ODU MINI-SNAP®

ODU MINI-SNAP

ODU MINI-SNAP

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

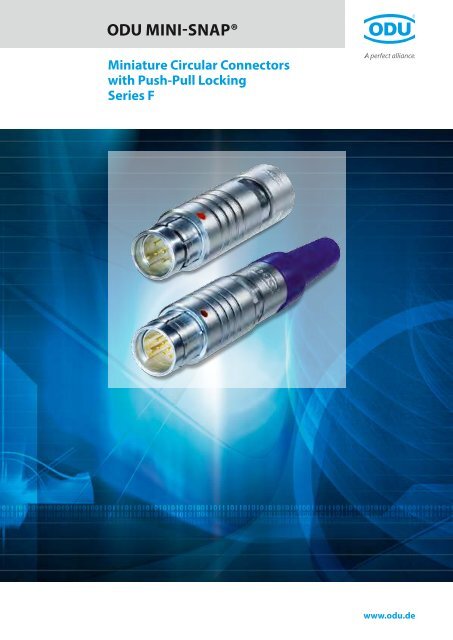

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong>Miniature Circular Connectorswith Push-Pull LockingSeries Fwww.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FMiniature Circular Connectors withPush-Pull Locking Series FApplications––Medical––Industrial––Measuring and testing––Military and security––Energy––AutomotiveFeatures––Fast and easy mating and demating inhard-to-access places easily possible––Fast and easy separating––Blind mating in difficult-to-reach places––Low space requirements on the devices––Clear and reliable locking states––Low power requirement––Robot-suitable––Easy cleaning of the housing possibleAll shown connectors are according toDIN EN 61984:2009 connectors withoutbreaking capacity (COC).All dimensions in mm.Most of the pictures are illustrations.All data and specifications subject to changewithout notice.<strong>ODU</strong> <strong>MINI</strong>-SNAP F––Achieves specifications of RoHS (2011/65/EU)––Has a licence (E110586)––Has a licence acc. to VDE (Reg.-No. 4000941)––is specified acc. to MIL: see page 79Issue: 2014-01Page 2www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FTable of Contents (Part I)ChapterFrom page1 Product description 5The <strong>ODU</strong> <strong>MINI</strong>-SNAP family of miniature circular connectorsfeatures Push-Pull lockingImportant issues at a glanceTurned contact6772 Series F, IP 50 and IP 68 9The FP locking principleFP locking scheme in cross-sectionAvailable housing sizesHousingsDetails for the part number key(keying possibilities, housing materials, cable collet system, rightangledprint contacts in the receptacle, definition of the back nut)10111112273 Inserts 33Insulator materialSize 0Size 1Size 1.5Size 2Size 3Super Shorty, Size 0Super Shorty, Size 1Contact type / surfaceTermination cross-sections for turned contactsPCB layouts for print contacts34353637384041424344454 Accessories 51Silicone cable bend reliefBack nut for cable bend reliefColour coding ringsDistance ring for wall thicknessadjustment for receptacles of style 2Locking washersSolder lugsProtective cover for plugsProtective cover for receptacles52535455565657585 Tools 61Crimping tools / assembly toolsCrimping and removal tools for crimp contactsSpanner wrenchNutdriver for slotted mounting nutRemoval tool for crimp-clip-contacts6263646465Assembly instructions 67Weblink to assembly instructions 68www.odu.dePage 3

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FTable of Contents (Part II)ChapterFrom page6 Technical information 69International Protection (IP) classes in accordance with DIN EN 60 529WatertightnessHousing materials / surfacesInsulator materialTermination technologiesConversions AWG – cross-sectionCurrent load – turned contactsOperating voltage acc. to SAE AS 13441-method 3001.1Electro magnetic compatibility (EMC)Autoclaving of <strong>ODU</strong> <strong>MINI</strong>-SNAPTest standardTechnical information / definitions / terms7071727273747576777879807 Company information 83Quality managementYour partner in many application areasOverview – all Push-Pull connector series from <strong>ODU</strong>The complete <strong>ODU</strong> product rangeEverything from one sourceApplication specific connectors848586878889Telefax inquiry 91The part number key 92Page 4www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FProduct DescriptionProduct Descriptionwww.odu.dePage 5

Product Description<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FProduct DescriptionThe <strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Family of Miniature Circular ConnectorsFeatures Push-Pull LockingCircular connectors are generally available with severallocking mechanisms.The most frequently used are––Threaded-locking sleeve––Bajonett locking––Push-Pull locking.Push-Pull connectors have a verysimple locking mechanism:––As the plug is pushed into thereceptacle, locking fingers on theplug snap into the receptaclecreating a reliable connectionbetween plug and receptacle.––Pulling on the cable or the rear ofplug causes the locking fingers tograb harder and a separation ofplug and receptacle is almostimpossible. Pulling on the outerplug housing causes the lockingfingers to retract and the plug andreceptacle separate easily.Page 6www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FImportant Issues at a GlanceTurned ContactProduct DescriptionProduct DescriptionCertificationThe series is certified acc. to RoHS and has licenses acc. toVDE and UL.5 SizesMetal housing available in 5 sizes.Outside diameter between 9.4 mm and 18 mm.Number of contacts: 2 to 27 positions, mixed insertspossible.Extensive range of termination possibilitiesPlugs and in-line receptacles for solder and crimptermination. Receptacles for solder, crimp and PCB termination.Applications and materialsGeneral application requirements(– 40° C to +120° C)Connectors which are autoclavable(+134° C, see page 78)Termination technologiesInsulatormaterialPEEK●●ContactmaterialMs●●Turned contacts are available in the diameters 0.5 mm to1.3 mm. They are available with following terminations:Solder, crimp and print (PCB).Mating cycles > 5,000MaterialBrassTreatment processing Ni, AuFor information regarding diameter, termination styleand current carrying capacity please see the contactconfiguration section.Standard pin contactsSolder Crimp-clip Print (PCB)InsulatormaterialPEEKContactmaterialMsCrimp termination ● 1 ●Solder termination ● ●Printed circuit board (PCB) termination ● ●1 Crimp-clip-contacts available with diameter 0.7 mm and 0.9 mm.Protection class IP 50 and IP 68 are available.www.odu.dePage 7

Product Description<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FFor Your NotesPage 8www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries F, IP 50 and IP 68FP Locking PrincipleHalf-Shell KeyingSeries F,IP 50 and IP 68Part Number Key See Fold-outPage in the Rear Coverwww.odu.dePage 9

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FThe FP Locking PrincipleWith Half-shellsSeries F,IP 50 and IP 68The first figure shows the<strong>ODU</strong> <strong>MINI</strong>-SNAPconnection in unmatedcondition.Conical sleeveOuter housingLocking groove Locking fingers (“jaws”) Back nutReceptaclePlugThe second figure showsthe <strong>ODU</strong> <strong>MINI</strong>-SNAPconnection in matedcondition.Pulling on the cable or onthe back nut causes the“jaws” to grip harder intothe groove in thereceptacle. A separation isvirtually impossible.Pulling on the outer plughousing disengages the“jaws” from the receptaclegroove and the connectorseparates easily.Page 10www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries F<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> FWith FP Locking Scheme in Cross-SectionReceptacleContacs Grounding ringInsulator Locking grooveLocking fingers(“jaws”)ContactsInnersleeveSingleconductorPlugShieldCablecolletCableSeries F,IP 50 and IP 68Housing Outer housing InsulatorEMI ringHex nut Conical sleeve Guiding ring Half-shellsBack nutAvailable Housing Sizes9,412 13 15 18Outside diameter(Plug)9.412131518Scale 1 :1Size011.5230 1 1,52 3Größen Serie <strong>MINI</strong>-SNAP F / 2013www.odu.dePage 11

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FStraight PlugConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68S 1 Style 1: IP 50, with standard back nutL2L1∅ DSW BSW AS 2 Style 2: IP 50, with back nut for cable bend relief 1)L2L1∅ DSW BSW ADimensions in mmS1S2Size L1 L2 D SW A SW B SW B0 0 ~ 37.0 ~ 27.0 9.4 8 7 71 1 ~ 46.0 ~ 35.0 12.0 10 10 10A 1.5 ~ 48.0 ~ 38.0 13.0 11 12 122 2 ~ 50.0 ~ 38.0 15.0 13 12 133 3 ~ 59.0 ~ 44.0 18.0 16 15 15Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles.1 Cable bend relief have to be ordered separately (see page 52).Page 12www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FStraight PlugConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0S 3 Style 3: IP 68, watertight, with standard back nutL2L1Series F,IP 50 and IP 68∅ DSW BSW AS 4 Style 4: IP 68, watertight, with back nut for cable bend relief 1)L2L1∅ DSW BSW ADimensions in mmS3S4Size L1 L2 D SW A SW B SW B0 0 ~40.0 ~30.0 9.4 8 7 71 1 ~49.0 ~38.0 12.0 10 10 10A 1.5 ~50.0 ~40.0 13.0 11 12 122 2 ~53.0 ~41.0 15.0 13 12 133 3 ~61.0 ~46.0 18.0 16 15 15Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles.1 Cable bend relief have to be ordered separately (see page 52).www.odu.dePage 13

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FRight-Angled PlugConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68W 1 Style 1: IP 50, with standard back nutL2L1CL3SW ASW CSW B∅ DW 2 Style 2: IP 50, with back nut for cable bend relief 1)L2L1CL3SW ASW CSW B∅ DDimensions in mmW1 W2Size L1 L2 L3 C D SW A SW B SW B SW C0 0 33.0 23.0 ~25.0 10.0 9.0 9 7 7 81 1 37.3 26.5 ~28.0 12.0 11.0 11 10 10 10A 1.5 39.0 29.0 ~31.0 14.0 13.0 12 12 12 112 2 41.6 29.5 ~34.5 16.0 14.0 14 12 13 133 3 50.0 35.0 ~41.0 18.0 17.0 16 15 15 16Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles.1 Cable bend relief have to be ordered separately (see page 52).Page 14www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FRight-Angled PlugConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0W 3 Style 3: IP 68, watertight, with standard back nutL2L1Series F,IP 50 and IP 68L3CSW ASW CSW B∅ DW 4 Style 4: IP 68, watertight, with back nut for cable bend relief 1)L2L1CL3SW ASW CSW B∅DDimensions in mmW3 W4Size L1 L2 L3 C D SW A SW B SW B SW C0 0 36.0 26.0 ~27.0 11.2 9.0 10 7 7 81 1 45.2 34.2 ~33.0 13.0 11.0 12 10 10 10A 1.5 41.5 31.5 ~34.5 14.5 13.0 13 12 12 112 2 46.3 34.2 ~36.0 16.0 14.0 14 12 13 133 3 59.7 44.6 ~41.0 18.0 17.0 16 15 15 16Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles.1 Cable bend relief have to be ordered separately (see page 52).www.odu.dePage 15

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FBreak-Away Connector (Without Locking)Connector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68A 7 Style 7: IP 50, with standard back nutL2L1∅ DSW BSW AA 8 Style 8: IP 50, with back nut for cable bend relief 1)L2L1∅ DSW BSW ADimensions in mmA7A8Size L1 L2 D SW A SW B SW B0 0 ~ 37.0 ~27.0 9.4 8 7 71 1 ~ 46.0 ~35.0 12.0 10 10 102 2 ~ 50.0 ~38.0 15.0 13 12 13Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles––Plug can be separated by pulling on the cable.1 Cable bend relief have to be ordered separately (see page 52).Page 16www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FPanel Mounted PlugCreated to Build Up a Docking ConnectionBetween Two Instruments (E.g. a Charging Station)Connector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68A A Style A: IP 50, with hex nut, without locking,installation from front of panelSW ASW BL1ML2CL3∅ DSWSWSWSWPanel cut-out+0.1+0.1 Type A+0.1+0.1+0.1+0.1+0.1Type B+0.1+0.1+0.1+0.1+0.1+0.1 +0.1SW SW+0.1 +0.1SW SWDimensions in mmPanel cut-out+0.1+0.1+0.1Technical data +0.1––Contact configuration see from page 35Size L1 L2 L3 C D SW SW M SW ∅ Type––PCB layouts see from page 45––Consistent with all followingmax.A Breceptacles and in-line receptacles0 0 ~12.0 ~4.0 10.0 1.5 10.0 8.2 11 9 × 0.5 8.3 9.1 A ––IP 50 related to the tightness of the1 1 ~15.5 ~4.0 10.8 1.5 14.0 11.1 14 12 × 1 11.2 12.1 B end device2 2 ~17.5 ~3.4 12.0 2.0 18.0 14.1 17 15 × 1 14.2 15.1 B ––Anti-rotation feature.3 3 ~17.0 ~5.5 15.0 1.2 22.0 15.2 19 16 × 1 15.3 16.1 BA D Style D: IP 68, watertight, with hex nut, without locking,installation from front of panelSW ASW BL1L2L3C∅ DSWSWSWSW+0.1+0.1+0.1 Panel cut-out+0.1+0.1+0.1 Type B+0.1+0.1+0.1+0.1 Type C+0.1+0.1+0.1+0.1+0.1 +0.1SW SW+0.1 +0.1SW SW+0.1+0.1Dimensions in mmPanel cut-outSize L1 L2 L3 C D SW SW M SW ∅ Typemax.A B0 0 ~14.5 ~4.5 10.0 3.0 13.0 – 11.0 9 × 0.5 – 9.1 C1 1 ~18.5 ~6.5 10.8 2.5 17.0 11.0 14.0 12 × 1 11.2 12.1 B2 2 ~20.0 ~7.0 12.0 3.0 22.0 15.2 19.0 16 × 1 15.3 16.1 BTechnical data––Contact configuration see from page 35––PCB layouts see from page 45––Consistent with all followingreceptacles and in-line receptacles––IP 68 related to the tightness of theend device also in unmated condition––Anti-rotation feature.Page 18www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FSuper Shorty Push-Pull PlugConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0S S Style S: IP 68, watertightL1L2∅ D1Series F,IP 50 and IP 68L3L1L2∅ D2∅ D1∅ D2Dimensions in mmSize L1 L2 L3 D1 D2 Max. cable ∅Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles.––Crimping of the cable shield causes strain relief.0 0 ~ 28.0 ~ 18.0 10.5 13.0 11.9 51 1 ~ 32.7 ~ 22.0 12.5 15.0 13.9 6.52 2 ~ 34.3 ~ 22.6 13.0 19.0 17.6 10A S Style S: IP 68, watertight, without lockingL3Dimensions in mmSize L1 L2 L3 D1 D2 Max. cable ∅Technical data––Contact configuration see from page 35––Consistent with all following receptacles and in-line receptacles––Crimping of the cable shield causes strain relief.0 0 ~ 28.0 ~ 18.0 10.5 13.0 11.9 51 1 ~ 32.7 ~ 22.0 12.5 15.0 13.9 6.52 2 ~ 34.3 ~ 22.6 13.0 19.0 17.6 10www.odu.dePage 19

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FIn-Line ReceptacleSuitable for Build Up a Cable to Cable ConnectionConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68K 1 Style 1: IP 50, with standard back nutL1∅ DSW BSW AK 2 Style 2: IP 50, with back nut for cable bend relief 1)L1∅ DSW BSW ADimensions in mmK1K2Size L1 D SW A SW B SW B0 0 ~ 35.0 9.5 8.0 7 71 1 ~ 44.0 12.0 10.0 10 102 2 ~ 48.0 15.0 13.0 12 133 3 ~ 58.0 18.0 16.0 15 15Technical data––Contact configuration see from page 35.1 Cable bend relief have to be ordered separately (see page 52).Page 20www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FIn-Line ReceptacleSuitable for Build Up a Cable to Cable ConnectionConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0K 3 Style 3: IP 68, watertight, with standard back nutSeries F,IP 50 and IP 68L1∅ DSW BSW AK 4 Style 4: IP 68, watertight, with back nut for cable bend relief 1)L1∅ DSW BSW ADimensions in mmK3K4Size L1 D SW A SW B SW B0 0 ~ 38.0 10.0 8.0 7 71 1 ~ 47.0 13.0 10.0 10 102 2 ~ 51.0 16.0 13.0 12 13Technical data––Contact configuration see from page 35.1 Cable bend relief have to be ordered separately (see page 52).www.odu.dePage 21

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FReceptacleConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68G 1 Style 1: IP 50, installation from front of panelSW ASW BL1L3ML2∅ DCSW SWSW SW+0.1+0.1Type A+0.1+0.1+0.1+0.1Type B+0.1+0.1Panel cut-out+0.1+0.1+0.1+0.1+0.1+0.1SW SW+0.1+0.1SW SWDimensions in mmPanel cut-outType C+0.1+0.1+0.1+0.1Size L1 1) L2 L3 2) C M D SW SW SW ∅ Typemax.A B0 0 ~ 20.0 ~ 9.0 14.5 1.5 M9 × 0.5 10.0 8.2 11.0 8.3 9.1 A1 1 ~ 24.0 ~ 8.0 16.5 1.5 M12 × 1 14.0 10.0 14.0 10.1 12.1 AA 1.5 ~ 25.0 ~ 8.0 15.5 2.0 M14 × 1 16.0 12.0 17.0 12.1 14.1 B2 2 ~ 27.0 ~ 10.0 18.5 2.0 M15 × 1 18.0 14.1 17.0 14.2 15.1 C3 3 ~ 30.5 ~ 13.0 22.5 2.0 M18 × 1 22.0 16.5 22.0 16.6 18.1 A1 L1 = max. length incl. contact insert2 L3 = length of housingTechnical data––Contact configuration see from page 35––PCB layouts see from page 45––IP 50 related to the tightness of theend device––Anti-rotation feature.Page 22www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FReceptacle+0.1Connector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0G 2 Style 2: IP 68 4), watertight, suitable forinstallation from front of panelL1L3SWSW+0.1+0.1+0.1+0.1Panel cut-outType C+0.1+0.1+0.1SW+0.1SW+0.1Series F,IP 50 and IP 68MSW ASW BL2∅ dC∅ DTechnical data––Contact configuration see from page 35––PCB layouts see from page 45––IP 68 related to the tightness of theend device also in unmated condition––Distance ring for wall thicknesscompensation see chapter accessories––No crimp contacts possible.Dimensions in mmPanel cut-outSize L1 1) L2 3) L3 2) C M D d SW SW ∅ TypeA B0 0 ~22.5 ~8.0 18.5 3.0 M9 × 0.5 14.5 10.0 11.0 11.0 10.1 C1 1 ~27.0 ~9.0 22.5 3.0 M14 × 1 18.0 14.0 14.0 17.0 14.1 CA 1.5 ~27.0 ~7.0 21.6 3.5 M14 × 1 19.0 14.0 15.0 17.0 14.1 C2 2 ~29.5 ~9.0 23.0 4.0 M16 × 1 22.0 16.0 17.0 19.0 16.1 C3 3 ~32.0 ~12.0 26.5 4.0 M20 × 1 26.0 20.0 24.0 25.0 20.1 C1 L1 = max. length incl.contact insert2 L3 = length of housing3 min. wall thickness without use of adistance ring4 tight potted receptacle see page 71,case IIIG 4 Style 4: IP 68, watertight, installation fromfront of panel, with small installation depthL1L3Panel cut-out+0.1SW CSW A∅ D2∅ D1SW+0.1Type A+0.1+0.1SWSW BL2MCSW+0.1+0.1+0.1+0.1SWDimensions in mmPanel cut-out Technical data+0.1– – Contact configuration see from +0.1 page 35Size L1 1) L2 3) L3 2) C M D1 D2 SW SW SW SW ∅ Type––PCB layouts see from page 45––IP 68 related to the tightness of themax.A B Cend device also in unmated condition0 0 ~22.5 ~4.0 17.5 11.0 M9 × 0.5 14.5 10.5 12.0 11.0 8.2 8.3 9.1 A ––Anti-rotation feature1 1 ~27.0 ~4.0 22.5 15.5 M14 × 1 18.0 13.0 14.0 17.0 12.0 12.1 14.1 A ––No crimp contacts possible.A 1.5 ~27.0 ~5.0 21.6 13.6 M14 × 1 19.0 13.5 15.0 17.0 12.0 12.1 14.1 A1 L1 = max. length incl. contact insert2 2 ~32.0 ~4.5 23.0 15.5 M16 × 1 21.0 16.0 17.0 19.0 14.0 14.1 16.1 A2 L3 = length of housing3 tight potted receptacle see page 71,case IIIwww.odu.dePage 23

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FReceptacleWith Continuous Thread / With Design NutConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68G 5 Style 5: IP 50, with continuous thread, installation fromfront and rear of panel with optimal distance adjustmentSW BSW AL1L3ML2CPanel cut-outSW C+0.1Type A+0.1∅ DSWSW+0.1+0.1+0.1+0.1+0.1SW+0.1SWDimensions in mmPanel cut-outSize L1 1) L2 L3 2) C M D SW SW SW SW ∅ Typemax.A B C0 0 ~ 20.0 ~ 8.0 14.5 2.5 M9 × 0.5 11.5 11.0 8.0 10.0 8.1 9.1 A1 1 ~ 24.0 ~ 8.0 16.5 4.0 M12 × 1 15.0 14.0 10.0 13.0 10.1 12.1 AA 1.5 ~ 25.0 ~ 8.0 15.5 3.0 M14 × 1 19.0 17.0 12.0 17.0 12.1 14.1 A2 2 ~ 27.0 ~10.0 18.5 4.0 M15 × 1 20.0 17.0 13.5 17.0 13.6 15.1 A3 3 ~ 30.5 ~12.0 22.5 5.0 M18 × 1 23.0 22.0 16.5 20.0 16.6 18.1 A+0.1Technical data +0.1––Contact configuration see from page 35––PCB layouts see from page 45––IP 50 related to the tightness of theend device––Anti-rotation feature.1 L1 = max. length incl.contact insert2 L3 = length of housingG 8 Style 8: IP 68 3), watertight, installation fromrear of panel, with design nutDimensions in mmSize L1 1) L2max.L3 2) C M D1 D2 SWASWB0 0 ~ 22.5 ~ 3.5 17.0 6.5 M9 × 0.5 12.0 14.0 8.2 11.0 8.3 9.1 B1 1 ~ 27.0 ~ 4.0 21.0 8.0 M14 × 1 18.0 18.0 12.0 – 12.1 14.1 AA 1.5 ~ 27.0 ~ 3.0 19.5 7.0 M14 × 1 18.0 19.0 12.0 – 12.1 14.1 B2 2 ~ 29.5 ~ 3.0 23.0 8.0 M16 × 1 22.0 21.0 14.3 – 14.4 16.1 A3 3 ~ 32.0 ~ 6.0 26.5 11.0 M20 × 1 25.0 26.0 18.0 – 18.1 20.1 A∅ D2SW AL1L3L2MCSW B∅ D1SWSW+0.1Type A+0.1+0.1Panel cut-out+0.1Type B+0.1+0.1Panel cut-out+0.1+0.1Technical data +0.1––Contact configuration see from page 35SW ∅ Type––PCB layouts see from page 45––IP 68 related to the tightnessSW+0.1of theend device also in unmated condition––Anti-rotation feature––No crimp contacts possible+0.1––Spanner wrench see page 641 L1 = max. length incl.contact insert2 L3 = length of housingSW+0.1SW+0.1+0.1SW+0.1+0.1+0.1Page 24www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FSeries FReceptacleProjecting ReceptacleConnector type1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0G H Style H: IP 50, projecting receptacle with small installation depth,installation from front and rear of panel,installation with optimal distance adjustmentSW ASW CL1L3SW B∅ D2∅ D1SWPanel cut-out+0.1Type A+0.1+0.1+0.1+0.1SWSeries F,IP 50 and IP 68L2MCSW+0.1+0.1+0.1SWDimensions in mmSize L1 1) L2max.L3 2) C M D1 D2 SWASWBSWC0 0 ~20.0 ~3.0 16.0 11.0 M9 × 0.5 11 9.0 11.0 8.2 – 8.3 9.1 A1 1 ~24.0 ~4.5 17.5 10.0 M12 × 1 14 11.7 14.0 10.0 12.0 10.1 12.1 AA 1.5 ~25.0 ~5.0 17.0 9.0 M14 × 1 18 13.5 17.0 12.0 15.0 12.1 14.1 A2 2 ~27.0 ~5.5 19.5 11.0 M16 × 1 19 16.0 19.0 13.5 17.0 13.6 16.1 APanel cut-out+0.1Technical data +0.1––Contact configuration see from page 35SW ∅ Type––PCB layouts see from page 45––IP 50 related to the tightness of theend device––Anti-rotation feature.1 L1 = max. length incl.contact insert2 L3 = length of housing+0.1G K Style K: IP 50, installation from rear of panel,with low installation depth∅ D1L1L3C∅ D2SWSW+0.1+0.1 Panel cut-out+0.1Type B+0.1+0.1+0.1SW+0.1SWSW BL2MSW A+0.1+0.1Dimensions in mmPanel cut-outSize L1 1) L2 L3 2) C M D1 D2 SW SW SW ∅ Typemax.A B1 1 ~ 24.0 ~ 4.0 16.5 8.0 M12 × 1 14.0 15.0 13.0 11.0 11.1 12.1 B2 2 ~ 27.0 ~ 5.0 18.5 9.0 M15 × 1 19.0 20.0 17.0 14.0 14.1 15.1 B3 3 ~ 30.5 ~ 12.0 22.5 17.0 M18 × 1 22.0 23.0 20.0 17.2 17.3 18.1 BTechnical data––Contact configuration see from page 35––PCB layouts see from page 45––IP 50 related to the tightness of theend device––Anti-rotation feature1 L1 = max. length incl.contact insert2 L3 = length of housingwww.odu.dePage 25

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FFor Your NotesSeries F,IP 50 and IP 68Page 26www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FDetails for the Part Number KeySeries F,IP 50 and IP 68Keying PossibilitiesHousing MaterialsCable Collet SystemRight-Angled Print Contactsin the ReceptacleDefinition of the Back NutPart Number Key See Fold-outPage in the Rear Coverwww.odu.dePage 27

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FDetails Series FKeying PossibilitesHousing Materials1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 01 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Series F,IP 50 and IP 68KeyingReceptaclefront viewSize0 1 1.5 2 3Housing materialHousing material1 ● ● ● ● ●Standard C Cu-alloy / matt chrome plated2 ● ● ● ● ●On Request S Cu-alloy / black chrome plated3 ● ❍ ● ● ●Special materials and surfaces on request.● Standard❍ On requestPage 28www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FDetails Series FCable Collet System1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Used by all plugs and in-line receptacles.CablediameterSizeEMI ringSealing ring*Anti-rotation featureCable diameterSeries F,IP 50 and IP 68in mm 0 1 1.5 2 3> 1.0 to 1.5 ● ● 1 5> 1.5 to 2.0 ● ● 2 0> 2.0 to 2.5 ● ● ❍ 2 5> 2.5 to 3.0 ● ● ❍ ● 3 0> 3.0 to 3.5 ● ● ● ● ● 3 5> 3.5 to 4.0 ● ● ● ● ● 4 0> 4.0 to 4.5 ● ● ● ● ● 4 5> 4.5 to 5.0 ● ● ● ● ● 5 0> 5.0 to 5.5 ● ● ● ● 5 5> 5.5 to 6.0 ● ● ● ● 6 0> 6.0 to 6.5 ● ● ● ● 6 5> 6.5 to 7.0 ● ● ● ● 7 0> 7.0 to 7.5 ❍ ● ● ● 7 5>7.5 to 8.0 ● ● 8 0> 8.0 to 8.5 ● ● 8 5> 8.5 to 9.0 ● ● 9 0> 9.0 to 9.5 ❍ ● 9 5> 9.5 to 10.0 ● 0 1> 10.0 to 10.5 ● 0 2> 10.5 to 11.5 ❍ 0 3without cable collet system 0 0● IP 50 and IP 68❍ Only IP 50. This cable collets are not available for applications with cable bend relief.Application: Cable collet for strain relief;EMI ring for the transmission of the shielding.* Sealing at style IP 68.www.odu.dePage 29

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FDetails Series FRight-Angled Print Contacts in the Receptacle1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0 0Series F,IP 50 and IP 68Right-angled print contactATechnical data––PCB layouts see frompage 45––Pin version on request.Page 30www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FDetails Series FDefinition of the Back Nut1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0Usable for all straight plugs, right-angled and Break-Awayconnectors, in-line receptacles, receptacles style 6.Standard back nut 0Series F,IP 50 and IP 68Back nut for silicone cable bend reliefsSCable bend reliefs see page 52.www.odu.dePage 31

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FFor Your NotesSeries F,IP 50 and IP 68Page 32www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsInsertsPart Number Key See Fold-outPage in the Rear Coverwww.odu.dePage 33

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsInsulator Material1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – –InsulatorPPEEKFurther special equipment on request.InsertsTurned contactTerminationPEEKSolder terminationCrimp terminationPCB termination●●●● AvailablePage 34www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsContact ConfigurationSize 02131221312131222 11 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19211 23 40 F – – 03 443213213132SizeInsulatorNumber of contactsContactdiametermmNominal 1current2load percontact 211)134 2 52 1 1AClearance andcreepage distanceContact tocontact in mmContact tohousing in mmTestvoltage 2)kVeffNominalvoltage 5)kVrmsTerminationSolderCrimp 3)Print 4)View 1 on the termination 1side22211211334 2 55 2 4Pin2 1piece11Socket1piece23 2 43 2 44231 10 P 0 2 0.9 1021.0 0.8 1.500 0.500 ● ●2 321 12 31 13 221232 1130 P 0 3 0.9 1020.6 0.8 1.200 0.400 ● ●4 352232413113513115322234Inserts2 1123 342321 70 P 0 4 0.7 7 1 0.8 0.7 0.900 0.300 ● ● ●4 3 4 652 12 1123 342321 714 3 4 652 1112243327 1 2 316 4 3 451 23 43 443223134450 P 0 5 0.7 7 0.6 0.6 1.100 0.366 ● ●21345223 173 1445650 P 0 7 0.5 5 0.7 0.6 0.900 0.300 ● ●2134523980 P 0 9 0.5 5 1 0.5 0.4 0.600 0.200 ● ●4 75 62213344521345223 173 144565213452 93 814 75 6211 23544 321354227131 365454213549 28 317 46 51 Derating factor see page 752 SAE AS 13441:1998 method 3001.1 (kVeff)3 Tools for assembling see page 624 PCB layouts see from page 455 Maximal operating voltage at sea level up to 2.000 m acc. to SAE 13441. More information on page 76.23 714 6523 714 652 2 937814675 5 623 714 6523 714 6523 714 652 2 937814675 5 623 714 6527 316 4527 316 459 2 287317646 5 527 316 45www.odu.de2 93 814 75 62 93 812 93 814 75 62 93 819 28 3176 59 28 31Page 4 35

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsInsertsContact ConfigurationSize 11 2 3 4 5 6 7 8 9110 11 12 13 14 15 16 17 18 191 F – –201SizeInsulatorNumber of contactsContactdiametermmNominal 1 12current2 3load percontact 11)1A122Clearance andcreepage distanceContact tocontact in mmContact tohousing in mm4 45Test 12Nominal Termination View 1 1on the termination 1 1side512126 1 3 112621 3 1111 3voltage 2) voltage 5)7 2 1022 33 2 7 10108 98 994 45 12 1 11 1 5 121226 1 3 112621 3 1111 3222 37 102 33 2 7 10108 98 994 41 15 12 1 11 1 5Pin pieceSocket piece121226 1 3 112621 3 1111 37 2 107 22 32 33 210108 98 994 41 1 14 5 121 1 141 5 12124112621 3 1111 32 7 2 107 22 332 2 33332 2 10108 98 991 14 1 144112222 332 33332kVeffkVrmsSolderCrimp 3)Print 4)1 P 0 2 1.3 1426 1 3 111.3 0.9 1.650 0.550 ● ●1 14 1 14411222 332 333321 P 0 3 1.3 1421.1 0.8 1.500 0.500 ● ●4 45 12 11 5 12126 1 3 116 1 3 1111 37 2 10222 7 10108 98 994 45 12 11 5 12126 1 3 116 1 3 1111 37 2 107 22210108 98 994 45 12 11 5 12126 1 3 116 1 3 1111 37 2 107 22210108 98 991111 1451 145541 12222333423 334433231 P 0 4 0.91111 451 45541210 1.2 0.7 1.500 0.500 ● ● ●222 32 33 23434431111 451 455412222334233443231 P 0 5 0.911111 12 1 4562 1 456654 1 2210 0.8 0.7 1.200 0.400 ● ● ●2232 32 33 23453345543444 311111 12 562 5665222233453345543444 31 p 0 6 0.711111 12 562 56652227 0.8 0.7 1.200 0.400 ● ● ●233453345543444 31121121213256732567765 322 1 2 11 2433465433465654 4345454531212121 P 0 7 0.73267326776327 1 0.8 0.7 1.200 0.400 ● ● ●114365436565434545451212123267326776321 114365436565434545451 P 0 8 0.71212122386723867768 327 417 0.7 0.6 1.000 0.333 ● ●4177143 653 656535 4565 4566 4552223 873 877834174177146665 5 65 5 66 5 51 P4 24 22415 12 3 8711 5 1212 53 877836 113 116 113 1111 3 4 74 7711 61 2 0.5 5 0.5 0.5 1.000 0.333 ● ●472 10 62 665 5 627 1010 22278 9585 96695 851 Derating factor see page 752223 873 87783114 74 77146665 5 65 5 66 5 52 SAE AS 13441:1998 method 3001.1 (kVeff)2223 83 88 33 Tools for assembling see page 624174177144 PCB layouts see from page 455 65 66 525 Maximal operating voltage at sea level 1 up to 2.000 m acc. to SAE 3 13441. 8 More information on page 76.11 32882324172241771435 6335 66 5Page 362341875 62341875 681www.odu.de7 426 53

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsContact ConfigurationSize 1.51 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19A F – – 0SizeInsulatorNumber of contactsContactdiametermmNominalcurrentload percontact 1)AClearance andcreepage distanceContact tocontact in mmContact tohousing in mm8 19Test 7182 6 171voltage 2)91011 3 5 16 412 15 13 14kVeffNominalvoltage 5)kVrmsTerminationSolderCrimp 3)Print 4)9View on the termination sidePin pieceSocket piece8 197182 613 5 412 15 13 141011171618 1917 616 515143 104 1 9A P 1 0 0.7 7 0.8 0.6 1.200 0.400 ● ●526 78453 10126 79810 39 18 27 6454 4 45 12 5 1212 56 1111 3 1 67 2 107 2 1010 2 78 98 99 86 1 3 111 3A P 1 2 0.7 7 0.7 0.7 1.200 0.400 ● ● ●Inserts8 19971810 2 6 1711 3 5 16 412 15 13 148 19971810 2 611 3 5 412 15 13 14A P 1 9 0.5 5 1 0.6 0.6 1.000 0.333 ● ● 11716818 19761 2 5 341514 13171691011121 Derating factor see page 752 SAE AS 13441:1998 method 3001.1 (kVeff)3 Tools for assembling see page 624 PCB layouts see from page 4543 101 95 Maximal operating voltage at sea level up to 2.000 m acc. to SAE 13441. More information on page 76.43 101910 39 14526 78526 78827 65www.odu.dePage 37

1<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FContact ConfigurationSize 22121210 611 93 24 1 8510 6711 93 24 1 8510 6711 93 24 1 85671Inserts2121212121210 611 93 24 1 8510 6711 93 24 1 8510 6711 93 24 1 85 769287928792871112 322 3232211 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 192 F – –2 3201SizeInsulatorNumber of contactsContactdiametermmNominal1currentload percontact 11)A2 32 32 31Clearance andcreepage distanceContact tocontact in mmContact tohousing in mm1011 93 24 1 85 710 611 9Test3 2voltage 2) 84 15 76kVeffNominalvoltage 5)kVrmsTerminationSolderCrimp 3)Print 4)122312 3View111on the termination1side2 3312 331322101 11 93 23 421 8510 6793 2421 85 76111Pin pieceSocket piece292879287Inserts2223 1 23 1 22 1 32 P 0 2 1.6 17 1 2.1 1.6 2.100 0.700 ● ●114 2 54 2 55 2 43 23 22 31114 54 55 43 1 23 1 22 1 32 P 0 3 1.6 17 1 1.6 1.5 1.800 0.600 ● ●112 32 33 24 54 55 427 1623 1 23 1 222 7 161 33 18 2 153 1183 2 15193161411 93161454684 55468864510 13104 5136 5 75211 7 16 126 77 5 632211 7 16 123 28 19 3 3 22 3 8 193 1892 18 3153 11893 2 18 15442 12 79442 1124 4 2 71492 Mixed inserts P 0 98 × 0.9 10 0.8 0.7 10 1.350 17 0.45010 1713 1 6● ●11 3 1 6 1454 698111654 6988611 45510 1310161 × 1.3 14 1.8 3.8 2.100 4 5 0.7004 56 555136 7 812 156711 126 7 88 612 153 213 77 63 211 1238 14 719 2 3 1338 14 199 18 3 9 18442 12 7442 1124 4 2 710 1710 1713 1 611 3 1 65 9811 165 988 11 55 164 594 566 7 812 15676 7 8877 7 612 151013 638 14 19 1010 1338 14 191142 99 18 1142 99 32 4119 184 22 74 22 4 2 7310 171 210 173 1 631 22 1 32 P 1 1 0.9 3 1 6410 5790.8 0.7 11 1.350 16 0.450 ● ●1 8457997115 164 51 88 1 44 556 7 8712 1556 7 87787612 5 1561338 14 19 66 1338 14 194 29 18 344 222 49184 22 72 4 2 710 1710 1713 1 611 3 1 657911 1657997115 164 54 51 Derating factor see page 756 76812 156 7688 76612 151338 14 19 1333 8 14 192 SAE AS 13441:1998 method 3001.1 (kVeff)9 18 9 184 22 74 22 4 2 710 1710 173 Tools for assembling see page 6213 1 611 3 1 65 911 165 99 11 5 164 54 56 7 812 156 7 88 7 64 PCB layouts see from page 4512 153 213 143 22 3 13 141115 Maximal operating voltage at sea level up to 2.000 m acc. to 4 SAE 13441. 1 More information on page 76.4 11 42 P 0 5 1.342 362 33 24 54 54 66 44 55 44 5510 135510 13211 7 16 1223 23 22211 7 16 1233 18 2 153 1183 2 15314 1 1.2 1.0 931.500 1614 0.500 ● ● ●11 9 16144 64 64 54 56 44 55 10 44 5510 135513211 7 16 122211 7 16 123 18 2 153 1183 2 159316149316142 P 0 6 0.94 64 54 66 410 13104 5555132311 7 16 12233211 7 16 1234 218 2 1534 2112 843 2 153310 1.5 1.2 9 1.800 1614 0.600 ● ●9 161111454674 55467764510 13104 5565665132311 7 16 12233211 7 16 1234 218 2 1534 2112 843 2 1593161493161111454674 55467764510 13104 55656651311 1211 12332334 24 2222 3342 P 0 7 0.9 10 11.1 1.0 1.650 0.550 ● ●115 75 77 54 54 56656433 233 224 24223 344 14 11 41115578557887554 54 5665646 76 77 63 3 23 3 22 3 34 24 22 44 14 11 42 P 0 8 0.9 10 1115 71.0 0.5 1.500 0.500 ● ●5 8557887556 6 7663 2 27 166 77 63 2 22 2 3 7 163 18 2 153 1183 2 154 11931641 414931614Page 3825 86 73 24 156 7825 826 73 24 156 788 57 62 31 4www.odu.de8 576161561413516 121561413516 121561413516 121561413516 121561413512161561413516 12 19151871714 6161351512 14 191871761651514 191871761651514 191871761651514 191871761651514

32322 314 51<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series F2 314 512 3531142InsertsContact Configuration23 1Size 24 619 188193161454 54 6610 13511 121 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 192 F – – 04324322115 75 77663 2Contact Nominal Clearance and Test3 2Nominal Termination1diameter current creepage distance voltage 2)1voltage 5)4 5load per4 55contact 1)3 23 24 1 mm A4 115 85 8826 727 166 723 18 2 153 13P 1 6 0.7 9 7 1614 0.8 0.6 1.100 0.366 ● ● ●4 64 54 66510 13511 12SizeInsulator4531Number of contacts34 25196 7 834 2526 77183451296 7 87 168 2 15Contact tocontact in mmContact tohousing in mmkVeffkVrmsSolderCrimp 3)Print 4)2 3View on the termination sidePin 4 piece57 62 7 16183 2 159316148 19 38 199 18 3 9 182 74 22 4 2 710 1710 173 1 611 3 1 611 165 99 11 5 164 54 512 156 7 88 612 1513 14 7 13 1454104 51311 1238 1993 9 182 74 22 4 2 710 1710 173 1 611 3 1 611 165 99 11 5 164 54 512 156 7 88 612 1513 14 7 13 14432234115 77 5663 22 34 11 45 88 56 77 62 P 1 9 0.7 7 0.7 0.6 1.000 0.333 ● ● ●1 Derating factor see page 75 62 SAE AS 13441:1998 method 3001.1 (kVeff)3 Tools for assembling see page 624 PCB layouts see from page 455 Maximal operating voltage at sea level up to 2.000 m acc. to SAE 13441. More information on page 76.3212 7 1683 2 159316144104 551311 1231612 344516 715 2 8146139135 41012 11Socket piece16 715 2 8146139135 41012 1119 818 97 217 106 1 316 115 415 1214 1319 818 97 217 106 1 316 115 415 1214 13Insertswww.odu.dePage 39

4 12151 116 32 10278 9<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series F12186 547 128 314131920 12 27219 10 11 222623 2425126574 121 1132 108 9Inserts121131094128567Contact ConfigurationSize 3ZeichnungfehltZeichnungfehlt1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19123 F – – 0SizeInsulator1Number of contacts254 1212111078 9Contactdiametermm45Nominal 16current2load7percontact 1)3108 910983A 24 171156 1512 13 14111Clearance andcreepage distanceContact tocontact in mmContact tohousing in mm3 6 P 0 3 2 3.0 25 1.7 1.3 6 1.800 3 0.600 6 3 ●2121211101015 14 9111514 9912161322381216136 5 12365 12 812 813 1 17 41 717 4131341 747 17 1718 4 2 18 2148 35618148 356181861915 9 1119 91120 10 16 17415 16 17171212 4 20 102111 55 2223 2421 2223 24 1124 123 2Test Nominal Termination View 1 on 11 the termination 11 side 16 33 6voltage 2) voltage 5)2 1010 222 778 99 8kVeff54 1212111078 9kVrms41 5121211102 78 9SolderCrimp 3)Print 4)10983Pin piece 24 171156 1512 4 12 13 145 111 13 610 27 29 88910Socket 2 3piece1 4715 651114 13 12 4 121 51 116 32 102 78 91212113109Inserts1271 27 13 P 1 0 1.3 14 1.2 0.9 20 1.350 0.450 ● ●541121 112 107 28 96895 410354 1212111078 93 6 P 1 3 2 1.3 614 3 1.0 0.8 1.350 0.450 ● ●Zeichnungfehlt141015 91415 1398161015 14916136 5 121613 88 106 35 1217 46 35 1212 13 14 15 51617 2417 2442 36177417 17118 2 4 1172 18 3 71 4718 2 188 3 7 2 188 31159 6 11 1519 91120 1021 2223 24 19 11536 1515 6581991110 10 112012 13 142012 211322 14 23 2421 2223 24 1110 9 192414 23 13 122022 213 P 1 5 0.9 10 0.9 0.7 1.100 0.366 ● ● ●1217 168 99 8 17 1618 1518 156 5 147 1010 765 1414 15 1 19 419 44131 22 1 7 1 13132 12 206 33 62 12 128 3 278 3 2792115 14 10 11 5 44 5 915 14 10 11 2721112226132226261616136 5 126 5 1212 13 123 2425 23 2425 25217 417 447 17 118 2 18 28 3 8 319 9 1119 91120 10 104 1212 4 20 2111 55 2223 2421 2223 24 1124 14 1212 423 21 5511 1111 1 1 1111 16 33 6 6 33 62 1010 2 2 1010 22 7 22 7 7728 99 8 8 99 8Zeichnungfehlt111010911 99101112 223812388 231213 1 713 1 7744141314 561814 56181865 1415 1017916109817 1618 1518 15 88635 142635 1414 15 1 16 171098891015 16 1717 16 1519 43 22 319 2442741 13714 1 13204132 712 120 2 1712 87115 3 2786 15115 3 2721921 6 1515 6121514 10 11 71 4712913 14 13121514 10 11 2722 221616 13 14 13146 5 126 5 1212 13 23 2425 2623 2425 26 1156 1515 65111115 1415 1426 116131216132526 5 1217 46 5 1212 13 14 15 13 1414 13 1251617 417 44 17 617 447 17 17 11 7118 2 18 2 18 2 18 2 18 28 3 8 3 3 319 9 11819 9 1119 91120 10 20 1021 2223 2421 2223 24 19 9 113 81120 10 20 10 24 121 2223 2421 2223 24 1110 9 1924232022 2123 23 P 1 8 0.9 10 0.9 0.7 1.100 0.366 ● ● ●10983 24 171156 1512 13 143 P 2 4 0.7 7 0.7 0.7 1.000 0.333 ● ●10983 24 15717 1618 156 5 1419 4Zeichnung7 1 1320 2 128fehlt 3 2721910910 11 22 23 2425 8263 24 17511 6 1511 6 151 Derating factor see page 7512813 91412 13 142 SAE AS 13441:1998 method73001.1 (kVeff)101 23 Tools for assembling see page 626 34 PCB layouts see from page 45 5 4111095 Maximal operating voltage at12 238Zeichnung sea level up to 2.000 m acc. to SAE 13441. More information on13 1 7Zeichnung page 76.4fehlt14 5618fehlt151716 16 1718 156 5 1419 47 1 1320 2 128 3 27219 10 11 22 23 2425 2617 1618156 5 1441 132 12 3 279 10 111972082122 23 2425 2617 161517 16186 518 151419 46 5 1419 47 1 13 Zeichnung7 1 1320 2 12 20 2 128 3 27219 10 11 8fehlt 3 2722 23 2425 26 219109910910 1188 1022 23 2425 8263 22 3 3 24 1471 47171156 1515 6 1151156 1512813 914149 13 81212 13 143 P 2 7 0.7 7 0.7 0.7 1.000 0.333 ● ● ●761 25 4103Zeichnungfehlt10 72 13 64 5 1110912 2381341 714 5618151716 16 1718 156 5 1419 47 1 1320 2 128 3 27219 10 11 22 23 2425 2614 15 16 17 4 5 186 1913 1 712 2 2027 3 81192126 108925 102224 232 31 4715 651114 13 12910118 23127 1Zeichnung4131865 fehlt 1417 17 1616 1518 1514 15 16 17 6 5 144 5 18196 19 413 1 71 1312 20 2 202 1227 3 83 2711 2110 92126 9 10 112522 22 23 2425 2624 2314 15 1 41312271126 1252Page 401110912 2381341 714 561815 16 17ZeichnungZeichnung1110912 2381341 714 561815 16 171110912 2381341 714 561815 16 17Zeichnung910118 23127 14131865 1417 16 15Zeichnung1110912 23813 1 7www.odu.de414 561815 16 1798718617

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsContact ConfigurationSuper Shorty Size 02131221312131222 11 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19211 23 40 F – – 5 5 0 C3 443213213132SizeInsulatorNumber of contactsContactdiametermmNominal 1current2load percontact 211)134 2 52 1 1AClearance andcreepage distanceContact tocontact in mmContact tohousing in mmTestvoltage 2)kVeffNominalvoltage 5)kVrmsTerminationSolderCrimp 3)Print 4)View 1 on the termination 1side22211211334 2 55 2 4Pin2 1piece11Socket1piece23 2 43 2 44231 10 P 0 2 0.9 1021.0 1.0 1.500 0.500 ●2 321 12 31 13 221232 1130 P 0 3 0.9 1020.6 1.0 1.350 0.450 ●4 352232413113513115322234Inserts2 1123 342321 70 P 0 4 0.7 7 1 0.8 0.9 1.350 0.450 ●4 3 4 652 12 1123 342321 714 3 4 652 1112243327 1 2 316 4 3 451 23 43 443223134450 P 0 5 0.7 7 0.6 0.8 1.100 0.366 ●21345223 173 1445650 P 0 7 0.5 5 0.7 0.8 0.900 0.300 ●21345230 P 0 9 0.5 5 1 0.5 0.7 0.600 0.200 ●984 75 62213344521345223 173 144565213452 93 814 75 6211 23544 321354227131 365454213549 28 317 46 51 Derating factor see page 752 SAE AS 13441:1998 method 3001.1 (kVeff)3 Tools for assembling see page 624 PCB layouts see from page 455 Maximal operating voltage at sea level up to 2.000 m acc. to SAE 13441. More information on page 76.23 714 6523 714 652 2 937814675 5 623 714 6523 714 6523 714 652 2 937814675 5 623 714 6527 316 4527 316 459 2 287317646 5 527 316 45www.odu.de2 93 814 75 62 93 812 93 814 75 62 93 819 28 3176 59 28 31Page 4 41

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsContact ConfigurationSuper Shorty Size 1Inserts1 2 3 4 5 6 7 8 9110 11 12 13 14 15 16 17 18 191 F – –27 0 0 C1SizeInsulatorNumber of contactsContactdiametermmNominal 1current2load percontact 11)1A2Clearance andcreepage distanceContact tocontact in mmContact tohousing in mm1 P 0 2 1.3 1426 1 3 111.3 1.3 1.650 0.550 ●4 45Test 12Nominal Termination View 1 on the termination 1side512126 1 3 116 1 3 1111 3voltage 2) voltage 5)7 2 10222 7 10108 98 994 45 12 1 11 1 5 121226 1 3 112621 3 1111 3222 37 102 33 2 7 10108 98 994 41 15 12 1 11 1 5Pin pieceSocket piece121226 1 3 112621 3 1111 37 2 107 22 32 33 210108 98 994 41 15 12 1 11 1 5 12122621 3 1111 37 2 107 22 32 33 210108 98 991 14 1 144112222 332 333321 P 0 3 1.3 1421.1 1.2 1.500 0.500 ●4 45 12 11 5 12126 1 3 116 1 3 1111 37 2 10222 7 10108 98 994 45 12 11 5 12126 1 3 116 1 3 1111 37 2 107 22210108 98 99kVeffkVrmsSolderCrimp 3)Print 4)1 14 1 14411222 332 33332Page 421 14 1 144112222 332 333321111 451 455412222334233443231111 451 455412222334233443231111 451 4554122223342334432311111 12 562 5665222233453345543444 311111 12 562 5665222233453345543444 311111 12 562 5665222233453345543444 31212123267326776321 114365436565434545451212123267326776321 11436543656543454545114 214 2145 122326711 5 1212 5326776326 1 1 3 116 1 1 3 1111 3 1 1 62743 2 10 65432 65654327 1010 2278 4598 4599 4582223 873 877834174177146665 5 65 5 66 5 52223 873 8778314174 77146665 5 65 5 66 5 512223 87113 87783212214 74 771436366535 65 5 66 5 53283288234174177145 65 66 53283288234174177145 65 66 51 4 3281 44 1 3288232 34174172 33 25 65 66 51 P 0 4 0.9 10 1.2 1.1 1.500 0.500 ●1 P 0 5 0.9 10 0.8 1.1 1.350 0.450 ●1 p 0 6 0.7 7 0.8 1.1 1.200 0.400 ●1 P 0 7 0.7 7 0.8 1.1 1.200 0.400 ●1 P 1 2 0.5 5 0.5 0.9 1.000 0.366 ●1 Derating factor see page 752 SAE AS 13441:1998 method 3001.1 (kVeff)3 Tools for assembling see page 624 PCB layouts see from page 455 Maximal operating voltage at sea level up to 2.000 m acc. to SAE 13441. More information on page 76.1www.odu.de7 4

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsContact Type / SurfaceFor All Sizes1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0TerminationContact typeSurfaceContact surfaceSolder terminationCrimp terminationSocket L AuPin M AuSocket N AuPin P AuInsertsPCB terminationSocket Q AuPin R Auwww.odu.dePage 43

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsTermination Cross-Sections for Turned ContactsFor All SizesCrimp contact1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – P – 0Solder contact1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19F – – 0InsertsSizeNumber ofcontactsContactdiameterContact diameterTerminationcross-sectionTerminationcross-sectionmm AWG mm 2F C 0 28 to 32 0.09 to 0.040 4 to 5 0.7F G 0 22 to 26 0.38 to 0.15F C 0 28 to 32 0.09 to 0.046 to 7 0.7F G 0 22 to 26 0.38 to 0.151J G 0 22 to 26 0.38 to 0.154 to 5 0.9J H 0 20 to 24 0.50 to 0.25F C 0 28 to 32 0.09 to 0.041,5 12 0.7F G 0 22 to 26 0.38 to 0.15F C 0 28 to 32 0.09 to 0.0416 to 19 0.7F G 0 22 to 26 0.38 to 0.152P H 0 20 to 24 0.50 to 0.255 1.3P L 0 18 to 20 1.00 to 0.5024 to 27 0.7 F G 0 22 to 26 0.38 to 0.153J G 0 22 to 26 0.38 to 0.1515 to 18 0.9J H 0 20 to 24 0.50 to 0.25Tools for crimping and their adjustments see page 62.ContactdiameterTerminationdiameterContact diameterTerminationcross-sectionTerminationcross-sectionmm mm AWG mm 20.5 0.4 C C 0 28 0.080.7 0.6 F D 0 26 0.150.7 0.85 F G 0 22 0.380.9 0.85 J G 0 22 0.381.3 1.1 P H 0 20 0.501.6 1.4 S N 0 18 1.002.0 1.85 T Q 0 14 1.52.0 2.4 T S 0 12 2.53.0 2.7 V T 0 10 4.0PCB (print) contact0.5 0.5 C 0 00.7 0.5 F 0 00.9 0.7 J 0 01.3 0.7 P 0 01.6 0.7 S 0 02.0 0.7 T 0 0Please consider for this the PCB layouts from page 45.For mixed inserts 1)1 Please provide details of termination cross-section!M 0Page 44www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FPCB Layouts for Print ContactsSize 03 × 120°2113 × 120°23 432,6∅ 2,15 2,624 4 × × 90° 90°1123 432,6∅ 2,15 2,64 4 × × 90° 90°Inserts2,54141 3232,54141 323Number ofcontactsStraight90° right-angledStraight90° right-angledDrill: 0.8 mmDrill: 0.7 mm∅ 2,22,2 2,221∅ 2,22,2 2,2212122,542,542,54122,542,542,54Drill: 0.8 mmDrill: 0.7 mm33 3 × 120°× × 120° 120°2132,15∅ 2,152,152,542,542,541 32342,6∅ 2,62,64 4 × 4 × 90° × 90° 90°142 32,542,542,54∅ 2,8555 5×72°72°72°5432,54 2,542,542,542,542,54www.odu.dePage 4566 6×60°60°6,3333 3 × 120°× × 120° 120°2132,15∅ 2,152,152,542,542,541 321,651,6524 4 × 4 × 90° × 90° 90°114232,542,542,541,84∅ 2,8555 5×72°72°72°13524151,621232,54 2,542,542,542,542,540,4551421,4566 6×60°60°6,3Drill: 0.6 mmDrill: 0.6 mm421342,6∅ 2,62,61,84All specifications are only valid for socket inserts. Pin inserts on request.3241,620,451,451,31,31,31,31,651,842,542,542,542,541,841,65∅ 2,85Number ofcontacts223∅ 2,853 4∅ 2,655 ×72°72°21 12345344 × 90°∅ 2,655 ×72°72°1 1454 × 90°1,620,451,621,4515151 4 1 424243 32 3 2 32,542,542,542,542,542,542,542,542,542,540,451,841,451,84Drill: 0.6 mmDrill: 0.6 mm5 × 72°5 × 72°5∅ 2,8532∅ 2,85413542511,620,45121,621,4530,452,54 2,5451421,45432,54 2,545Drill: 0.6 mmDrill: 0.6 mmInserts∅ 3 3734∅ 3 321566 ×60°60°736421566 ×60°60°761,3 1,3 1,3 1,31,3 1,3 1,3 1,3767621521534342,542,542,542,54 2,542,542,542,54Drill: 0.6 mmDrill: 0.6 mm9∅ 3∅ 3,3 3,32 9323 1414 5 6∅ 3∅ 3,3 3,322,5°22,5°58× 8× 45° 45°6 × 60°22,5°22,5°2 9823 831741 7645 6 658× 8× 45° 45°6 × 60°1,3 2,542,541,38792321,3 2,542,541,37113687665795211655432342,542,542,542,542,542,542,542,54All specifications are only valid for socket inserts. Pin inserts on request.∅ 3,334∅ 3,3122,5°2 95 68× 45°22,5°2 983817475 68× 45°2,542,548922,542,54713687 6591 5423 42,54 2,54 2,54 2,54

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FPCB Layouts for Print ContactsSize 1∅ 3∅ 3∅ 3222∅ 3∅ 3∅ 3∅ 311122223333 × 3 120° × 3 120° × 120°111133333 × 3 120° × 3 120° × 3 120° × 120°Inserts1,51,5 1,52,542,5412,5431 31 32221,51,51,51,52,542,5412,54312,5431 31232222,252,252,252,252,252,252,25Number ofcontactsStraight90° right-angled∅ 3,5 ∅ 3,5 ∅ 3,5Number ofcontacts111∅ 3,5 ∅ 3,5 ∅ 3,5 ∅ 3,522214 14 14 123232324Straight4 × 4 90° × 4 90° × 90°44433334 × 4 90° × 4 90° × 4 90° × 90°90° right-angled44 34 34 31 21 21 22,542,542,5434 34 341231 21 21 2,54 22,542,542,542,542,542,542,542,542,542,54Drill: 0.8 mmDrill: 0.9 mmDrill: 0.8 mmDrill: 0.7 mm∅ 2,8 ∅ 2,8 ∅ 2,82∅ 2,8 ∅ 2,8 ∅ 2,81112221112221 21 21 22,542,542,541 21 21 22,542,542,54∅ 3,5 ∅ 3,5 ∅ 3,55222111333∅ 3,5 ∅ 3,5 ∅ 3,5 ∅ 3,552 52 522 444111133335 × 5 72° × 5 72° × 72°555544445 × 5 72° × 5 72° × 5 72° × 72°2 2 20,550,550,555 45 4545 451435143512431 2 312 31 2 312,54 2 2,54 32,54 2 2,54 2,54 2 2,542,54 2,54 2,54 2,542,54 2,54 2,54 2,5422221,81,81,80,550,550,550,551,81,81,81,8InsertsDrill: 0.8 mmDrill: 0.9 mmDrill: 0.6 mmDrill: 0.7 mm∅ 3∅ 3∅ 33222∅ 3∅ 3∅ 31112223333 × 3 120° × 3 120° × 120°1113333 × 3 120° × 3 120° × 120°1,5 1,5 1,52,542,5412,5431 31 32221,51,51,52,542,5412,5431 31 32222,252,252,252,252,252,25∅ 3,7 ∅ 3,7 ∅ 3,76222333∅ 3,7 ∅ 3,7 ∅ 3,7 ∅ 3,71114446 × 60°6 × 60°6 × 60°6 × 60°6 × 60°6 × 60°6 × 60°116 52 1 6 6 5 6 516 5 1642 6 6 5612546 61546 1 4 21342 6 6 12 4312 43352 3 2 2,54 33 5 52 2,54 3 2 2,54 33 5 4 52,542,543 5 4 542,542,5441,61,61,61,61,61,61,61,61,61,61,6Drill: 0.8 mmDrill: 0.7 mmDrill: 0.6 mmDrill: 0.7 mm∅ 3,5 ∅ 3,5 ∅ 3,54111∅ 3,5 ∅ 3,5 ∅ 3,52224 14 14 13232324 × 4 90° × 4 90° × 90°4443334 × 4 90° × 4 90° × 90°4 34 34 31 21 21 22,542,542,544 34 34 31 21 21 22,542,542,542,542,542,542,542,542,547∅ 3,7 ∅ 3,7 ∅ 3,7333444∅ 3,7 ∅ 3,7 ∅ 3,7 ∅ 3,72221115556 × 60°6 × 60°6 × 60°33 73 73 744 64 64 62222111515556 × 60°6 × 60°6 × 60°6 × 60°777766661,6 1,6 1,6 1,6 1,67 6777 7 627 62 12 1 517 62 1 52 1 532 1453 4231 543 432,54 2,54 43 2,54 2,54 432,54 2,54 42,54 2,54 2,54 2,542,54 2,54 2,54 2,541,6 1,6 1,6 1,6 1,6 1,6All specifications are only valid for socket inserts. Pin inserts on request.Drill: 0.6 mm∅ 3,5 ∅ 3,5 ∅ 3,5222111333∅ 3,5 ∅ 3,5 ∅ 3,5552 522 4441113335 × 5 72° × 5 72° × 72°5554445 × 5 72° × 5 72° × 72°2 2 20,550,550,555 4545 454514351431 2 312 31 2 312 32,54 2 2,54 2,54 2 2,542,54 2,54 2,54 2,542,54 2,54 2,54 2,542221,81,81,80,550,550,551,81,81,8∅ 4,3 ∅ 4,3 ∅ 4,3∅ 1,64 ∅ 1,64 ∅ 1,6412555666777∅ 4,3 ∅ 4,3 ∅ 4,3 ∅ 4,3∅ 1,64 ∅ 1,64 ∅ 1,64 ∅ 1,649 × 40°9 × 40°9 × 40°9 × 40°9 × 40°9 × 40°9 × 40°44 5 4 124 12 5 4 124 5612 1 4 3 1212 5 12111 63113 111 63113 1112 637 1211 3 11272101027 102108 97 102108 9 8 9 108 9 8 98 9 8 93 ×3120°×3120°× 120°3 ×3120°×3120°×3120°× 120°On requestAll specifications are only valid for socket inserts. Pin inserts on request.6 × 60°6 × 60°∅ 3,7 ∅ 3,7 ∅ 3,7222333∅ 3,7 ∅ 3,7 ∅ 3,71114446 × 60°6 × 60°6 × 60°6 × 60°116 5 6 52 6 1 6 6 5 6 561541642 6 6 51 4 1 42 6 6 12 4321342 3 2 33 5 52 2,54 3 2 2,54 33 5 52,542,543 5 4 542,542,5441,61,61,61,61,61,61,61,61,61,6Page 466 × 60°6 × 60°6 × 60°www.odu.de226 × 60°226 × 60°6 × 60°

8× 45°8× 45°3 10 3 10<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series F9∅ 5,328 9 84 1 49 1 9 10 10 7 71 2 1 25 2 582 83 3 6 66 7 6 74 5 4 52,54 2,54 2,542,54 2,54∅ 5,321,81,8PCB Layouts for Print ContactsSize 1.522,5°22,5°2,45 2,452,45 2,452,032,03Inserts∅ 5,2∅ 2∅ 5,2∅ 29 × 40°9 × 40°3 × 120°1,7 1,71,82 1,694 45 12 Straight5 1211 1190° 12right-angled106 1 3 6111 3 113 934 247 2 17 2 1 810 105 58 9 8 96 7 63 × 120°1,7 1,71,82 1,691,691,692,32,310272,32,398Number ofcontacts2,54 2,54 2,542,54 2,54Drill: 0.6 mmDrill: 0.7 mm8× 45°8× 45°8× 45°8× 45°∅ 5,32 ∅ 5,32103 10 3 109 8 9 83 10 3 104 1 49 1 9 10 9 810798 74 1 49 1 9 10 1 210712 75 2 582 83 1 23612 65 2 582 86 7 6 73 4 53645 66 7 6 74 5 4 52,54 2,54 2,542,54 2,542,54 2,54 2,542,54 2,54∅ 5,32 ∅ 5,3222,5°22,5°1,81,822,5°22,5°1,81,82,45 2,45 2,45 2,45Drill: 0.6 mmDrill: 0.7 mm2,45 2,45 2,45 2,452,032,032,032,03Inserts12∅ 5,2 ∅ 5,2∅ 2 ∅ 2∅ 5,2 ∅ 5,2∅ 2 ∅ 29 × 40°9 × 40°9 × 40°9 × 40°3 ×3120°× 120°1,7 1,7 1,7 1,71,82 1,82 1,69 1,694 45 4 12 5 4 1211 115 12 5 12121011 111210121012106 1 3 6111 3 113 9396 1 3 6111 3 114 3 24932 94 2427 2 1 87 2 1 810 107 2 1 87 25 1 5 810 8 9 105 5 6 78 96 78 96 78 96 72,54 2,54 2,542,54 2,542,54 2,54 2,542,54 2,54Drill: 0.6 mm3 ×3120°× 120°1,7 1,7 1,7 1,71,82 1,82 1,69 1,691,691,69Drill: 0.6 mm1,691,692,32,32,32,32,32,32,32,312 × 30°12 × 30°19∅ 5,528 19 8 199 189 187 710 2 6101726 171 111 3 5 11163 5 164 412 1512 1513 14 13 14∅ 5,5215°2,856 × 60°15°2,856 × 60°1,251,2518198917 16 17 1618 156 56519 147 1 47 1 482 321339 1210 110 111,25 1,252,7 2,71,52,7 2,7221,5151413122,54 2,54 2,54 2,542,54 2,5422All specifications are only valid for socket inserts. Pin inserts on request.∅ 5,52 ∅ 5,5212 × 30° 12 × 30°12 × 30° 12 × 30°8 19 8 199 8 19 189 8 19 189 7 189 710 2187 6101727 6 1710 2 1 6101721 6 1711 3 1 5 11163 1 5 1611 3 4 5 11163 4125 164 1512 4 1512 13 14 1512 13 14 1513 14 13 1415°15°15°15°∅ 5,52 ∅ 5,522,852,856 × 60°6 × 60°2,852,856 × 60°6 × 60°1,25 1,251,25 1,2517 16 17 1618 17 18 16 17 15 16 1518 6 18 5615 519156 19 5614 5 1419 7 11947 14148147 1847 1 48 2 8 213 1332 213 39 9133 12 3 129 10 9 110 12 11 1210 110 112,54 2,54 2,54 2,542,54 2,542,54 2,54 2,54 2,542,54 2,541,25 1,25 1,25 1,252,7 2,7 2,7 2,71,51,51,52,7 2,7 2,7 2,722221,52 2 2 2www.odu.dePage 47

∅ 4,28 × 45° 8 × 45°1 810 310311 12,858 941112,853 82924 392 71 13 4 3 2 4 22 3243 9 2 2 2473 1 9 2 237 10164 1548 1 15°15981 92 3 2 335 3 5996 1086 4 55 51075957 86 6 7698 6 7 864 58 64758 77 71<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series F∅ 4,23 × 120°∅ 4,23 × 120°3 × 120°PCB Layouts for Print ContactsSize 2∅ 6,5∅ 1,22 6,45 ∅ 6,3 0,35∅ 6,545°6,45 ∅ 6,45∅ 1,22 6,45 ∅ 6,3 0,3545°45°4 × 37,5°45°2,2∅ 6,45 ∅ 6,45 ∅ 6,315°4 × 37,5°45° 45°45°45°4 × 37,5°8 × 45°15°15°2,215°15°45°45°4 × 37,5°4 × 37,5°4 × 37,5°2,215° 15°4 × 37,5°4 × 37,5°Inserts1,271,279 89210 10311 411726817635 4 52,54 2,54 2,542,54 2,54Inserts∅ 5,45∅ 5,5∅ 5,45∅ 4,28 × 45° 8 × 45°8 × 45° 8 × 1045°8 × 45° 8 × 45°1 10 8 11 12,858 93121 103 2Straight 190° right-angled10 Straight 1 10 8 1 81 12 525211 12,851198 92211 12,851199 8 927 3 392 71 11 13 12 14328129 1442478 192 872 3 2 32 3 9 2 3273 1092 36710 64 5 24353 4342 34413 438 10536810171 4137 1 7 6 62 3 2 33 10 364 10 5 5 6 4 5 92,54 2,54 2,54 2,545 5 6 7 5 5 64 5 76 6 64 54 5 4 58760°∅ 5,45∅ 4,2 ∅ 4,2∅ 4,290°Number ofcontacts60°∅ 5,5∅ 5,4590°3 × 120°∅ 4,2 ∅ 4,2Drill: 1.1 mm6 × 60°60°60°∅ 5,4590°∅ 4,290°Drill: 0.8 mm3 ×3120°× 3 120° × 120°6 × 60°60°90°3 ×3120°× 120°3 × 120°1,27 1,271,27 1,272,4 2,41,27 1,271,27 1,272,4 2,4Drill: 0.9 mm1,27 1,27∅ 6,51,22 ∅ 6,3 ∅ 6,52 0,35Number ofcontacts∅ 6,51,22 ∅ 6,52 ∅ 0,35 6,9445°∅ 6,51,22 ∅ 6,3 ∅ 6,3∅ 6,3 ∅ 6,52 0,35Drill: 0.8 mm45°10 × 36°∅ 6,5 ∅ 6,5∅ 6,51,221,22 1,220,350,35 0,35∅ 6,52 ∅ 6,9445°45°∅ 6,52,2∅ 6,45 ∅ 1,22 6,3 ∅ 2,65 6,3 0,354 × 37,5°∅ 6,5 ∅ 6,54 × 37,5°Drill: 0.6 mm45°15°45°45°45°1,22 ∅ 1,22 6,3 2,65 3,6 ∅ 0,35 6,52 0,3515°45°45°45°10 × 36°45°4 × 37,5°45°2,245°45°4 × 37,5°4 × 37,5°4 × 37,5°2,22,652,215°10 × 36°15°2,6515°15°45°45°4 × 37,5°45°45°4 × 37,5°4 × 37,5°2,22,215°15°4 × 37,5°2,2 2,652,54 2,54 2,54 2,5415°15°1,27Drill: 0.7 mm1,27Drill: 0.7 mm90° right-angled910111,272,54 2,54 2,54 2,541,271,271,272389104111,271,271,277263598101112,54 2,54 2,542,54 2,5427368144 52,54 2,54 2,5414 1418 × 45° 1013 132 2 3 27 16 71016 1011 10 109 8 72,85 92 915 6 15 61 4 1 4 2 511 2,85 99 8 731 10 113 21 103 23 1 18 1511108 152 11 119 8 72,8510 216 169 12,858 99 5 12 8 5 7 122 212 52523 12 14 8112 3 29 2 8 72On request10 106 1 64 53 4112,85119211 32,8511 6999 2 1 8 2712 5 2 59 3 1 6 9 14 1 141 11 14 312 4428 3 133 12 14381214 8 192 7877 2 710 23 1044 54 116114 53 1 6434 6 610 3 2 4 312 4 8 1 83 43 325 7 511 4 532,54 2,545 6105 7 351071110641564 5 4 53 413 10 138 3 8 33 6 3 644131 4481311 12 7 116112 786 763 11 10 32,54411105 52,545 4 52,54 2,54 2,54 2,545 5 6 7 5 5 6 6 7 64 511 9 4115 9 4 56 65 × 72° 5 × 72° 2,54 2,54 2,54 2,54 2,542,54 2,54 2,542,54 2,54 2,542,54 2,54 2,542,54 2,542,54 2,54 2,542,54 2,5410 × 36°18°10 × 36°10 × 36°18°10 × 36°3,62,54 2,54 2,542,54 2,54 2,54765∅ 5,5∅ 5,453460°∅ 5,5 5,45 ∅ 5,45∅ 5,4590°6 × 60°60°60°60°∅ 5,5∅ 5,45 ∅ 5,4590°90°90°Drill: 0.8 mm6 × 60°260°60°90°90°6 × 60°2 3 2 233 213 2 3 23 23 13121151 4 1 61 4 1 5 4 54 465 465 54 5 4 55 51,27 1,272,4 2,41,271,27 1,271,271,27 1,272,4 2,41,27 1,27 1,27 1,272,4 2,41 4 2 1 4 522 552 1521522 5521 132 551 1433 6 43 432,54 43 3 6 432,54 3 2,5464 2,54 2,542,54 2,54 2,54 2,54 2,54 2,542,54 2,54 2,54 2,54Drill: 0.7 mm1 416∅ 6,52 ∅ 6,9414137 1614 1415 61 10 8 1 10 151316131 10 125 127 16 2 7 16 9210 915 6 15 611 3 102 911 62 18 1 10 1581 10 911 2151 9142119 8 73 12216 16 53 12 2,85111214 8 14 9 875 124 112 11923 123 111469 4 53102 1 2 19 3 1 6 9 14 1 81412 14 1388 2 3413 3 210 1 64134133 12 14 3 81214 7 811 441312 77 744 54 11 114 51010 13 10 5 6 7135 1 6 788 3 8 3 3 941341311 12 7 511 6127565 × 710 11 10 4 55 6 5 6 672° 2,54 2,54 2,54 2,549 95 × 72° 5 × 72° 2,54 2,54 2,54 2,542,54 2,542,54 2,54 2,5410 × 36°6,52 ∅ 6,52∅ 6,52 ∅ 6,9418°10 × 36°∅ 6,510 × 36°10 × 36°10 × 36°1,22 2,65 ∅ 3,6 6,52 ∅ 0,35 6,52 ∅ 6,9418°10 × 36°10 × 36°10 × 36°45°2,652,653,62,6518°45°10 × 36°4 × 37,5°3,62,652,6515°2,54 2,54 2,54 2,54Drill: 0.6 mmDrill: 0.7 mm2,54 2,54 2,54 2,542,54 2,54 2,54 2,541,272,54 2,54 2,542,54 2,54 2,54∅ 5,8∅ 5,543542 23 2 3 2 2 22 3 2 313 413 13 216 3 1 15884 4 6 1 66 7 4 6 7 4 6 64 6 5 465 55 55 5∅ 5,55,5∅ 5,5 ∅ 5,822,5°6 × 60°8× 45°∅ 5,5 ∅ 5,5∅ 5,45Drill: 0.8 mm6 × 60°6 × 60°6 × 60°22,5°8× 45°60°90°6 × 60°6 × 60°2,42,4122,4 2,42,42,42,42,4453 62,541 41 421542 523563 2,54 632,5462,541,27 1,272,4 2,4 2,4 2,41 41 422255513 63 3 2,54 6 42,542,54 2,5419∅ 6,94 ∅ 718°18°18°12 × 30° 12 × 30°14 1414 13 14 1314 137 16 7 1614 14 138 19 8 1915 614 13156 139 18 8 9 7 16 15 18 7 1615 12 158 1515 6 15 68 158121613 1216 51312 5 127 16 7 16 7102 710 17210 152 61716 515216 4616 1153 6215 16 416 5112 1215 128 3 1 691581 96 21514 13 11 691423 1 62 1 2 19 1216 6 19 14 1 14716365 1 12 374 114 5451112113 411164 5 1610 33 12 14 87 74 114 54 114 56 13 102 11382 19 1 5649 14 1 517 7 2171072 1012 1512 15143 8 310 11 12 13 10 11 138 3 8 3413127 18 7 918104 114 54 11 913 4 14 5 13 14 1010 13 10 11 12 13 11 12 719883198893 10 9 1011 12 11 126105 × 72° 5 × 72° 2,54 2,54 1,279102,54 2,541,2792,54 2,545 × 72° 5 × 72°92,54 2,5492,54 2,542,54 2,545 × 72° 5 × 72° 2,54 2,54 2,54 2,542,54 2,54∅ 6,94 ∅ 6,94∅ 6,94 ∅ 718°10 × 36°6 × 60°∅ 3,6 6,52 ∅ 6,94 ∅ 3,57 6,9410 × 36°10 × 36°10 × 36°18°18°10 × 36°3,573,63,66 × 60°3,610 × 36°10 × 36°2,65 3,6 3,62,54 2,54 2,54 2,541,272,542,54 2,542,542,54 2,542,542,54 2,542,542,54 2,541,27All specifications are only valid for socket inserts. Pin inserts on request.2,54 2,54 2,54 2,54 2,54 2,54 2,54 2,542,54 2,54 2,542,542,54 2,542,542,54 2,542,542,54 2,5422,5°12 × 30°∅ 5,84538∅ 5,86 722,5°241588× 45°3∅ 5,8∅ 5,522,5°2 4 23518 6 76 7 4Drill: 0.8 mm38× 45°526 × 60°18168× 45°On request2,42,41 42 53 62,54∅ 712 × 30° 12 × 30°14 138 199 1815 14 1213102 714 13 14 138 19 8 191716 5 4 119 18 9 18 3 7 1 16615 12 15 126 15 1 6 37102 710 172 11817 151616 5 416115217 16 4 114 57 2 10 5 123 1 6 3 1 6 12 3 6 156 1 361 3 2 1119 1 1418 941116165 4 5 13 14 17 7 217107274 114 5191012 1512 15810 1318 918913 14 13 14 8 311 1219 8 19 8101,271,271,2795 × 72° 2,54 2,54 2,54 2,54∅ 76 × 60°∅ 7∅ 6,94 3,576 × 60°3,5718°10 × 36°6 × 60°3,573,61,271,272,54 2,54 2,54 2,541,27∅ 5,8∅ 5,8 ∅ 5,8∅ 5,822,5°8× 45°∅ 5,8 ∅ 5,822,5°22,5°22,5°∅ 6,458× 45°8× 45° 8× 45°45°22,5°22,5°34 23 2 3 29 3 2 3 1 23 2 4 3 2541 194 4114 5418516 87 85 8585 856 7 8 6 76 7 6 76 7 6 78× 45°8× 45°15°4 × 37,5°On requestAll specifications are only valid for socket inserts. Pin inserts on request.∅ 712 × 30° 12 × 30°12 × 30° 12 × 30°12 × 30°812 ×1930°8 199 8 19 18 9 8 19 188 19 9 18 9 71028719187 710210 172179 18 931 610181732 1 6 1711 3 1 7102 710 1724 6111634 1 6 1611 5 174111653 1 6 12 3 1 416561512 5 151141121613 4 14 1512165 5 13 14 1512 1512 13 14 15 13 1413 14 13 14∅ 7∅ 7∅ 76 × 60°∅ 7∅ 73,573,573,573,576 × 60°6 × 60°6 × 60°3,573,576 × 60°6 × 60°1,2714 13 14 1315 14 13 12 15 14 13 1214 1316 15 514 1341612151154 12 1115 16 1261554163121 6 1151 4 3 1116 5174166 1175 1 2174 3610117 1 2 3 106 1 17 3618 7 1 21739181072 9 1017 7 217181910782 91819108 918 918198 9 19 819 8 19 8 1,271,271,271,271,271,271,271,271,271,271,27Page 486,38 × 45°1822,5°2 9 78× 452,212 × 30°www.odu.de1413

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FInsertsPCB Layouts for Print ContactsSize 39 × 40°Number ofcontacts12∅ 7,9∅ 2,9Drill: 1.1 mm∅ 7,9 ∅ ∅ 7,9 8,45∅ 2,9 ∅ ∅ 2,9 4,35675Straight82 × 30°9 × 40°9 × 40°910 845 342 1254126 1 1 37 116 1 3 111156 157 2 107 12 2 14 108 1398 94 × 30°41 3291211103 × 120°3 ×3120°× 120°6 × 60°15°90° right-angledOn request15Drill: 0.8 mm∅ 8,45 ∅ 8,45∅ 8,4∅ 4,35 ∅ 4,352 × 30°2 × 30°1 112910 98 1010 12 83 31343 16 924 14 14 1517 8115 711556 15712 6 151412 13145 × 1372°4 × 30°4 × 30°11× 32,7°2 On request 113,8615° 15°6 × 60°6 × 60°1,279 810716 151261 13 14253 42,54 2,54 2,54 2,54Inserts∅ 5,318∅ 2Drill: 0.8 mm∅ 8,816 15 14 13 16 15 14 13 11× 32,7°11× 1032,7°5176 51741112 649127 1 7 1 1 1118 2 18122 212 11 88 3 3 1028123197 109 131910 311 13 1214249 10 1611 24 920 32021 23 13 16 94 145623221421 22151884 15 14 15 85 161775 6 765 × 72°5 × 72°∅ 5,3∅ 8,45∅ 8,4 ∅ 8,4 ∅ 4,353× 120°∅ 2∅ 8,83× 120°Drill: 0.6 mm7× 40°12× 30°40°15× 24°36°7× 40°45°40°15× 24°36°6× 60°3,863,861,27Drill: 0.7 mm12 12 24 2413 13 23 234 11 4 1114 5 14 5322 3 221 1019 8 1015 6On request 15 6210 9 2128 7 2171110 16 7915 9716 11 16 81216 15 20 8 6 208 1 1219 81314 1961182131814 52,54 2,54 2,54 22,54 32,54 4 2,54 5 2,542,54 2,5432,5442,542,54 2,54 2,54 2,541,271,271,27∅ 5,324∅ 2∅ 8,8∅ 8,45 ∅ 8,45∅ 4,35 ∅ 4,35∅ 212× 30°12× 30°7× 40°1615 14 13 1615 14 13105176 51741112 6411109127 1 7 1 918 2 18122 2 88 3 12 8 3 328193 79 131910 11 241 71349 10 11 2420 20 121 23 4562322 14 21 2256 1814181515 161716173× 120°∅ 5,3∅ 8,87× 40°3× 120°Drill: 0.6 mm40°15× 24°36°45°45°40°6× 6× 60° 60°15× 24°36°1,2712 24 12 2413 13 23 234 11 4 1114 5 14 3522 3 221 10 1 1015 6 15 2621 2 217 97916 16 8 20 8 208 19 8 1918 182,54 2,54 2,54 2,54 2,542,54 2,541,27Drill: 0.7 mm∅ 5,327∅ 2∅ 8,8∅ 5,3∅ 2∅ 8,89× 40°3× 120°9× 40°18 17 16 1518 17 16 155 14196 5 14194647 1 7 13 1 1320 2 20 12 2 128 3 8 32110 11 272110 11 279 2692622252223 23 2524 243× 120°40°15× 24°36°40°15× 24°36°1,2714 14 26 2615 13 15 27 13 25 27 254 4 11 1116 163124 3 245 12 5 10 12 1017 17 7 8723 8 236 26 92918 1822 2219 20 19 21 20 211,272,54 2,54 2,54 2,54 2,542,542,54 2,54All specifications are only valid for socket inserts. Pin inserts on request.www.odu.de∅ 5,3∅ 2∅ 8,8∅ 5,3∅ 2∅ 8,89× 40°9× 40°18 17 16 1518 17 16 155 14196 5 14194647 1 7 13 1 1320 2 20 12 2 1240°40°15161714 14 26 2613 15 27 13 25 274 4 11 11116312435 125 10 12 1071787238252423Page 49

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FFor Your NotesInsertsPage 50www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesPart Number Key See Fold-outPage in the Rear CoverAccessorieswww.odu.dePage 51

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesSilicone Cable Bend ReliefAccessoriesSize Part number Dim. L Cable(outer diameter)min. max.0123700.023._.965.0202.0 2.5700.023._.965.025 2.5 3.0700.023._.965.030 3.0 3.527700.023._.965.035 3.5 4.0700.023._.965.040 4.0 4.5700.023._.965.045 4.5 5.0701.023._.965.0252.5 3.0701.023._.965.030 3.0 3.5701.023._.965.035 3.5 4.0701.023._.965.040 304.0 5.0701.023._.965.050 5.0 6.0701.023._.965.060 6.0 6.5701.023._.965.070 6.5 7.5702.023._.965.025 2.5 3.0702.023._.965.0303.0 3.5702.023._.965.035 3.5 4.0702.023._.965.040 4.0 5.0702.023._.965.050 365.0 6.0702.023._.965.060 6.0 7.0702.023._.965.070 7.0 8.0702.023._.965.080 8.0 9.0703.023._.965.0404.0 5.0703.023._.965.050 5.0 6.0703.023._.965.060 6.0 7.0703.023._.965.070 7.0 8.042703.023._.965.080 8.0 9.0703.023._.965.090 9.0 10.0703.023._.965.100 10.0 11.0703.023._.965.110 11.0 12.0Temperature rangeSilicone: –50° C up to +200° C, short-term up to +230° C,autoclavableLColoursPlease indicate colour code.Colour code Colour RAL-no. 1)(similar)... 202 ... Red 3020... 203 ... White 9010... 204 ... Yellow 1016... 205 ... Green 6029... 206 ... Blue 5002... 207 ... Grey 7005... 208 ... Black 90051 Because of different raw materials the colours may slightly differ from RAL numbers.Page 52www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series F∅ Da ∅ DiBack Nut for Cable Bend ReliefSWAccessoriesSize Part number 1) Dimensions T in mmA ∅ B SWMounting exampleA0 700.022.117.3_.002 8.0 8.9 71 701.022.117.3_.002 10.0 10.9 101.5 715.022.117.3_.002 11.0 12.9 122 702.022.117.3_.002 11.5 13.9 133 703.022.117.3_.002 11.5 16.9 15∅ BCable bend relief1 In _ please indicate surface finish:15 = Cu-alloy / matt chrome plated11 = Cu-alloy / black chrome plated04 = Cu-alloy / nickelBack nutSWADistance RingBack Nut for silicone band reliefAccessories∅ Bwww.odu.dePage 53

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesColour Coding Rings∅ A∅ B 1SizeSize Part number ∅ A ∅ B0 700.422._.922.009 13.5 9.10 700.422._.922.010 16.5 10.11 701.422._.922.012 17.0 12.1∅ A∅ B 1Color coding1 701.422._.922.014 20.0 14.11.5 715.422._.922.014 21.0 14.12 702.422._.922.015 22.0 15.12 702.422._.922.016 23.0 16.1Color codingColor coding3 703.422._.922.018 25.0 18.13 703.422._.922.020 28.0 20.1ColoursPlease indicate colour code.Colour code Colour RAL-no. 1)(similar)Mounting exampleReceptaclePanelMatingdirectionColor codingAccessories... 202 ... Red 3020... 203 ... White 9010... 204 ... Yellow 1016Hex nutColour coding ring... 205 ... Green 6029... 206 ... Blue 5002... 207 ... Grey 7005Color coding... 208 ... Black 90051 Because of different raw materials the colours mayslightly differ from RAL numbers.Color codingOrder example700.422.202.922.009Size 0Housing ∅ M9Colour redPage 54www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesDistance Ring for Wall ThicknessAdjustment for Receptacles of Style 2 1)Size Part number Dimensions in mm∅ Da ∅ Di L T0 700.123.102.304.000 13.0 10.3 7.0 1 to 61 701.123.102.304.0002) 17.0 14.3 12.0 0.5 to 31 701.123.102.304.0013) 17.0 14.3 6.0 3 to 92 702.123.102.304.000 21.0 16.3 8.0 1 to 83 703.123.102.304.000 25.0 20.3 11.5 0.5 to 71 See page 232 Wall thickness: 0.5 to 6 mm3 Wall thickness: 6 to 16 mmMaterial: brassSurface: nickelDistance ringLAccessories∅ Da ∅ Di∅ Da ∅ DiSWSWMounting exampleReceptaclePanelTAMatingdirection∅ ∅ BDistance ringHex nutwww.odu.dePage 55

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesLocking WashersSolder LugsThread Part number Dimensions in mm∅ A ∅ C LM9 945.000.001.000.046 12.5 9.1 1.0M12 945.000.001.000.047 16.0 12.1 1.1M14 945.000.001.000.070 19.5 14.2 1.1M15 945.000.001.000.048 19.5 15.1 1.1M16 945.000.001.000.072 21.5 16.1 1.1M18 945.000.001.000.049 25.0 18.1 1.1M20 945.000.001.000.121 25.0 20.1 1.1Surface: nickel-platedThread Part number Dimensions in mm∅ A ∅ B C D ∅ E FM9 700.140.246.301.000 9.7 13.2 21.6 4.0 1.6 0.5M12 701.140.246.301.000 12.2 17.0 27.5 4.0 1.6 0.5M14 715.140.246.301.000 14.1 18.0 27.0 4.0 2.0 0.5M15 702.140.246.301.000 15.2 20.0 32.0 4.0 1.6 0.5M16 721.140.246.301.000 16.2 20.0 32.0 4.0 1.6 0.5M18 703.140.246.301.000 18.2 25.0 39.0 4.0 1.6 0.5M20 722.140.246.301.000 20.2 25.0 39.0 4.0 1.6 0.5Surface: silver-platedLocking washersSolder lugsAccessories∅ A ∅ A∅ C ∅ CLL∅ E∅ EDD∅ A∅ BA∅ BMounting exampleReceptacleHousing wallMounting exampleCCReceptacleHex nutFFLocking washersLocking washersMatingdirectionMatingdirectionHex nutLocking washerSolder lugHousing wallPage 56www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesProtective Cover for Plug (IP 50)Size Part number 1) Dimensions in mmA ∅ B C ∅ D ∅ E0 700.097.005.215._00 15.5 10 70 81 701.097.005.215._00 16.5 12 75 101.5 715.097.005.215._00 15.5 13 80 112 702.097.005.215._00 18.0 15 85 133 703.097.005.215._00 20.5 18 100 163.2CSurface: matt chrome plated1 With _ please register desired lanyard material:0 = Polyamide lanyard with loop1 = Stainless steel lanyard with loop2 = Polyamide lanyard with solder lug3 = Stainless steel lanyard with solder lugA∅ D∅ E∅ BProtective Cover for Plug (IP 68)AccessoriesSize Part number 1) Dimensions in mmA ∅ B C ∅ D ∅ E0 700.097.004.215._00 15.5 10.5 70 81 701.097.004.215._00 16.5 13.0 75 101.5 715.097.004.215._00 16.0 13.5 80 112 702.097.004.215._00 18.5 16.0 85 133 703.097.004.215._00 21.0 19.0 100 163.2CSurface: matt chrom plated1 With _ please register desired lanyard material:0 = Polyamide lanyard with loop1 = Stainless steel lanyard with loop2 = Polyamide lanyard with solder lug3 = Stainless steel lanyard with solder lugA∅ D∅ E∅ Bwww.odu.dePage 57

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesProtective Cover for Receptacle (IP 50)Size Part number 1) Dimensions in mmA ∅ B C ∅ D ∅ E0 700.097.003.215._00 10.5 10.0 70 8.01 701.097.003.215._00 12.5 12.0 75 13.01.5 715.097.003.215._00 13.3 13.0 80 11.02 702.097.003.215._00 15.0 15.0 85 13.03 703.097.003.215._00 16.6 18.0 100 16.03.2CSurface: matt chrome plated1 With _ please register desired lanyard material:0 = Polyamide lanyard with loop1 = Stainless steel lanyard with loop2 = Polyamide lanyard with solder lug3 = Stainless steel lanyard with solder lugA∅ D∅ E∅ BAccessoriesProtective Cover for Receptacle (IP 68)Size Part number 1) Dimensions in mmA ∅ B C ∅ D ∅ E0 700.097.007.215._00 10.0 10.0 70 8.01 701.097.007.215._00 12.0 12.0 75 10.01.5 715.097.007.215._00 13.3 13.0 80 11.02 702.097.007.215._00 15.0 15.0 85 13.03 703.097.007.215._00 17.0 18.0 100 16.03.2CSurface: matt chrome plated1 With _ please register desired lanyard material:0 = Polyamide lanyard with loop1 = Stainless steel lanyard with loop2 = Polyamide lanyard with solder lug3 = Stainless steel lanyard with solder lug∅ D∅ EA∅ BPage 58www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesAccessorieswww.odu.dePage 59

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAccessoriesAccessoriesPage 60www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FToolsPart Number Key See Fold-outPage in the Rear CoverToolswww.odu.dePage 61

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FToolsCrimping Tools / Assembly ToolsPart number crimping tool 080.000.051.000.000Part number positionersee table next pageToolsPage 62www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FToolsCrimping and Removal Tools for Crimp ContactsSizeNumber ofcontactsContactdiameterTermination cross-sectionAdjustmentdimensionPositioner Position Removal toolAWG mm² Pin Socket04 to 5 0.7 28 to 32 0.09 / 0.04 0.57 080.000.051.108.000 1 2 087.7CC.070.001.0004 to 5 0.7 22 to 26 0.38 / 0.15 0.67 080.000.051.108.000 1 2 087.7CC.070.001.0006 to 7 0.7 28 to 32 0.09 / 0.04 0.57 080.000.051.108.000 3 4 087.7CC.070.001.00011.56 to 7 0.7 22 to 26 0.38 / 0.15 0.67 080.000.051.108.000 3 4 087.7CC.070.001.0004 to 5 0.9 22 to 26 0.38 / 0.15 0.67 080.000.051.108.000 5 6 087.7CC.090.001.0004 to 5 0.9 20 to 24 0.50 / 0.25 0.67 080.000.051.108.000 5 6 087.7CC.090.001.00012 0.7 28 to 32 0.09 / 0.04 0.57 080.000.051.108.000 3 7 087.7CC.070.001.00012 0.7 22 to 26 0.38 / 0.15 0.67 080.000.051.108.000 3 7 087.7CC.070.001.00016 to 19 0.7 28 to 32 0.09 / 0.04 0.57 080.000.051.110.000 1 2 087.7CC.070.001.000216 to 19 0.7 22 to 26 0.38 / 0.15 0.67 080.000.051.110.000 1 2 087.7CC.070.001.0005 1.3 20 to 24 0.50 / 0.25 0.67 080.000.051.110.000 3 4 087.7CC.130.001.0005 1.3 18 to 20 1.00 / 0.50 1.12 080.000.051.110.000 3 4 087.7CC.130.001.00024 to 27 0.7 22 to 26 0.38 / 0.15 0.67 080.000.051.110.000 1 6 087.7CC.070.001.000315 to 18 0.9 22 to 26 0.38 / 0.15 0.67 080.000.051.110.000 7 8 087.7CC.090.001.00015 to 18 0.9 20 to 24 0.50 / 0.25 0.67 080.000.051.110.000 7 8 087.7CC.090.001.000Toolswww.odu.dePage 63

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FToolsSpanner WrenchPart numberDimensions in mmSW t B L b598.700.001.016.000 5 1.5 16 92 8598.700.001.015.000 5.5 1.5 16 92 8598.700.001.021.000 6 2 16 92 8598.700.001.011.000 7 2 16 92 8598.700.001.001.000 8 2 16 92 8598.700.001.022.000 9 2 21.5 102 9598.700.001.002.000 10 2 21.5 102 9598.700.001.012.000 11 2 24.5 115 10598.700.001.013.000 12 2.5 24.5 115 10598.700.001.017.000 12.5 4 24.5 115 10598.700.001.004.000 13 2.5 30.5 98 16.5598.700.001.005.000 14 2.5 30.5 98 16.5598.700.001.006.000 15 3 35.5 145 15598.700.001.007.000 16 3 35.5 145 15598.700.001.008.000 17 3 35.5 145 15598.700.001.023.000 18 3 42 172 16598.700.001.013.000 19 3 42 172 16598.700.001.009.000 20 3 42 172 16598.700.001.018.000 21 3 42 172 16598.700.001.010.000 22 3 47 119 23.5598.700.001.014.000 24 3 54 119 23.5598.700.001.024.000 27 3 55 150 25598.700.001.019.000 30 3 50 150 25598.700.001.020.000 31 3 50 150 25LBSWt = thicknessbNutdriver for Slotted Mounting NutToolsNutdriverThreadsuitable for style 8700.098.002.000.000 M 9 × 0.5700.098.001.000.000 M 10 × 0.5700.098.001.000.000 M 12 × 1701.098.002.000.000 M 14 × 1701.098.001.000.000 M 15 × 1702.098.001.000.000 M 16 × 1702.098.001.000.000 M 18 × 1703.098.001.000.000 M 20 × 1∅ 5050Page 64www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FToolsRemoval Tool for Crimp-Clip-ContactsPart numberContact diameterin mm087.7CC.070.001.000 0.7087.7CC.090.001.000 0.9087.7CC.130.001.000 1.3087.7CC.160.001.000 1.6Crimp-clip-contactRemoval toolToolswww.odu.dePage 65

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FFor Your NotesToolsPage 66www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAssembly InstructionsOur Assembly Instructionsare available for Downloadon Our Website:www.odu.de/downloadsAssembly Instructionswww.odu.dePage 67

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FAssembly InstructionsThe assembly instructions of <strong>MINI</strong>-SNAP F areavailable for download (www.odu.de/downloads):Assembly InstructionsPage 68www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FTechnical Information1201101009080706050403020100 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22Technical Informationwww.odu.dePage 69

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FTechnical InformationInternational Protection (IP) Classes in Accordance with DIN EN 60 529(or IEC 529 / VDE 0470 T1, respectively)Code letters(International Protection)IPFirst code number(Protection against solid foreign bodies)6Second code number(Protection against water)5Code number Extent of protection Code number Extent of protection0 No protectionNo protection against contact,no protection against solidforeign bodies0No protection againstwaterNo protection against water1Protection againstlarge foreign bodiesProtection against large-surfacecontact with the back of thehand,protection against foreign bodies≥ 50 mm1Protection againstdripping waterProtection against verticallyfalling water drops2Protection againstmedium-sizedforeign bodiesProtection againstcontact with the fingers,protection against foreignbodies.≥ 12 mm2Protection againstdripping water whentiltedProtection against fallingwater drops when tilted(any angle up to 15° fromthe vertical)3Protection againstsmall foreign bodiesProtection against contact withtools, wires, or the like with≥ 2.5 mm,protection against foreign bodies≥ 2.5 mm3Protected againstspraying waterProtection against waterspraying at any angle up to60° from the vertical4Protection againstgranularforeign bodiesThe same as 3,except ≥ 1 mm4Protection againstsplashing waterProtection against splashingwater from all directions5Protection againstdust depositsProtection against contact,protection against harmful dustdeposit in the interior5Protection againstwater jetProtection againstwater jet (nozzle) fromany angle6Protection againstdust ingressProtection against foreign bodies≥ 1 mm, protection againstdust ingress6Protection againstpowerfulwater jetProtection againstpowerful water jetfrom any angleTechnical Information78Protection againstimmersionProtection againstcontinuous immersionProtection againstwater ingress duringtemporary immersionProtection againstpressurized waterduring continuousimmersion9k 1Protection againsthigh pressureProtection against waterfrom high-pressure/ steam jetcleaners.1 IP x9k is not included in EN 60529 or IEC 60529, but is included in DIN 40 050-9.Page 70www.odu.de

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FTechnical InformationPrinciple of the Watertightness of <strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong>Case IIn-line receptacle2 12Cable termination area1PlugCable termination area22ContactsContactsCase IIReceptacle1133PlugCable termination area22Device termination areaContactsCase IIIReceptacle4 14 133PlugCable termination area22Device termination areaContactsProtection against water through following seals1):Case Termination area Mated UnmatedSealed Position Sealed PositionI Cable termination area Yes NoII Device termination area Yes NoIII Device termination area Yes Yes No.Sealing part O-ring Sealing ring 2) O-ring Potting1 Contacts: in mated condition the contacts are protected (in cases I, II, III) .In unmated condition the contacts can be protected using a protective cover (see page 57).The cover must be removed before mating the plug with the receptacle.2 The sealing ring acts as the cable sealing. It requires exact knowledge of the cable dimension.Important factors: Diameter tolerance, roundness, cable design and cable jacket hardness.All IP 68 submersible <strong>ODU</strong> <strong>MINI</strong>-SNAP connectorsare rated to 2 m water depth (0.2 bar) for24 hours in accordance with DIN EN 60 529.A watertight plug requires a cable grommet inthe collet. The grommet has to fit tightly overthe cable. The cable jacket must be smooth,cylindrical and free of grooves.The plug should be potted for watertightnessin unmated condition.Technical Informationwww.odu.dePage 71

<strong>ODU</strong> <strong>MINI</strong>-<strong>SNAP®</strong> Series FTechnical InformationHousing Materials and Surfaces Finish<strong>ODU</strong> <strong>MINI</strong>-SNAP housings are made from brass andare nickel-plated with a matt chrome plated surface finish(sand-blasted). Nickel-plated or black chrome platedfinished housings are available on special request.Inside metal components are made from nickel-platedbrass.Component parts Material name SurfaceHousingBack nutDesign nutCu-alloyCrCable colletEMI ringHalf-shellsLocking washersNutRetainer ringContact pin(solder / PCB)Contact socket(solder / PCBContact pin (crimp)Contact socket (crimp)Cu-alloyCu-alloyNiAuInsulator Material (recognized)Norm Unit PBT PTFE 1) PEEKDielectric strength DIN 53481 KV/mm 27 > 50 19Operation temperature ASTM D-149 ° C − 40/+140 − 100/+260 − 50/+250Flammability class UL–94 – V-0 V-0 V-0Creeping distance acc. to CTI IEC 60 112 – 275 600 1751 PTFE (Teflon) is only used for coax and triax connectors.Technical InformationPage 72www.odu.de