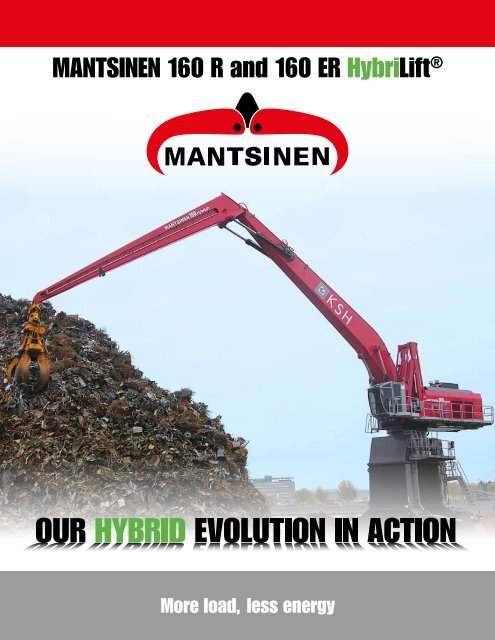

MANTSINEN 160 R and 160 ER HybriLift

MANTSINEN 160 R and 160 ER HybriLift® - Mantsinen USA

MANTSINEN 160 R and 160 ER HybriLift® - Mantsinen USA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

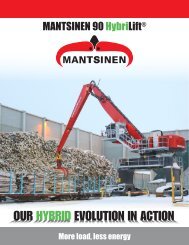

<strong>MANTSINEN</strong> <strong>160</strong> R <strong>and</strong> <strong>160</strong> <strong>ER</strong> <strong>HybriLift</strong> ®More load, less energy

<strong>MANTSINEN</strong> <strong>160</strong> R <strong>and</strong> <strong>160</strong> <strong>ER</strong> <strong>HybriLift</strong> ®<strong>MANTSINEN</strong> <strong>160</strong> R <strong>HybriLift</strong> ®Increases Energy Efficiencyby up to35%More load,less energy

lift your efficiency to the next level with hydraulic precision2006<strong>HybriLift</strong> ®testing <strong>and</strong> development2008200 <strong>HybriLift</strong> ® intoproduction <strong>and</strong> operation2010120 <strong>HybriLift</strong> ® intoproduction <strong>and</strong> operation2011<strong>160</strong> <strong>HybriLift</strong> ® intoproduction <strong>and</strong> operationThe unique <strong>HybriLift</strong> ® energy storage <strong>and</strong> redelivery systemincreases energy efficiency by recycling up to 35 % of theenergy used to lift the main boom.Mantsinen <strong>HybriLift</strong> ® cranes use smaller diesel engines orelectric motors for better fuel economy <strong>and</strong> lower emissions.Specially designed for bulk material <strong>and</strong> general cargoh<strong>and</strong>ling, with a wide range of attachments.Swing system with closed loop circuit <strong>and</strong> two swingmotors – another feature to improve operatorcomfort <strong>and</strong> fuel efficiency.201270 <strong>and</strong> 90 <strong>HybriLift</strong> ® intoproduction <strong>and</strong> operation

<strong>MANTSINEN</strong> <strong>160</strong> R <strong>and</strong> <strong>160</strong> <strong>ER</strong> <strong>HybriLift</strong> ®<strong>MANTSINEN</strong> <strong>160</strong> R <strong>HybriLift</strong> ®STICK FOOT & TIPThe stick foot <strong>and</strong> tip are hightensile strength, cast steel structures.The use of cast steel structures inthe high load stress areas ensuresthe component’s strength, durability<strong>and</strong> long service life.STICK BOXThe box of the stick isconstructed of two C profilesusing fine grain steel. Thedesign allows the stick to beconstructed with no weldingseams in high stress areas,making it extremely light<strong>and</strong> durable. Hydraulic linesare well protected within thestick.MAIN BOOM BOSSESMain boom bosses are constructed of high tensile strength cast steelstructures. The optimized design evenly distributes boom stresses acrossthe boom box structure.CAB ELEVATORThe Mantsinen cab elevator featuresindependent vertical <strong>and</strong> horizontal movementto position the operator for maximum visibilityof loading targets. The spacious stainless steel,heated, air conditioned cab has large windowsfor excellent visibility. The floor window ispositioned at a 15 degree angle <strong>and</strong> the cab isequipped with a folding instructor seat.SWING MECHANISMThe Mantsinen <strong>160</strong>R swing mechanism consists of twoswing motors <strong>and</strong> a heavy duty two row ball typeslewing ring with a 9’ diameter. Internal teeth run ina grease bath. The swing drive is a separate closedloop circuit pump providing an extremely smooth<strong>and</strong> controllable swing function for accurate <strong>and</strong> safeplacement of loads.More load,less energy

lift your efficiency to the next level with hydraulic precisionMAIN BOOM FOOTMain boom foot is constructed of high tensile strength cast steel, providingan extended service life to one of the most vital components on the machine.Double steel plates of the upperstructure extend from the boom pivot pointsto the counterweight providing an extremely rigid <strong>and</strong>strong upperstructure frame for a long service life.ENGINE AND PUMPSThe longitudinally mounted engine <strong>and</strong>hydraulic pumps are accessible from bothsides. The sound insulated compartmentkeeps engine <strong>and</strong> pump noise at aminimum.RADIATORSide by side mounted radiator <strong>and</strong>hydraulic cooler provide easy access<strong>and</strong> cleaning. Reversing fan functioncontinuously cleans radiator screenswithout interrupting machine operation.S<strong>ER</strong>VICE WALKWAYSThe wide internal <strong>and</strong> external servicewalkways provide safe <strong>and</strong> easy accessto all service points.UND<strong>ER</strong>CARRIAGEThe gantry undercarriage allows trucksor railcars to pass through for directloading. Gantry size is available indifferent heights <strong>and</strong> widths. Additionalfuel tanks are available.TRACKSThe long undercarriage is stable,durable <strong>and</strong> allows 360 degreelifting of rated loads on firm <strong>and</strong> levelunderfoot conditions.TRACK SHOESThe Mantsinen designed flat track shoesrun smoothly on gravel, asphalt <strong>and</strong>concrete surfaces.

<strong>MANTSINEN</strong> <strong>160</strong> R <strong>and</strong> <strong>160</strong> <strong>ER</strong> <strong>HybriLift</strong> ®Lifting capacity ranges – horizontal reach 90’104'96'88'80'72'V<strong>ER</strong>TICAL LIFTING RANGE (FEET)64'56'48'40'32'24'16'8'025,000 lbs35,000 lbs45,000 lbs55,000 lbs-8'-16'-24'-32'-40'96'88'80'72'64'56'48'40'32'24'16'8'0HORIZONTAL LIFTING RANGE (FEET)More load,less energy

lift your efficiency to the next level with hydraulic precisionLifting capacity ranges – Heavy lift – horizontal reach 90’104'96'88'80'72'V<strong>ER</strong>TICAL LIFTING RANGE (FEET)64'56'48'40'32'24'16'8'025,000 lbs35,000 lbs45,000 lbs55,000 lbs-8'-16'-24'-32'-40'96'88'80'72'64'56'48'40'32'24'16'8'0HORIZONTAL LIFTING RANGE (FEET)

<strong>MANTSINEN</strong> <strong>160</strong> R <strong>and</strong> <strong>160</strong> <strong>ER</strong> <strong>HybriLift</strong> ® - Technical specificationsFront equipmentMax. horizontal reach Approximately 105’Lifting capacity (approx.) 33,000 lbs @ 65’ (max. horizontal reach 90’)Lifting capacity Heavy Lift (approx.) 60,000 lbs @ 50’ (max. horizontal reach 60’)Lifting capacity Heavy Lift (approx.) 45,000 lbs @ 65’ (max. horizontal reach 84’)Engine <strong>160</strong> RTypeCaterpillar C-18 AC<strong>ER</strong>TPower522 kW @ 1,800 rpmNumber of cylinders 6Displacement18.1 litresElectric motor <strong>160</strong> <strong>ER</strong>Nominal powerVoltagesHydraulic systemOil flow, equipment <strong>and</strong> driveWorking pressuresOil flow, swingMax. swing speedSwing torque480 hp @ 1,800 rpm380 V to 690 V3 x 110 GPMEquipment 4,700 PSI. Heavy Lift <strong>and</strong> track drive 5,000 PSI132 GPM, closed loop circuit5,6 rpm276,000 lbftUndercarriageHeights 9’10” / 13’ Gantry 22’8” / 29’6”Load carrying track length 23’4”Track shoes3’3” flatDrive speeds0 – 1.2 mph <strong>and</strong> 0 – 2.1 km/hCab elevator N1-3000Horizontal movementVertical movementCab elevator N2-5000Horizontal movementVertical movementWeight without attachmentsDepending on configurationRefill capacitiesHydraulic oil reservoirFuel tanksAdditional fuel tank gantry, optionOperator eye max. 13’ from swing centerOperator eye level 5’ to 15’ + undercarriage heightOperator eye max. 28’ from swing centerCenter to center -8’ to +20’ + undercarriage height375,000 to 420,000 lbs400 gallons2 x 345 gallons530 / 1,060 gallons22’8” <strong>and</strong> 29’6” gantry undercarriages allow trucks or railroad wagons to pass through.Illustrated machines can have optional equipment. Specifications subject to change without prior notice.Mantsinen Group Ltd OyVälikankaantie 3,FI-80400 YlämyllyFINLANDYour dealer:Tel. +358 20 755 1230Fax +358 13 252 5555www.mantsinen.comMore load, less energy