Goulds 3700

Goulds 3700 - Goulds Pumps

Goulds 3700 - Goulds Pumps

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

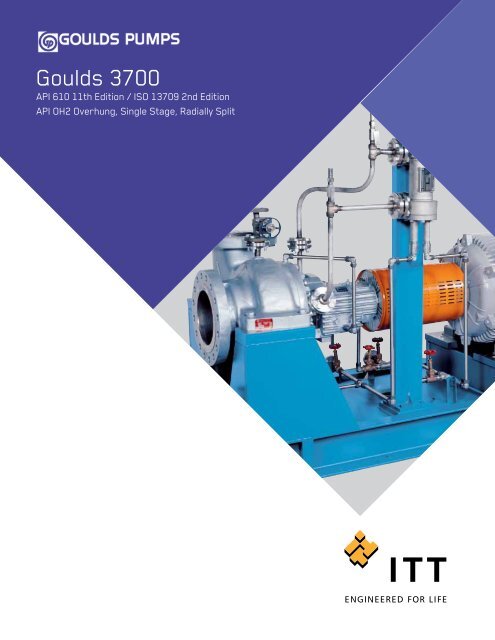

<strong>Goulds</strong> <strong>3700</strong>A Leader in API-Engineered Pump Package Solutions…Proven API LeadershipITT <strong>Goulds</strong> Pumps is a proven leader in API Pumps• More than 20,000 units installed- More than 17,000 OH2/OH3s- More than 3,000 BB1/BB2/BB3 pumps• 40+ years of API expertise• Participating member on API 610 andAPI 682 committeesFamily of API PumpsITT <strong>Goulds</strong> Pumps has a family of proven API pumps:• Overhung pumps• Single- and two-stage between-bearing pumps• Multistage between-bearing pumps— axially split• Barrel multistage - radially split• Vertical, double-casing pumps• Specialty pumpsIndustry-Leading Hydraulic Coverage• We offer extensive coverage to meet yourprocess needs.• Better hydraulic fits can mean improved efficiencyand long-term reliability and parts life.8000 HP/6000 kW Testing Capability• Our expanded test facility can test your pump inthe most demanding conditions.• Testing at rated speeds is critical to assess theimpact of dynamic conditions including vibration.API Engineering Expertise• We are experts in packaging engineered pumps thatmeet your demanding applications — with trueconformance to the latest API specifications.• We have extensive experience in nearly every type ofdriver, bearing, seal, piping configuration, nozzleconfiguration, flange and baseplate design to meetyour application needs.• ITT is a world leader in technology and engineeringincluding hydraulics, materials science, mechanicaldesign and fluid dynamics.Broad Applications• Petroleum refining, production and distribution• Petrochemical and demanding chemical processing• High-temperature applications includingboiler circulation• General industrial applications requiring hightemperatures or high pressures2 <strong>Goulds</strong> <strong>3700</strong>

<strong>Goulds</strong> <strong>3700</strong>High-Temperature and Pressure ProcessPumps That Meet or Exceed ISO 13709 andAPI 610 11th EditionSafety, reliability and versatility are the key words for ourend-suction, centerline-mounted, overhung (OH-2) API610 process pump.End Suction API 610/ISO 13709 Process Pump• Designed for optimum reliabilityModel <strong>3700</strong>• State-of-the-art mechanical design features• 54 casing sizes and choice of impellers with mostcasingsSafety and ReliabilityWe provide engineered solutions with true conformance tothe latest API specifications including the stringentemissions containment per API 682. The result is a safeand rugged overhung API process pump designed for a20-year life.Serviceability• Capacity to 8,500 GPM (1930 m3/h)• Total dynamic head to 1,200 feet (360 m)• Temperature to 800˚ F (425˚ C)• Pressure to 870 PSIG (60 bar)Materials: Available in a wide range of materialsincluding all API 610 constructions and custom applicationneeds.Model <strong>3700</strong> on high-temperature service at a U.S. Gulf Coast refinery.Engineered Hydraulics: An industry-leading 135hydraulic combinations to better match your process forefficiency and reliability. Custom hydraulics are available.Engineered Packaging with a wide range of drivers,seals, piping, nozzle configurations, flanges, baseplatesand QC testing.Gold Tailings Pumps in Australia - <strong>3700</strong> 4x6-19ServicesColumn reflux, hot oil, stabilizer overhead, columnbottoms, reboiler, stripper overhead, column charge,reactor feed, heat transfer, injection, tower bottoms,slop gas oil, fuel blending, heavy gas oil, scrubbercirculation, offsite hydrocarbon transfer<strong>Goulds</strong> <strong>3700</strong> 3

<strong>Goulds</strong> <strong>3700</strong>Standard Features for Optimum Reliability• Proven API 610 Nozzle-Load DesignRugged casing and baseplate/pedestal supportsystem provides flange-loading capability exceedingAPI 610 / ISO 13709 requirements without the use ofa bearing frame support.• Full Flange Rating Pressure CapabilityAll pumps designed to operate at two pole runningspeeds have casings designed for the full pressurecapability of a 300 RF flange.• Spiral-Wound Casing GasketCasing to cover joint sealed with a spiral-wound,controlled-compression gasket required by API 610.Provides positive sealing up to the maximum designpressure and temperature.Optional <strong>3700</strong>LF Design for Low-Flow ServicesNot All Pumps are Designed for Low FlowsMany users throttle pumps to attain low flow rates, whichcreates bearing and seal issues. The traditional enclosedimpeller passageways would be too small to properlymanufacture at these low flow rates.<strong>3700</strong>LF Low-Flow Solution - Fully API compliantThe <strong>3700</strong> LF semi-open radial vane Barske type impellereliminates these enclosed impeller limitations. The uniquecircular volute casing eliminates diffusers, thus reducingthe pump size, footprint and lifetime costs.Improved Bearing Environment• Bearing frame fins provide optimum heat dissipation.• Condition-monitoring sites allow easy and consistentmonitoring of temperature and vibration. Provisionfor instrumentation mounting per API 670 available.Optional Design for Solids Handling- Model 3703For over 19 years, ITT has offered a fully API compliantoptional design (Model 3703) that utilizes a traditionalstylesemi-open impeller - useful when you require a pumpwith high temperatures or pressures, yet need theimproved solids handling of an semi-open impeller.Examples of 3703 services are mine dewatering and PTAchemical plant services. The single stage Model 3703 hasinterchangeable parts with Model <strong>3700</strong>.• Large oil sight glass allows viewing of the conditionand level of oil, critical for bearing life.• Extra-large oil sump means cooler-running bearings.• Proven channeled oil lubrication system ensuresflow-through of cooled oil to thrust and radial bearings.• Standard dual oil rings, positively located, provide oilflow to channeled oil lubrication system and preventoil foaming.4 <strong>Goulds</strong> <strong>3700</strong>OILLEVEL

Model <strong>3700</strong>API 610 11th Edition / ISO 13709 2nd EditionAPI OH2 Overhung, Single Stage, Radially SplitDUAL VOLUTE CASINGStandard on 3-inch discharge and larger. Minimizesradial load and reduces shaft deflection for increasedmechancial seal life.TANGENTIAL DISCHARGE DESIGNMaximizes hydraulic efficiency.CONFINED CONTROLLED-COMPRESSION GASKETSpiral-wound gasket assures positive sealing withno chance of misalignment.RENEWABLE WEAR RINGS STANDARDON ALL SIZESPositively locked and set screwed.Front and rear rings control seal chamberflows and pressures. Optional non-metallicrings for improved efficiency. Wear rings notutilized in <strong>3700</strong>LF pumps.IMPELLERMultiple closed impellers for most casingsto meet specific hydraulic requirements.Balanced to stringent ISO 1940 Grade 1.0(exceeds API minimum). <strong>3700</strong>LF low flowpumps and 3703 high solids pumps utilizea semi-open impeller - they do not utilizeimpeller or casing wear rings.NOZZLE LOAD CAPABILITYCasing/baseplate design optimized to exceedtoughest API/ISO nozzle load criteria.FABRICATED BASEPLATEEnlarged drain connection to preventbuildup of debris. All joints are continuouslywelded. Extra-width sizes available to easemaintenance of seal systems.6 <strong>Goulds</strong> <strong>3700</strong>

3910 INTERCHANGEABILITYBearing frame, seal chamber, bearings, shaft,mechanical seal, impeller and wear ringscompletely interchangeable with <strong>Goulds</strong>Model 3910 bearing frame in-line processpumps. Entire back pull-out assemblyinterchangeable with Model 3710.RIGID, HEAVY-DUTY SHAFTMinimizes shaft deflection,maximizes bearing and mechanicalseal life.LABYRINTH OIL SEALSLabyrinth seal design prevents oilfrom leaking out and contaminantsfrom intruding. Made from nonsparkingmetal.BEARINGSDuplex 40° angular contact thrustbearings and deep-groove (Conrad)radial bearings sized for minimumthree-year bearing life under mostsevere operating conditions. ExceedsAPI 610 / ISO 13709 requirements.HEAVY-DUTY BEARING FRAMEPiloted and metal-to-metal fits assurerunouts and concentricities well withinlimits specified in API 610 / ISO 13709.Large oil sump capacity. Cast finsenhance cooling.LUBRICATION SYSTEMProven, engineered ring-oiledflow-through bearing lubricationoptimizes MTBPM.API-682 SEAL CHAMBEREnlarged seal chamber fully conformsto API-610 / ISO 13709 standards.Accepts wide range of API-682 / ISO21049 cartridge mechanical seals.Renewable throat bushing standard forcontrolled seal chamber environment.<strong>Goulds</strong> <strong>3700</strong> 7

<strong>Goulds</strong> <strong>3700</strong>Sectional View230 203 125 184100164122202101304356A,425Parts List and Materials of ConstructionItem Part Name S-4 S-6 S-8 C-6 A-8 D-1 D-2100 Casing Carbon Steel 12% Chrome 316L SS Duplex SS S. Duplex SS101 Impeller Carbon Steel 12% Chrome 316L SS 12% Chrome 316L SS Duplex SS S. Duplex SS122 Shaft ANSI 4140 * 316L SS 410 SS 316L SS Duplex SS S. Duplex SS125 Throat Bushing Cast Iron 410 SS 316L SS 410 SS 316L SS Duplex SS S. Duplex SS164,230202,203Wear Ring -Casing **Wear Ring -Impeller **Cast Iron 12% Chrome 316L SS 12% Chrome 316L SS Duplex SS S. Duplex SSCast Iron 12% Chrome Nitronic 60 12% Chrome Nitronic 60 Duplex SS S. Duplex SS184 Seal ChamberCarbon Steel 12% Chrome 316 SS Duplex SS S. Duplex SSCover304 Impeller Nut Steel 316 SS Duplex SS S. Duplex SS356A,425Casing Studs /Nuts* 410 SS on S-6 when temperature exceeds 350°F (175°C)* Not utilized on <strong>3700</strong>LF low flow pumps.ANSI 4140<strong>Goulds</strong> <strong>3700</strong> 9

PRservicesReliability has no quitting time.PRO Services provides an array of services focused onreducing equipment total cost of ownership (TCO) andincreasing plant output, including predictive monitoring,maintenance contracts, field service, engineered upgrades,inventory management, and overhauls for pumps andother rotating equipment.Parts & InventoryOperation PerformanceRepairs & UpgradesPRO Services provides OEMparts for <strong>Goulds</strong> Pumps,Bornemann Pumps, AC,Morris, Goyne, CB, HVC, UXNand ROV in a timely mannerto meet end userrequirements. Significantlevels of inventory and quickresponse capability providesthe necessary programs tomeet all repair needs.PRO Services provides programs ofreliability services, energyassessments, asset managementand training. These can be deployedas stand-alone or integratedsolutions, tailored to the needsof your company.PRO Services provides an arrayof repairs and upgradesservices to extend equipmentlife. PRO Services helpscustomers develop effectivemaintenance and assetmanagement programs tolower maintenance costs,improve uptime, reduceinventory costs and extendequipment life.<strong>Goulds</strong> <strong>3700</strong> 11