brickjournal7online

brickjournal7online

brickjournal7online

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

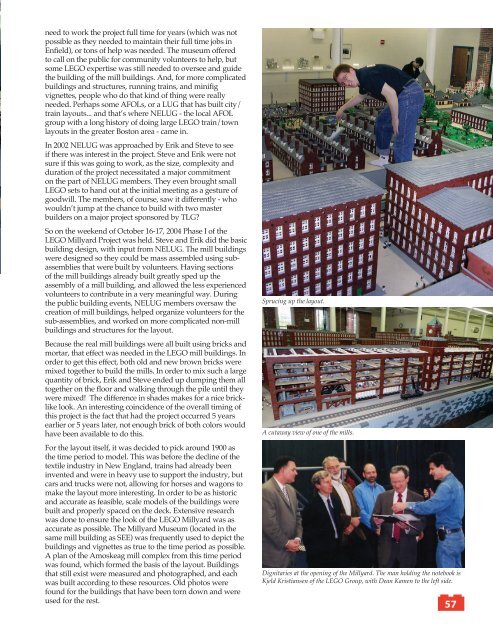

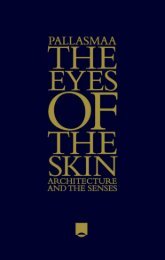

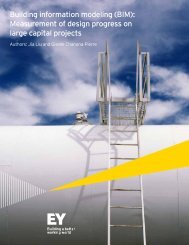

need to work the project full time for years (which was notpossible as they needed to maintain their full time jobs inEnfield), or tons of help was needed. The museum offeredto call on the public for community volunteers to help, butsome LEGO expertise was still needed to oversee and guidethe building of the mill buildings. And, for more complicatedbuildings and structures, running trains, and minifigvignettes, people who do that kind of thing were reallyneeded. Perhaps some AFOLs, or a LUG that has built city/train layouts... and that’s where NELUG - the local AFOLgroup with a long history of doing large LEGO train/townlayouts in the greater Boston area - came in.In 2002 NELUG was approached by Erik and Steve to seeif there was interest in the project. Steve and Erik were notsure if this was going to work, as the size, complexity andduration of the project necessitated a major commitmenton the part of NELUG members. They even brought smallLEGO sets to hand out at the initial meeting as a gesture ofgoodwill. The members, of course, saw it differently - whowouldn’t jump at the chance to build with two masterbuilders on a major project sponsored by TLG?So on the weekend of October 16-17, 2004 Phase I of theLEGO Millyard Project was held. Steve and Erik did the basicbuilding design, with input from NELUG. The mill buildingswere designed so they could be mass assembled using subassembliesthat were built by volunteers. Having sectionsof the mill buildings already built greatly sped up theassembly of a mill building, and allowed the less experiencedvolunteers to contribute in a very meaningful way. Duringthe public building events, NELUG members oversaw thecreation of mill buildings, helped organize volunteers for thesub-assemblies, and worked on more complicated non-millbuildings and structures for the layout.Because the real mill buildings were all built using bricks andmortar, that effect was needed in the LEGO mill buildings. Inorder to get this effect, both old and new brown bricks weremixed together to build the mills. In order to mix such a largequantity of brick, Erik and Steve ended up dumping them alltogether on the floor and walking through the pile until theywere mixed! The difference in shades makes for a nice bricklikelook. An interesting coincidence of the overall timing ofthis project is the fact that had the project occurred 5 yearsearlier or 5 years later, not enough brick of both colors wouldhave been available to do this.For the layout itself, it was decided to pick around 1900 asthe time period to model. This was before the decline of thetextile industry in New England, trains had already beeninvented and were in heavy use to support the industry, butcars and trucks were not, allowing for horses and wagons tomake the layout more interesting. In order to be as historicand accurate as feasible, scale models of the buildings werebuilt and properly spaced on the deck. Extensive researchwas done to ensure the look of the LEGO Millyard was asaccurate as possible. The Millyard Museum (located in thesame mill building as SEE) was frequently used to depict thebuildings and vignettes as true to the time period as possible.A plan of the Amoskeag mill complex from this time periodwas found, which formed the basis of the layout. Buildingsthat still exist were measured and photographed, and eachwas built according to these resources. Old photos werefound for the buildings that have been torn down and wereused for the rest.Sprucing up the layout.A cutaway view of one of the mills.Dignitaries at the opening of the Millyard. The man holding the notebook isKjeld Kristiansen of the LEGO Group, with Dean Kamen to the left side.57