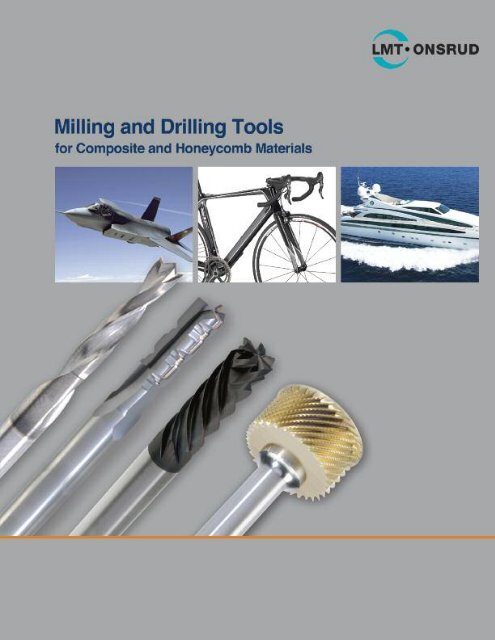

Milling and Drilling Tools for Composite and Honeycomb Materials

Milling and Drilling Tools for Composite and Honeycomb Materials

Milling and Drilling Tools for Composite and Honeycomb Materials

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

comprehensive trainingIncreased productivity equals lower cost, improvedprofitability, <strong>and</strong> ultimately, survival of your business intoday’s competitive environment. The LMT OnsrudPer<strong>for</strong>mance Team will work with all levels of youroperation to increase your productivity. All levels oftraining, general to production-specific on the shopfloor, are only a call away!factory technical supportLMT Onsrud provides your business withaccess to our staff of highly trained professionalfactory technicians. We can assist you wtihthose difficult production machining problems whileincreasing your per<strong>for</strong>mance <strong>and</strong> productivity.on-site trouble shootingCorrect tool selection, proper hold-down techniques,faster feed rates, fewer <strong>and</strong> quicker set ups areall pieces to the producivity puzzle. The LMTOnsrud Per<strong>for</strong>mance Team offers tailoredsolutions <strong>for</strong> problem solving <strong>and</strong> productivity gains.custom tool designNot only does LMT Onsrud offer the largestselection of cutting tools <strong>for</strong> day to day operations,but we will also design a tool <strong>for</strong> your specificapplication or material. We will take yourtool requirements from the drawing board,to sophisticated computer-aided design,to in-house testing on our CNC router <strong>and</strong>CNC Mill. Custom tooling made to meetyour productivity goals.

<strong>Composite</strong>s 3-10<strong>Honeycomb</strong> 11-18Drills 19-22Table of ContentsChiploads 23-24Quote Request Forms 25-36Terms <strong>and</strong> Conditions 38Table of Contents by MaterialCOMPOSITESPAGE HONEYCOMB54-200* NEWSC 3F & 4F Spiral <strong>for</strong> Glass Rein<strong>for</strong>eced Plastic456-000PSC 2F Straight463-000SC 1F Upcut Spiral566-800* NEWDFC Compression <strong>for</strong> <strong>Composite</strong>s566-900* NEWSC High Per<strong>for</strong>mance <strong>Composite</strong> Router667-000SC Fiberglass Burr Bits767-200SC 3F Phenolic/<strong>Composite</strong> Cutter867-220 NEWPCD 3F Phenolic/<strong>Composite</strong> Cutter867-300SC 2F Compression Spiral867-400*SC Un-Ruffer967-500SC Carbon Graphite Tool968-0002F PCD Tipped <strong>Tools</strong>968-200*DRILLINGPCD 2F SERF Cutter1068-300* NEWPCD 3F SERF Cutter1068-400* NEWPCD Ballnose10* Available In Metric29-000HSS Hollow Core Cutters29-050Diamond Grit Hogger29-100/29-100B*SC <strong>Honeycomb</strong> Hogger30-000Replaceable Ring Type <strong>Honeycomb</strong> Cutter30-300 HSSIntegral Shank <strong>Honeycomb</strong> Hogger Cutter30-700Reduced Weight <strong>Honeycomb</strong> Cutter31-000HSS Cutter31-100HSS <strong>Honeycomb</strong> Cutter with Teeth32-000HSS Hogger32-200 NEWHSS 3 Piece <strong>Honeycomb</strong> Hogger34-000Aircraft Panel <strong>Tools</strong>67-800*SC 8 Facet Drill68-900PCD 8 Facet Drills85-800* NEWSC CFRP Drills86-100SC DFC Parabolic DrillPAGE1212131314141515161617PAGE20212221* Available In MetricTable of Contents by Series Number29-000 HSS Hollow Core Cutters 1229-050 Diamond Grit Hogger 1229-100/29-100BSolid Carbide <strong>Honeycomb</strong> Hogger 1330-000 Replaceable Ring Type<strong>Honeycomb</strong> Cutter1330-300 HSS Integral Shank<strong>Honeycomb</strong> Hogger Cutter1430-700 Reduced Weight <strong>Honeycomb</strong> Cutter 1431-000 HSS Cutter 1531-100 HSS Cutter with Teeth 1532-000 HSS Hogger 1632-200 HSS 3 Piece <strong>Honeycomb</strong> Hogger 1634-000 Aircraft Panel <strong>Tools</strong> 1754-200 SC 3F & 4F Spiral GRP (Coated) 456-000P SC 2F Straight 463-000 SC 1F Upcut Spiral 566-800* DFC Compression <strong>for</strong> <strong>Composite</strong>s 566-900* SC HiPer<strong>for</strong>mance <strong>Composite</strong> Router 667-000 SC Fiberglass Burr Bits 767-200 SC 3F Phenolic/<strong>Composite</strong> Cutter 867-220 PCD Progressive Chipbreaker 867-300 SC 2F Compression Spiral 867-400* SC Un-Ruffer 967-500 SC Carbon Graphite Tool 967-800* SC 8 Facet Drills 2068-000 2F PCD Tipped <strong>Tools</strong> 968-200* PCD 2F SERF 1068-300* PCD 3F SERF 1068-400* PCD Ballnose 1068-900 PCD 8 Facet Drills 2185-800 SC CFRP Drills 2286-100 SC DFC Parabolic Drills 21www.onsrud.com 2

<strong>Composite</strong>Cutting <strong>Tools</strong>Using metal cutting tools to machine today’shighly abrasive composite materials can becostly in terms of tool wear <strong>and</strong> damage toworkpieces. LMT Onsrud makes an extensiveline of cutting tools designed <strong>for</strong> today’sdifficult-to-machine, space-age materials.LMT Onsrud manufactures solid carbide<strong>and</strong> PCD cutting tools designed specifically<strong>for</strong> machining CFRP (Carbon Fiber Rein<strong>for</strong>cedPlastic), GRP (Glass Rein<strong>for</strong>ced Plastic),Fiberglass, Phenolic, Kevlar®, Carbon Graphite<strong>and</strong> other composite materials.

Three & Four Flute - Solid Carbide Spiral<strong>for</strong> Glass-Rein<strong>for</strong>ced Plastic (Coated)54-200Updated line of three <strong>and</strong> four flute tools <strong>for</strong> machining glass-rein<strong>for</strong>ced plastic. Geometry has beenoptimized to shear the glass fibers while creating a chip which removes heat from the cut to avoidmelting of the material. <strong>Tools</strong> are coated to withst<strong>and</strong> the abrasive characteristics inherent to glassrein<strong>for</strong>cedplastic (GRP).UsageFiberglass <strong>and</strong> <strong>Composite</strong>sUPCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL FLUTES54-205 1/8 1/2 1/4 2-1/2 354-210 3/16 5/8 1/4 2-1/2 354-220 1/4 3/4 1/4 2-1/2 454-230 3/8 1-1/8 3/8 3 454-240 1/2 1-1/8 1/2 3-1/2 4DOWNCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL FLUTES54-206 1/8 1/2 1/4 2-1/2 354-211 3/16 5/8 1/4 2-1/2 354-221 1/4 3/4 1/4 2-1/2 454-231 3/8 1-1/8 3/8 3 454-241 1/2 1-1/8 1/2 3-1/2 4METRIC UPCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL FLUTES54-260 6mm 19mm 6mm 76mm 454-266 8mm 22mm 8mm 76mm 454-270 10mm 25mm 10mm 76mm 454-276 12mm 25mm 12mm 76mm 4METRIC DOWNCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL FLUTES54-261 6mm 19mm 6mm 76mm 454-267 8mm 22mm 8mm 76mm 454-271 10mm 25mm 10mm 76mm 454-277 12mm 25mm 12mm 76mm 4NEWDouble Flute - Solid Carbide Straight56-000PDesigned specifically to rout harder,more rigid plastics.UsageFoam, fiberglass, phenolic,acrylic, nylon, PVC, ABS,acetal <strong>and</strong> solid surfacePart Cutting Flute SHKNumber DIA LGTH DIAOAL56-041 1/8 1/4 1/4 256-061 3/16 3/8 1/4 256-062 3/16 5/8 1/4 256-062L 3/16 5/8 1/4 256-063* 3/16 5/8 1/4 456-081 1/4 3/8 1/4 2-1/256-082 1/4 3/4 1/4 2-1/256-082L 1/4 3/4 1/4 2-1/256-086* 1/4 1-1/4 1/4 456-121 3/8 5/8 3/8 2-1/256-122 3/8 7/8 3/8 2-1/256-122L 3/8 7/8 3/8 2-1/256-124* 3/8 1-5/8 3/8 656-162 1/2 1 1/2 356-162L 1/2 1 1/2 356-164* 1/2 2-1/8 1/2 6* These tools are designed <strong>and</strong> toleranced <strong>for</strong> Air Routers with guideL = Left H<strong>and</strong> Rotationwww.onsrud.com 4

63-000Single Flute - Solid Carbide Upcut SpiralDesigned <strong>for</strong> routing where upward chipremoval, tool rigidity, long life, <strong>and</strong> highquality finish is desired.UsageFiberglass, phenolic<strong>and</strong> aluminumPart Cutting Flute SHKNumber DIA LGTH DIAOAL63-040 1/8 1/2 1/4 263-050 5/32 9/16 1/4 263-060 3/16 5/8 1/4 263-080 1/4 3/4 1/4 2-1/263-100 5/16 13/16 3/8 2-1/263-160 1/2 1 1/2 3HELIX ANGLE ≈ 30°66-800DFC Compression <strong>for</strong> <strong>Composite</strong>s (Coated)The diamond film coated (CVD) solidcarbide compression routers uniquegeometry prevents delamination ontop <strong>and</strong> the bottom edges of thecomposites. The open flute geometrydissipates heat to prevent resin flow.Usage<strong>Composite</strong>Part Cutting Flute Upcut SHKNumber DIA LGTH LGTH DIAOAL Flutes66-802DFC 1/4 3/4 .325 1/4 3-1/2 466-811DFC* 3/8 1 .100 3/8 4 466-814DFC 3/8 1 .340 3/8 4 666-817DFC* 1/2 1-1/8 .100 1/2 4 666-823DFC 1/2 1-1/8 .350 1/2 4 6*DOWNCUT EDGE TO WITHIN .050” OF TOOL ENDNEWMETRICPart Cutting Flute Upcut SHKNumber DIA LGTH LGTH DIAOAL Flutes66-852DFC 6mm 20mm 7.75mm 6mm 90mm 466-858DFC 8mm 25mm 8mm 8mm 100mm 466-864DFC 10mm 25mm 8.5mm 10mm 100mm 666-870DFC 12mm 25mm 9mm 12mm 100mm 65 www.onsrud.com

High Per<strong>for</strong>mance <strong>Composite</strong> Router (Coated)66-900The new High Per<strong>for</strong>mance <strong>Composite</strong> Router isdesigned <strong>for</strong> more efficient routing of compositematerials, in both h<strong>and</strong>-fed <strong>and</strong> in CNC applications.Coated with AlTiN <strong>for</strong> increased tool life.Usage<strong>Composite</strong>s <strong>and</strong> fiberglassPart Point Cutting Flute SHKNumber Style DIA LGTH DIAOAL66-901ALTIN No 1/8 1/2 1/8 1-1/266-902ALTIN BURR 1/8 1/2 1/8 1-1/266-903ALTIN Endmill 1/8 1/2 1/8 1-1/266-904ALTIN Drill 1/8 1/2 1/8 1-1/266-905ALTIN No 3/16 5/8 1/4 266-906ALTIN BURR 3/16 5/8 1/4 266-907ALTIN Endmill 3/16 5/8 1/4 266-908ALTIN Drill 3/16 5/8 1/4 266-909ALTIN No 1/4 1 1/4 366-910ALTIN BURR 1/4 1 1/4 366-911ALTIN Endmill 1/4 1 1/4 366-912ALTIN Drill 1/4 1 1/4 366-913ALTIN No 1/4 1-1/2 1/4 3-1/266-914ALTIN BURR 1/4 1-1/2 1/4 3-1/266-915ALTIN Endmill 1/4 1-1/2 1/4 3-1/266-916ALTIN Drill 1/4 1-1/2 1/4 3-1/266-917ALTIN No 1/4 2-1/8 1/4 466-918ALTIN BURR 1/4 2-1/8 1/4 466-919ALTIN Endmill 1/4 2-1/8 1/4 466-920ALTIN Drill 1/4 2-1/8 1/4 466-921ALTIN No 3/8 1 3/8 366-922ALTIN BURR 3/8 1 3/8 366-923ALTIN Endmill 3/8 1 3/8 366-924ALTIN Drill 3/8 1 3/8 366-925ALTIN No 3/8 1-5/8 3/8 3-1/266-926ALTIN BURR 3/8 1-5/8 3/8 3-1/266-927ALTIN Endmill 3/8 1-5/8 3/8 3-1/266-928ALTIN Drill 3/8 1-5/8 3/8 3-1/266-929ALTIN No 3/8 2-1/8 3/8 466-930ALTIN BURR 3/8 2-1/8 3/8 466-931ALTIN Endmill 3/8 2-1/8 3/8 466-932ALTIN Drill 3/8 2-1/8 3/8 466-933ALTIN No 1/2 1-1/8 1/2 366-934ALTIN BURR 1/2 1-1/8 1/2 366-935ALTIN Endmill 1/2 1-1/8 1/2 366-936ALTIN Drill 1/2 1-1/8 1/2 366-937ALTIN No 1/2 1-5/8 1/2 466-938ALTIN BURR 1/2 1-5/8 1/2 4Part Point Cutting Flute SHKNumber Style DIA LGTH DIAOAL66-939ALTIN Endmill 1/2 1-5/8 1/2 466-940ALTIN Drill 1/2 1-5/8 1/2 466-941ALTIN No 1/2 2-1/8 1/2 466-942ALTIN BURR 1/2 2-1/8 1/2 466-943ALTIN Endmill 1/2 2-1/8 1/2 466-944ALTIN Drill 1/2 2-1/8 1/2 466-945ALTIN No 1/2 3-1/8 1/2 566-946ALTIN BURR 1/2 3-1/8 1/2 566-947ALTIN Endmill 1/2 3-1/8 1/2 566-948ALTIN Drill 1/2 3-1/8 1/2 566-949ALTIN No 1/2 4-1/8 1/2 666-950ALTIN BURR 1/2 4-1/8 1/2 666-951ALTIN Endmill 1/2 4-1/8 1/2 666-952ALTIN Drill 1/2 4-1/8 1/2 666-971ALTIN No 4mm 16mm 6mm 50mm66-972ALTIN BURR 4mm 16mm 6mm 50mm66-973ALTIN Endmill 4mm 16mm 6mm 50mm66-974ALTIN Drill 4mm 16mm 6mm 50mm66-975ALTIN No 6mm 19mm 6mm 75mm66-976ALTIN BURR 6mm 19mm 6mm 75mm66-977ALTIN Endmill 6mm 19mm 6mm 75mm66-978ALTIN Drill 6mm 19mm 6mm 75mm66-979ALTIN No 6mm 25mm 6mm 75mm66-980ALTIN BURR 6mm 25mm 6mm 75mm66-981ALTIN Endmill 6mm 25mm 6mm 75mm66-982ALTIN Drill 6mm 25mm 6mm 75mm66-983ALTIN No 8mm 25mm 8mm 63mm66-984ALTIN BURR 8mm 25mm 8mm 63mm66-985ALTIN Endmill 8mm 25mm 8mm 63mm66-986ALTIN Drill 8mm 25mm 8mm 63mm66-987ALTIN No 10mm 25mm 10mm 75mm66-988ALTIN BURR 10mm 25mm 10mm 75mm66-989ALTIN Endmill 10mm 25mm 10mm 75mm66-990ALTIN Drill 10mm 25mm 10mm 75mm66-991ALTIN No 12mm 25mm 12mm 75mm66-992ALTIN BURR 12mm 25mm 12mm 75mm66-993ALTIN Endmill 12mm 25mm 12mm 75mm66-994ALTIN Drill 12mm 25mm 12mm 75mmNEWBurr PointDrill PointEnd Mill PointNo Pointwww.onsrud.com 6

67-00067-250Solid Carbide Fiberglass RouterDesigned as fiberglass routers. Their upcut/downcutdiamond design effectively shears fibrous materials.Certain tools in the line have been further developedto cut aramid fiber composites.UsageFiberglass <strong>and</strong> <strong>Composite</strong>MEDIUM BURR W/END MILL POINTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-003 1/8 1 1/8 267-010 1/4 3/4 1/4 2-1/267-011 1/4 1-1/8 1/4 367-012 1/4 1-1/4 1/4 367-014 1/4 1-1/2 1/4 367-017 1/4 2-1/8 1/4 467-030 3/8 7/8 3/8 2-1/2MEDIUM BURR W/END MILL POINTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-023 3/8 1-5/8 3/8 367-027 3/8 2-1/8 3/8 467-031 1/2 1-1/8 1/2 367-033 1/2 1-5/8 1/2 467-037 1/2 2-1/8 1/2 467-039 1/2 3-1/8 1/2 567-065 3/4 4-1/8 3/4 6MEDIUM BURR W/DRILL POINTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-080 1/4 3/4 1/4 2-1/267-120 3/8 7/8 3/8 2-1/267-160 1/2 1 1/2 33 FLUTE DOWNCUT DIAMOND GRIT TOOLPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-254 1/4 1-1/8 1/4 33 FLUTE DOWNCUT DIAMOND GRIT TOOLPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-256 1/4 1-3/8 1/4 367-258 3/8 1-3/8 3/8 37 www.onsrud.com

Three Flute - Solid Carbide Phenolic Cutter67-200Equally adaptable to low or high spindle speed applications in any CNC machining environment.The free cutting action of the tools provides <strong>for</strong> better finishes <strong>and</strong> significantly lower noise levels.UsagePhenolicUPCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-205 3/8 7/8 3/8 367-211 1/2 1-1/8 1/2 367-215 1/2 2-1/8 1/2 4DOWNCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-206 3/8 7/8 3/8 367-212 1/2 1-1/8 1/2 3-1/267-216 1/2 2-1/8 1/2 4-1/2HELIX ANGLE ≈ 10°METRIC UPCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-207 10mm 22mm 10mm 75mm67-209 12mm 28mm 12mm 75mmMETRIC DOWNCUTPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-208 10mm 22mm 10mm 75mm67-210 12mm 28mm 12mm 75mmHELIX ANGLE ≈ 10°Three Flute - PCD Progressive Chipbreaker <strong>for</strong> <strong>Composite</strong>s67-220Provides superior chip control <strong>and</strong> increased tool lifewhen cutting dense <strong>and</strong> abrasive materials. The newchipbreaker incorporates a unique geometry with aPCD cutting edge to support a wide range of feed rates<strong>and</strong> depth of cut combinations while extending the lifeof the tool. This is accomplished by utilizing a distinctHi-Low asymmetrical chipbreaker profile which reducesvibration <strong>and</strong> chatter, caused by harmonic imbalance,resulting in improved surface finishes, while reducingnoise levels <strong>and</strong> wear on the tool.Usage <strong>Composite</strong>s <strong>and</strong> phenolicPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-221 3/8 3/8 3/8 367-225 1/2 5/8 1/2 367-227 1/2 1-1/8 1/2 3METRICPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-230 10mm 12mm 10mm 76mm67-233 12mm 20mm 12mm 100mmNEWDouble Flute - Solid Carbide Compression Spiral67-300Compression design <strong>for</strong> fast feed <strong>and</strong> excellentfinish on both sides of the material.Usage<strong>Composite</strong> panels <strong>and</strong>honeycomb corePart Cutting Flute SHK Diamond CoatedNumber DIA LGTH DIAOALPart Number67-305 1/4 7/8 1/4 2-1/2 -67-314 3/8 1-1/8 3/8 3 67-314DFC67-320* 1/2 7/8 1/2 3 -67-322 1/2 1-1/8 1/2 3 67-322DFC* = Mortise Compression HELIX ANGLE ≈ 30°www.onsrud.com 8

67-400Solid Carbide Un-RufferPATENTEDThe unique design allows <strong>for</strong> the cuttingper<strong>for</strong>mance of a burr while achieving agood surface finish.UsageMETRIC<strong>Composite</strong> panelsPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-426M 6mm 25mm 6mm 64mm67-435M 10mm 25mm 10mm 76mm67-445M 12mm 25mm 12mm 76mmPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-423 1/4 3/4 1/4 267-426 1/4 1 1/4 2-1/267-428 1/4 1 1/4 367-435 3/8 1 3/8 367-445 1/2 1 1/2 367-500Solid Carbide CG Tool (Carbon Graphite)The geometry of these tools increases theamount of effective cutting flutes resulting insuperior per<strong>for</strong>mance over a st<strong>and</strong>ard burr.UsageCarbon graphite <strong>and</strong>carbon fiber panelsPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-505 1/8 1/2 1/8 267-508 3/16 5/8 3/16 267-511 1/4 3/4 1/4 367-514 1/4 1-1/2 1/4 367-520 3/8 1-1/8 3/8 3-1/267-523 1/2 1-1/8 1/2 3-1/267-526 1/2 2-1/8 1/2 468-000Double Flute - PCD Tipped ToolingDesigned <strong>for</strong> use in abrasive materials wherecut quality <strong>and</strong> tool life are important.Usage<strong>Composite</strong> panels<strong>and</strong> fiberglassPCD TippedPCD Full Facewith Plunge PointPCD FULL FACEPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-005 1/4 3/4 1/4 368-010 3/8 3/4 3/8 368-020 1/2 3/4 1/2 468-030 3/4 1 3/4 4HELIX ANGLE ≈ 0-3°PCD FULL FACE with PLUNGE POINTPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-050 1/4 3/4 1/4 368-055 3/8 7/8 3/8 368-062 1/2 1-1/4 1/2 468-070 3/4 1-1/4 3/4 468-072 3/4 1-1/4 3/4 4Down Shear9 www.onsrud.com

Double Flute - PCD SERF Cutter68-200This tool is designed to act like a rougher <strong>and</strong>finishing tool in one. The unique geometryreduces the cutting <strong>for</strong>ces resulting in longertool life, higher feed rates <strong>and</strong> reduced noise.UsageMETRIC<strong>Composite</strong>sPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-213M 6mm 20mm 6mm 76mm68-226M 10mm 25mm 10mm 88mm68-236M 12mm 32mm 12mm 100mmPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-210 1/4 3/8 1/4 368-213 1/4 3/4 1/4 368-216 1/4 1 1/4 3-1/268-220 3/8 3/8 3/8 368-223 3/8 3/4 3/8 368-226 3/8 1 3/8 3-1/268-230 1/2 3/4 1/2 468-233 1/2 1 1/2 468-236 1/2 1-1/4 1/2 4Three Flute - PCD SERFIN Cutter68-300Three-Flute tool with two roughing edges thathave geometry to reduce cutting <strong>for</strong>ces <strong>and</strong>shear fibers in high-strength composite <strong>and</strong>other fiber rein<strong>for</strong>ced plastic materials. Thefinishing edge cleans up after roughing cutsto create a smooth edge on material.Usage<strong>Composite</strong>sPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-315 3/8 1/2 3/8 468-320 3/8 7/8 3/8 468-340 1/2 5/8 1/2 468-345 1/2 1 1/2 468-350 1/2 1-1/4 1/2 468-360 3/4 1-3/8 3/4 5METRICPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-310 8mm 10mm 8mm 76mm68-325 10mm 14mm 10mm 100mm68-330 12mm 14mm 12mm 100mm68-335 12mm 26mm 12mm 100mm68-355 16mm 26mm 16mm 100mmNEWDouble Flute - PCD Ballnose68-400Designed <strong>for</strong> use in abrasive materials wherecut quality <strong>and</strong> tool life are important.Usage<strong>Composite</strong>sPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-405 1/4 3/8 1/4 2-1/268-410 3/8 1/2 3/8 368-420 1/2 5/8 1/2 468-425 5/8 7/8 5/8 468-430 3/4 1 3/4 4METRICPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-440 6mm 10mm 6mm 76mm68-445 8mm 10mm 8mm 76mm68-450 10mm 12mm 10mm 76mm68-455 12mm 20mm 12mm 100mmNEWwww.onsrud.com 10

<strong>Honeycomb</strong>Cutters & HoggersLMT Onsrud produces the industry’s largestselection of cutting tools used to machinehoneycomb core <strong>and</strong> s<strong>and</strong>wiched structuredcomposite panels. These materials are usedwhere ever strong, yet, lightweight constructionis needed in aerospace, marine, transportation<strong>and</strong> wind energy applications. LMT Onsrudmanufactures roughing tools, used <strong>for</strong> rapidstock removal, finishing tools <strong>for</strong> detail worksuch as contouring, carving <strong>and</strong> chamfering<strong>and</strong> specialty panel tools <strong>for</strong> cutting, sizing<strong>and</strong> grooving panel material.

HSS Hollow Core Cutters29-000This specialized cutter is designed to verticallycut the honeycomb cells producing a clean,flag free edge. The core material will remainattached at the bottom <strong>and</strong> can be removedusing one of our valve style honeycomb cutters.This product along with our 31-100 or 30-000series tools is an effective combination to createpockets in honeycomb core <strong>and</strong> get a perfectlyclean edge.Part Cutting Flute SHKNumber DIA LGTH DIAOAL29-003 1/4 1-1/2 1/4 3-3/429-006 3/8 1-7/8 3/8 3-3/429-009 1/2 2-7/8 1/2 529-012 5/8 2-7/8 5/8 529-015 3/4 2-7/8 3/4 5Usage<strong>Honeycomb</strong>Diamond Grit Hogger29-050Diamond grit hoggers are used on abrasivecores (graphite, phenolic, or fiberglass) inorder to achieve long tool life. The tools areavailable in a ball nose version <strong>and</strong> as atraditional hogger capable of holdingexisting honeycomb blades. A 35% weightreduction has been designed into the largerdiameter tools resulting in better per<strong>for</strong>manceon 3 or 5 axis machines.BALL NOSEPart Cutting Flute SHKNumber DIA LGTH DIAOAL29-053 1/4 (6.35mm) 1 1/4 1/4 429-058 3/8 (9.52mm) 2 1/2 1/2 429-063 1/2 (12.7mm) 3 1/2 529-068 3/4 (19.05mm) 3 1/2 529-074 1 (25.4mm) 2 3/4 4Usage<strong>Honeycomb</strong>HONEYCOMB HOGGER CUTTING BLADE OPTIONS SPARE PARTSPart # Cutting DiameterSolidHogger ShankOAL Blade Diameter HSSHSS SolidCarbideDiamond HSS AdapterDepth DIAw/Teeth Carbidew/TeethPlated Saw RingScrew29-052 1/4 (6.35mm) 1 1/4 1/4 4 - - - - - - - - -29-057 .345 (8.76mm) 2 1/2 1/2 4 3/8 (9.52mm) 30-016 30-316 - - - - - HRD5164629-062 .470 (11.94mm) 3 1/2 5 1/2 (12.7mm) 30-017 30-317 - - - - - HRD5164629-067 .720 (18.28mm) 3 1/2 5 3/4 (19.05mm) - - 30-015 30-318 - - - 30-011-229-072 .970 (24.63mm) 1 1/2 3 1 (25.4mm) - - 30-012 30-313 30-113 30-213 - 30-011-229-073 1 .970 (24.63mm) 2 3/4 5 1 (25.4mm) - - 30-012 30-313 30-113 30-213 - 30-011-229-078 1.470 (37.33mm) 1 1/2 3 1 1/2 (38.10mm) - - 30-014 30-314 30-114 30-214 30-020-3 30-020-429-079 1 1.470 (37.33mm) 2 3/4 5 1 1/2 (38.10mm) - - 30-014 30-314 30-114 30-214 30-020-3 30-020-429-083 1.742 (44.24mm) 1 1/2 3 1.772 (45mm) - - 30-026 30-326 30-126 2 30-226 2 30-020-3 30-020-429-084 1 1.742 (44.24mm) 2 3/4 5 1.772 (45mm) - - 30-026 30-326 30-126 2 30-226 2 30-020-3 30-020-429-088 1.970 (50.03mm) 1 5/8 3 2 (50.8mm) - - 30-022 30-322 30-122 30-222 30-020-3 30-020-429-089 1 1.970 (50.03mm) 2 3/4 5 2 (50.8mm) - - 30-022 30-322 30-122 30-222 30-020-3 30-020-429-093 2.450 (62.23mm) 1 5/8 3 2.480 (63mm) - - 30-036 30-336 30-136 30-236 30-030-3 30-030-429-095 2.970 (75.43mm) 1 3/4 3 3 (76.20mm) - - 30-032 30-332 30-132 30-232 30-030-3 30-030-429-096 1 2.970 (75.43mm) 1 3/4 4 3 (76.20mm) - - 30-032 30-332 30-132 30-232 30-030-3 30-030-429-098 3.970 (100.83mm) 1 3/4 3 4 (101.6mm) - - 30-042 30-342 30-142 30-242 30-040-3 30-040-429-099 1 3.970 (100.83mm) 1 3/4 4 4 (101.6mm) - - 30-042 30-342 30-142 30-242 30-040-3 30-040-41 = non-stock st<strong>and</strong>ard. 4 week lead time2 = 50mm diameter honecomb bladeSee page 13 or 15 <strong>for</strong> Images of Cutting BladesSee Page 17 <strong>for</strong> Wrench <strong>and</strong> Torque Specwww.onsrud.com 12

29-100/29-100BSolid Carbide <strong>Honeycomb</strong> Hogger (Coated)Designed to be a versatile tool <strong>and</strong> cut mosthoneycomb core materials. The solid carbidebody offers long tool life while the proven hoggergeometry shreds the core <strong>and</strong> evacuates chips.The long flute length allows <strong>for</strong> deep pocketapplications <strong>and</strong> can also be used to surfacelarge areas. Hoggers are coated with ZRN.Usage<strong>Honeycomb</strong>Part Cutting Flute SHKNumber DIA LGTH DIAOAL29-110 1/4 (6.35mm) 1-1/4 1/4 429-115 3/8 (9.52mm) 2 3/8 429-125 1/2 (12.7mm) 3 1/2 629-130 1/2 (12.7mm) 4-1/2 1/2 6-1/229-140 3/4 (19.05mm) 3 3/4 629-145 3/4 (19.05mm) 4-1/2 3/4 6-1/2METRICPart Cutting Flute SHKNumber DIA LGTH DIAOAL29-120 12 (.472”) 60 12 15029-135 16 (.629”) 80 16 150BALLNOSEPart Cutting Flute SHKNumber DIA LGTH DIAOAL29-130B 1/2 (12.7mm) 4-1/2 1/2 6-1/229-140B 3/4 (19.05mm) 3 3/4 629-145B 3/4 (19.05mm) 4-1/2 3/4 6-1/230-000Replaceable Ring Type <strong>Honeycomb</strong> CutterThese tools are <strong>for</strong> contouring, carving <strong>and</strong> chamferingcuts of .25" or less. The unique patented holding systemprevents the solid carbide blades from coming out of theholder if it is fractured.The HSS saw blades <strong>and</strong> the diamond plated blades dishon the bottom so they clear the cut core finish like thehollow ground solid carbide style rings. The solid carbiderings may be reground several times at the factory makingthem very economical to use.The HSS saw <strong>and</strong> diamond plated blades are disposable,offering the convenience of a constant diameter.UsageFor contouring, carving <strong>and</strong>chamfering cutsSHANK ASSEMBLY CUTTING BLADE OPTIONS SPARE PARTSShankPart # Blade Diameter DIA Solid CarbideSolid Carbidewith TeethDiamond Plated HSS Saw Adapter Ring Screw30-011 1” (25.4mm) 1/2 30-012 30-313 30-112 30-213 - 30-011-230-021 2” (50.8mm) 1/2 30-022 30-322 30-122 30-222 30-020-3 30-020-430-031 3” (76.2mm) 1/2 30-032 30-332 30-132 30-232 30-030-3 30-030-430-041 4” (101.6mm) 1/2 30-042 30-342 30-142 30-242 30-040-3 30-040-4See page 13 or 15 <strong>for</strong> Images of Cutting BladesSee page 17 <strong>for</strong> Wrench <strong>and</strong> Torque SpecCutting Blades <strong>for</strong> Cutters <strong>and</strong> HoggersHSSHSS with TeethSolid CarbideSolid Carbidewith Teeth Diamond Plated HSS SawPM-HSSWavy Ring13 www.onsrud.com

HSS Integral Shank <strong>Honeycomb</strong> Hogger Cutter 30-300High Speed Steel Hoggers • High Speed Replaceable Saw BladeSolid Carbide Replaceable Blade • Diamond Plated Replaceable BladeThe spiral hogger geometry ground integral to the shank allows <strong>for</strong> fasterfeed rates <strong>and</strong> deeper cuts than any previous cutter. The availability ofseveral different blades makes this cutter suitable <strong>for</strong> most core types. Thehogger design also imparts less <strong>for</strong>ce as it evacuates <strong>and</strong> shreds scrap.Shank DiameterOALUsageCNC machining of honeycomb coreHogger DepthCutting DiameterHONEYCOMB HOGGER CUTTING BLADE OPTIONS SPARE PARTSPart # Cutting DiameterSolidHogger ShankOAL Blade DiameterSolidCarbideDiamond HSS AdapterDepth DIACarbidew/TeethPlated Saw RingScrew30-310 7/8 (22.22mm) 1 1/2 1/2 3 1/2 1 (25.4mm) 30-012 30-313 30-113 30-213 - 30-011-230-315 1 1/4 (31.75mm) 1 1/2 1/2 3 1/2 1 1/2 (38.1mm) 30-014 30-314 30-114 30-214 30-020-3 30-020-430-321 1 3/4 (44.45mm) 1 1/2 1/2 3 1/2 2 (50.8mm) 30-022 30-322 30-122 30-222 30-020-3 30-020-430-331 2 3/4 (69.85mm) 1 1/2 3 1/2 3 (76.2mm) 30-032 30-332 30-132 30-232 30-030-3 30-030-430-341 3 3/4 (95.25mm) 1 3/4 3 1/2 4 (101.6mm) 30-042 30-342 30-142 30-242 30-040-3 30-040-4See page 13 or 15 <strong>for</strong> Images of Cutting BladesSee page 17 <strong>for</strong> Wrench <strong>and</strong> Torque SpecReduced Weight <strong>Honeycomb</strong> Cutter 30-70035% weight reduction has been designed into the largerdiameter tools resulting in better per<strong>for</strong>mance on 3 or 5axis machines. Part lifting <strong>and</strong> flagging have also beenreduced due to the new tooth <strong>and</strong> flute design. Existinghoneycomb blades will mount on these hoggers.UsageCNC Machining of<strong>Honeycomb</strong> CoreHONEYCOMB HOGGER CUTTING BLADE OPTIONS SPARE PARTSPart # Cutting DiameterSolid SolidHogger ShankOAL Blade Diameter HSSHSSCarbide CarbideDiamond HSS AdapterDepth DIAw/Teethw/TeethPlated Saw RingScrew30-703 .345 (8.76mm) 1 1/2 3 3/8 (9.52mm) 30-016 30-316 - - - - - HRD5164630-705 .470 (11.93mm) 1 1/2 3 1/2 (12.7mm) 30-017 30-317 - - - - - HRD5164630-707 .720 (18.28mm) 1 1/2 3 3/4 (19.05mm) - - 30-015 30-318 - - - 30-011-230-710 .970 (24.63mm) 1 1/2 3 1 (25.4mm) - - 30-012 30-313 30-113 30-213 - 30-011-230-715 1.470 (37.33mm) 1 1/2 3 1 1/2 (38.10mm) - - 30-014 30-314 30-114 30-214 30-020-3 30-020-430-720 1.742 (44.24mm) 1 1/2 3 1.772 (45mm) - - 30-026 30-326 30-126 1 30-226 1 30-020-3 30-020-430-725 1.970 (50.03mm) 1 5/8 3 2 (50.8mm) - - 30-022 30-322 30-122 30-222 30-020-3 30-020-430-730 2.450 (62.23mm) 1 5/8 3 2.480 (63mm) - - 30-036 30-336 30-136 30-236 30-030-3 30-030-430-735 2.970 (75.43mm) 1 3/4 3 3 (76.20mm) - - 30-032 30-332 30-132 30-232 30-030-3 30-030-430-740 3.970 (100.83mm) 1 3/4 3 4 (101.6mm) - - 30-042 30-342 30-142 30-242 30-040-3 30-040-41 = 50mm diameter honecomb bladeSee page 13 or 15 <strong>for</strong> Images of Cutting Bladeswww.onsrud.com See page 17 <strong>for</strong> Wrench <strong>and</strong> Torque Spec14

31-000High Speed Steel CutterDesigned primarily <strong>for</strong> use on aluminum core,offering the versatility of smaller sizes <strong>for</strong> useon h<strong>and</strong>-held machines in field or maintenancetype repairs. This cutter offers the strength ofan integral shank <strong>and</strong> blade that has an edgesharpness unattainable with any other material.This sharpness <strong>and</strong> the relieved bottom yieldpart surfaces that require a minimum ofpreparation be<strong>for</strong>e bonding operation.Part Cutting SHKNumber DIA DIAOAL31-010 1/2 1/4 2-1⁄1631-015 3/4 1/4 2-3/3231-020 1 1/4 2-1/831-025 1-1/2 1/2 2-1/431-030 2 1/2 2-3/431-040 3 1/2 2-15/16UsageAluminum CoreCore TypeRatingAluminum, Lo Density (Less than 5#/cuft) 1Aluminum, Hi Density (More than 5#/cuft) 2Paper 2Paper, Rein<strong>for</strong>cedNFiberglassNPhenolicNPolycarbonateNAramidN1 - Excellent, 2 - Good, N - Not Recommended31-100High Speed Steel <strong>Honeycomb</strong> Cutter With TeethSmall diameter honeycomb cutters weredesigned to offer the flexibility of cuttingsmall slots or pockets in honeycomb core.The tools are versatile <strong>and</strong> can be used onCNC machines or h<strong>and</strong> held machines <strong>for</strong>field or maintenance type repairs.UsageFor contouring, carving, pocketing,<strong>and</strong> chamfer cutsPart Cutting SHKNumber DIA DIAOAL31-102TCN 3/8 1/4 331-104TCN 1/2 1/4 331-106TCN 5/8 1/4 331-108TCN 3/4 1/4 3Cutting Blades <strong>for</strong> Cutters <strong>and</strong> HoggersHSSHSS with TeethSolid CarbideSolid Carbidewith Teeth Diamond Plated HSS SawPM-HSSWavy Ring15 www.onsrud.com

High Speed Steel HoggerThese cutters are specifically designed <strong>for</strong> fast (low <strong>for</strong>ce) removal of excesscore followed by a final finish pass to obtain excellent finishes with one tool.These cutters enable cuts of up to .60” depths in a single pass. The availabilityof several different blades makes this cutter suitable <strong>for</strong> most core types.All assemblies require a shank, hogger <strong>and</strong> blade.32-0001/2ShankUsageFast removal of excess coreHoggerHONEYCOMB HOGGER SHANK CUTTING BLADE OPTIONS SPARE PARTSPart #Cutting DiameterHoggerPart #ShankBlade DiameterSolid Diamond HSS Wavy HSS AdapterDepthDIACarbide Plated Ring Saw RingScrew32-022 1.732 (44mm) .629 (16mm) 32-021 1/21.771 (45mm) 32-026 - 32-023 - - -1.968 (50mm) - 32-029* - 32-027* 32-028 -32-032 2.421 (61.5mm) .629 (16mm) 32-031 1/22.480 (63mm) 32-036 - 32-033 - - -2.952 (75mm) - 32-039* - 32-037* 32-038 -32-100 - Wrench <strong>for</strong> 32-000 <strong>Tools</strong> See page 13 or 15 <strong>for</strong> Images of Cutting Blades* Requires Adapter RingHSS Three Piece <strong>Honeycomb</strong> Hogger (Coated)32-200Designed with more aggressive hogger geometry than the 32-000series. Both the hogger <strong>and</strong> blade with teeth have a fine tooth grindpattern resulting in increased feed rates <strong>and</strong> improved part finish.All hoggers <strong>and</strong> blades are coated with a ZRN coating <strong>for</strong> increasein tool life. All hogger assemblies require a shank, a hogger <strong>and</strong> ablade. This design also allows the tool to be use without the hoggerby replacing the hogger with a spacer. Torque Spec = 18 in-lb.ArborArborSpacerHoggerBladeScrewBladeScrewUsageFast removal of excess coreHONEYCOMB HOGGER SHANK CUTTING BLADE OPTIONS SPARE PARTSPart #Cutting DiameterHoggerPart #Shank OALBlade DiameterSolid Solid CarbideSpacerRetainingDepthDIACarbide w/TeethScrew32-210 0.94" (23.88mm) 1" (25.4mm) 32-221 3/8" 4" 1" (25.4mm) 32-412 32-512 32-221-3 32-221-432-225 1.94" (49.28mm) 1" (25.4mm)32-235 2.94" (74.68mm) 1" (25.4mm)32-220 1.72" (43.69mm) 1" (25.4mm)32-230 2.42" (61.47mm) 1" (25.4mm)32-231 1/2" 4"32-241 5/8" 4"32-231 1/2" 4"32-241 5/8" 4"32-231 1/2" 4"32-241 5/8" 4"32-231 1/2" 4"32-241 5/8" 4"32-201 - Wrench <strong>for</strong> 32-200 <strong>Tools</strong> (<strong>for</strong> Shank Diameters 1/2” & 5/8”)32-202 - Wrench <strong>for</strong> 32-200 <strong>Tools</strong> (<strong>for</strong> Shank Diameters 3/8”)2" (50.8mm) 32-422 32-522 32-231-3 32-231-43" (76.2mm) 32-432 32-532 32-231-3 32-231-41.77" (45mm) 32-426 32-526 32-231-3 32-231-42.48" (63mm) 32-436 32-536 32-231-3 32-231-4See page 13 or 15 <strong>for</strong>Images of Cutting Bladeswww.onsrud.com 16

34-000Aircraft Panel <strong>Tools</strong>This modular tool is designed toproduce slots in composite panelsso potting compound can be appliedto strengthen the edge. This toolconsists of a PCD arbor whichaccepts a diamond grit or HSS undercutting tool to be screwed into it.UsageHCC PanelsArborDiamond GritHSSPart Cutting Flute SHKNumber DIA LGTH DIA34-008 1/2 - 1/2 Arbor (non-cutting)34-010 1/2 1/4 1/2 PCD Arbor34-022 7/8 0.130 n/a Diamond Grit Cutter34-024 7/8 0.250 n/a Diamond Grit Cutter34-026 7/8 0.380 n/a Diamond Grit Cutter34-028 7/8 0.500 n/a Diamond Grit Cutter34-030 7/8 0.630 n/a Diamond Grit Cutter34-042 7/8 0.130 n/a HSS Cutter34-044 7/8 0.250 n/a HSS Cutter34-046 7/8 0.380 n/a HSS Cutter34-048 7/8 0.500 n/a HSS Cutter34-050 7/8 0.630 n/a HSS Cutter<strong>Honeycomb</strong> Tool Wrench <strong>and</strong> Torque SpecScrew Wrench Torque SpecHRD51646 HRD52642 15 - 18 in-lb30-011-2 HRD51905 15 - 18 in-lb30-020-4 HRD51903 15 - 18 in-lb30-030-4 HRD51904 15 - 18 in-lb30-040-4 HRD52608 15 - 18 in-lb32-000 Series 32-100 15 - 18 in-lb32-221-4 32-202 18 in-lb32-231-4 32-201 18 in-lb17 www.onsrud.com

<strong>Honeycomb</strong> Technical Data Sheets29-000HONEYCOMB CORE ALUMINUM NOMEX PAPERPart # RPM Feed Rate RPM Feed Rate RPM Feed Rate29-003 (1/4”) 500-10,000 100 IPM 500-10,000 120 IPM 500-10,000 120 IPM29-006 (3/8”) 500-10,000 100 IPM 500-10,000 120 IPM 500-10,000 120 IPM29-009 (1/2”) 500-10,000 100 IPM 500-10,000 120 IPM 500-10,000 120 IPM29-012 (5/8”) 500-10,000 100 IPM 500-10,000 120 IPM 500-10,000 120 IPM29-015 (3/4”) 500-10,000 100 IPM 500-10,000 120 IPM 500-10,000 120 IPM29-050 29-10030-000/30-30030-70032-20031-000/32-000SPINDLE SPEED CORE TYPE SPINDLE SPEEDDIA Max RPM Feed Rate Feed Rate Max RPM DIA1/4 25,000 NR Aluminum, less than 5#/cuft 100 25,000 1/43/8 25,000 NR Aluminum, More than 5#/cuft 100 25,000 3/81/2 25,000 800 Paper based 400 25,000 1/23/4 25,000 800 Paper, based w/Fiber Rein<strong>for</strong>cement 800 25,000 3/41 25,000 800 Fiberglass 6001-1/2 18,000 800 Phenolic 6001-3/4 18,000 NR Carbon Fiber 8002 16,500 100 Aramid, less than 5#/cuft 8002-1/2 15,000 100 Aramid, More than 5#/cuft 8003 14,0004 12,000FEEDS & SPEEDS FEED RATES SPINDLE SPEEDCore TypeSolid CarbideSolid Carbidew/TeethDiamondSawHSS DIA MAX RPMAluminum, Less than 5#/cuft 100 100 NR 150 1/4 25,000Aluminum, More than 5#/cuft 100 100 NR 100 3/8 25,000Paper based 400 400 NR 250 1/2 25,000Paper, based with Fiber Rein<strong>for</strong>cement 800 800 400 150 3/4 25,000Fiberglass 600 600 600 NR 1 25,000Phenolic 200 200 400 NR 1-1/2 18,000Carbon Fiber NR NR 800 NR 1-3/4 18,000Aramid, Less than 5#/cuft 800 800 400 150 2 16,500Aramid, More than 5#/cuft 800 800 400 NR 2-1/2 15,000Note: 30-300 assembly requires one (1) hogger <strong>and</strong> one (1) blade3 14,0004 12,000FEEDS & SPEEDS FEED RATES SPINDLE SPEEDCore TypeSolid Diamond HSS HSS HSS HSSCarbide Plated Saw Wavy (31-000) (31-100)DIAMAX RPMAluminum, Less than 5#/cuft 100 NR 150 100 100-140 90-140 3/8 25,000Aluminum, More than 5#/cuft 100 NR 100 100 70 70 1/2 25,000Paper based 300 NR 200 300 50 50 3/4 25,000Paper, based w/Fiber Rein<strong>for</strong>cement 400 300 600 300 100-150 100-150 1 25,000Fiberglass NR 600 NR NR NR NR 1-1/2 25,000Phenolic NR 600 NR NR NR NR 1-3/4 25,000Carbon Fiber NR 800 NR NR NR NR 2 18,000Aramid, Less than 5#/cuft 200 NR 150 200 100-150 100-150 2-1/2 18,000Aramid, More than 5#/cuft 200 400 NR NR NR NR 3 18,00034-000Core Type Cutter RPM Feed Rate Cut DirectionFiberglass panels with paper core (Nomex) Diamond Grit 18,000 220 lpm ConventionalAluminum panels with aluminum core HSS Saw 16,000 120 lpm Conventionalwww.onsrud.com 18

Drills<strong>Composite</strong> Cutting <strong>Tools</strong><strong>Drilling</strong> holes in composite materials is justas important as machining. In fact, 60% ofall rejected parts are due to drilled holes.The reason <strong>for</strong> the rejection is delaminationof material caused by excessive pressurecreated while drilling. LMT Onsrud offersmany styles of solid carbide <strong>and</strong> PCD drillsbased on the material, application <strong>and</strong>accuracy of the hole being produced.LMT Onsrud offers a wide variety of st<strong>and</strong>arddrills, but realize that many special sizes arerequired. Quote request <strong>for</strong>ms have beenmade in the most popular drill styles tomake the quote request process efficient.

Solid Carbide 8 Facet Drill67-800Designed to reduce cutting <strong>for</strong>ces <strong>and</strong> eliminatingdelamination when exiting the material.Usage<strong>Composite</strong>s, Carbon fiber, mechanicalplastics, <strong>and</strong> fiber rein<strong>for</strong>ced plasticsWhat is an 8 Facet Drill?An 8 facet drill consists of4 cutting edges with2 facets per cuttingedge. These facetsconsist of the lip relief<strong>and</strong> the lip clearance angle.X∞X∞FRACTIONAL DRILLSPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-807 1/8 (0.1250) 1-1/4 0.125 2-1/467-808 9/64 (0.1406) 1-3/8 0.140 2-1/267-809 5/32 (0.1563) 1-3/8 0.156 2-1/267-810 11/64 (0.1719) 1-5/8 0.172 2-3/467-811 3/16 (0.1875) 1-5/8 0.188 2-3/467-812 13/64 (0.2013) 1-3/4 0.203 367-813 7/32 (0.2188) 1-3/4 0.219 367-814 15/64 (0.2344) 2 0.234 3-1/467-815 1/4 (0.2500) 2 0.250 3-1/467-816 17/64 (0.2656) 2-1/8 0.266 3-1/267-817 9/32 (0.2813) 2-1/8 0.281 3-1/267-818 19/64 (0.2969) 2-3/8 0.297 3-3/467-819 5/16 (0.3125) 2-3/8 0.313 3-3/467-820 21/64 (0.3281) 2-1/2 0.328 467-821 11/32 (0.3438) 2-1/2 0.344 467-822 23/64 (0.3594) 2-1/2 0.359 467-823 3/8 (0.3750) 2-3/4 0.375 4-1/467-824 25/64 (0.3906) 2-7/8 0.391 4-1/267-825 13/32 (0.4063) 2-7/8 0.406 4-1/267-826 27/64 (0.4219) 2-7/8 0.422 4-1/267-827 7/16 (0.4375) 2-7/8 0.438 4-1/267-828 29/64 (0.4531) 3 0.453 4-3/467-829 15/32 (0.4688) 3 0.469 4-3/467-830 31/64 (0.4844) 3 0.484 4-3/467-831 1/2 (0.5000) 3 0.500 4-3/4LETTER DRILLS (CONT.)Part Cutting Flute SHKNumber DIA LGTH DIAOAL67-850 A (0.2340) 2 0.234 3-1/467-851 B (0.2380) 2 0.238 3-1/467-852 C (0.2420) 2 0.242 3-1/467-853 D (0.2460) 2 0.246 3-1/467-854 E (0.2500) 2 0.250 3-1/467-855 F (0.2570) 2 0.257 3-1/467-856 G (0.2610) 2-1/8 0.261 3-1/267-857 H (0.2660) 2-1/8 0.266 3-1/267-858 I (0.2720) 2-1/8 0.272 3-1/2LETTER DRILLS (CONT.)Part Cutting Flute SHKNumber DIA LGTH DIAOAL67-859 J (0.2770) 2-1/8 0.277 3-1/267-860 K (0.2810) 2-1/8 0.281 3-1/267-861 L (0.2910) 2-1/8 0.291 3-1/267-862 M (0.2950) 2-3/8 0.295 3-3/467-863 N (0.3020) 2-3/8 0.302 3-3/467-864 O (0.3160) 2-3/8 0.316 3-3/467-865 P (0.3230) 2-3/8 0.323 3-3/467-866 Q (0.3320) 2-1/2 0.332 467-867 R (0.3390) 2-1/2 0.339 467-868 S (0.3480) 2-1/2 0.348 467-869 T (0.3580) 2-1/2 0.358 467-870 U (0.3680) 2-3/4 0.368 4-1/467-871 V (0.3770) 2-3/4 0.377 4-1/467-872 W (0.3860) 2-7/8 0.386 4-1/267-873 X (0.3970) 2-7/8 0.397 4-1/267-874 Y (0.4040) 2-7/8 0.404 4-1/267-875 Z (0.4130) 2-7/8 0.413 4-1/2NUMBER DRILLSPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-876 1 (0.2280) 1-3/4 0.228 367-877 2 (0.2210) 1-3/4 0.221 367-878 3 (0.2130) 1-3/4 0.213 367-879 4 (0.2090) 1-3/4 0.209 367-880 5 (0.2055) 1-3/4 0.206 367-881 6 (0.2040) 1-3/4 0.204 367-882 7 (0.2010) 1-3/4 0.201 367-883 8 (0.1990) 1-3/4 0.199 367-884 9 (0.1960) 1-3/4 0.196 367-885 10 (0.1935) 1-5/8 0.194 2-3/467-886 11 (0.1910) 1-5/8 0.191 2-3/467-887 12 (0.1890) 1-5/8 0.189 2-3/467-888 13 (0.1850) 1-5/8 0.185 2-3/467-889 14 (0.1820) 1-5/8 0.182 2-3/467-890 15 (0.1800) 1-5/8 0.180 2-3/467-891 16 (0.1770) 1-5/8 0.177 2-3/467-892 17 (0.1730) 1-5/8 0.173 2-3/4NUMBER DRILLS (CONT.)Part Cutting Flute SHKNumber DIA LGTH DIAOAL67-893 18 (0.1695) 1-5/8 0.170 2-3/467-894 19 (0.1660) 1-5/8 0.166 2-3/467-895 20 (0.1610) 1-3/8 0.161 2-1/267-896 21 (0.1590) 1-3/8 0.159 2-1/267-897 22 (0.1570) 1-3/8 0.157 2-1/267-898 23 (0.1540) 1-3/8 0.154 2-1/267-899 24 (0.1520) 1-3/8 0.152 2-1/267-900 25 (0.1495) 1-3/8 0.150 2-1/267-901 26 (0.1470) 1-3/8 0.147 2-1/267-902 27 (0.1440) 1-3/8 0.144 2-1/267-903 28 (0.1405) 1-3/8 0.141 2-1/267-904 29 (0.1360) 1-3/8 0.136 2-1/267-905 30 (0.1285) 1-1/4 0.129 2-1/467-906 31 (0.1200) 1-1/4 0.120 2-1/4METRIC DRILLSPart Cutting Flute SHKNumber DIA LGTH DIAOAL67-961 3.00 (0.1181) 32 3.00 5767-962 3.50 (0.1378) 35 3.50 6467-963 4.00 (0.1575) 35 4.00 6467-964 4.50 (0.1772) 41 4.50 7067-965 5.00 (0.1969) 44 5.00 7667-966 5.50 (0.2165) 44 5.50 7667-967 6.00 (0.2362) 51 6.00 8367-968 6.50 (0.2559) 51 6.50 8367-969 7.00 (0.2756) 57 7.00 8967-970 7.50 (0.2953) 60 7.50 9567-971 8.00 (0.3150) 60 8.00 9567-972 8.50 (0.3346) 64 8.50 10267-973 9.00 (0.3543) 64 9.00 10267-974 9.50 (0.3740) 70 9.50 10867-975 10.00 (0.3937) 73 10.00 11467-976 10.50 (0.4134) 73 10.50 11467-977 11.00 (0.4331) 73 11.00 11467-978 11.50 (0.4528) 76 11.50 12167-979 12.00 (0.4724) 76 12.00 121www.onsrud.com 20

68-900PCD 8 Facet DrillsThe PCD 8 facet drill works well in compositematerial where long tool life <strong>and</strong> a delaminationfree hole is required. The drill diameters areoversize allowing <strong>for</strong> aircraft fasteners to extendthrough the holes.Usage<strong>Composite</strong>sPart Cutting Flute SHKNumber DIA LGTH DIAOAL68-902 0.100 1 1/4 368-904 0.129 1 1/4 368-908 0.147 1 1/4 368-910 0.192 1 1/4 368-914 0.251 1 1/4 368-918 0.313 1 5/16 368-922 0.376 1 3/8 368-926 0.502 1 1/2 386-100Diamond Film Coated Solid Carbide Parabolic DrillDesigned to produce a clean, delamination freehole in composite materials. The diamond filmcoated (CVD) parabolic drill is an economicalsolution to PCD composite drills.UsageCarbon fiber <strong>and</strong> othercomposite materialsPart Cutting Flute SHKNumber DIA LGTH DIAOAL86-102 0.100 1 1/4 386-106 0.129 1 1/4 386-110 0.147 1 1/4 386-114 0.192 1 1/4 386-118 0.251 1 1/4 386-122 0.313 1 5/16 386-126 0.376 1 3/8 386-130 0.502 1 1/2 321 www.onsrud.com

Solid Carbide CFRP Drill (Coated)85-800The CFRP drill is designed to ensure hole quality <strong>and</strong> diameter. The “W”point of the drill centers the drill to let the peripheral cutting edges shearthe material producing a clean, tight tolerance hole without fraying ordelamination. The drills are coated with a Diamond Like Carbon (DLC).UsageCarbon Fiber Rein<strong>for</strong>ced Plastics, Kevlar ® <strong>and</strong> <strong>Composite</strong>sNEWFRACTIONAL DRILLSPart Cutting Flute SHKNumber DIA LGTH DIAOAL85-807 1/8 (0.1250) 0.500 1/8 385-808 9/64 (0.1406) 0.500 3/16 385-809 5/32 (0.1563) 0.500 3/16 385-810 11/64 (0.1719) 0.500 3/16 385-811 3/16 (0.1875) 0.500 3/16 385-812 13/64 (0.2031) 0.500 1/4 385-813 7/32 (0.2188) 0.500 1/4 385-814 15/64 (0.2344) 0.500 1/4 385-815 1/4 (0.2500) 0.500 1/4 385-816 17/64 (0.2656) 0.500 5/16 385-817 9/32 (0.2813) 0.500 5/16 385-818 19/64 (0.2969) 0.500 5/16 385-819 5/16 (0.3125) 0.500 5/16 385-820 21/64 (0.3281) 0.500 3/8 385-821 11/32 (0.3438) 0.500 3/8 385-822 23/64 (0.3594) 0.500 3/8 385-823 3/8 (0.3750) 0.500 3/8 385-827 7/16 (0.4375) 0.500 7/16 385-831 1/2 (0.5000) 0.500 1/2 3METRIC DRILLSPart Cutting Flute SHKNumber DIA LGTH DIAOAL85-961 3.00 (0.1181) 12.000 3 7685-963 4.00 (0.1575) 12.000 4 7685-965 5.00 (0.1969) 12.000 5 7685-967 6.00 ( 0.2362) 12.000 6 7685-971 8.00 (0.3150) 12.000 8 7685-975 10.00 (0.3937) 12.000 10 7685-979 12.00 (0.4724) 12.000 12 76NUMBER DRILLSPart Cutting Flute SHKNumber DIA LGTH DIAOAL85-876 1 (0.2280) 0.500 1/4 385-877 2 (0.2210) 0.500 1/4 385-878 3 (0.2130) 0.500 1/4 385-879 4 (0.2090) 0.500 1/4 385-880 5 (0.2055) 0.500 1/4 385-881 6 (0.2040) 0.500 1/4 385-882 7 (0.2010) 0.500 1/4 385-883 8 (0.1990) 0.500 1/4 385-884 9 (0.1960) 0.500 1/4 385-885 10 (0.1935) 0.500 1/4 385-886 11 (0.1910) 0.500 1/4 385-887 12 (0.1890) 0.500 1/4 385-888 13 (0.1850) 0.500 3/16 385-889 14 (0.1820) 0.500 3/16 385-890 15 (0.1800) 0.500 3/16 385-891 16 (0.1770) 0.500 3/16 385-892 17 (0.1730) 0.500 3/16 385-893 18 (0.1695) 0.500 3/16 385-894 19 (0.1660) 0.500 3/16 385-895 20 (0.1610) 0.500 3/16 385-896 21 (0.1590) 0.500 3/16 3NUMBER DRILLS (CONT.)Part Cutting Flute SHKNumber DIA LGTH DIAOAL85-897 22 (0.1570) 0.500 3/16 385-898 23 (0.1540) 0.500 5/32 385-899 24 (0.1520) 0.500 5/32 385-900 25 (0.1495) 0.500 5/32 385-901 26 (0.1470) 0.500 5/32 385-902 27 (0.1440) 0.500 5/32 385-903 28 (0.1405) 0.500 5/32 385-904 29 (0.1360) 0.500 5/32 385-905 30 (0.1285) 0.500 5/32 385-906 31 (0.1200) 0.500 1/8 2-1/285-907 32 (0.1160) 0.500 1/8 2-1/285-908 33 (0.1130) 0.500 1/8 2-1/285-909 34 (0.1110) 0.500 1/8 2-1/285-910 35 (0.1100) 0.500 1/8 2-1/285-911 36 (0.1065) 0.500 1/8 2-1/285-912 37 (0.1040) 0.500 1/8 2-1/285-913 38 (0.1015) 0.500 1/8 2-1/285-914 39 (0.0995) 0.500 1/8 2-1/285-915 40 (0.0980) 0.500 1/8 2-1/285-916 41 (0.0960) 0.500 1/8 2-1/2www.onsrud.com 22

CP<strong>Composite</strong> Cutting DataAPPLICATION GOOD BETTER BESTFinishing 54-200<strong>Honeycomb</strong> 67-300 32-000 30-300CFRP 66-900 66-800 68-300G10/G11Fiberglass56-000P 67-000 54-200Fiberglass 67-000 67-400 67-200Phenolic 53-000P 67-200 67-220Single Pass 56-000P 67-250 68-000DEPTH OF CUT:1 x D Use recommended chip load2 x D Reduce chip load by 25%3 x D Reduce chip load by 50%CHIP LOAD PER TOOTHCutting Edge DiameterSeries Cut 1/16 3/32 1/8 5/32 3/16 7/32 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8 1 1/4 1 1/2 1 3/4 254-200 1 x D .002-.004 .002-.004 .002-.004 .003-.006 .005-.01056-000P 1 x D .002 - .004 .002 - .004 .004 - .006 .004 - .006 .004 - .00663-000 1 x D .003 - .005 .003 - .005 .003 - .005 .004 - .006 .005 - .00766-800 1 x D .001-.002 .002-.003 .003-.00466-900 1 x D .002-.004 .002-.004 .004-.006 .004-.006 .006-.00867-000 1 x D .004 - .006 .004 - .006 .004 - .00667-200 1 x D .002 - .010 .002 - .01067-220 1 x D .001-.002 .001-.00267-250 1 x D .002 - .004 .004 - .006 .004 - .00667-300 1 x D .004 - .006 .006 - .008 .010 - .01267-400 1 x D .002 - .004 .004 - .006 .004 - .006 .004 - .00667-500 1 x D .001 - .003 .001 - .003 .002 - .004 .002 - .004 .003 - .005 .004 - .00668-000 1 x D .004 - .006 .004 - .006 .004 - .006 .008 - .01068-200 1 x D .0005 - .001 .001 - .002 .001 - .00268-300 1 x D .001-.002 .001-.002 .004-.006NOTE: Spindle RPM’s generally range from 9,000 - 12,000when cutting composite materialsFORMULAS:DEFINITIONS:Chip Load = Feed Rate / (RPM x # of cutting edges)Feed Rate (IPM) = RPM x # of cutting edges x chip loadSpeed (RPM) = Feed Rate / (# of cutting edges x chip load)IPM = Inches Per MinuteIPR = Inches Per Revolution23 www.onsrud.com

<strong>Drilling</strong> Cutting DataDrill DiameterSeries SFM 3mm 1/8 3/16 5mm 6mm 1/4 5/16 8mm 3/8 10mm 7/16 12mm 1/2 5/8 3/4 7/8 167-800 <strong>Composite</strong>s 230 .001-.002 .001 - .003 .001 - .003 .001-.003 .002-.004 .002 - .004 .002 - .004 .002-.004 .003 - .005 .003 - .005 .003 - .005 .003-.005 .003-.00568-900 <strong>Composite</strong>s 230 0.001 0.001 0.001 0.0015 0.0015 0.0015 0.001585-800 <strong>Composite</strong>s 230 0.0005 0.0005 0.001 0.001 0.001 0.001 0.00186-100 <strong>Composite</strong>s 165 0.001 0.001 0.0015 0.0015 0.0015 0.0015FORMULAS: RPM = (3.82 x SFM) / tool dia. DEFINITIONS:Feedrate (IPM) = RPM x IPRIPM = Inches Per MinuteIPR = Inches Per Revolutionwww.onsrud.com 24

SOLID CARBIDE 8 FACET DRILL OR CFRP DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comDesigned to reduce cutting <strong>for</strong>ces <strong>and</strong> eliminating delamination when exiting the material.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________CFRP DRILL8 FACET DRILLTOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________L1 ___________________________________d ___________________________________OAL ___________________________________8 Facet Drill CFRP Drill____________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________________25 www.onsrud.com

PCD 8 FACET DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comThe PCD 8 facet drill works well in composite materials where long tool life <strong>and</strong> delamination free holes are required.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________L1 ___________________________________d ___________________________________OAL _______________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)www.onsrud.com 26

SOLID CARBIDE DFC PARABOLIC DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comThe parabolic drill is designed to produce a clean, delamination free hole in composite materials. The diamond film coated drill is an economicalsolution to PCD composite drills.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________L1 ___________________________________d ___________________________________OAL _______________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)27 www.onsrud.com

SOLID CARBIDE DOUBLE MARGIN PILOTED STEP DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comDouble margin piloted step drills are used to drill close tolerance holes (.003”) in a single operation. The step diameter lowers the initial drilling<strong>for</strong>ce <strong>and</strong> can serve as a guide in pilot holes. They are designed <strong>for</strong> use in thin material that does not exceed 2 times the drill diameter.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________D2 ___________________________________L1 ___________________________________L2 ___________________________________d ___________________________________OAL _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________www.onsrud.com 28

SOLID CARBIDE PILOTED CORE DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comPiloted Core drills are used to enlarge a drilled or punched hole. These drills are often used as a second pass tool in a multi-step drilling process<strong>and</strong> the pilot acts as a guide <strong>for</strong> the drill. This style of drill greatly increases the hole quality <strong>and</strong> accuracy compared to a 2 flute drill. With a properset up, the core drill should produce a hole within +/- .002”.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________D2 ___________________________________L1 ___________________________________L2 ___________________________________d ___________________________________OAL _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________29 www.onsrud.com

SOLID CARBIDE ONE SHOT DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comOne shot drills are designed to drill <strong>and</strong> ream a hole in one pass. This style of drill is used on single sheet carbon fiber or woven or tapegraphite epoxy.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________D2 ___________________________________L1 ___________________________________L2 ___________________________________d ___________________________________OAL _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________www.onsrud.com 30

SOLID CARBIDE DRIVMATIC ® DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comDrivmatic ® Drills are specially designed <strong>for</strong> use in automatic fastening machines. They are produced to the exacting st<strong>and</strong>ards of the aerospaceindustry <strong>and</strong> available in three design configurations <strong>for</strong> the machining of Aluminum, <strong>Composite</strong> <strong>and</strong> Titanium.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________D2 ___________________________________L1 ___________________________________L2 ___________________________________SL ___________________________________OAL _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________31 www.onsrud.com

SOLID CARBIDE DRILL REAMER QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comDrill Reamers are designed <strong>for</strong> single-pass drilling <strong>and</strong> reaming to achieve a final hole size with a one-step process. The tools are constructedwith four reamer margins which maximize hole roundness <strong>and</strong> are capable of holding size to a tighter tolerance than drilling alone. They aredesigned <strong>for</strong> use in Aluminum, <strong>Composite</strong> <strong>and</strong> Titanium.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________D2 ___________________________________L1 ___________________________________L2 ___________________________________d ___________________________________OAL _____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________www.onsrud.com 32

SOLID CARBIDE CORE DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comCore drills are used to enlarge a drilled or punched hole. These drills are often used as a second pass tool in a multi-step drilling process. Thisstyle of drill greatly increases the hole quality <strong>and</strong> accuracy compared to a 2 flute drill. With a proper set up, the core drill should produce a holewithin +/- .002”.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________L1 ___________________________________d ___________________________________OAL _______________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________33 www.onsrud.com

SOLID CARBIDE DAGGER DRILL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comDagger drills are used to cut single sheet material which is usually carbon fiber, or woven or tape graphite epoxy. The feed rate must be controlledin order to prvent fiber breakout.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________L1 ___________________________________d ___________________________________OAL _______________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________www.onsrud.com 34

SOLID CARBIDE REAMER QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.comReamers are used to accurately size a hole. The accuracy <strong>and</strong> hole quality will be based on the condition of the roughed hole. With a proper setup, the reamer should produce a hole within +/- .001”.Usage: CP • Material: <strong>Composite</strong>sEND USER INFORMATIONDISTRIBUTOR INFORMATIONCompany __________________________________________________Contact __________________________________________________Address ______________________________________________________________________________________________________________________________________________________Distributor__________________________________________________Contact __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________Phone __________________________________________________Fax __________________________________________________Email __________________________________________________TOOL DIMENSIONSSPECIAL TOLERANCESD1 ___________________________________L1 ___________________________________S1 ___________________________________d ___________________________________OAL ______________________________________________________________________________________________________________________________________________________________________________________________________________________________________Material(s) Cut________________________Hardness________________________Quantity Breaks________________________(Min. 6 pieces)Coating________________________35 www.onsrud.com

CUTTING TOOL QUOTE REQUEST FORM1081 S. Northpoint Blvd. • Waukegan, Illinois 60085 • Phone (847) 362-1560 • Fax (800) 557-6720 • www.onsrud.com*Starred Items = Required in<strong>for</strong>mation*Distributor Name____________________________________________ *Distributor's Reference Number ___________________*Distributor Address ___________________________________________________________________________________________*Contact____________________________________________________ *Email Address __________________________________*Telephone __________________________________________________ *Fax ___________________________________________End User Name _______________________________________________ Customer Reference Number ________________________End User Address_____________________________________________________________________________________________Contact _____________________________________________________ Email Address ____________________________________Telephone __________________________________________________________ Fax _________________________________________________*Material being machined ______________________________________ Hardness _______________________________________Machine type (Check all that apply): CNC Router CNC Mill Inverted Air Router H<strong>and</strong> OtherIf other, describe_______________________________________________________________________________________________H.P.= _________________________________________________Max. Spindle Speed____________________________________________ Coolant Type _____________________________________*Tool Material: HSS Solid Carbide Carbide Tip Powder Metal PCD Full Face PCD Tip OtherIf other, describe_______________________________________________________________________________________________*Flute Style: Spiral Up Spiral “O” Up Straight “V” Flute CompressionSpiral Down Spiral “O” Down Straight “O” Flute Morise Compression*Flute Form: Rougher Chipbrk/Finisher Finisher Other*Point Geometry: Square Ball Nose Drill Point OtherCenter CuttingNon-Center Cutting*If other, describe _____________________________________________________________________________________________*Tool Similar To: ______________________________________________________________________________________________Cutting Diameter (CED) _________________________________Cutting Length (CEL) ___________________________________OLShank Diameter (SHK) __________________________________NLOverall Length (OAL) ___________________________________Neck Diameter (ND) ____________________________________SDNDCDNeck Radius (NL) ______________________________________Corner Radius (CR) ____________________________________TransitionLoCCoolant Through Yes NoGrindCRTransition Grind Needed ________________________________Flat Y / N What Type? ________________________________Coating Types: TiN TiCN AlTiN Diamond Grit ZrN TiAlN DFC Diamond “Like” OtherIf other, describe_______________________________________________________________________________________________*Quantities Needed: __________________________________________________________________________________________Minimum is 6 piecesAny Target Pricing? ____________________________________________________________________________________________Distributor / End User?Additional Notes:__________________________________________________________________________________________________________________________________________________________________________________________________________www.onsrud.com 36

NOTES37 www.onsrud.com

LMT Onsrud Terms & ConditionsShipping - F.O.B. Waukegan, IL. All shipments ground unless otherwise specified.Claims – Any claims <strong>for</strong> shortage, damage or loss must be made within 30 days ofinvoice date. United Parcel Service is a preferred method of shipment because ofreliability <strong>and</strong> ease of tracing problem shipments.Guarantee - Our products are guaranteed against defects in material <strong>and</strong> quality ofmanufacture when used in the proper manner. If tools are returned <strong>and</strong> found to bedefective, we will repair or replace the tools. Continued tool breakage caused by impropertool usage without the knowledge of LMT Onsrud’s technical staff is not a condition<strong>for</strong> return <strong>and</strong> replacement of such tools.Errors - LMT Onsrud, LP cannot be held responsible <strong>for</strong> incorrect parts made with ourproducts due to mislabeling or defect.Return Goods Policy – No merch<strong>and</strong>ise can be returned without prior authorization.Credit will not be issued <strong>for</strong> merch<strong>and</strong>ise returned without a return authorization number.Product must be a current revision catalog item in new <strong>and</strong> saleable condition. All returnssubject to a 15% restocking fee or offsetting order of equal value.Specials - LMT Onsrud, LP has the right to over or under ship by 10% all specials.Special orders less than 10 pieces are subject to +/- 1 piece. Specials <strong>and</strong> modifiedtools are not returnable <strong>for</strong> credit. Specials cancelled will be assessed an in-processcharge based on the status of the order <strong>and</strong> expenses incurred at the time ofcancellation. If a special tool has been completed, the tool will be shipped <strong>and</strong> theprice quoted will be billed.Safety Precautions – Cutting tools should only be used to per<strong>for</strong>m operations that arecompatible with the original tool design. Safety glasses <strong>and</strong> other appropriate safetyequipment should be worn by all people in the vicinity of tool use.Prices & Terms - All prices <strong>and</strong> terms are subject to change without notice. All orders aresubject to acceptance at LMT Onsrud.

LMT Onsrud LP1081 S. Northpoint Blvd.Waukegan, IL 60085TOLL FREE +1 800 234 1560www.onsrud.comISO 9001 CertifiedDistributed By:Printed in USA/Catalog OCComp-12