MULTI-PLATE PRODUCT GUIDE - Armtec

MULTI-PLATE PRODUCT GUIDE - Armtec

MULTI-PLATE PRODUCT GUIDE - Armtec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

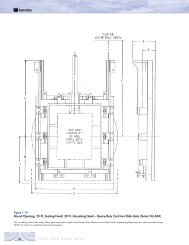

<strong>MULTI</strong>-<strong>PLATE</strong>TYPICAL SPECIFICATION FOR <strong>MULTI</strong>-<strong>PLATE</strong> STRUCTURE1. General1.1. This specification is for the supply of[number of structures] - ____ mm spanx ____ mm rise galvanized <strong>Armtec</strong>Multi-Plate structure[s]. The length is___ metres (___ feet) with a nominalplate thickness of _.0 mm.1.2. Proposed product delivery andconstruction schedules shall becommunicated to all parties.1.3. <strong>Armtec</strong> shall submit Multi-PlateAssembly Drawings and InstallationGuidelines prior to the commencementof construction.1.4. <strong>Armtec</strong> Installation Guidelines areintended to be used in conjunction withthe project specifications and are not tosupersede them.1.5. All earthworks, de-watering, siteworks and plate assembly are by thecontractor.1.6. Construction shall comply with theproject specifications and drawingsincluding the <strong>Armtec</strong> Assemblydrawings.1.7. Monitoring compliance with note 1.6and inspection of works will be theresponsibility of the Owner’s ProjectManagement team.2. Products2.1. Multi-Plate sheet and plate shall befabricated in accordance with CSA G401“Corrugated Steel Pipe Products”.2.2. Each Multi-Plate sheet shall be hotdip galvanized in accordance with CSAG164 with a zinc mass as specified inCSA G401 unless an alternate coatingmass is specified.2.3. The nominal plate thickness shall be_.0 mm.3. Assembly of Plates3.1. Offloading of the Multi-Plate at thejob site is the responsibility of theOwner.3.2. The Owner, during plate assemblyand placement of backfill, shall provide adry and accessible work site andexcavation.3.3. An <strong>Armtec</strong> authorized erector, whohas a minimum of five years experiencein similar work, shall perform theMulti-Plate assembly.3.4. The structure shall be assembled inaccordance with the <strong>Armtec</strong> AssemblyInstructions provided.3.5. Bolting must be done with thecurved surface of the nut against theplate.3.6. Before backfilling, all bolts shall betightened to a torque between 200 and350 N.m (150 to 250 ft-lbs).4. <strong>Armtec</strong> Supervision (Optional)4.1. <strong>Armtec</strong> will provide an experiencedSite Inspector to supervise constructionat the following key times (at the optionof the owner) at an agreed upon interval;4.1.1. Start of plate assembly.4.1.2. Prior to the commencement ofbackfilling (assembled structure shapecheck).4.1.3. Start of critical backfillplacement.4.1.4. During backfill placement(shape monitoring).4.1.5. When Initial covering andcrossing of backfill and equipmentover the structure takes place.4.1.6. During backfill/cover placementto final grade.4.2. The <strong>Armtec</strong> Site Inspector shallhave full “Stop Work” authority for when<strong>Armtec</strong> Installation Instructions orprocedures are not being followed orwhen the shape monitoring programindicates that backfilling shouldtemporarily cease.5. Winter Construction5.1. Winter construction shall be avoidedwhenever possible.5.2. If winter construction is required,special conditions for cold weatherconstruction must be followed. An<strong>Armtec</strong> representative must beconsulted for further details.<strong>Armtec</strong> is a leading Canadian infrastructure and construction materials company combining creativeengineered solutions, relevant advice, dedicated people, proven products and a national presence witha local focus on exceptional customer service.1-877-5-ARMTEC | ARMTEC.COM<strong>Armtec</strong> / Products and Services / Drainage Solutions and Water Treatment / Multi-Plate / Technical Brochure | 2011–07