CEMA Rated Idlers

CEMA Rated Idlers - Asgco

CEMA Rated Idlers - Asgco

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

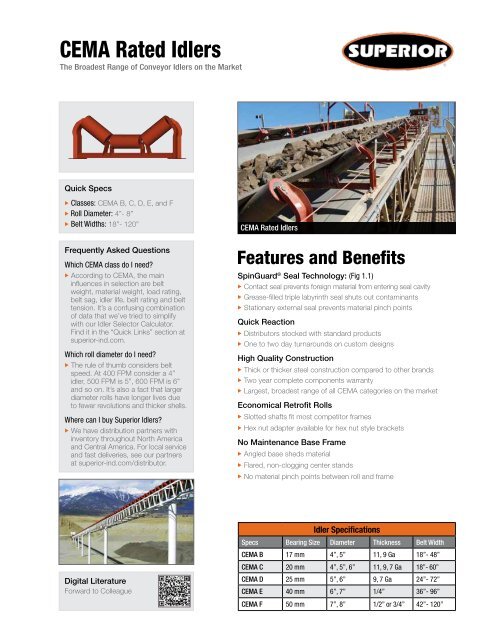

<strong>CEMA</strong> <strong>Rated</strong> <strong>Idlers</strong>The Broadest Range of Conveyor <strong>Idlers</strong> on the MarketQuick Specsu Classes: <strong>CEMA</strong> B, C, D, E, and Fu Roll Diameter: 4”- 8”u Belt Widths: 18”- 120”Frequently Asked QuestionsWhich <strong>CEMA</strong> class do I need?u According to <strong>CEMA</strong>, the maininfluences in selection are beltweight, material weight, load rating,belt sag, idler life, belt rating and belttension. It’s a confusing combinationof data that we’ve tried to simplifywith our Idler Selector Calculator.Find it in the “Quick Links” section atsuperior-ind.com.Which roll diameter do I need?u The rule of thumb considers beltspeed. At 400 FPM consider a 4”idler, 500 FPM is 5”, 600 FPM is 6”and so on. It’s also a fact that largerdiameter rolls have longer lives dueto fewer revolutions and thicker shells.Where can I buy Superior <strong>Idlers</strong>?u We have distribution partners withinventory throughout North Americaand Central America. For local serviceand fast deliveries, see our partnersat superior-ind.com/distributor.<strong>CEMA</strong> <strong>Rated</strong> <strong>Idlers</strong>Features and BenefitsSpinGuard ® Seal Technology: (Fig 1.1)u Contact seal prevents foreign material from entering seal cavityu Grease-filled triple labyrinth seal shuts out contaminantsu Stationary external seal prevents material pinch pointsQuick Reactionu Distributors stocked with standard productsu One to two day turnarounds on custom designsHigh Quality Constructionu Thick or thicker steel construction compared to other brandsu Two year complete components warrantyu Largest, broadest range of all <strong>CEMA</strong> categories on the marketEconomical Retrofit Rollsu Slotted shafts fit most competitor framesu Hex nut adapter available for hex nut style bracketsNo Maintenance Base Frameu Angled base sheds materialu Flared, non-clogging center standsu No material pinch points between roll and frameIdler SpecificationsSpecs Bearing Size Diameter Thickness Belt Width<strong>CEMA</strong> B 17 mm 4”, 5” 11, 9 Ga 18”- 48”<strong>CEMA</strong> C 20 mm 4”, 5”, 6” 11, 9, 7 Ga 18”- 60”Digital LiteratureForward to Colleague<strong>CEMA</strong> D 25 mm 5”, 6” 9, 7 Ga 24”- 72”<strong>CEMA</strong> E 40 mm 6”, 7” 1/4” 36”- 96”<strong>CEMA</strong> F 50 mm 7”, 8” 1/2” or 3/4” 42”- 120”

SpinGuard Seal Technology32112Flat SurfaceMaterial will not build up across the flat end disc surfaceStationary External SealStationary external seal helps prevent material pinch pointsbetween the frame and the end of the roller43Centrifugal Force ChamberCentrifugal force creates a self-cleaning flinger effect,keeping water and dirt out4Contact SealFirst defense against contaminants is the contact seal, whichcreates less drag than a rubber sealProducer PerspectiveFig 1.1 Idler Can Cutaway576567Snap RingCreates positive locking for seals and bearings on shaftTriple Labyrinth SealSecond defense is the triple labyrinth seal which makescontaminants travel a longer distanceu The labyrinth is also grease filled to keep contaminantsaway from the ball bearingu The seal material is more durable and is less susceptible tocorrosionBall BearingFactory sealed metric ball bearing on all <strong>CEMA</strong> rated idlersIdler Features1Base PlateOpen end stand design gives better access for single ordouble bolt hole mounting2345623No Pinch PointsNo pinch points between roll and frame means no fugitivematerial jammingLocking MechanismIntegrated locking tab or retainer clip holds roll tight to theframe and offers easy roll change out145Narrow Roll GapNo pinch point that leads to belt damageCenter StandsNon-clogging6Base AngleSheds material, preventing build-up

Producer PerspectiveWet and Wild“ In the beginning, our plant was stocked by anotherbrand and some of them were lasting just threemonths! We run a lot of wet sand and they weren’tmaking the cut. ”Seal Power“ With other brands, the problems were directlyrelated to bearing failure. Sand was getting throughthe seals and into the can. I read about Superior’sseal in magazines and now I’m witnessing it! ”Competitive Comparison“ Comparing brand to brand, we get three – sometimesfour – times the life with Superior <strong>Idlers</strong>. They definitelyfit the bill! ”Plant Superintendent at Eastern Colorado Aggregates, La Junta, COPart Number Guide<strong>CEMA</strong>RatingRollDiameterTroughingAngleIdlerTypeBeltWidthB, C, D, E, E, F 4” - 8” 20˚, 35˚, 45˚ See Below 18” - 120”12345<strong>CEMA</strong> Rating or Seriesu Specify either <strong>CEMA</strong> B, C, D, E, or FRoll Diameteru Specify either 4, 5, 6, 7, or 8 for the roll size diameterTroughing Angleu Specify either 20, 35, or 45 for the troughing angleIdler Typeu Specify the idler identification letter for the particular idler,you may need from the chart to the rightBelt Widthu Specify the belt widthIdler TypeE Troughing Idler Equal Length RollsEI Rubber Cushion Troughing IdlerEA Self-AlignerBA Bi-Directional Aligning IdlerRET Return IdlerFLT Flat Carrier IdlerFLTI Flat Carrier Rubber Cushion IdlerRETI Return Rubber Cushion IdlerRETU Urathon ® ReturnRETUSP Spiral Urathon ® Return RollRETA Return Self-Aligning Idler RollRETAI Return Self-Aligning Rubber Cushion IdlerRETV V-Return IdlerP Picking Idler Length RollsU Troughing Idler Unequal Length RollsCM Low-Profile Channel Mount IdlerCMI Channel Mount Impact Low Profile IdlerSM Low-Profile Standard Mount IdlerSMI Standard Mount Impact Low Profile IdlerGO Offset Troughing IdlerEW Wire Rope IdlerVPE Variable Pitch IdlerMOX Moxie ® RollCB CB504 SeriesLS Live ShaftLSB Live Shaft Beater

Idler StylesEqual TroughingMoxie ® RollsUnequal TroughingCB504 SeriesFeeder/PickingChannel Mount Low Profile Impact Offset Center Roll Wire RopeVariable PinchV-ReturnSelf-AlignerSelf-Aligning ReturnLive Shaft RollersBeater Bar ReturnFlat Carrier IdlerRubber Lagged Flat Carrier Return Rubber Disc Return Urathon ® Return RollSpiral Urathon Return RollGarlandIdler StylesProducts Available in <strong>CEMA</strong> <strong>Rated</strong> <strong>Idlers</strong>Idler Style <strong>CEMA</strong> B <strong>CEMA</strong> C <strong>CEMA</strong> D <strong>CEMA</strong> E <strong>CEMA</strong> FEqual Troughing x x x x xMoxie ® Rolls – x x – –Unequal Troughing – x x x xFeeder/Picking – x x x xChannel Mount Low Profile x x x – –Impact x x x x xOffset Center Roll x x – – –Wire Rope – x x – –Variable Pitch – x x x –Self-Aligner x x x x xFlat-Carrier x x x x xRubber Lagged Flat Carrier x x x x –Steel Return x x x x xSelf-Aligning Return x x x x –Urathon ® Return Roll x x x x –Spiral Urathon ® Return Roll – x x x –Rubber Disc Return x x x x –Rubber Lagged Return – x x – –Beater Bar – x x – –V-Return – x x x –Live Shaft Return – x x – –Garland Return – x – – –1-800-321-1558Find local distribution at superior-ind.com/distributor© 2011 Superior Industries CL-101EXCLUSIVE PATENTPATENTEDTECHNOLOGYCUSTOMER CARE PLAN