S U M M A R Y

Facnor catalogue 2011

Facnor catalogue 2011

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FULL MAST / RIGGING / FURLING SYSTEMSGroup synergy and innovationFour joint companies, all specialised in marineequipment, form the Losange Group: Facnor (furling& reefing systems), Sparcraft (mast & spars),Sparcraft-US (located in USA) and SparcraftRigging. The activity of the subsidiaries being complementary,the Losange Group is able to offer a fullmast/rigging/furling system package and remainsan advantageous partner for boat builders, dealersand charter sailing companies.w w w . g r o u p e - l o s a n g e . c o mINNOVATION & SYNERGYThe Losange Group, focussing on a long-term based development, has become one of the leaders within the worldwidemarine industry. This pole position results from great involvement in innovation - supported by an engineeringsynergy (design and development department) - and from a constant dialogue with customers. A wide distributionnetwork in France and abroad also explains this successful growth.F U R L I N G & R E E F I N G S Y S T E M S■ FACNOR : Facnor is a worldwide leader in designing and manufacturingfurling systems. The company supplies many shipyards as well as ocean sailorswho participate in well known races like the Vendée Globe, The Race andthe Volvo Race, all sailing genuine "Formula 1" boats. Distribution wise,Facnor has developed a global network of dealers covering 35 countries.➮w ww.facnor.com4 /■ FACNOR : PARTNER OF HUMANITARIANASSOCIATIONSIn a socially responsible approach, Facnor supportshumanitarianprojectsundertaken bymodest sailorsready to sail milesaway sometimesin difficult seas fornoble reasons.Among other involvements, Facnor has become partner of some charity orhumanitarian associations on board of Podorange (challenge 67), Element3 (First 405), Chamade (Ovni 365), Jolokia (Rhum 50), Alioth (Azzuro 53).Web sites : www.voile-australe.com / www.element3.ch /www.chamade.ch / www.defi-integration.com / www.team-alioth.frLong sailing to these projects!Photo Credit : Défi Intégrationwww.facnor.comPhoto Credit : Barry Pickthall / PPL /F. Konyukhov

FULL MAST / RIGGING / FURLING SYSTEMSGroup synergy and innovationR U N N I N G& S T A N D I N G R I G G I N G■ SPARCRAFT RIGGING (SP.R) :SPR assembles and markets high qualitystanding and running rigging. Thisis designed to complement theSparcraft masts and booms. The riggingcomponents are of EC origin andmade from carefully selected alloy.Furthermore, the SPR products aremanufactured using experienced andreliable machining and forging methods. The numerous controls and the exhaustive traceability of these productshave placed SPR at the top rank of rigging suppliers. Moreover, SP.R. has invested in the field of architecture andinterior design with new exclusive stainless steel concept.➮www.sparcraft-rigging.comM A S T S & H A R D W A R E■ SPARCRAFT : Sparcraft, associated with "excellence" and "innovation" in marine engineeringfor over 40 years, has been focusing on design and productionof high quality masts, booms and deck equipment. The company ownsmodern production means run by highlyskilled teams spread over four productionsites. Many shipyards and charter sailingcompanies rely on Sparcraft products. A strongdistribution network supports these productsworldwide.➮www.sparcraft.com■ SPARCRAFT US : This factory, located in North Carolina, is the Americanentity of the Losange Group. Sparcraft-US has its own productionunit that covers 4000 m 2 and this includes one of theworld largest anodising baths (21.3 m long). With a networkof dealers across the United States, Sparcraft-US has becomeone of the most important aluminium mast manufacturers inthe USA.➮www.sparcraft-us.com/ 5www.facnor.com

FULL MAST / RIGGING / FURLING SYSTEMSGroup synergy and innovationEXPERIENCE IN MARINE INDUSTRY■ An experience of over 30 years;■ An engineering team qualified in metallurgy as well as compositematerials;■ A synergy of means in computerised design and production;■ Human resources based on skills and dynamism;■ Products tested in extreme conditions by the most experiencedocean skippers.QUALITY CONTROL■ Our metrology department is equipped with the measuringtools needed to insure the constant conformityof the machined parts;■ A series of mechanical and chemicaltests ensures reliability ofmaterialscrédit photo : J.M. EnaultPRODUCTION : PERFORMANCE & QUALITY■ Wide production capacity including 5 production sites : 5000 masts, 7000 furlingsystems, 8000 sets of rigging (about 80 000 cables) a year;■ The longest anodising baths in the world (Sparcraft-US) and Europe (Sparcraft);■ Electrostatic powder painting box(Sparcraft-US);■ Plasma CNC cutting machine;■ CNC and traditional machining.CUSTOMER SERVICE: “LOUD AND CLEAR”6 /■ A distribution network offering an after-sale service in 35 countries;■ Our sales team is based around sailing people with real experienceto advise you from;■ Short and respected delivery time;■ Goods shipping well managed;■ An efficient after sale service;■ Our dealers' faith proves the Facnor "value".www.facnor.com

T A I L O R M A D E>> From racing to cruisingcrédit photo : CIM/B.HenryOcean racing yachts demand theabsolute highest quality of equipmentand the latest technology. Facnor furlershave been selected by skippers inthe Vendee Globe, Volvo Race,Around alone, The Race and theAmerica's Cup to handle their specialfurling requirements.We work closely with these and othersailing teams to develop and enhanceour products considering what conditionsthey must endure. The result ishigh quality products tested in the roughestconditions and pushed to thelimit by great sailors. In return theseinnovations are made available to allsailors who desire the very best gear.CUSTOMINTRODUCTIONP8CARBON FURLING GEARSCUSTOM STRUCTURAL FURLERSCUSTOM GENNAKER FURLERSP9HALYARD LOCKSSPECIAL FITTINGP10C U S T O M E Q U I P M E N T/ 7www.facnor.com

MAXI-YACHTS & MAXI-COURSECustomKnow-how & Tailor made solutionsPhoto : M49 © Azzura MarineThe custom projects for ocean cruising or racing maxi-yachts requirehigh tech means: computerised design, technical knowledge in metallurgyand composite materials, and a data-base constantly updated.Our team offers a good response, an efficient shipping managementas well as an innovative spirit and capacity. Facnor has been successfullyplaced at the top rank of custom equipment suppliers.MAXI-YACHTS EXCELLENCEMeeting a technical capacity in design andproduction as well as the specific knowledgeof the requirements of ocean racingequipment, Facnor is now considered as "the mostexcellent" in furling systems. Facnor Team has achieveda 30-year experience in designing and manufacturingnew furling equipments thanks to our investment inresearch (patents) and the cooperative projects withmany ocean skippers. This leads Facnor to the top rangeespecially in custom gears (ocean and maxi yachts).Dark Shadow (Wally 100’) -Adolfo OriaFacnor and the Maxi-yachts :“Haute couture” & tailor made productsAs supplier for Ocean racing boats (Open 60, maxiocean trimarans), we have also offered our knowledgeto maxi-yachts. The great loads for ocean racing boats(“Formule 1 of the seas”) and maxi-yachts both requirevery high quality equipment. Those gears of “Haute couture”are designed and produced by Fanor Team withcare and the necessary resources.By this way, Facnor has succeeded in supplying the mostprestigious classic maxi-yachts.MAXI-COURSE EXCELLENCEFacnor is one of the best-known manufacturers of furlingsystems for ocean racing mono - and multihulls.The repeated successful tests carried out at sea bywinning ocean racers as well as Facnor Team's inclinationfor challenges and innovation pushed our companyto a leading position.Ocean races obviously require a high level ofskills in boat equipment manufacturing. Like inFormula One the greatest assets of a team is thecapacity of finding ahead the most adequate technologicalsolutions. Every parameter of such complex projectsneeds to be calculated with precision and testedbefore the race. For this reason, project managers ofocean racing boats work with the equipment suppliersfar ahead before the race starts. This is the race beforethe Race... Our Teams like meeting such challengeskeeping in mind that our products have "to cross theline" (generally in both ways).We worked on various boat equipment projects and allwere highly requiring: 70’ ABNAMRO (winner of the VolvoRace), many Open 60’, somemaxi multihulls (Géant,Groupama), Mari-Cha (amongthe 140’ one) and the MultiOne Design 70 (MOD 70).Motivated by the same desire tosucceed in our projects, we areproud of our long term cooperationwith the most famousboat racing Teams. For instance,we have collaborated withMichel Desjoyeaux on all his mono- and multihull units.We had already prooved our capacity of innovating,the constant high quality of our products and our reactivesolutions to their problems. Like the skippers and theproject managers we are very demanding and give ourbest to succeed...Photo : © J. Nash, TEAM ABN AMRO8 /FACNOR : PARTNER OF GLOBAL OCEAN RACE■Facnor supports this Class 40 racing project originally initiated by Josh Hall. Throughout GLOBALOCEAN RACE 2011-12 the participating boats will sail in the most difficult seas of the planet.Starting in Mallorca (Spain), the race will stop in Cape Town (South Africa), Wellington (NewZealand), Punta del Este (Uruguay) and Charleston (USA) before coming back to Mallorca, i.e. 30.000 miles totally.www.facnor.com

CustomKnow-how & Tailor made solutionsCUSTOM PARTSCARBON FURLING SYSTEMSIn comparison with existing products fitted with foil sections, the carbon furling system gives asubstantial reduction in weight (approx 50%). The “water drop" shaped sections offers betteraerodynamismics. The section components are glued together giving superior resistance totorque than a screwed assembly.Two models : SC40 & SC50 - section length: 4 meters.CUSTOM STRUCTURAL SYSTEMSUnlike continuous line Code zero & Gennaker furlers, these"structural systems" are fitted permanently on the sailingboat. It is an "in and out" furling system to handle Genoa,Solent, Staysail, or even ORC. The structural system componentsare: a swivel fixed on the mast, a continuous line drum fixed on thechain plate, and an anti-twist cable linking both mechanisms. Thiscable transfers efficiently the rotation from the drum to the swiveland is captive from the sail tape. The sail is latched at the tack andhalyard points. The advantage of the system is the total reduction ofweight. It is lighter to fit a textile forestay than a structural furler with carbon sections. Seepage 29.CUSTOM CODE ZERO & GENNAKER FURLERSFacnor has managed to createa significant know-how todesign and conceive customparts.Photo Credit : Y. Zedda (Groupama III)Facnor is "the" precursor in manufacturing continuous lineCode zero & Gennaker furlers, we have supplied these since1998 and in that we are often copied but never equalled.Most 60' monohulls and multihulls are now equipped with Facnorcontinuous line Code zero & Gennaker furlers: very light, reliableand safely handled alone. These furlers are designed to supportthe high working and breaking loads of over 500m 2 Gennakers(working loads up to 40 tons). See page 33.KNOW-HOW, RESEARCH ANDDEVELOPMENTOur Design teamcreates tailor madeequipment in order toimprove the performance of the product: tension,resistance, weight, handling... Everyparameter is measured and simulated thanksto our research and development means(powerful softwares and computers). Eachproject is considered as unique and dealtwith as such.Photo Credit : Barry Pickthall / PPL /F. Konyukhov/ 9www.facnor.com

CUSTOM HALYARD LOCKSCustomKnow-how & Tailor made solutionsHALYARD LOCKSUse : This system is mainly dedicated to flying forestays that once down reduce the headweights and the heel. Used also for mainsail, this locking device is widely fitted now onmaxi yachts.Functioning : When the sail is up, by pulling the halyard sharply, it locks or unlocks thehook.1Locking : pullsharply thehalyard (sail up).2Unlocking : pull sharplyagain the halyardOnce the lock isfastened, thehalyard is freefrom any loadand becomes thecontrol rope forunlocking the lock.Without the lock : thehalyard under loadcompresses additionallythe mast.With the lock, thehalyard does notadd anycompressiononto the mast.Photo : Gilles Martin-Raget / Groupe BelThe advantages : The high rig and halyard loads used by racing boats is transmittedinto the rig, giving high mast compression loads. By locking the halyard directlyonto the front head of the mast, the loads onto the mast are reduced by half.Moreover, the removable Solent gives a possible gain in weight. Furthermore, with thehalyard lock the sheaves at the head and the blocks at the step of the mast supportconsequently less load.External/Internal fitting to the mast : The halyard lock canbe equally fitted inside the mast or outside on an existing head attachment (for instanceattachment for a removable baby stay).- Internally fitted lock : in this case, the external body of the lock is directly laminated (compositemast) or riveted/bolted onto the front head of the mast. The luff reaches an optimumlength. The halyard runs down directly inside the mast. A large sheave can be fitted for smotheroperation.- Externally fitted lock : It can be fixed onto one head attachment with an articulated device(toggle, latching, Unibal ball or others). In this case, a small diameter sheave is integrated inthe hooking system. The halyard can then run down inside or outside the mast.Photo : AwentechMast fitted-in lockSPECIAL FITTINGS10 /Conception and production capacity combined withquick responsiveness : thanks to a Design team and productionmeans of ESIM, a CNC machining company andalso Losange Group member. Facnor specialises in providingmany "One Off" special products to maxi yachts : titaniumpadeyes, chainplates high-load blocks,...etcwww.facnor.com

HEADSAIL FURLING& REEFING SYSTEMSNEW!>> Your furling system foryour navigation programFacnor team is very much involved ininnovation and customer needs. This,as well as the expertise of the mostcompetent skippers, has led to theadaption and improvement of theFacnor headsail reefing system range.For each range, specific features hasbeen developed. Each sailor will beable to find the Facnor furling gearsuitable for his navigation : classicdrum (LS/LX/RX), webbing drum (FD),continuous line drum (RC) or electricalmotorised drum (RMEJ).GENOA & STAYSAILFOUR RANGESOF JIB FURLERSLS/LX/RX CLASSIC DRUM FURLING& REEFING SYSTEMSP12RC CONTINUOUS LINE FURLING& REEFING SYSTEMSP18NEW!FD WEBBING FURLING & REEFINGSYSTEMS P20 & 21ELECTRIC MOTORIZED FURLING &REEFING SYSTEMS RMEJ P24 & 25Photo : © Marc Ducrey / ChamadeHEADSAIL FURLING & REEFING SYSTEMS/ 11www.facnor.com

CLASSIC DRUM FURLING & REEFING SYSTEMSLS-LX-RXStrength and reliabilityFrom the smallest of cruising yachts to the biggest roundthe world race yachts, they all have something in common,the same Facnor technology. As a result, the LS/LX/RXranges guarantee a secure and long life navigation.Photo Credit : Voile Australe / www.podorange.comRACE DEVELOPED TECHNOLOGYBearing box : STRENGTH and RELIABILITYLike the Facnor carbon furling systemson board of Jean Luc Van DenHeede’s 80 footer, the Ls/Lx/Rxdrum and swivel are fitted with a “bearingbox” (see above). This was testedover ocean races under loads up to 20to 30 times higher than a 30ft cruisingboat. Even under high halyard tensionfurling remains easy. This innovativesystem is now available for every boatthanks to Facnor continuous development.Other interesting advantages :the easy installation of Facnor reefingequipment, well-known and experiencedby marine professionals.DRUM&SWIVELWATERPROOFThanks to 2 elastomer mouldedtwin rim joints proofingagainst salt water and ultraviolet raysROTATING TACK FITTING(LX & RX)Fitted with torlon®bearing, this systemtakes upautomaticallythe sail fullnesswhen furling andoffers a bettersail shape whenit is partially furled1/4BEARING BOXComponents: a stainlesssteel thrust bearing between2 large self-lubricatingpolymer fibre bearingsSMOOTH ROTATIONThis bearing box takes theaxial loads (halyard tension)and lateral loads(outhaul tension)HARD ANODISINGA hard anodising (40microns), similar towinches, protects theseparts against impacts andabrasion12 /www.facnor.com

LS-LX-RXStrength and reliabilityCLASSIC DRUM FURLING & REEFING SYSTEMSSAIL FEEDER(LX range)The included pre feedergives the idealfitting to hoist thesail aloneHALYARD DEFLECTOR WHEELPrevents the Genoa halyard and anyother halyard from wrappingaround theforestayEASED INSTALLATIONwith the bottom telescopicsection, no need to cut thetop foil section(see p. 28)SWIVEL SMOOTHROTATIONEven under high loads,featuring the innovativebearing box like the drumSTRONG CONNECTIONSImproved torque resistancemakes the furling easy even underloads (see details p.28)FACNOR ADVANTAGES360°LARGE RANGE OFSECTIONS (5 SIZES)These sections allow agradual and regular furling(see details page 28)SYNTHETIC INSULATIONSituated between differentmaterials to prevent electrolysis360° ADJUSTABLEFURLING LINE GUIDEFor an optimal runningof the furling line (norubbing)■ Smooth rotation even under high loads■ Maintenance free■ Large range of sections■ Strong connections■ Smooth stainless steel feeder + pre feeder (LX range)■ Rotating tack fitting (LX/RX range)■ Adjustable guides■ Insulation between different materials■ 40 micron hard anodising (mechanisms)■ Easy installation thanks to the bottom telescopicsection (see p. 28)“SAILOR TIP“Sail downwind to furl in”Sylvain Letouzé, Technical/Salesassistant & ex-professional skipperBy strong wind, when it is tough to furlin the Genoa, the right reaction is tosail downwind. The apparent wind and the pressurein the sail decrease. Sheets very slack, this makeseasier to furl. Other care: before departure, checkthat with the Genoa out the furling line has a fewturns left round the drum, this will be useful in caseyou furl in the sail tighten afterwards!...”./ 13www.facnor.com

CLASSIC DRUM FURLING & REEFING SYSTEMS LS-LX-RXEasy installation & widely developped ranges4 POSSIBLE TYPES OF INSTALLATIONThe drum fixation depends on the bottom forestay terminal fitted on your boat.As shown below, 3 extra options can be added to the standard furling kit (1) :- short link plates (bent stainless steel plates) (2)- internal turnbuckle option + short link plates (extended drum nose) (3)- long link plates (4)1 23 4internalturnbuckleAll models: The bottom fixingpin (marine quality stainlesssteel) is delivered with a nut(nylock) that insures a reliablefixing of the forestay and thefurling system.chain plates(not included)short link plateslong link platesBottom forestayterminalEye+ chain platesEye+ jaw toggleTurnbuckle+ double jaw toggleTurnbuckle+ double jaw toggleType ofinstallationStandard with short link plateswith internal turnbuckleoption + short link plateswith long link platesLS STANDARD & LX UPGRADEDRANGESLS / LX / RX according to your sailing programme : you will find within the three ranges of headsail furlingand reefing systems, the Facnor product adapted to your needs either cruising, ocean navigation or racing.LS / LX cruising programme : the LS range offers a large choice of standard models. Besides, the LX rangecorresponds to an "upgraded" range featuring a removable drum, a rotating tack fitting, and a stainless steel feeder.M o d e lBoat Length (mètres)LS 60 LS 70 LS 100 LS 130 LS 165 LS180 LS 200 LS290 LS330LX 60 LX 70 LX 100 LX 130 LX 165 LX 180 LX 200 LX290 LX3305,5 to 720’ to 23’6,5 to 821’ to 28’7,5 to 924’ to 29’8 to 1126’ to 36’9 to 1229’ to 40’10 to 1340’ to 43’11,5 to 1438’ to 45’13 to 1843’ to 60’15 to 2850’ to 90’Max forestay ø*removable eye or tunrbuckle55/32”55/32”61/4”6 - 7*1/2”9/32”*8 - 10*5/16”3/8”*8 - 10*5/16”3/8”*10 - 12*3/8”1/2”*12 - 14*1/2”9/16”*14 - 22*9/16”3/4”*SECTION :SX 25SX 25SX 33SX 33SX 39SX 39SX 47SX 47SX 53Weight per meter577 g577 g658 g658 g914 g914 g1095 g1095 g1413 gHalyard swivel CX 25 CX 25 CX 33 CX 33 CX 39 CX 39 CX 47 CX 47 CX 53OPTIONSOPTIONS : Link plates / internal turnbuckle fittingSTANDARD LSSTANDARD DRUMALUMINIUM SAIL FEEDERFIXED TACK FITTINGLUXE LXREMOVABLE DRUMSTAINLESS STEEL FEEDERROTATING TACK FITTING14 /www.facnor.com

LS-LX-RXRX:REMOVABLE DRUMCLASSIC DRUM FURLING & REEFING SYSTEMSEasy installation & widely developped rangesPhoto credit : Grand SoleilRX racing/cruising programme : If you race, the RX furlingsystems will meet your satisfaction with their aerodynamicsections (see page 28), the rotating tack fitting and the removabledrum allow you to use the system as a head foil.1Removable drum : system used as a simple head foilJust a few minutes are needed to change the furling systeminto a twin groove head foil ready for racing.234Photo credit : Demé VoilesUnscrew andremove the furling line guideRemove thehalf platesFit the twohalf protectionringsOnce the half plates are removed,a racing Genoa can be hoistedusing the twin groove head foilM o d e l RX 70 RX 100 RX 130 RX 165 RX 220 RX260 RX300Boat LengthMax.forestay ø6,5 to 821’ to 24’55/32”7,5 to 8,524’ to 29’61/4”8 to 9,528’ to 30’6 or 71/4” or 9/32”9 to 11,529’ to 37’85/16”10 to 12,532’ to 42’8 or 105/16”11,5 to 1537’ to 49’103/8”13 to 1842’ to 60’12,71/2”necessary to have removable eye or turnbuckleSECTION :Weight per meterR 14451 gR 14451 gR 14451 gR 24555 gR 26641 gR 26641 gR 34991 gHalyard swivel CX 14 CX 14 CX 14 CX 24 CX 26 CX 26 CX 34OPTIONSOPTIONS : link plates / internal turnbuckle fittingSAILOR TIPGreasing screws…Patrick LanéelleHead of Facnor Design Dpt“When assembling and servicingduring the winteryour furling gear, put grease onthe screws situatedat the bottom telescopic sectionand the top of the drum linkplates. This will simplify the dismantlingor turnbuckle access ifnecessary”.Photo Credit : Alubat - Ovni/ 15www.facnor.com

WEBBING FURLING & REEFING SYSTEMSF latD eckSafety - Innovation - PerformanceFlatDeck is a powerful furling system fitted with awebbing. This great Facnor innovation offers safeand easy headsail furling: no reefing line overridingand an important torque. Overall, with the FD lowprofile drum, you benefit from a maximum luff !WEBBING FURLER : A GREATCOMFORT IN USEGREAT TORQUE SINCE THE BEGINNING:Due to the bigger diameter of the webbingdrum, you benefit from a maximum power assoon as you furl in the Genoa (see oppositedrawing).INNOVATIONMaximum furling power!123When you start furling in, you benefit from a maximum power (pict.1)Webbing furling system : SAFETY, INNOVATION, PERFORMANCESAFETYNO RISK OF OVERRIDING :The webbing is guided evenly andsmoothly onto the drum. Thiseliminates overrides as thewebbing lays flat inside thedrum.WEBBING GUIDE EXITin stainless steel, this narrowexit guides well the webbingwhen the Genoa furls out.Photo Credit : JBoats / J111INNOVATIONThis new webbing concept illustratesour commitment to innovation anddesign in the furling system manufacturing.All the kit elements have been carefully designedfor easy and simple use featuring; newwebbing to furling line swivel, adapted stanchionblocks, large diameter drum and torlonball bearings.PERFORMANCEMaximized luff thanks to the low profile drumand the Genoa tack and foot that lays closeto the deck. The Flat Deck offers 20 cm ofadditional luff length compared to an equivalentclassic drum style furler.FlatDeckmaxSMOOTH ROTATIONBearing box supports bothhalyard and sail foot tensionsLOW BASEfitted with shortlink platesgives maximumluff length16/www.facnor.comHIGH RESISTANCE WEBBINGLow stretching webbing resistantagainst U.V. and high loads

F latD eckSafety - Innovation - PerformanceWEBBING FURLING & REEFING SYSTEMSSWIVEL :NEW DESIGNSMOOTH ROTATION- Torlon® ball bearing;- light and sturdy.LS/LX CONVERSIONINTO FlatDeckThe new FlatDeck system hasbeen designed to give Facnorcustomers the possibility toupgrade their classicFacnor furling system*by adding a new FDdrum.* LS/LX/RXHALYARDDEFLECTOR WHEEL“R” OR “SX” FOIL SECTIONSTwo types of sections accordingto navigation : “R” (elliptical) or“SX” (rounded section).See page 19 & 28.FACNOR ADVANTAGESINTERNALTURNBUCKLE FITTING(delivered in the standard kit)360° ROTATING TACK FITTINGFitted with torlon® balls, this system takes upautomatically the sailfullness when furlingand offers a better sailshape when it is partiallyfurled.■ Maximum power when you start furling in■ Maximum luff thanks to the low profile drum■ No risk of overriding■ Perfect guiding of the webbing■ Pre-fitted webbing line kit with blocks■ 360° rotating tack fitting (LX & RX)■ Matching with LS/LX/RX models■ Resistant webbing (more than 1 ton load) andagainst ultra violet rays■ Easy installation (bottom telescopic section)>> PRE-FITTEDWEBBING LINE KIT- Swivel (Stainless steel / bronze);- Webbing (from 10 to 27 m.)- Standard 360° furling line;- Blocks.WEBBING TO THEFURLING LINE SWIVELThis high resistance swivel(more than 1 ton load)prevents the webbingfrom twisting. The oblongdesign of the swivel guaranteesa free run./ 17www.facnor.com

WEBBING FURLING & REEFING SYSTEMSF latD eckSafety - Innovation - PerformanceEASY INSTALLATION WEBBING AND DRUMFEF ORTLESSWebbing fitting : the webbing kitdelivered enables a quick andsimple installation. Regarding theway the furling webbing/line runs onthe deck, your Facnor agent will suggestyou the most adapted solution.Furling system assembly : theswapping kit element offers differentinstallation schemes. Like LS/LX/RXranges (see page 14), the drum fittingdepends on the forestay terminal. You can even change yourLX/LS/RX drum for a FlatDeck one with keeping the existing foil sections.If queries, your Facnor agent will be pleased to explain thepossible configuration.>> NO OVERLAPPINGFURLING LINEWEBBING>> WEBBING TOFURLING LINE SWIVELCompactness : the gain in luff length with low profile FDdrum is obvious (see chart below).To achieve this aim, the base of thedrum has been lowered and standardlink plates are short(54mm, FD110).FlatDeckMaximum luffwebbingMin.ropeFD Dimension chartMODEL E J E+JROPE>> SPECIALSTANCHION BLOCKSAllow the swivel andthe webbing to runcorrectly through.EJFD90FD110FD170FD190FD210FD23088 48 13692 66 15892 66 158FD280FD310105 77 18218 /www.facnor.com

F latD eckSafety- Innovation - PerformanceCOMPLETE STANDARD KITWEBBING FURLING & REEFING SYSTEMSFD Standard kit : it includes drum/internal turnbuckle fitting/short link plates/foilsections & connectors / swivel as well as a furling line/webbing kit (the webbing isconnected to the line with a swivel and specific stanchion blocks are delivered). TheFD furling systems is divided in two main ranges, one orientated towards regattawith the “RX” elliptical sections (lighter and aerodynamic) and the other onetowards cruising with “SX” round comfortable sections (see the different sectionspage 28).“RACING/CRUISING” FD RANGERacing / Cruising navigation programParameters / ModelELLIPTICAL SECTIONSBoat length (feet)(meters)SECTION :weight/meterMax Forestay ø*(mm)FD 110 FD 190 FD 230 FD 31026’ to 29’8 to 9 mR 14451 gø 7*9/32”(closed turnbucklecage if open cageø > 24mm)29’ to 39’9 to 12 mR 24555 gø 8*5/16”36’ to 43’11 to 13 mR 26641 gø 10*3/8”41’ to 60’12,5 to 18 mR 34991 gø 12,7*1/2”Photo Credit : JBoats / J111Halyard swivel CHD 14 CHD 24 CHD 26 CHD 34* necessary to have removable eye or turnbuckle“R” retro-fitting : Facnor offers to the owners of 26 to 60’ racing boat equipped with Facnor “R/RX” furlingsystem (R sections) to switch for an FD drum (FD110, FD190, FD230, FD310).Comfort/cruising navigation program“COMFORT -CRUISING” FD RANGEParameters / ModelROUNDED SECTIONSFD 90 FD 170 FD 210 FD 280Boat length (feet)(meters)20’ to 26’5,5 to 8 m24’ to 36’7,5 to 11 m29’ to 43’9 to 13 m38’ to 60’11,5 to 18 mSECTION :weight/meterSX 25577 gSX 33658 gSX 39914 gSX 471095 gMax Forestay ø (mm)ø 55/32”ø 6 / ø7*1/4” - 9/32”ø 8 / ø10*5/16” - 3/8”ø 12 / ø14*1/2” - 9/16”Halyard swivel CHD 25 CHD 33 CHD 39 CHD 47* necessary to have removable eye or turnbuckle“SX” retro-fitting: Boat owners possessing a Facnor LS/LX furling equipment (SX sections)can enjoy the comfort and performance brought by the drum FD models (FD90FD170, FD210, FD280). For further information, please contact your Facnor agent./ 19www.facnor.com

CONTINUOUS LINE FURLING & REEFING SYSTEMS RCContinuous line & maximum luffThe RC furling range is fitted with a low profile drum giving amaximum luff length. The continuous line wheel generates aconstant torque and prevents line from overlapping. These specificperformances and safety features combined with sturdiness,have lead to a wide reputation specially for single-handed sailing.The RC low drum design meets the satisfaction of the mostrequiring sailors who like discreet and neat products.EFFICIENT & AESTHETICOur experience in designing continuous line furlersIn the past the continuous line furling systems used to be fitted onGennaker furlers or Headsail structural furlers. However, they are nowavailable on the RC headsail reefing systems. Compared to a conventionaldrum, the advantages of a continuous line system are numerous: a bigger luff available, greater furlingpower due to a larger diameter drum, no risk of overriding. A technology directly developed fromracing Gennaker furlers or "structural systems" (structural furler, see page 10) fitted on Open 60's.Furthermore, this model can be fitted on existing Facnor reefing system (R range).MAXIMUM LUFFPhoto Classic 35 - David RéardMAXIMUM LUFFCONTINUOUS LINE DRUMThe large diameter of the continuousline drum increases thefurling power and reduces theefforts. It also prevents the furlingline from overriding.RC model “maximum luff”Conventional drumTack pointon classic drumTack pointon RC drumDeck fixation point20 /www.facnor.com

RCCONTINUOUS LINE FURLING & REEFING SYSTEMSContinuous line & maximum luffBEARING BOXComponents: stainless steelthrust bearing and twofibered polymer bearing(LS/LX/RX models)Photo Credit : © Ed Tadzik / Southern Cross SparsFACNOR ADVANTAGESPhoto : LoftboatsHEAD FOIL :RACING ELLIPTICAL SECTIONSThis range of aerodynamic sectionsoffers a good penetration inthe air and the double-grooveallows changing the sail easily. The "R"section improves the performance of theRC continuous line system.■ Maximised luff thanks to low profile drum : theGenoa outhaul follows the deck■ Furling power increased■ A constant pull supplied by the furling line■ Easy handling■ Low profile design■ Internal housing for turnbuckle■ Waterproof bearings■ Simple installation as a classic Facnor furling system■ Eliminates risk of furling line overriding■ Possible adaptation on former "S" or "R" sections■ Rotating tack fitting with torlon ® ball bearings totake up sail fullness■ Large range : RC100, RC180, RC220, RC300Photo : A 35 - Ettore YachtingSIMPLE FITTING & EASY ACCESSTO THE TURNBUCKLEEasy access to the turnbuckle.This fitting system of the drum allows toquickly check the forestay bottom parts.FURLING LINE EXITAllows guiding the furling line around the clam cleatwithout any risk of wearing/ 21www.facnor.com

CONTINUOUS LINE FURLING & REEFING SYSTEMS RCContinuous line & maximum luffRC FURLING SYSTEM FITTING TO YOUR BOATMODEL RC 100 RC 180 RC 220 RC 300Boat LengthMax. Forestay øSECTION :Weight per meterStandard length sectionmfeet8 to 9 m26’ to 30’7*9/32”*R 14451 g2 M6’8”9 to 12 m30’ to 40’8*5/16”*R 24555 g2 M6’8”11 to 13 m38’ to 43’10*3/8”*R26641 g2 M6’8”12,5 to 18 m+ 43’12,7*1/2”*R 34991 g2 M6’8”Halyard swivel CX 14 CX 24 CX 26 CX 34OPTIONspliced furling line■ ■ ■ ■* removable eye or turnbuckleRC 220A SIMPLE INSTALLATION22 /Easy access to the turnbuckle :The new RC continuous line furling and reefing system can be fittedeither on a rigging screw or an eye/link plate terminal. Thering fitting at the bottom of the drum allows an easy and quickaccess to the forestay terminal for a simple check or a slightadjustment. This ring fitting sets separately the forestay from thedrum. By removing a few screws, the drum can be lifted up.Moreover, this fitting contributes to an additional articulation ofthe furling system that eases the drum bearings.“Halyard slack…”Pierre Legoff, SparcraftTechnical and Product ExpertIt is not because theGenoa is fitted with afurling system that thehalyard cannot be slackwhen sailing downwindor by light wind (and inversely), in order toimprove boat performance. Also, aftercruising or racing, one should not forget toslacken the halyard when back at berth,this will usefully release tension in the sail,sheaves and above all the swivel.”“SAILOR TIPwww.facnor.comInstallationwith turnbuckleRing fittingRingfittingInstallation withEye terminalBottom eye orrigging screwInsulating ringFixing pinToggleChain plateInternal turnbucklefittingForestayterminalRotating tackfittingFurling lineexitsScrew

RCCONTINUOUS LINE FURLING & REEFING SYSTEMSContinuous line & maximum luffEXAMPLE FOR INSTALLATIONSee the example of how the continuousfurling line can run on the deck (to beadjusted according to the boat deckplan). In this case, you can put a slighttension into the furling line and use thewinch.Continuous furling line installed with a jammerMINIMUM DIMENSIONSTurnbuckle“RC” drum dimensionsMODEL ø mechanism A D* ø Furling lineø Continuousline drumD = diameter ofinternal turnbucklefittingRC 100 ø 165 56 33 ø 8RC 180 ø 220 72 38 ø 8RC 220 ø 220 72 38 ø 8RC 300 ø 271 85 40 ø 10*D = inner diameterSAILOR TIPCharly FernbachChantier Structure Salesman“Like others, I will recommend tosecure the reefing line with a stopperand to keep the line under tension.Specially by strong wind, furlingin the sail tight and then keep the sheets tighteneddownwards. ”.photo credit : Mathéophoto - Pogo 10.50 / StructuresA = distancebetween thetack and thefixation points/ 23www.facnor.com

ELECTRIC MOTORIZED FURLING SYSTEMSRMEJComfortable sailingFacnor offers a range of motorized furling and reefingsystems for any boat over 9 meters. With these electricfurling systems, the headsail becomes easy to handlefrom the cockpit with any abrupt interruption. This secureddevice will make your cruising very pleasant…photo credit : CONRAD / Conrad 66Quality: our new motor blocks are CNC machined from one piece of aluminium and protected witha hard anodising (40 microns) like all Facnor products. They are also waterproof and thereforemaintenance free.Use: the furling device is small and compact but supplies enough power to furl quickly the Genoa. The drivebelt transmission is smoother, more powerful and more efficient than conventionalgearboxes. The Facnor electric furling systems are delivered complete with sections,electric furling device, pin and link plates.RMEJ RATIO MOTOR : MAINTENANCE FREEThe worm gear ensures that the reefed sail does not unfurl. This gear is permanentlylubricated and does not require heavy maintenance. The electric furlinggear operates quietly thanks to the high precision machining of each part.Incidently, the gear can rotate either clockwise or anticlockwiseBOXTRON RELAY SYSTEMThis separate relay box eases the installationand wire connections for the motorization(see page 27)COMPACT & ELEGANT MOTORIZED UNITThe aerodynamic design of the electricdevice does not take up too much room onthe foredeck. It enables easier access tothe anchor.photo credit : Patrice Queyras24 /www.facnor.com

RMEJComfortable sailingELECTRIC MOTORIZED FURLING SYSTEMSUSE OF THE EXISTING FORESTAYThe design of the motorized devicecan be fitted with the existingforestay (eye orturnbuckleterminal).photo credit : HINCKLEY 42 DS © © Phil BennettFACNOR ADVANTAGESEASY LS-LX TO RMEJCONVERSIONLS/LX and RMEJ drums are fitted withthe same SX foil sections. Therefore it issimple to switch from an LS/LX manualgear to an RMEJ electrical equipment.■ Waterproof motorized device therefore maintenance free■ Installation over the existing forestay without any modification■ Low sound level■ Elegant and compact■ Worm gear locks the reefed sail. This gear islubricated for life.■ Quick connections with Boxtron box (optional)■ Easy switching from LS-LX manual toRMEJ motorized reefing furler■ Light weight■ Available in 12 or 24 voltsHEIGHTADJUSTMENTThe pre-drilled stainlesssteel link plates raisethe motorized device toa suitable height inorder to leave sufficientaccess for anchor. The link platesthat adjust the motorised device canbe cut to measure in order to modifythe height of the tack.SAFETYIn case of power failure,the FacnorRMEJ furling systemis fitted with amanual back- updevice so that youcan use a winchhandle or alternatively our emergencycontinuous line system(see page 27)./ 25/ 25www.facnor.com

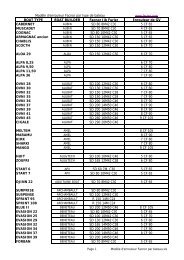

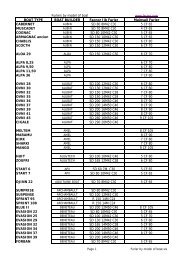

ELECTRIC MOTORIZED FURLING SYSTEMSRMEJComfortable sailingTHE ELECTRIC FURLING GEAR SUITABLE TO YOUR BOATELECTRIC MODELRMEJ 1.02SX 39RMEJ 1.02SX 47RMEJ 2.02SX 53BOAT LENGTHmfeet9 to 13 m30’ to 42’12 to 18 m40’ to 60’+ 16 m+ 55’Max. forestay Ø(*turnbuckle necessary)8 mm - 10 mm*3/8”12 mm - 14 mm*9/16”14 mm and ++ 9/16”SECTION REF SX39 SX47 SX53POWER 400 w** 400 w** 900 w**SWIVEL REF CX 39 CX 47 CX 53** This power develops high performance while consuming low energy, therefore saving batteries.SECTIONS & SWIVELSSX SECTIONSThe sections fitted on RMEJ electric system are the same as on the LS/LX range (see page 28). These performancesections ensure a torque resistance even under high loads.CX SWIVELSThe swivels feature the same quality as the swivel delivered with the RC racing range. They are fitted withbearing box (see page 12 & 13).USE OF THE EXISTING FORESTAYThe hollow inside of the motorized device allows fitting the existingforestay (even with a turnbucklebottom terminal). Ifnecessary, it is possible toinstall the furling gear withthe forestay fixed on the masthead. You only need to removethe bottom fixation pin ofthe forestay (in some cases,you may need to add extraaccessories at the bottom ofthe forestay, see drawingbelow).TOGGLEIncluded in the standard kit26 /www.facnor.comphoto credit : CONRAD / Conrad 66

RMEJELECTRIC MOTORIZED FURLING SYSTEMSBoxtron relay systems & emergency systemsBOXTRON RELAY SYSTEMSThe BOXTRON system is a pre-assembled box containing all electrical components necessaryfor operating the electric furling gear. This compact system provides added protection for yourboat electrical installation. It is available in two versions: “TELE” (wire) or “RADIO” control.BOXTRON RELAY SYSTEM advantages :■ Protection from overloads by an adjustable electronic cut-outdevice with automatic reset.■ Sound alarm in case of failure. ControlLED’s.■ Furling begins slowly then increasesquickly with accelerated ramp up.■ Available in two versions: “tele” and“radio” control".The boxtron system (box above) can be supplied in“tele” or “radio” (wireless) control. In this case, thebox cover includes the “radio” device.Operating in any circumstancesThe “FACNOR emergency system” is made up of a notched drive wheel and a continuousline. If an electrical failure were to occur, this device allows the operator toquickly and easily furl in the headsail(standing one meter behind). As the wheel is flat,it is possible to fit it even with a narrow pulpit access. The accelerated emergency operationis an additional safety feature, especially in tough weather conditions. An innovative devicewith safety at the forefront.Simple and efficientEMERGENCY SYSTEM OPTIONThe Facnor emergency system is fitted like the emergency handle, with a standard square drive winch socket.Once the wheel is fixed, stand one meter behind the pulpit and pull the continuous line to manually operate thefurling system.TECHNICAL FEATURES■ Corrosion proof■ Auto-locking fitting on to the furling unit■ Adaptable on any standard model of electric/hydraulic furlers■ Constant torque when furling■ Headsail and mainsail easily and quickly furled in case of engine failure■ Shorter than a winch handle then less close to the pulpit■ 12 mm diameter line and protection bag included in delivery/ 27www.facnor.com

CONNECTIONS & SECTIONS FOR FURLERS SX & RFacnor ranges conversionSTURDINESSThe SX or R foil sections are common to all Facnor reefing furlers : classic drum (LS,LX, RX), continuous line drum (RC), webbing drum (FD) and motorized drum (RMEJ).So you can easily switch from one model of drum to another one (SX to SX, R to R).HIGH PERFORMANCEPOLYAMID BEARINGProtects the forestay andprevents from wearingHEAD FOILSCNC MACHINED HOLESInsuring the sectionsto be perfectly alignedMATERIAL INSULATEDScrews covered withtuff lock ® (blocking andinsulating product)2 METER ANODISEDEXTRUDED ALUMINIUMSECTIONSType of aluminium :série 6000TELESCOPIC SECTIONSAllows adjusting the section length. Like theconnectors, the telescopic section offers a hightorque resistanceStandardsectionlength 2 m( 6’8”)CONNECTORSWITH HIGHTORQUERESISTANCEGuarantee agreat rigidity atthe sectionconnectionsSX 25 / SX 33 / SX 39 / SX 47 / SX 53 ROUNDED SECTIONS (LS LX RANGES):The SX twin groove foil sections, round shaped, offer smooth furling as well as a high rigidity. We recommenda 5mm finished luff tape.øøøøø = 6mmøSX25 SX33 SX39 SX47 SX5328,5 32,6 41,5 51,5 59,628 /R14 / R24 / R26 / R34 ELLIPTICAL SECTIONS:This range of sections offers a good aerodynamicsand the double-groove allows easy sail changing.We recommend a 5mm finished luff tape except forthe R14 (4.5 mm).www.facnor.comø = 5,5 mm ø = 7 mm ø = 7 mm ø = 8 mmø ø øR14 R24 R26 R3422 25 29 34,5ø

STRUCTURALSTAYFURLERS>> Structural furler :the in/out furling systemsThe structural furler - unlike theGennaker furler - supports bothmast and sail loads. The Facnor14-100T systems are fitted withanti-twist fiber forestay from 40footers. Their reliability widelytested on ocean races hasenabled Facnor to enlarge therange from 14 to 100 tons. Thedifferent STG 3T, must be fittedwith a classic wire forestay from24 to 30 footers.GENOA & STAYSAIL14-100T STRUCTURAL STAYFURLERSTEXTILE FORESTAY (40’ to +70’)P30-313T3-4T STG STRUCTURAL WIRE FURLERS(24 to 30’) P32Photo Credit : matheophoto - Pogo10.50 Structures14-100T & STG 3-4T STRUCTURAL STAYFURLERS/ 29www.facnor.com

STRUCTURAL STAYFURLERS14-100 TFurling power & performanceFacnor has adapted the Open 60’ Staysail furlers to otherranges of fast racing boats. These structural furlers supportmast loads and can entirely furl in and out headsails (such asSolent, Staysail, Genoa). This system particularly dedicated toserials of racing boats, like Class 40’ already widely equipped,is also suitable for ocean cruising yachts.IN/OUT FURLING SYSTEMSUnlike the headsail furling and reefing system, but like the Gennaker furler, the structural wire furlerdoes not allow to reef the sail. This “in/out” system offers an optimum cut of the sail. However, unlikea Gennaker furler, it is structural: it holds the mast at the front. The forestay, traditionally in highquality textile fibres, turns. The furling principle is simple: by pulling the continuous line, the drum generatesthe rotation to the thimble of the textile forestay and the attached tack of the sail. Easy and efficient.This is the reason why this furling gear has been chosen by Class 40’ and 60’ skippers.MAXIMUM LUFF & LIGHTNESSThe structural wire furler offers the same advantages as thecontinuous line drum: a constant furling power, a maximum luffthanks to the low profile drum that keeps the jib tack low. Extrafeature: the weight saved (up to 2 times lighter than a conventionalfurling system). Ideal for “racing” boats orCruising/Racing boats!MADE FROM A SINGLEALUMINIUM BLOCKThe continuous line drum is madefrom a single aluminium block thatis CNC machined in order to offer ahigh resistanceTWO POSSIBLE ASSEMBLIESThe Facnor structural furlerscan be assembled with aclassic thimble fitted into ajaw or with a threadedthimble screwed into thedrum (Navtec screwed deviceon the drawing below)BOTTOM TERMINALallows to fit the continuous linedrum to the foredeck chain plate(Directly integrated to the drum)30 /www.facnor.comPhoto Credit : matheophoto - Pogo10.50 StructuresFURLING LINE EXITAllows to guide and keeps thefurling line around the drum

14-100 T STRUCTURAL STAYFURLERSFurling power & performanceHEAD SWIVELJoins the wire and the mast, this swivelenables the wire to turn and supportsthe mast loadsTACK EYEfor the fixation of theswivel at the head ofthe mast (delivered)ANTI-TWISTSTRUCTURAL STAYIt supports the mast andalso transmits the rotationof the bottom drumto the top swivelFACNOR ADVANTAGES■ Saving in weight (up to 5 times lighterthan a conventional furling system)STAY TERMINAL(THIMBLE OR THREADED CONNECTION)The terminal (against a thimble)transfers efficiently the furlingrotation of the torque rope.■ Product conception based on a system tested in oceanraces, waterproof and therefore maintenance free■ Constant and great furling power thanks to the continuousline drum■ Maximum luff thanks to the low profile drum : theGenoa outhaul reaches the deckCONTINUOUS LINE DRUMThe large diameter of the continuousline drum increases thefurling power and reducesefforts. And it also preventsthe furling line fromoverriding.■ Simple installation■ Resistant to heavy loads■ Possibility to tighten the halyardwith a 2-to-1 block at the bottom■ Mechanisms/wire connections:thimble fitted in a jaw or wire terminal(Navtec type) screwed in thedrum/swivelPhoto Credit : © Matheophoto.com / PogoTHE WIRE FURLER SUITABLE TO YOUR BOATParameters / Furler model 14 T 20 T 24 T 31 T 40 T 54 T 75 T 100 TBoat length (feet) 40’ 45’ 50’ 60 60/70’ 70’ +70’Kevlar wire breaking loads* 14 T 20 T 24 T 31 T 40 T 54 T 75 T 100TROD equivalence -17 -22 -30 -40 -48 -60 -76 & -90 -115 & -150Wire 1x19mmequivalence (mm)Kevlar wire working loads(safety coefficient x 2)**10 mm 12 mm 14 mm 16 mm 19 mm 22 mm - -5T 7T 8T 11T 14 T 20 T 27 T 35 T*model name = Kevlar stay breaking loads** If we replace a metal wire or a rod forestay by a textile wire, this one will be largely over dimensioned, as the essential criteria to choose themodel is not the solidity but the resistance against stretching. This is why the safety coefficient is so high./ 31www.facnor.com

WIRE FURLERS424 to 30 feet unitsSTG FROM 24 TO 30 FEETTop stainless steel toggleFixes the top swivel on the mast(included)Head swivel Joins the wire and themast, this swivel allows the wire toturn and supports the loadsSTG functioning :For smaller sailboats, the STG is a wire structural furler, light and easy to install.Just add a metal wire with terminals to the STG furling kit including a continuousline drum, deck+mast toggles, head swivel connected to the mast, and a halyardswivel connected to the sail head/halyard.HalyardswivelThe STG advantages:- up to 5 times lighter than a conventional furling system;- waterproof bearing and maintenance free;- Maximum luff thanks to the continuous line drum;- Simple installation, sail fitted on snap shackles;- Strong (3 and 4 tons loads).photo credit : Kyansailing - CB66 RacerThrust bearingwith Torlon® ballbearings.Twin rim jointsproofing againstsalted water andsun lightStainlesssteel wireø 5 to ø 7 mm(not included).Sail fitted withhanks or zip luff.Link platesAllows adjustingthe length of theforestay that iseasily removed.Ideal for unsteppingoperations)Continuous line drum(see previous page)Bottom stainless steeltoggleModel Boat length Forestay ø Breaking load Drum øSTG 3Tfrom 7,5 to 9,5metersfrom 23 to 31’ø 5 mm or ø 6 mm5/32” or 1/4”according to boat type3 tons6673 lbs119 mm** in comparison, it is1mm smaller thana Cd-RomSTG 4Tfrom 8 to 10 metersfrom 25 to 32’ø 7 mm9/324 tons8818 lbs227 mm5 mm to ø 7 mm STAINLESS STEEL WIREThe stainless steel wire is not delivered with the kit. We recommend reliable,strong and high quality products of Sparcraft Rigging, joint company of theLosange Group.Stainless steel wire(type 1x19) used on3-4 T Facnor wirefurler32 /www.facnor.com➮www.sparcraft-rigging.com

Photo Credit : Shipman / Shipman 50CODE ZERO, GENNAKER &ASYMMETRIC SPINNAKERFURLERSFX GENNAKER & CODE ZEROFURLERS P34-38BOWSPRITSP39>> Sailing fast and safeIn regatta each second savedwhile handling sails is important. Along experience in supplying tophigh quality racing Gennaker furlershas led Facnor to be a reliable partnerfor the fastest sailing boats.Facnor has kept the same innovativespirit in developing a full range offurlers : the FX for Codezero/Gennakers and the Asym-FXfor the asymmetric Spinnakers. As acomplementary equipment to flyingsails, the Sparcraft innovative bowspritmakes cruising easier.GENNAKER, CODE ZERO & ASYMMETRIC SPINNAKERAFX ASYMMETRIC SPINNAKERFURLERS P40-42F X & A S Y M F X F U R L E R S/ 33www.facnor.com

CODE 0 AND GENNAKER FURLERSSailing fast and safeThe widely installed FX range enables Gennaker andCode 0 sails to be hoisted easily, quickly and safely.Removable furling line and quick fastenings give aneven greater ease of use. The neat design gives lightnessto the high resistance mechanisms: the FX furlerslet you benefit from the race developed technologyfor a more comfortable cruising.FX Flying sail furlers : Comfortable sailingLike the structural furler, the Code zero & Gennaker furler is an in/out systemthat does not allow reefing of the sail. The anti-twist rope is captive within thesail luff tape. The sail head and tack are seized to thimbles. These are fixedto the swivel and the drum with quick-release pins. The advantage is the quick installation.The furled sail can quickly be stored after use. With the Code zero &Gennaker furler, no more knots with the Spinnaker around the forestay: in light windthe Code zero & Gennaker can be quickly hoisted and unfurled. This is perfect whenyou are sailing downwind: with Facnor the performance is worry free!SAFETY PINto release or secure thethimble (drum & swivel)** for FX 2500,4500 & 7000modelsSAILOR TIP“FURLING LINE TIGHTEN & ROPE...”Christian ChardonnalSkipper of “Neurodon” (Class 40’)“When racing, we attacha piece of rope atthe clew of the Gennakerthat the foredeck crewmember easily grabs inorder to quickly jibe. Whensailing single handed werecommend to keep thereefing line under tension sothat the sail does not furl out without control”.blog : http://lesloustikspourleneurodon.blogspot.comweb : http://www. neurodon.comA STRONGONE-BLOCK DRUMThe main body of the drum ismade of one aluminiumblock and is CNC machined.(sturdier than a casting part).CONTINUOUSLINE DRUMThis system eliminates furlingline overrides.REMOVABLEFURLING LINE34 /www.facnor.comQUICK FASTENING DEVICEFX furlers are fitted with quick fastening device(see p.36).

Sailing fast and safeCODE 0 AND GENNAKER FURLERSTORQUE ROPEIt transfers efficiently the furlingrotation from the drum to theswivel. The torque rope is captivewithin the sail luff tape.(supplied on request)SWIVELAvailable in differentversions (ex. Two-to-oneversion, advantage : optimalhalyard tension)THIMBLE- Stainless steel forFX2500/4500 models- Aluminium for FX7000/12000/20000models (options p. 38)Photo Credit : Shipman / Shipman 50FACNOR ADVANTAGES■ Handy : removable furling line without any mechanicaloperation, possibility to leave the furling line fittedalongside the deck■ Lightness : optimized system and ultracompact■ Easily installed and stored (the continuousdrum is fitted with quick-release-pin fastenings ).■ Sturdiness : strong one-block drum■ Maintenance free : high protection of the mechanisms■ Stainless steel guide insures a smooth and perfect runof the furling line■ Continuous line drum: low profile design (just abovedeck), i.e. a maximum sail luff■ Design neat and purified on all the range■ Large range of fitting options : 2-to-1 swivel, specialtextile shackles, Thimble,...(See page 38)REMOVABLEFURLING LINEGUIDE/RUBBER RINGCONCEPTThanks to a clever innovation,the continuous furlingline can be quickly removedwithout any complication.This special feature offersthe advantage that the furlingline can remain on thedeck for further use. Thereis no need to remove thestanchion blocks. Just removethefurlerand thefurledrubber ring to allow thecontinuous line furlersail.1 - 3Put on / Remove2 - 23 - 1/ 35www.facnor.com

CODE ZERO AND GENNAKER FURLERSUSE CONDITIONS OF THE FURLERUse conditions :The use range of the sails as shownon the diagram opposite varieswith the force of the wind. We canmainly bear in mind that the FXfurlers are better adapted for usewith flying headsails betweenbeam and broad reach (i.e. CodeZero and Gennaker). The complementaryuse with closer reachheadsails is possible, however,under certain conditions (see p. 37). Please contact the closest Facnor agent for further advice.Installation of the Code zero and Gennaker furler:the short sequence below shows how easily the Gennaker furler is installed :Sailing fast and safeE A S Y I N S T A L L A T I O N O N B O A R D1 2 3 4 5 6- Lie the Gennaker furled on the deck, fit the bottom thimble onto the drum (fig 1&2);- Fit the upper thimble onto the swivel (fig 3), and adjust the bowsprit (fig 4);- Hoist (fig 5), unfurl while controlling the sheet (fig 6). Ready !Note: always keep the reefing line under tension and fit a line stopper. Lower the furled sail after use.36 /FURLING LINE AND FASTENING DEVICESRemoving the furling line : “as easy as abc” : Thanks to a clever innovation, the continuousfurling line can be quickly removed without any complication. This special feature offers the advantage that thefurling line can remain on the deck for further use. There is no need to removethe stanchion blocks. Just remove the furler and the furled sail.Easy installed and stored : The continuous drum is fitted with quickrelease-pinfastenings (snap shackles or special textile shackles) that make forquick and easy installation and removal of the Gennaker or Code 0.Quick - release - pin fastenings : The sail can be removed from thefurler in one "click". Fitted with :Push-pin (FX 12 000 & FX 20 000 models)SAILOR TIPNew safety-clip fastening (FX 2500, 4500, & 7000 models)G-ring (FX 900 & 1500 models)Easy change and re-use of continuous line furlerAs it is very simple to remove the sail from the furler and to fit theblock option on to the swivel, the Gennaker can be quickly changedfor the staysail if needed*. Furthermore, it is also easy to storethe sail and clean the furler mechanism.* provided that the loads are equivalent for both sailswww.facnor.comThe intermediate models arefitted with a safety-clip deviceBernard de RavignanNantes ShipshandlerTighten well theGennaker luff beforefurling and securethe reefing line so that the sail does notfurl out without any control.”.“

Sailing fast and safeThe Standard Code zero & gennaker furler (FXT) includes a drum as on the classic headsail furlingsystems. The drum is fitted with a shackle or a jaw at the top (tack) and with a snap shackle at the bottom(deck fixing). It is quickly installed and removed after use. Able to support high loads, the “SDG STD” model helpsto furl easily a Gennaker or a flying sail. The mechanism of the drum and the swivel are made of aluminium andfitted with steel bearings protected by waterproof joints (maintenance free). An alternative solution for users whoprefer a discontinuous furling line.* The S.W.L. is the maximum safe working load over which distortions of the furler can appear. This load is approx. 50% of the breaking load (depending on models)■ The swivel and the drum are fitted with the same bearings (top shackle for halyard fitting).CODE ZERO AND GENNAKER FURLERSTHE STANDARD CODE 0 AND GENNAKER FURLER (DRUM) FXTThe main criteria to select the FXT model is the loads of the sail (see below) :FXT MODEL FXT 4500 FXT 7000 FXT CUSTOMBoat lengthMax. sail areaSafe Working Load*9,5 à 1631’ to 55’+ 16+ 55’200 m 2100 m 21073 ft 2 2147 ft 24 500 Kg 7 000 Kg9921 lbs 15432 lbson requestTHE GENNAKER CONTINUOUS LINE FURLER FXThe continuous line Code zero & gennaker furler (FX) are made of two main components, one flat continousline drum and one swivel. This model eliminates the override of the furling line (no overlapping round the drum).The low profile design of the drum allows a maximum luff and the large diameter gives more furling power. It is halfweight of a standard Gennaker furler. The new opening guide makes the Fx furler easier to use. Facnor offers a widerange of gennaker furlers suitable from 6.50 up to the mega-yachts. Facnor, as originator of Gennaker continuousline furlers, has the longest experience in this type of products.The main criteria to select the FX model is the loads of the sail (see below) :FX MODEL FX 900 FX 1500 FX 2500 FX 4500 FX 7000 FX 12000 FX 20000Boat lengthmfeet6 to 10,5 m20’ to 30’10 to 12 m30’ to 40’12 to 14 m40’ to 45’13 to 16 m42’ to 55’16 to 20 m55’ to 70’+ 20 m+ 70’+ 25 m+ 82’Sail area advised30 m 2 55 m 2 80 m 2 140 m 2 250 m 2 350 m 2 + 500 m 2322 ft 2 590 ft 2 861 ft 2 1500 ft 2 2690 ft 2 3770 ft 2 + 5380 ft 2Safe WorkingLoad*900 kg1984 lbs1,5 ton3306 lbs2,5 tons5511 lbs4,5 tons9920 lbs7 tons15 432 lbs12 tons26 455 lbs20 tons44 100 lbs* The S.W.L. is the maximum safe working load over which distortions of the furler can appear. This load is approx. 50% of the breaking load (depending on models)STAYSAIL FITTED ON FX FURLERSA Staysail can be fitted on a FX furler : in this configuration, we recommend to install a 2-to-1 block (halyardbetter tighten and less tension in the mast). See next page.The main criteria to select the FX model is the loads of the sail (see below) :FX MODEL FX 1500 FX 2500 FX 4500 FX 7000 StaysailStaysail area maxi.(à titre indicatif )20 m 220 ft 2 30 m 2322 ft 2 50 m 2538 ft 2 70 m 2753 ft 2 over 70’ boat,it is highlyrecommended to fita structuralfurler (see page 29)Safe Working Load* 1,5 tons 2,5 tons 4,5 tons 7 tonsWe remind you that an adapteddeck attachment must beinstalled* The S.W.L. is the maximum safe working load over which distortions of the furler can appear. This load is approx. 50% ofthe breaking load (depending on models)/ 37www.facnor.com

CODE ZERO AND GENNAKER FURLERS OPTIONSBlocks, thimbles, sheaves, pin fastenings2-to-1 swivel(Example ofstaysailinstallation)Code Zeros and Gennakers are finished with luff ropesthat provide the sail with strength to handle the highhalyard load required for proper function. Facnor furlersare designed with this important feature in mind and wemanufacture thimbles that fit the jaw of the furler to accommodatedifferent luff ropes. The FX code zero and gennakerfurlers are designed with an open jaw to transmit the twist ofthe luff rope.Thimble pict.1TorqueRopeThimblepict.1The thimblesLuff ropes finished with Facnor lightweight aluminumthimbles fit the exact inside dimension of the jaw onthe furler for a clean finish at the tack and head. Thethimble and luff rope quickly transfer the furling action from the drum to the luff fortight and even furling. Facnor thimbles are CNC machined from asolid block of aluminum so they resist crushing under high loads.Consult with your sailmaker to find the best luff rope configuration foryour boat. However, you can be sure that Facnor makes thimbles thatwill suit your needs :standard thimbles : FX 2500 to FX 20000- Stainless steel (rep.1) for FX2500/4500 models;- aluminium for FX7000/12000/20000 models;NS latching thimbles (rep.2).Blocks and sheaves :Often high halyard loads are required to properly sail with Code Zerosso Facnor offer many variations of 2 to 1 fittings. Compact sheaves integratedinto the halyard swivel reduce weight aloft and increase lufflength while a block installed on the bottom of the drum can reduce theamount of mast compression. Many options are available to accommodateany specific need.Thimblepict.1Customthimblepict.22-to-1swivelFX 2500FX 4500FX 7 000FX 12 000FX 20 000Quick - release - pin fastenings :FX furlers can be fitted with different quick fasteningdevice : loops, snapshackles, shackles, ...Furling lineFX 900FX 1500FX 2 500FX 4 500FX 7 000FX 12 000FX 20 00038 /COVERS FOR CONTINUOUS LINE DRUM AND SWIVELSCover for continuous line drum(photo : Asym-FX)www.facnor.comContinuous line drum covers : The new Facnor FX and Asym FX cover is idealfor protecting your continuous line furlers from deck impacts. The cover is made ofpadded PVC and assembled with thick and strong strips. Thanks to hook-and-loop fastenersthe cover is quickly fitted.Standard available for the FX & Asym-FX 2500, FX &Asym-FX 4500, FX & Asym-FX 7000 (other cover modelon request).Swivel covers : they have the same features as the coversof the continuous line drum but with additional benefit of securingthe mast and the sailing crew. Standard available forFX 2500, FX & FXT 4500, FX & FXT 7000.

Facnor offers a Sparcraft range of bowsprits. Easily removedfrom the deck these innovative spars can be fitted onsailing boats from 25 to 57 feet. They have been speciallydesigned for Gennakers/Code zero or asymmetricSpinnakers. The deck fixing device allows a free foredeckwhen arriving at the harbour or mooring.Simple and easy functionningDeck fixing blockIntegrated line stopperComplete kit including : Easy fixation thanks to an automaticlocking device on deck fixing blocks; Simple installation (only a short backwardsmovement is needed to fit the bowspriton the deck); Quick removal and storage on a thirdfixing block; Integrated line stopper for holding thetackline; The locking system incorporates ananti-theft device. Aluminium bowsprit with special end fittings : bridle attachmentat the front and fixing block device at the back (deliveredpre-installed); Adjustable Central fixing collar; Deck fixing blocks.Technical datasOptionsREMOVABLE BOWSPRITFor Code zero, Gennaker and asymmetric Spinnaker furlerssection ø(mm) Alu.Workingdeck fittingTotal length(mm - feet)”Parking”deck fittingMinimum lengthinside (mm-feet)Deck fittingcoverMaximum lengthoutside (mm)StemheadfittingPhoto Credit : Jacques Vapillon / Dufour YachtsREMOVABLE BOWSPRITWORKINGPOSITIONErgonomic design End fitting has an integralmachined sheave; Bridle attachment integratedin the front end fittingdesign; The central fixing collar iscaptive from the bowsprit but it isremovable from the fixing block.The foredeck is therefore totallyfree (no more fixed collar in theway).Use exampleBoat length(feet)*with bridles ** FX7000 with snapshakle optionArticulating togglefor Gennaker andCode zero furlerMaximum sail area (m 2 )asymmetric GennakerSpinnaker & Code O“PARKING”fitted-in sheaveBridle attachmentFX &Asym-FXequipmentø 70 1600 - 5’3” 800 - 2’7” 800 - 2’7” 25-36’ 60 37* 1500/2500ø 80 1800 - 5’10” 900 - 2’11” 900 - 2’11” 36-40’ 82 52* 2500/4500ø 90 1900 - 6’2” 950 - 3’1” 950 - 3’1” 40-47’ 102 65* 4500/7000**ø 100 2000 - 6’6” 1000 - 3’3” 1000 - 3’3” 48-57’ 130 / 150* 105* 4500/7000**Options(see against)➮The SPARCRAFT bowsprit advantages: Easy foredeck installation and removal; Suitable for a large range of sailboats; For Code zero and Gennaker. Sparcraft Rigging, Losange group member company specializedin high level rigging, can offer you solutions for bowspritbridles. Please contact Sparcraft agents.➮www.sparcraft.comArticulating toggle forGennaker / Code zerofurler attachment,/ 39www.facnor.com

ASYMMETRIC SPINNAKER FURLERSAsym-FXSimple handlingsThe Asym-Fx allows to furl in the asymmetric Spinnakers from the cockpitby pulling the bottom furling line. The anti-twist rope rotates up to the topend. The central line connecting the sail luff and the torque rope by themiddle starts furling in. Unlike the Gennaker (Code Zero), the torque ropeis not captive from the luff tape. The drum continuous furling line preventsfrom overriding and can be left fitted on deck or easily removed.Therefore, the furled sail is quickly ready to be used.Regular furling (in/out) thanks to a simple systemStart furlingthe AsymmetricSpinnakerby pullingthe furlinglineFurling first thecentre of the luff(thanks to a centralfurling rope)Then the sail is furledand can be easilyloweredand removedSAILOR TIPErick LedouxCherbourg ChantierChantereyne dealer“As often, a careful preparationof the sailboateases the navigation at sea :you can adjust a strip*round the sail at the sheetposition, in order to hoist safely theasymmetric Spinnaker ”.* Your sailmaker can advise youREMOVABLE FURLING LINE(as for the FX, see page 31)thanks to the clever design of the stainless steelguide & the rubber ringPOINTATTACHMENTfixed on the tackor the head of the sailFURLING LINE(REMOVABLE)40 /www.facnor.com

Asym-FXSimple handlingsASYMMETRIC SPINNAKER FURLERSSWIVELRotating head fittingFACNOR ADVANTAGES■ Tested mechanism (derived from Fx range of Gennakerfurlers)■ Use of your existing asymmetric Spinnaker under certainconditions and modifications (strips+central rope)LUFF ROPETERMINALwith splicelessdevice(adjustable length)■ Safe System to fit the anti-twist luff rope into the topand bottom mechanisms (exact calculation of the luffrope length)■ Maintenance free bearings■ Stainless steel guide for aperfect grip of the furling lineANTI TWIST LUFF ROPEKevlar ® coreCENTRALCONNECTIONLINELUFF ROPE/SAIL LUFF(line + strip)■ No risk for the furling line tooverride■The sail tightly furled does notput any load in the rig■ Optional fitting (see below) :adapted system for FX continuousline drum (Facnor patent).CONTINUOUS LINEDRUMwith fitted-in ropeconnection (rotatingtack fitting)Option FittingFX / ASYM-FXsystemsuitablefor usewith anexistingFxfurler/ 41www.facnor.com

ASSYMETRIC SPINNAKER FURLERSAsym-FXOptional fittingTHE ASYMMETRIC SPINNAKER FURLER SUITABLE FOR YOUR BOATAsym-FX MODEL AFX 1500 AFX 2500 AFX 4500 AFX 7000 AFX 12000BOAT LENGTH(feet)(meters)20’ to 38’6 to 11,5 m38’ to 45’11,5 to 14 m42’ to 55’13 to 16 m55’ to 70’16 to 20 m+70’+ 20 mAsymmetric Spinnaker area (max.)Weight50 m 2 90 m 2 170 m 2 270 m 2 500 m 2538 ft 2 969 ft 2 1830 ft 2 2906 ft 2 5382 ft 2Continuous line drum 395 g 986 g 1317 g 2180 g 3440 gSwivel 250 g 531 g 755 g 990 g 1640 gAFX OPTIONSAJUSTMENT OF THE TACKFacnor has developed two options in order to be able to adjustthe tack of the asymmetric Spinnaker fitted with an Asym-Fx: 2-to-1 block and the friction block. Both devices allow to enlargethe belly of the sail and to forward the sail further downwind.2-to-1 block2-to-1 BLOCK (Draw.1)The 2-to-1 block allows to reduce the loads generated by the adjustabletack line. This option is available for the Asym-Fx2500/4500/7000/20000 models.Daw.1FRICTION BLOCK (Draw.2)This cheaper option is available from the AFX1500 up to the AFX7000 models (2-to-1 or 3-to-1 possible fittings).● The more the twoattachment points are spread,the better is the torqueDraw.2FrictionblockSplies furling line available in6, 8, 10, 12 et 14 mm diameter(Length: 12,16 or 20 mand further on request).SAILOR TIP“ADJUSTING THE TACK”Philippe TouêtIncidences Sailmaker“To sail closer to the wind even better, it isnecessary to lower the tack of the sail, thiswill push forward the belly. Inversely, lift up the tackand the belly of the sail will go backwards, you willbe able to sail further downwind.”Yann Zedda42 /www.facnor.com

FACSLIDE + LOCKSM AINSAIL FURLERS>> Full mainsail set :Above a certain area, a full battenmainsail needs to be fittedwith ball bearing cars for morecomfortable cruising. In additionto Lazy-jacks, Facslide®sets ease to hoist, lower andreef the mainsail. Furthermore,the new reefing locks completescunningly this car and trackdevice. For mainsail without anyfull batten, the Facnor CF furlinggear remains an alternativeequipment.MAINSAILFACSLIDE + FULL BATTEN CARSYSTEMS P44-46REEFING LOCKSP47MAINSAIL FURLING & REEFINGSYSTEMS P48-50FACSLIDE + - LOCKS - MAINSAIL FURLERS/ 43www.facnor.com

BATTEN CARS FOR FULLY BATTEN MAINSAILS FACSLIDE +Hoisting, reefing and lowering effortlesslyThe system of recirculating ball bearing cars is designed for full batten mainsail. Ithelps to raise, lower and reef the sail easily. The FACSLIDE® system combined witha Lazy Bag is the installation to handle perfectly your mainsail on your own.PERFORMANT & AESTHETICThe FACSLIDE® systemaims at “effortless sailing”like all Facnorproducts. The tracks (FACS-LIDE® components) areeasily fitted to the mast withslugs slided inside the mastgroove.- This installation requires no modification of themast.- Different car models can be mixed together on thesame FR25 tracks. This way, when the cars aredown, the stack height of the sail can be kept to aminimum.- The FACSLIDE® system combined with a Lazy Bagfitting becomes the perfect fitting for solo mainsailhandling.*- The cars allow adjusting the sail even when youare sailing before the wind- The FACSLIDE® components are: 2 m tracks (new),one head board car, batten and intermediate cars.* For information, a 50 m 2 mainsail weights approx. 35 kg for amonohull or 70 kg for multihull.TRACKS FITTING TO THEMAST WITHOUTMODIFICATIONThe tracks are easily fixed withslugs alongside the existingmast without unstepping(see page 46)Photo Credit : Outremer44 /www.facnor.com

FACSLIDE + BATTEN CARS FOR FULLY BATTEN MAINSAILSHoisting, reefing and lowering effortlesslyTOP AND BOTTOM STOPPERSDelivered in the FACSLIDE® kits,these stoppers prevent the carsfrom sliding out of the tracks.HEADBOARD CARScan be fitted on thehead board of theexisting sail or simplyon a ring.+ than 180°Safety-clip device(similar to the FXGennaker furlers))MONOBLOCK CARSThe FACSLIDE® cars are CNCmachined in one block of aluminium,this makes them shockproofwhen lowering the sail.FACNOR ADVANTAGES■ Monoblock design of the cars eliminates the problem of weaknesswhen caps are fitted on each edge of the car.■ The ball race is CNC machined to high precision.■ Possibility of mixing the car models (F10-20-30) in order tolower the sail stack height when the cars are down. It alsohelps reduce the total cost.■ The head board car can be fitted on the existing mainsailhead board or a ring.■ The toggle of the batten cars can turn more than 180° and fitto most batten boxes (M10-12).■ The intermediate cars are delivered with “sleeve” that easesthe fitting of the sail webbing.■ The cars are supplied with torlon® balls. The torlon® ballbearings offer a higher resistance against wearing.■ F10-20-30: flat and light tracks, safety and quick pins (seebelow) most enduring anodization (40 microns) and insulationmaterialsAUTOMATIC REEFINGReefing the sail is easy due to thelow tension on the mainsail halyard.Tensioning the luff also becomeseasy even when you aresailing before the wind.For the F40 models,Facnor has developedan efficient outhaul car.123/ 45www.facnor.com

BATTEN CARS FOR FULLY BATTEN MAINSAILSFACSLIDE +Hoisting, reefing and lowering effortlesslyTHE FACSLIDE + SYSTEM SUITABLE FOR YOUR BOATFACSLIDE MODELMONOHULLmainsail areaMULTIHULLmainsail areaF.07 * 20 M 2* / 215 ft 2F.10 45 M 2 / 484 ft 2 40 M 2 / 430 ft 2F.20 60 M 2 / 645 ft 2 55 M 2 / 590 ft 2F.30 85 M 2 / 915 ft 2 70 M 2 / 755 ft 2TRACK INSTALLATION WITH SLUGS* F07 is suitable for sailing boats under 30’F.40 130 M 2 / 1400 ft 2 90 M 2 / 968 ft 2 Two types of slugs :■ The tracks are easily fitted to your mast with slugs without unstepping and modifying it. The varioustypes of slugs ensure the compatibility of our system in most existing mast grooves. The tracks are CNCdrilled with high precision. Made of aluminium extrusion, they are also perfectly straight.Facslide + : hard 40 microns anodization of the tracks.Different type of tracksaccording to the mainsailarea:SAILOR TIP“Salted water at the head…”Pierre Legoff, SparcraftTechnical and Product Expert“Even though the head cars arepositioned 10 meter high, theyreceive sea water, therefore donot hesitate to rinse the cars withfresh water.Facnor advice: once a year put adrop of washing up liquid on the car balls.”FR07 TRACK FOR F07 CARSRAIL FR+ 25 x 15FR+25x15 TRACK FOR F10-20-30 CARSflat and round (varioussizes available)FR40 TRACK FOR F4046 /www.facnor.com

H3T-5TEasy reefingREEFING LOCKSONE LOCK FOR THE FULL BATTEN MAINSAILSFor an easy mainsail reefingFunctioning : This clever device locks the attachment of the mainsail reefing point onto the back of the boom.This installation is particularly helpful on board of multihulls equipped with powerful mainsail and also in case ofreduced sailing crew.The advantages :- This lock eases the reefing line from the load that the line normally supports (compression onto the boom),the elasticity of the rope in case of long reefing line is consequently diminished;- A stopper is no more necessary for the reefing line.The handling : After a basic preparation (mainsail sheet slack, etc, …),Locking : 1. Tighten the reefing line 2. Keep on tightening it as far as possible 3. Let it go.Unlocking : 1. Tighten the reefing line as far as possible 2. Let it go 3. Give slack.STAINLESS STEEL BODYGood resistance of use guaranteed.locked positionATTACHING LOOPAttach with a shackle or apiece of rope at the reefingpoint of the mainsail (eyeor strip).ROCKETThe internal part (rocket) slides inside theexternal body of the lock and is activated bytightening the locking line (reefing line).LOCKING LINEIt activates the rocket insidethe lock body (lockingand unlocking operations).Towards boom sheavesStainless steel rocket,reefing line unlockedATTACHMENT POINT ON THE BOOMThe end of the rocket is attached to the back of theboom (by a piece of rope).THE LOCK ADAPTED FOR YOUR BOATChoice of lock model : Lot of parameters are to be taken into account when choosing a lock, however, themost important criteria is the load levelParameters / Model 3T 5T applied to the mainsail. Therefore, it isrecommended to check with the naval90 MMainsail area135 M 2968 ft architect or sailmaker the value of these1450 ft 2loads./ 47www.facnor.com

MAINSAIL FURLING AND REEFING SYSTEMS CFSailing effortlesslySailing differently but safely: the Facnor mainsail furling system makes your sailing safe andcomfortable. No more effort to reef the sail in choppy seas: by a simple handling, you willalways have the right surface of sail adapted to the wind conditions. No more hard job offolding or flaking the sail: by a simple handling, your mainsail is quickly furled or unfurled.Your boat will always be ready to leave with sails already set up.SIMPLICITY IN INSTALLATIONSimplicity in the design:The principle of the Compact F (CF) system meets: simplicity – reliability – innovation.The CF principle: a furling system that turns a headsail inside housingsections. The drive unit of the sections is situated just above the goose neckand is operated with a continuous furling line (Facnor patent).Simplicity of installation, strong fixing :The housing sections are fixed with slugs alongside the mast (drilling not necessary).The drive unit is easy to install and does not require any modificationto the gooseneck. This kit is suitable for most of the masts and is quickly fittedwithout unstepping the mast. The CF mainsail furling system is produced usinghigh tech means. As a result: an excellent quality/price ratio.MAINSAIL WITHOUTBATTENSMainsail to be made to measurefrom suitable dacron orlaminate materials to supportstorage when furledDRIVE UNITThe furling sections turns by operating thedrive unit with a continuous line system.The drive unit is fitted with two sets of stainlesssteel ball bearings and fixed to themast above the goose neck with slugs.PLEASE NOTE: The system does not interferewith the goose neck, therefore, nomodification is necessary.48 /www.facnor.com

CFSailing effortlesslyMAINSAIL FURLING AND REEFING SYSTEMSHALYARD SWIVELFURLING SECTIONS(2 meters long)They fit inside the housing sections.The sail is furled round them.HOUSING SECTIONSThe housing sections (1,7meter long) are fixed withslugs to the mast withoutmodification.CFFACNOR ADVANTAGES■ Safe handling of the mainsail■ Simple to use■ Installation without modifying or drilling the mast■ This system allows keeping the original goose neckBOTTOM SECTIONS DESIGNThe section design prevents damaging the sail. The edges of the housing sectionincorporate a round groove so that a spare sail or protection strip can behoisted.BOOM EQUIPMENTThe mainsail furling system includes a boom kit thatallows perfect positioning of the clew. There are twoversions available:-standard kit (ref. RC): includes a ball bearing carand track (fixed onto the boom with slugs insertedinto the groove like the housing section);-special kit (ref. KB): avoids using the existing boomsheaves that are not really suitable because of theirsmall diameter. The sheaves supplied are fitted withneedle bearing substantially reducing friction (seenext page)./ 49www.facnor.com

MAINSAIL FURLING AND REEFING SYSTEMS CFSailing effortlesslyTHE MAINSAIL FURLING & REEFING SYSTEM SUITABLE FOR YOUR BOATFacnor offers a range of mainsail furling systems suitable for 6 to 17 meter sailing boat. The chart belowallows to determine the model that suits your boat (please ask for advice to our dealers, see on the website).Parameters / Model CF80 CF105CF model reference 4CF80 5CF80 6CF80 7CF80 7CF105 8CF105 9CF105 10CF105(meters)Maximum luff length(feet)6,80 M 8,50 M 10,20 M 11,90 M 11,90 M 13,60 M 15,30 M 17,00 M22’ 28’ 33’ 39’ 39’ 45’ 50’ 56’Max. boom length (meters / feet) 3,90 M / 12’ 6 M / 20’Housing section (weight / meter) 1,850 kg 3,030 kgFurling section Ø 30 mm - 1”3/4SIMPLE INSTALLATIONEASY FIXING OF THE HOUSING SECTIONSThe housing sections are fitted to the mast by inserting slugs inside the mastgroove. The housing sections and the slugs are fixed together by stainless steelscrews and Nylock nuts. All housing sections are pre-drilled and no modificationhas to be done on your mast.HOUSING AND FURLING SECTIONSThese sections are made of extruded aluminium and anodised after machining.They combine resistance and lightness. The furling sections are twingroove.The standard length of the housing section is 1.70 meter in order tolower freight cost.Photo Credit : Philippe MayoussierBOOM KITS: standard and special-standard version: track on which a ball bearing car fitted with a shackle(pict 1).-special version: track on which slides a ball bearing car fitted with a pivotingsheave (pict 2); includes two needle bearing sheaves(pict 1)Photo Credit : Meltemi(pict 2)50 /www.facnor.com