100012201220h193093011301130h21000100012001200h31310131015601560Wastewater contentSludge trap Separator200 l 212 l400 l 354 l700 l 567 l1000 l 794 l<strong>Grease</strong><strong>separator</strong>106 l177 l302 l423 lPage 8

DescriptionKESSEL Version „E+S“ PV grease <strong>separator</strong>s are designed accordingto EN 1825-1 and are equipped with a fully automated disposal, selfcleaningand refill system. These <strong>separator</strong>s distinguish themselvesthrough their ease of installation and nearly maintenance free characteristics.The advantage of the Version „E+S“ PV <strong>separator</strong>s is that a completedisposal can take place through permanently installed disposal lineswhile the twin covers of the <strong>separator</strong> remain closed. With this advantage,the disposal truck can hook up to a connection on an exterior wallof the building so that the pump(s) of the Version „PV“ <strong>separator</strong> canpump the <strong>separator</strong> contents into the waiting disposal truck withoutany unpleasant odors escaping. After the contents of the <strong>separator</strong>have been pumped out, the interior of the <strong>separator</strong> is automaticallyrinsed and cleaned with warm water in a multi-step automated process.The complete procedure occurs with the press of a button and isalso available with a remote control system so that the driver of thedisposal vehicle can handle the entire procedure without the necessityof any building personnel being present. According to DIN V 4040-2,the complete contents of the <strong>separator</strong> should be emptied, the unitcleaned and refilled with clean cold water every fourteen days or at aminimum of once every month.Installation hintsImportant is that a testing or sampling chamber is installed after the outletside of the <strong>separator</strong>.The <strong>separator</strong> is installed completely level on a flat firm surface in a frostfree area.The height of the room in which the <strong>separator</strong> is installed should alloweasy removal and access of the two lids.In the case that the outlet of the <strong>separator</strong> is located below the localdefined backwater level, a lifting station is to be installed according toDIN EN 12056. In situations where the interruption of <strong>separator</strong> serviceis not allowable, a lifting station with double pumps is to be installed.NoticeKESSEL „E+S“ <strong>separator</strong>s should be installed in all areas where nuisanceodor problems are either undesired or not allowed.The KESSEL „E+S“ PV systems allow the user to customize settingsto improve disposal performance and also allow the disposal vehicledriver to handle the complete disposal procedure which can also beconducted during off hours.In cases where the Version „PV“ <strong>separator</strong> is installed in an operationproducing large amounts of sludge (ie. slaughterhouses/butchers) itis recommended that the <strong>separator</strong> be equipped with twin pumps -one pump for the disposal of the sludge and the second pump for thedisposal of wastewater and separated grease. For more informationplease contact KESSEL directly.Page 9

<strong>Grease</strong> <strong>separator</strong> Euro “E+S” M according to EN 1825-1NS 2/4/7/10 with manual system and Shredder-Mix-Systemfor free standing installation in frost free areasIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> Euro “E+S” M NS ...with manually controlled disposal system,Shredder-Mix-System, according to EN 1825,made of polymerFor free standing installation in frost free areas, with integratedsludge trap, domed covers made of polymer, with snapclosures and sealed odour-tight, inspection window, with(manual) disposal system M System KESSEL with switchingdistribution, with jet nozzle and conical nozzle for mixing andrinsing, with exterior submersible pump (IP 68), with integratedmacerator and closure valve, controls in flow directionleft or right as desired (Protection IP 68, 400 V, 50 Hz, with2.6 kW > 25 m 3 /h at 0.7 bar middle pumping height and/or4.0kW>30m 3 /h at 1.0 bar middle pumping height), withcontrol cabinet, with inlet for rinsing and filling accordingto DIN 1988, disposal flange Ø 65, PN 10 according toDIN 2501, Storz-B-Coupling 2 1 /2 inch for disposal trucks.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PP, AS or HT accordingto DIN 19560.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: .......................Weight: ...... kg Certification no. Z-54.1-474Delivery: System completely assembled.On-site welding available on request.Art. # 93 004.00/M1 Version in flow direction rightInstallation sitefor free standing installationin frost free areas* other sizes and custom-made <strong>separator</strong>savailable on requestNominal size* Weight approx.Article #NS 2NS 4NS 7NS 10140 kg155 kg190 kg215 kgPump left93 002.50/ M193 004.50/ M193 007.50/ M193 010.50/ M1Pump right93 002.00 / M193 004.00 / M193 007.00 / M193 010.00 / M1Pump size2.6 kW2.6 kW2.6 kW4.0 kWDimensioned illustrationl420h2h1h3Ø = Outer diameterab1 = Installation dimensionsbb1Nominal sizeNS 2NS 4NS 7NS 10Ø110110160160a1030150016002430Access openingl1250181018502700x b670730990990b11000100012201220h193093011301130h21000100012001200h31310131015601560Wastewater contentSludge trap Separator200 l 212 l400 l 354 l700 l 567 l1000 l 794 l<strong>Grease</strong><strong>separator</strong>106 l177 l302 l423 lPage 10

DescriptionKESSEL Version „D+S-P1“ grease <strong>separator</strong>s are designed accordingto EN 1825-1 and are equipped with an automatically controlledpump for mixing and cleaning of the <strong>separator</strong>´s contents andinner walls. These <strong>separator</strong>s are offered with a modern controlunit with digital display. It is now possible to automate specificsteps of the grease <strong>separator</strong> disposal process. The “D+S-P1”<strong>separator</strong>s distinguish themselves through their ease of installationand nearly maintenance free characteristics.The advantage of the Version „D+S-P1“ <strong>separator</strong>s is that disposalcan take place through permanently installed disposal lineswhile the twin covers of the <strong>separator</strong> remain closed. With thisadvantage, the disposal truck hooks up to a connection on an exteriorwall of the building and, using its own pump, suction out theentire contents of the <strong>separator</strong> without any unpleasant odorsescaping.The Shredder-Mix- System macerates and liquifies its contentsand also cleans its interiror walls all simultaneously. This preparedwastewater is then suctioned into the waiting disposal vehicle.According to DIN V 4040-2, the complete contents of the <strong>separator</strong>should be emptied, the unit cleaned and refilled with clean coldwater every fourteen days or at a minimum of once every month.Installation hintsA sampling chamber is to be installed immediately after the grease<strong>separator</strong>.The <strong>separator</strong> is installed completely level on a flat firm surface in afrost free area.The height of the room in which the <strong>separator</strong> is installed shouldallow easy removal and access of the two <strong>separator</strong> covers.In the case that the outlet of the <strong>separator</strong> is located below the localdefined backwater level, a lifting station is to be installed accordingto DIN EN 12056. In situations where the interruption of <strong>separator</strong>service is not allowable, a lifting station with double pumps is to beinstalled.NoticeThe KESSEL „D+S-P1“ grease <strong>separator</strong> is ideal for installationswhere the presence of strong odors during disposal of the <strong>separator</strong>´scontents can not be permittedThe “Shredder-Mix-System” liquifies, macerates and cleans the<strong>separator</strong>´s contents all in one step.In circumstances where large amounts of sludge are expected (i.e.slaughterhouses / meat processing plants), the <strong>separator</strong> should beequipped with two macerating pumps - one pump for the wastewaterand grease, the second pump solely for the sludge. For furtherinformation please contact your KESSEL distributor.Page 13

<strong>Grease</strong> <strong>separator</strong> Euro “D+S” according to EN 1825-1NS 2/4/7/10 with direct disposal and Shredder-Mix-Systemfor free standing installation in frost free areasIllustrationArt. # 93 004.00 / DS1Version flow direction right/ inspection window as accessoryArticle description<strong>Grease</strong> <strong>separator</strong> Euro “D+S” NS ...with direct disposal and Shredder-Mix-Systemaccording to EN 1825,made of polymerFor free standing installation in frost free areas, with integratedsludge trap, domed covers made of polymer,with snap closures and sealed odour-tight, with refill inletleft/right options available (with the exception of NS 2) 1 inch,with installed suction system for disposal both from the sludgetrap and the grease separating chamber, with flange connectionfor intake pipe, disposal flange Ø 65, PN 10 accordingto DIN 2501, Storz-B-Coupling 2 1 /2 inch for disposal truckconnection, with high pressure cleaning system.The Shredder-Mix-System serves to simultaneously macerateand recycle the sediment and to clean the container.Separator requires disposal vehicle for emptying.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PP, AS or HT according toDIN 19560.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: .......................Weight: ...... kg Certification no. Z-54.1-474Delivery: System completely assembled.On-site welding available on request.Installation sitefor free standing installationin frost free areas* other sizes and custom-made <strong>separator</strong>savailable on requestNominal size* Weight approx.Article #NS 2NS 4NS 7NS 10130 kg140 kg170 kg215 kgDisposal pipe connectionleft right93 002.50 / DS193 004.50 / DS193 007.50 / DS193 010.50 / DS193 002.00 / DS193 004.00 / DS193 007.00 / DS193 010.00 / DS1Scope of deliveryContainer with 2 domedcovers, internal and externalpiping complete with disposalpipe connection, Shredder-Mix-System with on/offswitch, inletDimensioned illustrationl420h2h1h3abb1Ø = Outer diameterb1 = Installation dimensionsNominal sizeNS 2**NS 4NS 7NS 10Ø110110160160a1030150016002430Access openingl1250181018502700x b670730990990b11000100012201220h193093011301130h21000100012001200h31310131015601560Wastewater contentSludge trap Separator200 l 212 l400 l 354 l700 l 567 l1000 l 794 l<strong>Grease</strong><strong>separator</strong>106 l177 l302 l423 l** Please note: In the case of NS 2 the disposal pipe must be attached to the side opposite the pump.Page 14

DescriptionKESSEL Version „D+S“ grease <strong>separator</strong>s are designed accordingto EN 1825-1 and are equipped with a manually controlled pumpfor mixing and cleaning of the <strong>separator</strong>´s contents and inner walls.These <strong>separator</strong>s distinguish themselves through their ease ofinstallation and nearly maintenance free characteristics.The advantage of the Version „D+S“ <strong>separator</strong>s is that disposal cantake place through permanently installed disposal lines while thetwin covers of the <strong>separator</strong> remain closed. With this advantage,the disposal truck hooks up to a connection on an exterior wall ofthe building and, using its own pump, suction out the entire contentsof the <strong>separator</strong> without any unpleasant odors escaping.The Shredder-Mix- System macerates and liquifies its contentsand also cleans its interiror walls all simultaneously. This preparedwastewater is then suctioned into the waiting disposal vehicle.According to DIN V 4040-2, the complete contents of the <strong>separator</strong>should be emptied, the unit cleaned and refilled with clean coldwater every fourteen days or at a minimum of once every month.Installation hintsA sampling chamber is to be installed immediately after the grease<strong>separator</strong>.The <strong>separator</strong> is installed completely level on a flat firm surface in afrost free area.The height of the room in which the <strong>separator</strong> is installed shouldallow easy removal and access of the two <strong>separator</strong> covers.In the case that the outlet of the <strong>separator</strong> is located below the localdefined backwater level, a lifting station is to be installed accordingto DIN EN 12056. In situations where the interruption of <strong>separator</strong>service is not allowable, a lifting station with double pumps is to beinstalled.NoticeThe KESSEL “D+S” grease <strong>separator</strong> is ideal for installations wherethe presence of strong odors during disposal of the <strong>separator</strong>´s contentscan not be permittedThe “Shredder-Mix-System” liquifies, macerates and cleans the<strong>separator</strong>´s contents all in one step.In circumstances where large amounts of sludge are expected (i.e.slaughterhouses / meat processing plants), the <strong>separator</strong> should beequipped with two macerating pumps - one pump for the wastewaterand grease, the second pump solely for the sludge. For furtherinformation please contact your KESSEL distributor.Page 15

<strong>Grease</strong> <strong>separator</strong> Euro “D” according to EN 1825-1NS 2/4/7/10 with direct disposalfor free standing installation in frost free areasIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> Euro “D” NS ...with direct disposal, according to EN 1825,made of polymerFor free standing installation in frost free areas,with integrated sludge trap, domed covers made of polymer,with snap closures and sealed odour-tight, with installedsuction system in flow direction left or right for disposal bothfrom the sludge trap and the grease separating chamber,with flange connection for intake pipe, disposal flange Ø 65,PN 10 according to DIN 2501,Storz-B-Coupling 2 1 /2 inch for connection to disposal trucks.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PP, AS or HT accordingto DIN 19560.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: .......................Weight: ...... kg Certification no. Z-54.1-474Delivery: System completely assembled.On-site welding available on request.Art. # 93 002.00 / D1 Version in flow direction rightInstallation siteNominal size*Weight approx.Article #Disposal pipe connectionScope of deliveryfor free standing installationin frost free areas* other sizes and custom-made <strong>separator</strong>savailable on requestNS 2NS 4NS 7NS 1054 kg69 kg104 kg129 kgleft93 002.50 / D193 004.50 / D193 007.50 / D193 010.50 / D1right93 002.00 / D193 004.00 / D193 007.00 / D193 010.00 / D1Container with domed covers,piping complete with disposalpipe connectionDimensioned illustration420lh2h1h3DN/ODabb1Ø = Outer diameterb1 = Installation dimensionsNominal sizeNS 2NS 4NS 7NS 10Ø110110160160a1030150016002430Access openingl1250181018502700x b670730990990b184084010801080h193093011301130h21000100012001200h31310131015601560Wastewater contentSludge trap Separator200 l 212 l400 l 354 l700 l 567 l1000 l 794 l<strong>Grease</strong><strong>separator</strong>106 l177 l302 l423 lPage 16

DescriptionKESSEL Version „D“ <strong>separator</strong>s are designed according to EN 1825-1.These <strong>separator</strong>s distinguish themselves through their ease of installationand nearly maintenance free characteristics.The advantage of the Version „D“ <strong>separator</strong> is that disposal can takeplace through permanently installed disposal lines while the twincovers of the <strong>separator</strong> remain closed. With this advantage, the disposaltruck can hook up to a connection on an exterior wall of the buildingand, using its own pump, suction out the entire contents of the<strong>separator</strong> without any unpleasant odors escaping. According to DIN V4040-2, the complete contents of the <strong>separator</strong> should be emptied, theunit cleaned and refilled with clean cold water every fourteen days orat a minimum of every month.Installation hintsImportant is that a testing or sampling chamber is installed after the outletside of the <strong>separator</strong>.The <strong>separator</strong> is installed completely level on a flat firm surface in a frostfree area.The height of the room in which the <strong>separator</strong> is installed should alloweasy removal and access of the two lids.In the case that the outlet of the <strong>separator</strong> is located below the localdefined backwater level, a lifting station is to be installed according toDIN 1986-7. In situations where the interruption of <strong>separator</strong> service isnot allowable, a lifting station with double pumps is to be installed.NoticeThe KESSEL Version „D“ <strong>separator</strong> should be inspected and fullycleaned during every third disposal.In all circumstances where the accessibility of the disposal truck’ssuction hose to the <strong>separator</strong> is highly limited or impossible, KESSELrecommends the installation of a Version „D“ unit.With the installation of the refill equipment, the KESSEL Version „D“<strong>separator</strong> can be refilled after disposal without the need of openingany of the covers and releasing strong and aggressive odors.The KESSEL Version „D“ <strong>separator</strong> is not intended for use in meatprocessing plants.Page 17

<strong>Grease</strong> <strong>separator</strong> Euro “G” according to EN 1825-1, NS 2/4/7/10for free standing installation in frost free areasIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> Euro “G” NS ...according to EN 1825,made of polymerFor free standing installation in frost free areas, with integratedsludge trap, domed covers made of polymer,with snap closures and sealed odour-tight.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PP, AS or HT accordingto DIN 19560.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: ........................Weight: ...... kg Certification no. Z-54.1-474Delivery: System completely assembled.On-site welding available on request.Retrofit set from Euro “G” to Euro “D” available on request.Art. # 93 002Installation siteNominal size*Weight approx.Article #Scope of deliveryfor free standing installationin frost free areas* other sizes and custom-made <strong>separator</strong>savailable on requestNS 2NS 4NS 7NS 1050 kg65 kg100 kg125 kg93 00293 00493 00793 010Container with domed coversand snap closuresDimensioned illustration420h2h1h3abØ = Outer diameterNominal sizeNS 2NS 4NS 7NS 10Ø110110160160a1030150016002430Access openingl1250181018502700x b670730990990h193093011301130h21000100012001200h31310131015601560Wastewater contentSludge trap Separator200 l 212 l400 l 354 l700 l 567 l1000 l 794 l<strong>Grease</strong><strong>separator</strong>106 l177 l302 l423 lPage 18

DescriptionKESSEL Version „G“ <strong>separator</strong>s are designed according to EN 1825-1.These <strong>separator</strong>s distinguish themselves through their ease of installationand nearly maintenance free characteristics.According to DIN V 4040-2, the complete contents of the <strong>separator</strong>should be emptied, the unit cleaned and refilled with clean cold waterevery fourteen days or at a minimum of every month. To empty thecontents of the <strong>separator</strong> the odor tight covers need to be removed.The suction hose of the disposal truck is then used to empty and rinsethe inside of the <strong>separator</strong>.Installation hintsImportant is that a testing or sampling chamber is installed after the outletside of the <strong>separator</strong>.The <strong>separator</strong> is installed completely level on a flat firm surface in a frostfree area.The height of the room in which the <strong>separator</strong> is installed should alloweasy removal and access of the two lids.In the case that the outlet of the <strong>separator</strong> is located below the localdefined backwater level, a lifting station is to be installed according toDIN 1986-7. In situations where the interruption of <strong>separator</strong> service isnot allowable, a lifting station with double pumps is to be installed.NoticeThe KESSEL Version „G“ <strong>separator</strong> can be upgraded to a KESSELversion „D“ <strong>separator</strong> (with permanently installed disposal lines) atany time.The KESSEL Version ”G” <strong>separator</strong> should only be installed in areaswhere:• the release of strong and aggressive odors will not pose a problem• accessing the <strong>separator</strong> with the disposal hose of the disposaltruck will not cause problems or inconveniences.Page 19

<strong>Grease</strong> <strong>separator</strong> SE CNS for self-disposal NS 2-25for free standing installation in frost free areasIllustrationArticle descriptionh3h1lbh2b1SE CNS self disposal grease <strong>separator</strong>according to EN 1825,made of High Density Polyethylene (HD-PE)For free standing installation in frost free areas, withintegrated sludge trap, quick release and odour-tightDuroplast 2K removable access cover, Ø 110 inlet / outletfor NS 2 and NS 4, Ø 160 inlet / outlet for NS 7 and NS 10,Ø 200 inlet / outlet for NS 15 and NS 20, connectionto SML pipe in accordance with DIN 19522.Separate disposal of sludge and grease with manual valves.Visual control of disposal with see-thru disposal hoses, disposalpossible during <strong>separator</strong> operation, includes total of 4 disposalbuckets (2 for grease disposal / 2 for sludge disposal).With plug-in-ready control unit with operational status signal.Technical information:Voltage: 230 V / 50 HzStart up power: 2 kWNominal current: 7 AmpProtection class: IP 54Fuse: 16 Amp.Manufacturer: KESSEL GermanyIllustration showsversion NS 2, 4, 7, 10Installation sitefor free standing installationin frost free areasDimensioned illustrationNominal size Weight in kgArticle #NS 2NS 4NS 7NS 10NS 15NS 20NS 2597 kg128 kg186 kg192 kg485 kg505 kg535 kg93 202.00 / SE1-CNS93 204.00 / SE1-CNS93 207.00 / SE1-CNS93 210.00 / SE1-CNS93 215.00 / SE1-CNS93 220.00 / SE1-CNS93 225.00 / SE1-CNSScope of deliverySystem completelyassembledIllustration shows version NS 15, 20, 25lh1h2b1bh3Ø = Outer diameterb1 = Installation dimensionsNominal sizeNS 2NS 4NS 7NS 10NS 15NS 20NS 25Ø110110160160200200200Access openingl1760183022302230360041004600x b93093013001300120013001400b11330133017001700165017501850h11230163016301730173017301730h21300170017001800180018001800h31700210022002300230023002300Total volumein liter600 l950 l1450 l1600 l2950 l3650 l4350 lPage 20

<strong>Grease</strong> <strong>separator</strong> “Under sink”for free standing installation in frost free areasIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> “Under sink”made of polymerFor free standing installation in frost free areas,with integrated sludge trap, polyethylene quick releaseodour-tight covers.Inlet and outlet Ø 50.Sludge trap content:7 Liter<strong>Grease</strong> trap content:7 LiterManufacturer: KESSEL GermanyApplication:Especially suitable in areas in which limited amountsof fat and sludge occur, and above all wherever vegetableoil is used.<strong>Grease</strong> <strong>separator</strong> system should be emptied on a daily basis.KESSEL-advantages:- System made from polymer for corrosion-free,compact structure.- No encrustation because of smooth, wax-like surface.- Light handling of system because of low weight.- Fast removal of cover using quick release odour tight covers.- Fully adjustable inlet: 360° rotatable and verticallyadjustable inlet meets all on-site requirements.Installation sitefor free standing installationin frost free areasNominal size (l/sec.) Weight approx.Article #NS 0.25 4 kg 93 025.00 / USDimensioned illustration426290 to 420260350Ø 50296Ø 50790 to 930Nominal sizeNS 0.25Ø50Storage volumesSludge trap <strong>Grease</strong> trap7l7lPage 21

<strong>Grease</strong> <strong>separator</strong> Euro “G” according to KESSEL Standards, NS 0.25/0.5/1for free standing installation in frost free areasIllustrationArticle descriptionArt. # 93 025Art. # 93 050Art. # 93 001<strong>Grease</strong> <strong>separator</strong> Euro “G” NS....according to KESSEL Standards, made of polymerFor free standing installation in frost free areas,with integrated sludge trap, domed cover made of polymer,with snap closures and sealed odour-tight.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PP, HT accordingto DIN 19560.Sludge trap content:... Liter Manufacturer: KESSELSeparator content: ... Liter Article #: ..........................Weight:... kgDelivery: System completely assembled.Based on EN 1825-1 the grease <strong>separator</strong>s are intended foruse under the following conditions:- Connection of a commercial dishwasher with a minimumcycle time of 1.5 minutes- Consumption of rinsing water in a commercial dishwasherVS = max. 5 Liter- In addition to the dishwasher, a maximum of one drainagefacility is to be connected to the dishes pre-rinse (shortterm operation)Operating Instructions:The separated grease is to be decanted on a daily basis andemptied and cleaned once a week.Installation siteNominal sizeWeight approx.Article #Scope of deliveryfor free standing installationin frost free areasNS 0.25NS 0.5NS 120 kg45 kg65 kg93 02593 05093 001Container with domed coverand snap closuresDimensioned illustration510510500453710570520710570520990540Ø = Outer diameter11501020Nominal sizeNS 0.25NS 0.5NS 1Ø5050110Wastewater contentSludge trap Separator25 l28 l50 l42 l100 l75 l<strong>Grease</strong><strong>separator</strong>15 l30 l60 l1200Page 22

AccessoriesSeparator according to EN 1825 for free standing installationIllustration and dimensioned drawingArticle description 110 160120575750 160 110460SonicControl level sensing systemwith ultra sonic sensor for grease <strong>separator</strong>sAccurate monitoring and data transfer of grease levels.230 V - 50 Hz power connection. With battery back up, connection forremote speaker.Insallation set with easy assembly and maintenance. For use on aboveground or below ground <strong>separator</strong>s. For retrofit use on existing <strong>separator</strong>s.Control unit with optical and audible alarm with potential free contact.Electronic log book with 12 month capacity. Data transfer by telemetry.Voltage: 230 V ~ 50 Hz Protection: IP 54Plug: Schuko (double pole)Cable length: 5 m (extendable on-site to 30 meters)Art. #917 821Sampling chamber Ø 400 made of polymerfor separation systemsFor connection to outlet pipe of <strong>separator</strong>.Inlet and outlet Ø 110/160 available options for synthetic material pipes in:PE-HD (according to DIN 19537); PVC-HT, PP or AS, drop height 120 mm.Cover sealed odour-tight with snap closure.Manufacturer: KESSELModelOutlet horizontalArt. #915 871635 110 160298800484580 160 1101 inch threaded connection26563Sampling chamber Ø 400 made of polymerfor separation systemsFor connection to outlet pipe of <strong>separator</strong>.Inlet and outlet Ø 110/160 available options for synthetic material pipes in:PE-HD (according to DIN 19537); PVC-HT, PP or AS.Cover sealed odour-tight with snap closure.Manufacturer: KESSELModelOutlet verticalRefill inlet made of polymerfor separation systemsaccording to DIN 1988, for connection to filling and rinsing connectioncouplings of the separation systems, with two pipe clamps and attachmentelement together with pipe sealing gasket Ø 63.Modelleft 1 inchright 1 inchArt. #915 870Art. #915 800915 801135R15415448308Inspection window for separation systemsFits KESSEL Separation systems for free standing installation.In flow direction left or right with cleaning system.Can only be retrofitted by KESSEL Customer Service (on request).Modelin flow direction leftin flow direction rightArt. #917 770917 771Page 23

AccessoriesSeparator according to EN 1825 for free standing installationIllustration and dimensioned drawingArticle descriptionRemote controlFits KESSEL Separation systems for free standing installationModel “E+S” program-controlled, fully automatedaccording to EN 1825.Cable length 10 m.Model-Art. #916 601440400640600160Remote ControlStorz-B-CouplingStainless steel access panelFor recessed wall installationwith Storz-B disposal pipe hook up connection and remote controlfor use with fully automated grease <strong>separator</strong>s.Dimensions: 640 x 440 x 160 mm (Width x Height x Depth)Model: “Recessed”, 2 doors, lockableArt. #917 414600160Stainless steel access panelFor wall installationwith Storz-B disposal pipe hook-up connection and remote controlfor use with fully automated grease <strong>separator</strong>s.Dimensions: 600 x 400 x 160 mm (Width x Height x Depth)Model: “Wall installation”, 2 doors, lockable400Remote ControlStorz-B-CouplingArt. #917 413Page 24

AccessoriesSeparator according to EN 1825 for free standing installationIllustration and dimensioned drawingArticle descriptionØ*Art. #Ø110Twin lifting stationmade of polymer for above ground installationWith twin removable pumps, integrated backwater flap,Pressure diaphragm control.Inlet Ø 110, ventilation connection Ø 75 (incl. pipesealing gasket), control with potential free contact.Pressure connection: 1 1 /2 inch outer thread orpressure pipe Ø 40 mm for PVC glued connection.Inlet height: 530 mmTotal height: 720 mm, Ø 450 mmVoltage:230 V ~ 50 HzMax. container size: 55 lmax. pumping height: 8 mIntake power: 2 x 0.5 kWPower cable: 5 mWeight:approx. 25 kgØ 40 28 541258530575720Ø 40500LGAType-testedand monitoredguaranteed withtested qualityCertification: Z-53.3-310EN 12050-2Ø 40Ecolift ® wastewater lifting systemfor pipes with natural gradient to the sewerThe alternative to a classical lifting stationFor wastewater with or without sewage,for installation in an exposed wastewater pipeWith protective cover. With integrated pump and abackwater valve locked by a motor. During normalconditions, the pipe cross section is open, in the caseof backwater the valve is closed and locked completelyautomatically. During the backwater period, soiledwater is drained using a pump with chopping device,via a pressure pipe over the backwater level. Plug-incontrol and warning unit with display, self-diagnosissystem (SDS) and battery buffering for maximumsafety, with logbook (diary function) for reading outthe past operating states.Ø 110Ø 125Ø 160Ø 20021 10021 12521 15021 200HPower cable / cable length: 5 mMains voltage/frequency: 230 V AC / 50 HzProtective rating: IP 54 (switch unit)Protective rating: IP 68 (motor)9LØØ 110 L: 642 mm H: 405 mmØ 125 L: 645 mm H: 405 mmØ 160 L: 656 mm H: 405 mmØ 200 L: 720 mm H: 405 mm*Ø= Outer DiameterCertification: Z-53.2-487Page 25

AccessoriesSeparator according to EN 1825 for free standing installationIllustration and dimensioned drawing7885907511032Inlet height300Article descriptionLifting station Aqualift ® F DuoTwin stationfor wastewater with or without sewagefor separation systemsConsisting of:Polyethylene storage chamber, chamber volumeapprox. 120 liters, pumping volume approx. 50 liters,with air pressure level detector, clean-out opening.Connection for inlet Ø 110 (inlet height 300 mm) andventilation Ø 75, connection coupling for manualdiaphragm pump Ø 32.Twin wastewater pump with non-chokable impellerto pump wastewater with or without sewage (openchannel passage 40 mm). Pump is rated submersible(IP 68), power cable length 5 m.Horizontal outlet with integrated non-return valve,connection coupling Ø 110 with hose section,with closure valve (provided loose)Electric control unit for fully automated pumpoperation, control unit is splash proof (IP 65),wall mounted, voltage 400 V DS at 50 Hz.With potential-free contact.Total weight approx. 84 kg.PowerWith closure valvewith horizontal pressure outlet:1.1 kW2.2 kWCurrentconnection400 V400 VArt. #28 65928 631780773160EN 12050-1105598513851296Lifting station Aqualift ® F Duo XXLtwin lifting station with closure valvefor wastewater with or without sewage(For use with grease <strong>separator</strong>s size NS 10 and larger)for free standing installation in frost free areasConsists of:Polyethylene collection chambers,storage volume 750 liter, pumping volume 300 liter,pneumatic level control, twin 420 mm OD access /maintenance covers, Ø 160 inlet (Ø 200 availableupon request), inlet height 1055 mm, ventilation connectionsize Ø 110.Twin wastewater pumps with macerating (cuttingassembly) for pumping wastewater with or withoutraw sewage, IP 68 submersible pumps, Duty / Standbyoperation, 5 meter power cable length.Vertical pressure outlet with Ø 110 connection andflange, with closure valve and integrated backflowpreventer.Electrical control for fully automated pump control,IP 54 splash proof control unit housing, for wallmounting, operational voltage - 400 V DS,with potential free contact (BMS) connections).Total weight empty: approx 220 kg2.6 kW3.5 kW4.8 kW400 V400 V400 V28 63828 63928 64018372000EN 12050-1*Ø= Outer DiameterPage 26

<strong>Grease</strong> <strong>separator</strong>sfor underground installationWPolyethylene Warrantyt20Years

<strong>Grease</strong> <strong>separator</strong> Euro “G”according EN 1825-1, NS 1/2/4for underground installationVariable upper section:inclinableheight adjustableby 100 to 550 mmIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> Euro “G” NS ...according to EN 1825, made of polymerfor underground installation,installation depth D = ..................... mm,with integrated sludge trap, upper section made of polymer,continuous height and level adjustment, can be tilted upto 5°, sealed odour-tight with cover Class B, D accordingto EN 124 in cast iron, incl. removal mechanism, certified statics.Inlet and outlet Ø 110 for synthetic material pipes in:PE-HD (according to DIN 19537); PVC (according toDIN V19534); PP or AS.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: .........................Weight: ...... kg Certification no. Z-54.1-440Delivery: System completely assembled.Handles groundwater depths up to 500 mmArt. # 93004/120D + 915880DInstallation site Nominal size Weight approx. Installation depth D Art. # Class B Art. # Class Dfor underground installation NS 1 111 kg550 to 950 mm 93 001/80 B 93 001/80 Dfrost free depth 800 mmNS 2 120 kg550 to 950 mm 93 002/80 B 93 002/80 D(Type 80)NS 4 130 kg550 to 950 mm 93 004/80 B 93 004/80 Dfor underground installationfrost free depth 1200 mm(Type 120)Dimensioned illustrationNS 1NS 2NS 4111 kg120 kg130 kgOther installation depths available on request800 to 1200 mm800 to 1200 mm800 to 1200 mm93 001/120 B93 002/120 B93 004/120 B93 001/120 D93 002/120 D93 004/120 D 875 610h2Inlet Dh1OutlethbaD = Installation depthØ = Outer diameterNominal sizeNS 1NS 2NS 4Ø110110110a138013801380b110611061106h*105013001550h15407901040h26108601110Wastewater contentSludge trap Separator140 l230 l200 l370 l400 l370 l<strong>Grease</strong><strong>separator</strong>70 l120 l160 l* Details apply for Type 80. For Type 120 h* =h+250mmapplies.Page 28

DescriptionKESSEL Version „G“ <strong>separator</strong>s are designed according to EN 1825-1.These <strong>separator</strong>s distinguish themselves through their ease of installationand nearly maintenance free characteristics.According to DIN V 4040-2, the complete contents of the <strong>separator</strong>should be emptied, the unit cleaned and refilled with clean cold waterevery fourteen days or at a minimum of every month. To empty thecontents of the <strong>separator</strong> the cover needs to be removed. The <strong>separator</strong>is then completely emptied and cleaned by the disposal truck.not possible, heated drainage piping should be used between the fixturesand the <strong>separator</strong>. It is important to note that the inlet level of the<strong>separator</strong> must always be located below the frost level. This can beaccomplished by the use of the vertically adjustable upper section andby the use of an extension section when necessary. The <strong>separator</strong>manhole covers for load classes B (12.5 ton) and D (40.0 ton) are odortight and secured with bolts according to EN 124.The underground <strong>separator</strong> should be located as close as possible tothe fixtures (drains) to which it is connected. In the case where locatingthe <strong>separator</strong> in close proximity to the fixtures which it drains isInstallation hintsThe underground <strong>separator</strong> must be placed on a firm and level base ofcompacted sand or gravel which will be able to support the predeterminedloads.The <strong>separator</strong> should then be placed in the prepared hole and filled withwater to the outlet level.The hole should be then filled and thoroughly compacted at equal increments(approx 0.5 meters) with sand or gravel. For <strong>separator</strong>s needingto withstand heavy tractor trailer loads (up to 40.0 ton), please consultKESSEL for installation instructions.Connect the inlet and outlets of the <strong>separator</strong> to the drainage piping.Separators for underground installation below the groundwater level areavailable from KESSEL upon request.NoticeThe KESSEL Version ”G” underground <strong>separator</strong> should be installedonly in areas where:• the release of strong and aggressive odors will not pose a problem• accessing the <strong>separator</strong> with the disposal hose of the disposal truckwill not cause problems or inconveniences.Page 29

<strong>Grease</strong> <strong>separator</strong> Euro “G”according EN 1825-1, NS 7/10/15/20/25/30/35for underground installationVariable upper section:inclinableheight adjustableby 100 to 550 mmIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> Euro “G” NS ...according to EN 1825, made of polymerfor underground installation,installation depth D = ......................mm,with integrated sludge trap, upper sections made of polymer,continuous height and level adjustment, can be tilted up to 5°,closed odour-tight with covers Class B, D according to EN 124in cast iron, incl. removal mechanism, Private vehicle trafficproof (Depth of earth coverage DEC 700 to 1800 mm),Traffic proof for heavy duty vehicles (depth of earth coverageDEC 700 to 1500 mm and additional concrete slab providedon-site), certified statics.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PVC (according toDIN V19534); PP or AS.Installation in groundwater is possible, if groundwater level isnot higher than outlet pipe base.Sludge trap content:...... Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: ..........................Weight: ...... kg Certification no. Z-54.1-440Delivery: System completely assembled.Art. # 93 020/120 B and 915 880 B-200Installation site Nominal size Weight approx. Installation depth D Art. # Class B Art. # Class Dfor underground installationfrost free depthMinimum installation depth canbe achieved by cutting off theupper sectionDimensioned illustrationNS 7NS 10NS 15NS 20NS 25NS 30NS 35305 kg360 kg455 kg530 kg570 kg570 kg570 kg760 to 1260 mm760 to 1260 mm760 to 1260 mm760 to 1260 mm880 to 1380 mm880 to 1380 mm880 to 1380 mm93 007/120 B93 010/120 B93 015/120 B93 020/120 B93 925/120 B93 930/120 B93 935/120 B93 007/120 D93 010/120D93 015/120D93 020/120 D93 925/120 D93 930/120 D93 935/120 DDDEC**NS 7/10/15/20:NS 25/30/35:Ø 160: D-DEC = 155 mmØ 200: D-DEC = 180 mmØ 200: D-DEC = 480 mmØ 250: D-DEC = 330 mmh2h1D = Installation depthLØ = Outer diameterB**DEC = Depth of earth coverageClass D = 700 mm ≤ DEC ≤ 1500 mmClass B = 700 mm ≤ DEC ≤ 1800 mmNominal sizeNS 7NS 10NS 15NS 20NS 25NS 30NS 35Ø160160200200200250250L2080286023003060374037403740B1200120017601760201020102010h11030103015601560155015501700h21100110016301630165016501800Wastewater contentSludge trap Separator700 l1100 l1000 l1600 l1500 l2800 l2000 l3800 l2500 l5300 l3000 l4800 l3500 l4800 l<strong>Grease</strong><strong>separator</strong>280 l400 l600 l800 l2000 l2000 l2000 lPage 30

<strong>Grease</strong> <strong>separator</strong> “G”according to EN 1825-1, NS 1/2/4for underground installationVariable upper section:inclinableheight adjustableby 100 to 550 mmIllustrationArticle description<strong>Grease</strong> <strong>separator</strong> “G” round, NS ...according to EN 1825-1, made of polymerFor underground installation, installation depthD = ...................... mm,With integrated sludge trap, upper section made of polymer,continusous height and level adjustment, closed odor-tightwith covers class A/B/D according to EN 124 in cast iron,incl. removal mechanism, private vehicle traffic proof.Inlet and outlet Ø ... for synthetic material pipes in:PE-HD (according to DIN 19537); PVC-KG (according toDIN V19534); PP or AS.Sludge trap content: ...... Liter Liter Manufacturer: KESSELSeparator content: ...... Liter Article #: ...........................Weight: ...... kg Certification no. Z-54.6-344Delivery: System completely assembled.NS 7, 10, 15, 20 on requestArt.Nr. 98 202/80 D + 915 880 D-200Installation sitefor installation in the groundin frost free areasfor installation in the groundfrost free depth 800 mmfor installation in the groundfrost free depth 1200 mmNominal size Weight approx. Installation depth D Art. # Class A/B Art. # Class DNS 1NS 2NS 4NS 1NS 2NS 4NS 1NS 2NS 4140 kg190 kg330 kg145 kg195 kg340 kg155 kg360 kg370 kg330 to 480330 to 480330 to 480650 to 800650 to 800650 to 800760 to 1200760 to 1200760 to 120098 201/00B98 202/00B98 204/00B98 201/80B98 202/80B98 204/80B98 201/120B98 202/120B98 204/120B98 201/00D98 202/00D98 204/00D98 201/80D98 202/80D98 204/80D98 201/120D98 202/120D98 204/120DDimensioned illustrationDDN 100161052DN 100860Illustration shows NS 1h234h1h3 h4bLInletOutletSludge TrapSeparation ChamberUpper section withcover class A/B/DD = installation depthNominalsize124*Ø110110110L105513552635B102013001300h1102011361136h2112012361236h3650750750h4720750750Wastewater contentSludge trapSeparator120 l405 l200 l935 l600 l1150 l<strong>Grease</strong> <strong>separator</strong>40 l80 l160 l* NS 4 consists of two chambersPage 31

AccessoriesSeparator according to EN 1825 for underground installationIllustration and dimensioned drawingArticle descriptionSonicControl level sensing systemwith ultra sonic sensor for grease <strong>separator</strong>sAccurate monitoring and data transfer of grease levels.230 V - 50 Hz power connection. With battery back up, connection forremote speaker.Insallation set with easy assembly and maintenance. For use on aboveground or below ground <strong>separator</strong>s. For retrofit use on existing <strong>separator</strong>s.Control unit with optical and audible alarm with potential free contact.Electronic log book with 12 month capacity. Data transfer by telemetry.Voltage: 230 V ~ 50 Hz;Protection: IP 54;Plug: Schuko (double pole);Cable length: 5 m (extendable on-site to 30 meters).Art. #917 821AccessoriesAudible alarm Art. # 20 162,25 m cable extension available upon request.PE-HD conduit entrance connection(for conduit connection to underground <strong>separator</strong>s)Art. #917 822D100-550Sampling chamber Ø 1000 mmin polyethylene synthetic material,for separation systems, for underground installationInlet and outlet Ø ... for synthetic material pipes in: PE-HD(according to DIN 19537); PVC (according to DIN V19534); PP or AS.Installation depth D ..... mm, in monolithic structure, water-tight, resistantto aggressive wastewater, with integrated access steps, with telescopicallyheight-adjustable upper section made of polymer, sealed odour-tight withcover Class B/D according to EN 124 in cast iron, incl. removal mechanism.Drop height 160 mm.160Installationdepth D (mm)1180-16301180-16301180-1630Inlet/OutletØ 110Ø 160Ø 200fits <strong>separator</strong>NS 1, NS 2 and NS 4NS 7 and NS 10NS 15, NS 20 andcustom-madeArt. #Class B Class D915 10 10 B915 10 15 B915 10 20 B915 10 10 D915 10 15 D915 10 20 DOther installation depths available on request1200740660686628Extension section made of polymerfor separation systemsFits all KESSEL Separation systems for underground installation,extension height 510 mm / 1010 mm; incl. gasketsmaller/larger extension sections available on request63080620°11615ModelExtension height = 510 mmExtension height = 1010 mmArt. #917 406917 407Page 32

AccessoriesSeparator according to EN 1825 for underground installationIllustration and dimensioned drawing50-40070100Article descriptionSampling chamber Ø 400 made of polymerfor separation systems, for underground installationFor connection to outlet pipe of <strong>separator</strong>.For installation depth D = ...... .Inlet and outlet Ø 110/160 available options Ø 200 for synthetic materialpipes in: PE-HD (according to DIN 19537); PVC (according to DIN V19534);PP or AS. Sampling chamber middle diameter 400 mm, telescopic uppersection with clamping ring, cover Class A/B/D, screwed down odour-tight,drop height 120 mm.D900 110 160 160 110Installationdepth D (mm)* 400-1300* 400-1300Inlet/outletØ110/160200Class A915 880 AArt. #Class B915 880 BClass D915 880 D915 880 A-200 915 880 B-200 915 880 D-200120575750* Minimum installation depth can be achieved by cutting offExtension by 600 mm with extension section Art. # 915 402Extension sectionFor deep installationExtension height max. 600 mm (can be reduced).600ModelExtension height = 600 mmArt. #915 402440400640600160Remote ControlStorz-B-CouplingStainless steel access panelFor recessed wall installationwith Storz-B disposal pipe hook up connection and remote controlfor use with fully automated grease <strong>separator</strong>s.Dimensions: 640 x 440 x 160 mm (Width x Height x Depth)Model: “Recessed”, 2 doors, lockableArt. #917 414600160Stainless steel access panelFor wall installationwith Storz-B disposal pipe hook-up connection and remote controlfor use with fully automated grease <strong>separator</strong>s.Dimensions: 600 x 400 x 160 mm (Width x Height x Depth)Model: “Wall installation”, 2 doors, lockable400Remote ControlStorz-B-CouplingArt. #917 413Page 33

Size CalculationKESSEL-Calculation for <strong>Grease</strong> SeparatorsBased on Euro-Norm EN 1825-2The KESSEL calculations sheets listed below serve to properly size the<strong>separator</strong> to its facility and also to help choose the proper model.1. General Information1.1. Project/LocationProject/Site locationBuilderPlannerVersion1.2. FacilityCare facility (retirement home)Hotel kitchenFine cuisine kitchenBusiness kitchen/cafeteriaSlaughter/Meat processing plantsMeat processing plant (with slaughtering)Meat processing plant (without slaughtering)Butcher with slaughteringOil/grease processing plantsButter/margarine manufacturerCooking oil refineryOil manufacturerHospital/University kitchen Butcher without slaughtering Prepared meal manufacturerAll day service kitchenSupermarket withFish processing plantmeat processingStandard restaurantPoultry slaughterhouse1.3. Times of operationDaily operation Weekly operation Wastewater discharge........................ hours/day ........................ days/weekcontinuousdiscontinuous1.4. Legal limits for wastewater entering public / private sewage systems(Consult local statutes or local water authority for legal limits / concentrations)Values to be identified at the wastewater’s point of entry into the (public) sewage systemWastewater temperature °C Allowable pH-value Saponifiable oils and greases(lipophilic substance)........................ °C ........................ pH-value max. ........................ mg/ lPage 34

Size Calculation2. Sizing the grease <strong>separator</strong> (NS - liters/second)2.1. Calculating the maximum wastewater flow Q sMethod 1:Q s-Calculation based on maximum wastewater flow during peak kitchen operation measured with a flow metering deviceMeasured flow Q s :......................... ......................... l/s Q s = ......................................................... l/sMethod 2: Q s-Calculation based on types of kitchensThe maximum wastewater flow is calculated for either a) commercial kitchens or b) meat processing plants based on volume and type ofwastewater.a) Commercial kitchenQ s = ......................................................... l/sCalculating maximum wastewater flow Q sV M : wastewater volume per warm meal in liters (l) (See Table 1)EquationInputsQ s =V M x F x M Mt x 3600........... x ........... x ...........Q s = = ...................... x 3600F: Surge factor relevant to of operational conditions (See Table 1)M M : Monthly average of the DAILY prepared warm meals(avg. meals per day)t: Average hours of operation when the <strong>separator</strong> will bereceiving fat laden wastewaterTable 1 (Types of facilities)Types of commercial kitchensHotel restaurant kitchenFine cuisine restaurant kitchenFast food restaurant kitchenHospital/Retirement facility kitchenMilitary base barracks kitchenStandard restaurant kitchenV M (liters)100505201015F58.520132210M Mt (hours)b) Meat processing plantsQ s = ......................................................... l/sEquationQ s =V P x F x M Pt x 3600V P : facility specific wastewater volume per kilogram meat/sausageproduction in liters (l) (See Table 2)InputsF: Surge factor irrelevant of operational conditions (See Table 2)Q s =........... x ........... x ...................... x 3600= ...........M P : Daily average of meat/sausage production (kg)t: Average hours of operation when the <strong>separator</strong> willbe receiving fat laden wastewaterTable 2 (Meat processing facilities)Meat processing facilitiesSmall up to 5 large livestock*MediumLargeup to 10 large livestock*up to 40 large livestock**1 large livestock = 1 cow (cattle) = 2.5 pigsV P(Liter)201510F303540M P (kg) t (hours)Page 35

Size CalculationMethod 3: Q s -Calculation based on actual fixtures installed in kitchenThis calculation is based on summing the maximum output (flow) of each fixture (kettles, rinse downs, dishwashing machines, etc.)Calculating maximum wastewater flow Q s(K)from kitchen fixturesQ s(K) = ....................................................... l/sTable 3 (Wastewater flow (Q s(K) in liters/second) from kitchen fixturestotal cooking kettle tiltable cooking sinks with sinks withoutnumber (outlet) kettle (outlet) odor trap odor trap(n) 25 50 75 110 40 50 40 5012345678910n>100.450.620.750.8411.21.41.61.82n x 0.20.91.241.51.6822.42.83.23.64n x 0.40.450.620.750.8411.21.41.61.82n x 0.21.351.862.252.5233.64.24.85.46n x 0.60.360.50.60.670.80.961.121.281.441.6n x 0.160.680.931.131.261.51.82.12.42.73n x 0.31.131.551.882.12.533.544.55n x 0.51.82.4833.3644.85.66.47.28n x 0.8Total*Potato peeling machines are to be connected to an independent starch <strong>separator</strong>.Dishwashingmachine1.222.42.7233.64.24.85.46n x 0.6tiltablefryingfryingpanspans0.45 0.050.62 0.060.75 0.070.84 0.081 0.11.2 0.121.4 0.141.6 0.161.8 0.182 0.2n x 0.2 n x 0.02High pressurefloorwasher0.91.241.51.6822.42.83.23.64n x 0.4Peelingmachine*0.680.931.131.261.51.82.12.42.73n x 0.3Vegetablewashingmachine0.91.241.51.6822.42.83.23.64n x 0.4The calculation below is based on summing the maximum output (flow) of each kitchen faucet. Please note that if a fixture in the above tablehas already been included for calculation (for example a sink) that the faucet connected to this sink should not be counted. This would result indouble counting certain values. Please count one or the other.Calculating maximum wastewater flow Q s(A)from kitchen faucetsTable 4 (Wastewater flow Q s(A) in liters/second) from kitchen faucetsTotal number of faucetsDN 15(n)12345678910n>10TotalR 1 /20.230.310.380.420.50.60.70.80.91n x 0.1Q s(A) = ....................................................... l/sOutlet size (inches)DN 20R 3 /40.450.620.750.8411.21.41.61.82n x 0.2DN 25R10.771.051.281.431.72.042.382.723.063.4n x 0.34Q s -Calculation based on actual fixtures installed in kitchenTotal maximum output from all kitchen faucets and fixturesin liters per second Q s =Q s(K) +Q s(A)Q s = ....................................................... l/sPage 36

Size Calculation2.2. Calculation of influencial factorsThe following three factors (f d , f t , f r ) are required to properly size a grease <strong>separator</strong>.2.2.1. Calculation of density factor f dDensity of oils and fats at 20°Cup to 0.94 g/cm 3over 0.94 g/cm 3f d = ..............................................................Density factor f d1.01.5**for substances such as castor oil, wool fat, resin / rosin oil, beef drippings.For wastewater from kitchens, restaurants, hospitals, slaughter/meat proecessing plants as well as fish processing plants a density factor (f d )value of 1 is generally applicable.2.2.2. Wastewater temperature factor f tf t = ..............................................................Incoming wastewater temperatureup to 60°Cover 60°CTemperature factor f t1.01.32.2.3. Cleaner (detergent) solution factor f rAre standard cleaners used in the kitchen ?Cleaner solution factor f rNo1.0Yes1.3In special circumstances (Hospital for example) a cleaner solution factor of f r ≥ 1.5 could be required.f r = ..............................................................2.3. Calculating the <strong>separator</strong> size (NS) (liters/second) according to DIN V 4040-2, date 02/1999NS = Q s x f d x f t x f r NS = .............. x .............. x .............. x .............. = ..............Appropriate authorityApplicantlocation, datelocation, datesignaturesignature3. Choosing the type of grease <strong>separator</strong>3.1. Calculating the sludge trap volumeRestaurants, hotels:cafeterias, meat processing plants without slaughter, etc.Slaughter houses:meat processing plants with slaughterNS ............... x 100 liter = ............... liter NS ............... x 200 liter = ............... literPage 37

Size Calculation3.2. Type of grease <strong>separator</strong>Installation location:free standing in frost free areaDelivery to installation siteSmallest passage through which <strong>separator</strong> must pass:L x W= ............... mm x ............... mmMake and Type of free standing grease <strong>separator</strong>:Version „G“ Standard <strong>separator</strong>(Manual disposal and cleaningthrough opened covers)Version „D“ Standard <strong>separator</strong>*(Manual disposal through permanently installed disposal pipe,cleaning through opened covers)Version „D+S“ Comfort <strong>separator</strong>*(Automated cleaning and manual disposal through permanentlyinstalled disposal pipe)Version „E+S“ M Comfort <strong>separator</strong>*(Control unit controlled disposal and cleaning throughpermanently installed disposal pipe)Version „E+S“ PV Comfort <strong>separator</strong>*(Remote controlled disposal and cleaning throughpermanently installed disposal pipe)Version „SE“ for self disposal*(Self disposal of sludge and grease into separate 60 literstorage tanks)* Desired position of accessories (in direction of flow):Inspection windowleftrightAccessoriesDisposal hook-upleftrightRefill pumpsleftrightInspection window on left side (in direction of flow)Inspection window on right side (in direction of flow)Refill equipment on left side (in direction of flow)Refill equipment on right side (in direction of flow)Sampling chamber with lateral outletSampling chamber with vertical outletPump/lifting stationInstallation location:Underground installation in frost free areasOutdoor underground installation.Groundwater susceptible areaMake and Type of underground grease <strong>separator</strong>:Version „G“ Standard underground <strong>separator</strong>(Manual disposal and cleaning through opened covers, outdoors)Version „D“ Standard underground <strong>separator</strong>(Manual disposal through permanently installed undergrounddisposal pipe, cleaning through opened covers, outdoors)Made-to-order versions on requestInstallation depth D:The local frost free depth must be considered.T is measured from ground level to the bottom of the inletof the grease <strong>separator</strong>.D= ...................... mmManhole covers:Class B (12.5 ton) passenger carClass D (40 ton) tractor trailerAccessoriesSampling chamberPump in collection chamber3.3. Chosen grease <strong>separator</strong><strong>Grease</strong> <strong>separator</strong>/AccessoriesArticle Number............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................ ............................................................................................................................................................................................ ..................Page 38

NoticesPage 39

www.kessel.comQuality for more safety, more success and satisfied customersLeading in DrainageBackwater ValvesLifting Stations/PumpsDrainsSeparation TechnologySeptic SystemsPolymer ChambersRainwater Management SystemsRights reserved for technical changes.KESSEL AG · Bahnhofstr. 31 · 85101 Lenting · Germanyexport@kessel.de010-382 KA/CS 04/11