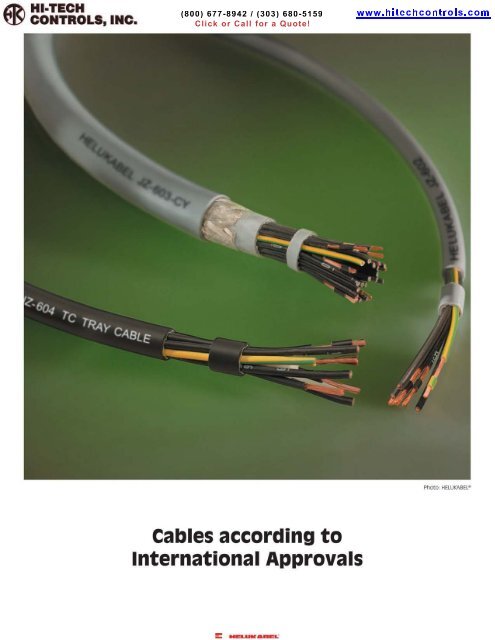

Cables according to International Approvals

Cables according to International Approvals - Hi-Tech Controls

Cables according to International Approvals - Hi-Tech Controls

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comPho<strong>to</strong>: HELUKABEL•<strong>Cables</strong> <strong>according</strong> <strong>to</strong><strong>International</strong> <strong>Approvals</strong>

~ HI·TECH (800) 677-8942 1 (303) 680·5159 www.hitechcontrols.com~ CONTROLS, INC. Click or can <strong>to</strong>r a Quotel<strong>Cables</strong> <strong>according</strong> <strong>to</strong> <strong>International</strong> <strong>Approvals</strong>The installation of cables and wires <strong>according</strong> <strong>to</strong>overseas standards is getting more and moreimportant for the machine and plant industries.HELUKABEL® knows this problem from hiscus<strong>to</strong>mers and has for a long time deliveredsingle core and multicore cables <strong>according</strong> <strong>to</strong>the following standards. Due <strong>to</strong> our extensives<strong>to</strong>ck capacity, we are in a position <strong>to</strong> cover yourrequirements quickly and correctly.Please enquire <strong>to</strong> our sales department.ULAWMMTWCEICSASEVUSASICNOMOGOSTCCCBSUnderwriters Labora<strong>to</strong>ries Inc.Appliance Wiring MaterialMachine Tool WireComita<strong>to</strong> Elettrotecnico ItalianoCanadian Standard AssociationSchweizerischer Elektrotechnischer VereinUSA Standard InstituteComite De Normalisation Des MoyensDe ProductionGOST-R CertificationChina Compulsory CertificationBritish Standard

~ HI·TECH~ CONTROLS, INC.Contents(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comDescription~-------------------------------------------------------------------------------------------PageJZ-602, two approvals control cable, 90'C, 600V ........................................................................................................................... 1!1 ~ 1•1JZ-603, three approvals control cable ........................................................................................................................................ ~ 1•1 •JZ-600 UL/CSA, flexible, number coded. 0,6/1kV .......... ............................... ,...................... .......................................,......,.................. 1•1JZ 604 TC TRAY CABLE, PVC power cable, exposed run. 90'C. 600V ........................................................................................................ 1•1HOSVV-F/SJT, 300V, <strong>according</strong> <strong>to</strong> DIN VDE 0281 and UL62 ............................................................................................................ .Q:. - 1•1 •HOSVV-F/SJT. 300V. <strong>according</strong> <strong>to</strong> DIN VDE 0281 and UL 62 ............................................................................................................ .Q:. 1•1 •HOSVV -F/U L, VDE-HAR-UL 500 V, <strong>according</strong> <strong>to</strong> DIN VDE 0281 and UL-Style 20195 ...................................................................................... ~ - •FROR CEI 20-22 II .............................. ............ ............................... ................................................... ....................................... ......... I IC.N.O.M.O, Type NOVVS-F <strong>according</strong> <strong>to</strong> NFC 32-207 .................................................................................................................................... I IJZ-602-CY, EMC-preferred type, 90'C 600V. screened two approvals control cable................................................................................ 1!1 ~ ~ 1•1JZ-603-CY, three approvals control cable. Cu-screened. EMC-pref erred .................................................................................................. ~ 1•1 •JZ-600-Y-CY UL/CSA, flexible. number coded. 0.6/1kV. EMC-preferred type .............................................................................................. ~ 1•1JZ 604-FCY TC TRAY CABLE, PVC power cable. exposed run. screened. go•c. 600V, EMC-preferred type ......................................................... !!!:: 1•1JZ 604-YCY TC TRAY CABLE, PVC power cable. exposed run. screened, go•c. 600V. EMC-preferred type ......................................................... ~ 1•1JZ-602-PUR, 8o•c. 600V. two approvals control cable ...................................................................................................,....................,.... ~ 1•1JZ-602-PUR DC/AC, 8o•c. 600V, two approvalscontrol cable .................................................................................................................. 5 1•1JZ-600 PUR, tear and coolant resistant. 0,6/1kV ................................................................................................................,.................. - 1•1OB-602 PUR YELLOW, 8o•c. 600V. two approvals control cable ................................................................................ ..............................JZ-602-C-PUR, screened two approvals control cable. 80'C, 600V, EMC-preferred type ...................................................................................JZ-600-YC-PUR, tear and coolant resistant. 0,6/1kV, Cu-screened. EMC-preferred type ..................................................................................MEGAFLEX® 500, halogen-free, flame retardant. oil-resistant. UV-resistant. flexible .......................................................................................MEGAFLEX® 500-C, halogen-free. flame retardant. oil-resistant. uv-resistant. flexible. screened. EMC-preferred types ...........................................Command Cable UL CLiYYl, style 24641300 v. t80'C> .................................................................................... ......................................Command Cable UL ............................................. ..................................................................Command Cable UL CLiYY-TP>. style 2464t3oov. 80'C ................................................................................................................. .....Command Cable UL

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ·602JZ·603JZ·600 UL/CSAJZ 604 TC TRAY CABLEHOSVV·F/SJTHOSVV·F/SJTHOSVV·F/ULFROR CEI 20·22 IIC.N.O.M.OJZ·602·CYJZ·603·CYJZ·600·Y·CY UL/CSAJZ 604·FCY TC TRAY CABLEJZ 604·YCY TC TRAY CABLEJZ·602·PURJZ·602·PUR DC/ACJZ·600 PUROB·602 PUR YELLOWJZ·602·C·PURJZ-600· YC·PURMECAFLEX® 500MECAFLEX® SOO·CUL/CSA control <strong>Cables</strong>Pho<strong>to</strong>: HELUKABEL 8

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ-602 two approvals control cable, 90°C, 600V~~~~---~=~H8LUKABELJZ-802 "'AWM 14 AWG C2.1 mm2J3C E170315 C8A AWM 1AIB 2A1B FT 1 100 V IO"C C (Technical data• Control cable of special-PVC <strong>to</strong> UL CSAAWM 1/11 A/B Style 2S87 (jacket insulation!and CSA• Temperature rangef lexing -soc <strong>to</strong> +90°Cf ixed installation -40°C <strong>to</strong> +90°C• Nominal voltage<strong>according</strong> <strong>to</strong> UL + CSA 600 V• Test voltage 3000 V• Breakdown voltage m in. 6000 v• Insulation resistancemin 20 MOhm x km• Minimum bending radiusf lexing 7,Sx cable 0f ixed installation 4x cable 0• Radiation resistanceup <strong>to</strong> 80x10 6 cJ/kg (up <strong>to</strong> 80 MradlCable structure• Bare copper. fine wire stranded <strong>to</strong>DIN VDE 029S cl. S, BS 6360 cl. S andIEC 60228 cl. S• Special PVC core insulation Tl3, <strong>to</strong>DIN VDE 0281 part 1 and class 43 <strong>to</strong>UL-Std. 1S81• Black conduc<strong>to</strong>rs with consecutivenumbering in white• Green-yellow earth core in the outer layer

~ HI·TECH~ CONTROLS, INC.JZ-600 U L/CSA(800) 677·8942 I (303) 680·5159Click or Call for a Quotelflexible. number coded, 0,6/1kVwww. h itech controls .com~~ ~·• ~ .-.' , ,_. HEI UKAflfl Jl.&JO ·1GO 5 QI.IM!XlAWG c'nlua AWM STYLE 21179 80' C VW-1 CSA ll113926 AWM 1111 AlB llll ' C FT1 •,...- __.,Technical data• Special PVC control cables Adapted <strong>to</strong>DIN VDE 0276 part 627, DIN VDE 0281part 13, with insulation t hickness for 1 kVtype and UL·Std. 758 Style 21179• Temperature rangeflexing -5"C <strong>to</strong> +80"Cfixed installation -40"C <strong>to</strong> +80°C• Nominal voltage 1000 v• Test voltage 4000 v• Breakdown voltage min. 8000 v• Insulation resistancemin. 20 MOhm x km• Power ratingas per DIN VDE 0298• Minimum bending radiusf lexing 7 ,5x cable 0fixed installation 4x cable 0• Radiation resistanceup <strong>to</strong> 80x10 6 cJ/kg

* HI·TECH(800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelJZ-600 UL/CSA flexible, number coded, 0,6/1kV11§1•1Part No. No. cores x AWC·no. outer o Cop. Weight Part No. No.cores x AWC·no. outer o Cop. WeightJacket cross-sec. ca. mm weight ca. kg 1 Jacket cross-sec. ca.mm weight ca. kg 1colour mm 2 kg / km km colour mm 2 kg / km kmblackgrey11844 12 G 1.5 16 16,6 173,0 370,0 11909 12 G 1,5 16 16,6 173,0 370,011845 18 G 1,5 16 19.7 259,0 520,0 11910 18 G 1.5 16 19,7 259,0 520,011846 25 G 1.5 16 23,9 360,0 730.0 11911 25 G 1,5 16 23,9 360,0 730.011847 2 x2.5 14 9.4 48,0 160,0 11912 2 X 2,5 14 9.4 48,0 160,011848 3 G 2,5 14 9,9 72.0 175,0 11913 3G2,5 14 9,9 72.0 175,011849 4 G 2,5 14 11,1 96,0 203,0 11914 4G2,5 14 11,1 96,0 203,011850 5 G 2.5 14 12,4 120,0 251,0 11915 5 G2,5 14 12.4 120,0 251,011851 7 G 2,5 14 15,0 168,0 330,0 11916 7 G2,5 14 15,0 168.0 330,011852 12 G 2,5 14 18,4 288,0 553.0 11917 12 G 2.5 14 18.4 288.0 553,011853 18 G 2,5 14 22,0 432.0 795,0 11918 18 G 2,5 14 22.0 432,0 795,011854 25 G 2,5 14 26.9 600,0 1110.0 11919 25 G 2,5 14 26.9 600,0 1110,011855 2X4 12 11.4 77.0 180.0 11920 2x4 12 11.4 77.0 180.011856 3G4 12 12.3 115,0 230,0 11921 3G4 12 12.3 115,0 230.011857 4G4 12 13.8 154.0 310,0 11922 4G4 12 13.8 154.0 310.011858 5G4 12 15.3 192,0 410.0 11923 5G4 12 15,3 192,0 410.011859 7G4 12 16,8 269,0 540.0 IJ1924 7G4 12 16,8 269.0 540,011860 12 G 4 12 22,9 461,0 860,0 11925 12 G 4 12 22.9 461.0 860,011861 3G6 10 14,1 173.0 370.0 11926 3G6 10 14,1 173,0 370.011862 4G6 10 15.6 230.0 430.0 11927 4G6 10 15.6 230.0 430,011863 5G6 10 17,3 288,0 650,0 11928 SG6 10 17.3 288,0 650,011864 7G6 10 19,3 403,0 860.0 11929 7G6 10 19.3 403,0 860,011865 3 G 10 8 16.5 288,0 660.0 11930 3G10 8 16,5 288,0 660,011866 4 G 10 8 18.4 384,0 790.0 11931 4 G 10 8 18.4 384,0 790.011867 5 G 10 8 20,5 480,0 960.0 11932 5G 10 8 20,5 480,0 960.011868 7 G 10 8 22.5 672.0 1300.0 11933 7 G 10 8 22.5 672,0 1300.011869 3 G 16 6 19.6 461.0 760.0 11934 3 G 16 6 19.6 461.0 760.011870 4 G 16 6 21.7 614,0 1100.0 11935 4 G 16 6 21.7 614,0 1100,011871 5 G 16 6 24,2 768.0 1600.0 11936 5G16 6 24.2 768,0 1600,011872 7 G 16 6 25.7 1075,0 1890.0 11937 7G16 6 25.7 1075,0 1890,011873 3 G 25 4 24.0 720,0 1450.0 11938 3G25 4 24.0 720.0 1450,011874 4 G 25 4 26.9 960.0 1600.0 11939 4 G 25 4 26,9 960.0 1600,011875 5 G 25 4 29.3 1200.0 2050.0 11940 5G25 4 29,3 1200.0 2050,011876 7 G 25 4 32,6 1680,0 2900,0 11941 7 G 25 4 32,6 1680,0 2900,0Dimensions and specifications may be changed without prior notice. (RN01l

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a QuotelJZ 604 TC TRAY CABLE PVC power cable. exposed run. gooc.600Vwww. h itech controls .com_...., , ....., ,...., I·I ELUKABEL JZ-604 TC-ER Ul 1277 18AWG /1 OMM 7C 600V 90C DRY 75C WET SUN RES.~ ·~ ~· ,,_. OIL RES I DIR BUR FT4 OR 'iU AWN STYLE 2587 CSA AWM 111 AlB 90C FT4 600V Ll 113926 ( (Technical data• PVC power cable <strong>to</strong> UL-standard 1277TRAY CABLE• MultinormThe TRAY CABLE also conforms <strong>to</strong> thefollowing standards:AWM-Style 2S87 <strong>to</strong> UL-Std. 7S8 andCSA C22.2 No 210.2 1111 A/B 90C 600 V• Temperature rangedry environmentf lexing -soc <strong>to</strong> +90°Cf ixed installation -25°C <strong>to</strong> +90°Cwet environmentf lexing -soc <strong>to</strong> +7S°Cf ixed installation -2soc <strong>to</strong> +75°C• Nominal voltage <strong>to</strong> UL 600 v• Test voltage 3000 V• Breakdown voltage min. 6000 v• Insulation resistancemin. 20 MOhm x km• Minimum bending radius7,5x cable 0• Radiation resistanceup <strong>to</strong> 80x106 cJ/kg !up <strong>to</strong> 80 Mrad)Cable structure• Bare copper, f ine wire conduc<strong>to</strong>rs.<strong>according</strong> <strong>to</strong> DIN VDE 029S cl. s. BS 6360cl. 5 and IEC 60228 cl. 5• Special PVC core insulation class 12 B <strong>to</strong>table S0.155 u L -standard 1581.type TFF <strong>to</strong> UL-Std. 62 table 6.2!AWG 20-AWG 16),type TH HW <strong>to</strong> UL-Std. 83 table 5.2 (?!AWG 14)• Black cores with continuous whitenumbering <strong>according</strong> <strong>to</strong> DIN VDE 0293• Green-yellow earth core in the outer layer(3 cores and above)• Cores stranded in layers with optimallay- lengt• Special PVC outer sheath. <strong>to</strong> UL-Std. 1277table 11.2• Sheath colour black (RAL 9005)Properties• Material self-extinguishing and flameretardant <strong>to</strong> UL -standard 1277• The materials used in manufacture arecadmium-free and contain no silicone andfree from substances harmful <strong>to</strong> thewetting properties of lacquersNote• G = with green-yellow earth core;x =without green-yellow earth core (QZ).• AWG sizes are approximate equivalentvalues. The actual cross-section is in mm 2 .ApplicationUSA NFPA79, edition 2007 conformant flexible power cables up <strong>to</strong> 600 V, for all machinery in <strong>to</strong>ol and plant constuction, suitable for installationin dry, humid and damp environments. in the open and in pipes. For underground installation and for open. unprotected installation fromthe cable rack <strong>to</strong> machines and industrial plants.CE= The product is conformed with the EC Low-Voltage Directive 73/23/EEC and 93/68/EEC.Part No. No.cores x AWC-no. Outer o cop. Weight Part No. No.cores x AWC-no. outer o cop. Weightcross-sec. ca.mm weight ca. kg 1 cross-sec. ca.mm weight ca. kg 1mm~ kglkm km mm• kglkm km69661 2x1 17 a.o 19,2 74,0 696a9 2 X 2,5 14 9,4 48,0 111,069662 3 G 1 17 a .a 29.0 a7.0 69690 3G2.S 14 9.9 72.0 140.069663 4 G 1 17 9.1 39,0 99.0 69691 4 G2,5 14 10,8 96,0 161,069664 SG1 17 10.0 4a.o 117.0 69692 SG2,S 14 11,8 120,0 194,069665 7 G 1 17 11,7 67,0 151,0 69693 7 G2,5 14 14.7 168,0 257,069666 9G1 17 12,6 a4.0 172.0 69694 aG2,S 14 16,0 192.0 339,069667 10 G 1 17 14,3 96,0 206,0 69695 9G2,5 14 16,0 216,0 341.06966a 12 G 1 17 14,7 11S,O 260,0 69696 10 G 2.S 14 17.1 240.0 392.069669 1a G 1 17 17,1 173,0 371,0 69697 12 G 2,5 14 17.7 2a8.0 470.069670 2S G 1 17 20.3 240.0 4a1,0 6969a 1a G 2,5 14 20.a 432,0 6a2.069671 34 G1 17 23.7 326,0 551,0 69699 25 G 2,5 14 25.8 600,0 a91.069672 soc 1 17 26,1 4ao.o 9S9.069700 3G4 12 11,0 115.0 190,069673 2 X 1,S 16 a.4 2a.a 91,0 69701 4G4 12 12.0 1S4,0 229,069674 3 G 1,5 16 a.8 43.0 105,0 69702 5G4 12 13,2 192,0 284,069675 4 G 1.5 16 9.6 5a.o 122.0 69703 7G4 12 16.5 269.0 394.069676 5 G 1,5 16 10,5 72,0 147.0 69704 9G4 12 17.8 346,0 480,0696n 7 G 1.5 16 12,3 101.0 192.0 69705 12 G 4 12 19.9 461.0 a41.06967a 8G 1,5 16 13,3 115,0 213,0 69706 18 G4 12 24.2 691,0 981,069679 9 G 1,5 16 13,3 130.0 261.069680 10 G 1,5 16 15,1 144,0 294.0 69707 3G6 10 12,5 173,0 290,0696a1 12 G 1.S 16 15.6 173.0 331.0 69708 4C6 10 14.5 230,0 3a4,0696a2 16 G 1,5 16 17.1 230,0 402,0 69709 5C6 10 15,8 288,0 46a.o696a3 1a c 1.5 16 1a.2 259.0 430,0 69710 7C6 10 17,3 403.0 654,069684 25 G 1.5 16 22.7 360.0 S97,0696a5 34 C1,5 16 25.3 4a9.0 714.0 69711 3010 a 16.9 288.0 S11,0696a6 41 G 1,5 16 26.7 590,0 803.0 69712 4 G 10 a 1a.6 384,0 S87.0696a7 soc 1.5 16 27.3 720.0 1021.0 69713 SG 10 a 20.4 480.0 7a4.06968a 61 G 1.5 16 29.4 878,0 1238,0 69714 7 G 10 a 23.5 672.0 970,0Dimensions and specifications may be changed without prior notice. !RN01)!: NCLUKA...a.Continuation •

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ 604 TC TRAY CABLE PVC power cable, exposed run, 90°C,600VPart No. No.cores x AWC·no. outer e Cop. Weight Part No. No.cores x AWC·no. outer e Cop. Weightcross-sec. ca. mm weight ca. kg 1 cross· sec. ca.mm weight ca. kg 1mm 2 kglkm km mm 2 kg lkm km69715 3 G 16 6 21.0 461,0 651,0 69729 3 G 70 2/0 37,6 2016,0 2831 ,069716 4G 16 6 23,9 614,0 869.0 69730 4 G 70 210 42,0 2688.0 3494,069717 5 G16 6 26.3 768,0 1117,0 69731 5 G 70 2/0 47,6 3360,0 4260.069718 7 G16 6 28.8 1075.0 1364.069732 3 G 95 310 41,8 2736,0 5010.069719 3 G25 4 24,9 720,0 1090,0 69733 4 G 95 310 47,0 3648,0 6104,069720 4 G25 4 27.2 960,0 1421,0 69734 5 G 95 310 52.5 4560,0 7891 ,069721 SG 25 4 30.3 1200,0 1611.069722 7 G 25 4 33,1 1680,0 1943,0 69735 3 G 120 4/0 46,0 3456.0 5940,069736 4 G 120 410 51,5 4608.0 7604,069723 3G35 2 27.1 1008,0 1734,0 69737 5 G 120 410 56,5 5760.0 8751 ,069724 4G35 2 29,8 1344,0 2011,069725 S G 35 2 33,0 1680,0 2347.069726 3 G 50 33.2 1440,0 2041,069727 4 G 50 36.7 1920,0 2539.069728 S GSO 41,5 2400,0 2894,0Dimensions and specifications may be changed without prior notice. (RN01 l~ 1•1

~ HI·TECH~ CONTROLS, INC.(800) 677-8942 1 (303) 680·5159 www.hitechcontrols.comClick or Call for a QuotelHOSVV·F/SJT 300V, <strong>according</strong> <strong>to</strong> DIN VDE 0281 and UL 62 A~ 1•1HELUKABEL CE E 192384 CSA SJT 18/3 VW-1/FT1IRoHSIHELUKASEL4voe.4tAR.-. CE E 182384 CSA SJT1813VW..'IFT1Technical data• PVC control cable <strong>to</strong> DIN VDE 0281 part 5and part 2. IEC 60227-5, HD 21.5 S3 andUL-Std. 62 and CSA 22.2 No. 49• Temperature rangef lexing -soc <strong>to</strong> +70°Cf ixed installation -4o·c <strong>to</strong> +70°C• Nominal voltageDIN VDE 0281 = Uo/U 300/500 VUL 62 = U 300 VCSA = U 300 V• Test voltage 2500 V, 5 min.• Breakdown voltage m in. 5000 V• spark-Test 6000 V• Insulation resistancemin. 20 MOhm x km• Minimum bending radiusapprox. 7 .sx cable IZl• Radiation resistanceup <strong>to</strong> 80x10G cJ/kg (up <strong>to</strong> 80 MradlCable structure• Bare copper. f ine wire stranded conduc<strong>to</strong>r<strong>to</strong> DIN VDE 0295 cl. 5, BS 6360 cl. 5,IEC 60228 cl. 5, HD 383 and UL-Std. 62• PVC insulation Tl2 <strong>to</strong> DIN VDE 0281 part 1and class 43 <strong>to</strong> UL-Std. 62

~ HI·TECH~ CONTROLS, INC.(800) 677-8942 1 (303) 680·5159 www.hitechcontrols.comClick or Call for a QuotelHOSVV·F/SJT 300V, <strong>according</strong> <strong>to</strong> DIN VDE 0281 and UL 62 A II§§ 1•1HELUKABEL ~VDEI>~HARI> CE E 192384 CSA 1813 VW·11FT1IRoHSITechnical data• PVC control cable <strong>to</strong> DIN VDE 0281 part 5and part 2. IEC 60227-5, HD 21.5 53 andUL-Std. 62 and CSA 22.2 No. 49• Temperature rangeflexing -soc <strong>to</strong> +70°Cfixed installation -40°C <strong>to</strong> +70°C• Nominal voltageDIN VDE 0281 = Uo/U 300/500 VUL 62 = U 300 VCSA = U 300 V• Test voltage 2500 V, 5 min.• Breakdown voltage min. 5000 v• Spark-Test 6000 v• Insulation resistancemin. 20 MOhm x km• Minimum bending radiusapprox. 7 ,5x cable 0• Radiation resistanceup <strong>to</strong> 80x10 6 cJ/kg (up <strong>to</strong> 80 MradlCable structure• Bare copper, fine wire stranded conduc<strong>to</strong>r<strong>to</strong> DIN VDE 0295 cl. 5, BS 6360 cl. 5,IEC 60228 cl. 5, HD 383 and UL-Std. 62• PVC insulation Tl2 <strong>to</strong> DIN VDE 0281 part 1and class 43 <strong>to</strong> UL-Std. 62 (Table 50.182.UL-Std. 1581) <strong>according</strong> <strong>to</strong> CSA-Std. C 22.2No 49 Type SJT• Core identification <strong>according</strong> <strong>to</strong> colour codeDIN VDE 0293-308, one coloured• Green-yellow earth core, 3 cores and above• Core stranded wit h optimal lay-length• PVC outer jacket TM2 <strong>to</strong> DIN VDE 0281part 1 and class 43 <strong>to</strong> UL-Std. 62(Table 50.182, UL-Std. 1581) <strong>according</strong> <strong>to</strong>CSA-Std. C 22.2 No 49 Type SJT• Jacket colour by request• Imprint on the outer jacket: e.g.Properties• PVC self-extinguishing and flame retardant<strong>according</strong> <strong>to</strong> VDE 0482-332-1 -2, DIN EN60332-1-2/ IEC 60332-1 (equivalentDIN VDE 0472 part 804 test method Bl• The materials used in manufacture arecadmium-free and contain no silicone andfree from substances harmful <strong>to</strong> thewetting properties of lacquersNote• G =with green-yellow earth core;x = without green-yellow earth core.• Colour code:0 = RAL 5015, blue1 = RAL 6018, green2 = RAL 8003, brown3 = RAL 1021. yellow4 = RAL 3000, red5 = RAL 2003, orange6 = RAL 4005. violet7 =gold8 = dusky gold• Please add the individual part no. for orderwith t he identification colour code.Further colours on request.ApplicationThese f lexible PVC control cables, VDE-HAR-UL-CSA approved. are designed for the export and also for the export-orientated-equipment.These cables are especially suited <strong>to</strong> use for the appliance with medium mechanical stresses with free movement without tensile stress inhouseholds, kitchens and offices, also for household appliances in damp and wet areas, e.g. refrigera<strong>to</strong>rs. washing machines. spin-driveretc., as far as this cable is admitted <strong>to</strong> the relevant specifications of the equipment.These cables are suited <strong>to</strong> be used for cooking and heating apparatus under the condition that cable does not come in direct contact withhot parts of the apparatus and no other influences or heat.The cables are suitable for fixed installation in furnitures. partition walls, decoration covering and in hollow spaces of prefabricated buildingparts.They are not suitable for use in open air, in industries (also permitted <strong>to</strong> tailor workshops and of that kindl and in agriculture plants and forconnecting commercial electrical <strong>to</strong>ols.C € = The product is conformed with the EC Low-Voltage Directive 73/23/EEC and 93/68/EEC.Part NO. No.cores x outer 111 Cop. weight AWC•NO. Part No. No.cores x Outer 111 Cop. weight AWC·NO.cross·sec. ca. mm weight ca. kg 1 km cross-sec. ca. mm weight ca. kg 1 kmmm• kg lkm mm• kglkm3110_ 2 X 1 7,2 19.2 56.0 17 3118_ 2 x2,5 9.2 48,0 118,0 143111_ 3C1 7.6 28,8 73.0 17 3119_ 3 2.5 10,0 72.0 152.0 143112_ 4C1 8,6 38.4 86,0 17 3120_ 4 2.5 10.9 96,0 192.0 143113_ 5C1 9.4 48,0 105.0 17 3121_ 5 c 2.5 12.2 120,0 243,0 143114_ 2 X 1,5 7,6 28.8 82.0 16 3122_ 2X4 10,6 76.8 195.0 123115_ 3 c 1,5 8.3 44.0 96.0 16 3123_ 3C4 11,5 115.0 235.0 123116_ 4 c 1.5 9,3 58.0 117,0 16 3124_ 4C4 12.4 154.0 300.0 123117_ 5 c 1,5 10.4 72.0 144,0 16 3125_ 5C4 14,1 192,0 361.0 12Dimensions and specifications may be changed without prior notice.

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a QuotelC. N. 0. M. 0 Type NOVVS·F <strong>according</strong> <strong>to</strong> NFC 32·207www. h itech controls .comI IC .N.O .M .O. FN 05 VV5-F ((lRoHSITechnical data• Special PVC based core insulation• As per <strong>to</strong> the f rench mo<strong>to</strong>r industrystandard f or <strong>to</strong>ol machines 04-24-22• Temperature rangef lexing -5°C <strong>to</strong> +80°Cf ixed installation -30°C <strong>to</strong> +80°C• Nominal voltage soo v• Test voltage 2000 v• Insulat ion resistancem in. 20 MOhm x km• Radiation resistanceup <strong>to</strong> 80x106 cJ/kg (80 Mrad>• Minimum bending radius15x cable 0Cable structure• Plain copper conduc<strong>to</strong>rs• Special core insulation• cores laid up• cores available in either red or black withwhite f igure imprint• Green-yellow earth core• PVC outer jacket greyProperties• PVC self-extinguishing and f lame retardant.text method Band IEC 60332-1• The materials used in manufacture arecadmium-free and contain no silicone andfree from substances harmful <strong>to</strong> thewetting properties of lacquers• Resistant <strong>to</strong>OilPetrolCutting oil <strong>according</strong> <strong>to</strong> C.N.O.M.Orecommendation E 03.40.150NNote• G = with green-yellow earth core;x = without green-yellow earth core kg / km mm2 kg / km60000 2 X 0,75 6.2 14.4 50,0 60034 2 X 2,5 10.5 48.0 122.0 1460001 3 G 0,75 6.6 21.6 59.0 60035 3 G2,5 11.0 72.0 151.0 1460002 4 G0.75 7.2 29.0 72.0 18 60036 4 G2.5 12,0 96.0 191.0 1460003 5 G 0,75 8.0 36,0 87,0 18 60037 5G2,5 13,1 120,0 244,0 1460004 6 G 0,75 8,9 50,0 105,0 18 60038 6G2,5 15,0 168,0 292,0 1460005 12 G 0.75 11,6 86,0 175,0 18 60039 12 G 2.5 18.0 288.0 524.0 1460006 18 G 0.75 13,9 144,0 267,0 1860007 27 0,75 17.2 230,0 404.0 18 60040 2x4 10.4 77,0 178,0 1260008 36 c 0.75 19.7 288.0 503.0 18 60041 3C4 11.3 115.0 230,0 1260009 48 G 0.75 22.8 360.0 670,0 18 60042 4G4 12.8 154.0 300.0 1260010 60 G 0,75 24,9 439,0 805,0 18 60043 5G4 14,2 192,0 362,0 1260011 2 X 1 6.5 19.0 56,0 17 60044 2x6 11,6 115,0 218.0 1060012 3G1 6,9 29,0 72.0 17 60045 3G6 12,7 173,0 325.0 1060013 4G1 7,7 38,0 84,0 17 60046 4G6 14.2 230,0 481,0 1060014 5C1 8,5 48,0 104,0 17 60047 5C6 15,7 288,0 584.0 1060015 6C1 9.2 67.0 124,0 1760016 12 G 1 12.4 115,0 219,0 17 60048 2 X 10 15,0 194,0 505.0 860017 18 G 1 15,2 192.0 314,0 17 60049 3 G10 16.6 288,0 610.0 860018 27 1 18,7 308.0 485,0 17 60050 4 C10 18,4 384,0 736.0 860019 36 c 1 21.1 384,0 620.0 17 60051 5 c 10 20.9 480,0 913.0 860020 48G 1 24,3 480,0 809.0 1760021 60 G 1 26.4 586,0 1000,0 1760022 2 X 1.5 7,5 29,0 76,0 1660023 3 c 1,5 8.1 43,0 94.0 1660024 4 G 1.5 9.1 58.0 116.0 1660025 5 c 1,5 10,1 72.0 143.0 1660026 6 c 1,5 11,0 101,0 173.0 1660027 12 c 1.5 15.1 173.0 307,0 1660028 18 G 1.5 17.9 263.0 464,0 1660029 24 c 1,5 21,0 341,0 629.0 1660030 27 G 1,5 21,8 372,0 708.0 1660031 36 c 1,5 24,5 498.0 985.0 1660032 48 G 1,5 28.4 641.0 1175.0 1660033 60 c 1,5 31,3 878.0 1415,0 16Dimensions and specifications mav be changed without prior notice.

~ HI·TECH~ CONTROLS, INC.(800) 677-8942 I (303) 680-5159Click or Call for a Quotelwww. h itech controls .comJ Z • 602 • CY EMC-preferred type, gooc GOOV, screened two approvalscontrol cable_ HEWKABEL .JZ-802-cY til AWM 18 AWQ (1.15 mmii7C &170316 CSA AWM t AIB 2AIB FT 1 800 V W C C (Technical data• Special PVC-insulated sheathed cable<strong>according</strong> <strong>to</strong> UL AWM Style 10012

* HI·TECH (800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelJZ·602·CY EMC·preferred type, gooc aoov. screened two approvalscontrol cablePart No. No.cores x AWG·no. outer o Cop. Weight Part No. No.cores x AWG·no. Outer o Cop. Weightcross· sec. ca. mm weight ca. kg 1 cross· sec. ca.mm weight ca. kg 1mm 2 kg l km km mm 2 kg lkm km8294S 3G10 8 19.2 416.0 741 ,0 82488 3 G SO 1 3S.O 1490.0 2870.082946 4G 10 8 21,3 571,0 988,0 82780 4G 50 1 40.5 2474,0 3960,082947 SG10 8 23.9 690,0 1202.0 82781 S G SO 1 44,4 2794,0 4371,082948 7 G 10 8 26,7 971,0 1743,082782 3 G 70 210 41.4 2288.0 3647,082941 3G16 6 24,4 660,0 1088,0 82783 4 G 70 2/0 46,1 3120,0 4882,082942 4 G 16 6 27,4 821,0 1662.0 82914 SC70 2/0 S0.6 370S,O S876.082943 SG 16 6 30,8 1127,0 2021,082944 7 G 16 6 33,8 1S12,0 2720.0 8291S 3 9S 3/0 46,2 3094,0 47S1,082916 4 95 3/0 50.7 4043.0 6368.082937 3G 2S 4 30.4 830,0 1947,0 82917 s c 9S 310 56,1 S026.0 7843,082938 4G25 4 33,5 1170,0 2591,082939 SG 2S 4 40,0 1430,0 3197.0 82918 3G 120 410 52,0 3812,0 S899,082940 7 G25 4 40,8 2150,0 4530,0 82919 4 G 120 410 57,0 5069,0 8010.082920 S G 120 4/0 62,7 5877,0 920S,O82934 3G35 2 34.0 1345.0 2701,08293S 4 G 35 2 37,9 1690,0 3277.082936 5G35 2 41,7 2104,0 4530,0Dimensions and specifications may be changed without prior notice.

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ-603-CY three approvals control cable. cu-screened, EMC-preferred~· c--J' --·C£IRoHSITechnical data• Special PVC control cable with oil resistan<strong>to</strong>uter sheath <strong>to</strong> DIN VDE 0281 part 13,HD 21.13 S1 and <strong>to</strong> UL-Stvle 2587• Temperature rangeflexing -soc <strong>to</strong> +70°C -soc <strong>to</strong> +90°C fixed installation -40°C <strong>to</strong> +70°C -40°C <strong>to</strong> +90°C • Nominal voltageUo/U 300/500 V U 600 V • Test voltage 3000 v• Breakdown voltage min. 6000 V• Insulation resistancemin. 20MOhm x km• Minimum bending radiusflexing 10x cable 0fixed installation 5x cable 0• Radiation resistanceup <strong>to</strong> 80x10 6 cJ/kg • coupling resistancemax. 250 Ohm/kmCable structure• Bare copper, fine wire conduc<strong>to</strong>rs<strong>to</strong>DIN VDE 0295 cl. 5, BS 6360 cl. 5 andIEC 60228 cl. S• Special PVC core insulation Tl1, <strong>to</strong>DIN VDE 0281 part 1, H D 21.1 S2 and class 43<strong>to</strong> UL-Std. 1581• Black cores with white continuousnumbering• Green-yellow earth core in the outer layer• PVC based inner sheath• Tinned copper braiding screening, 85%coverage• Special PVC outer sheath TM5, oil resistant<strong>to</strong> DIN VDE 0281 part 1, HD 21.1 S4 andclass 43 <strong>to</strong> UL-Std. 1581• Colour grey Properties• Oil resistant as per HD/EN 60811-2-1,UL1581 part50.182• PVC self-extinguishing and flame retardant<strong>according</strong> <strong>to</strong> VDE 0482-332-1-2, DIN EN60332-1-2/ IEC 60332-1 UL-VW 1• The materials used in manufacture arecadmium-free and contain no silicone andfree from substances harmful <strong>to</strong> thewetting properties of lacquersNote• G =with green-yellow earth core;x = w ithout green-yellow earth core .• The follwing amendments in the cabledesignation result from the newDIN VDE 0281 part 13 I harmonised inaccordance with HD 21.13S1 : NYSLYO-J and NYSL YCYO-J . SEV-approval is no longerapplicable as a result of the harmonisation.• unscreened analogue type:JZ-603ApplicationUL-CSA-HAR approved cables offer any company exerting anywhere in the world, primarily designed for exporters. used in machine <strong>to</strong>ols,control systems, assembly lines and other industrial equipment. These cables are suitable for flexible use for medium mechanical stressesw ith free movements in dry, moist and wet rooms but not for open air.EMC =Electromagnetic compatibillityTo optimise the EMC features we recom mend a large round contact of the copper braiding on both ends.C €;:: The product is conformed w it h t he EC Low-Voltage Directive 73/23/EEC and 93/68/EEC.Part No. No.cores x AWC-no. outer o cop. weight Part NO. No.cores x AWC-no. outer ocross-sec. ca. mm weight ca. kg 1 cross-sec. ca. mmmm• kg /km km mm•83709 2 xO,S 20 7,7 30,0 90,0 83747 18 G 1 17 17,383720 3 GO.S 20 8,3 42,0 105,0 83748 25 1 17 21,183721 4 c 0,5 20 8.9 51.0 123.0 83749 34 1 17 23.583722 5 G 0.5 20 9,7 56,0 147,0 83750 41 c 1 17 25,583723 7 c 0.5 20 11.2 75.0 195.0 83751 soc 1 17 27.683724 12 G 0.5 20 13,6 124,0 276.0 83752 61 C 1 17 32.483725 18GOS 20 15,4 166,0 418.083726 25 G 0.5 20 18.6 196,0 504.0 83712 2 X 1,5 16 9,483727 34 C 0.5 20 20.8 242.0 632.0 83753 3 c 1,5 16 10,183728 41 G 0,5 20 22.6 351,0 750.0 83754 4 G 1,5 16 11.083729 50 G 0 ,5 20 24.8 398.0 968.0 83755 SG1.5 16 12.383730 61 G 0.5 20 26.0 447.0 1068.0 83756 7 G 1.5 16 14,283757 12 1.5 16 17.183710 2 X 0,75 18 8.0 41.0 101,0 83758 18 c 1.5 16 20.083731 3 G 0.75 18 8.6 50,0 127.0 83759 25 G 1.5 16 24.083732 4 G 0.75 18 9,4 61.0 155.0 83760 34 G 1,5 16 27.183733 5 G 0.75 18 10.1 73.0 180.0 83761 41 G 1 .5 16 29.783734 7 G 0,75 18 11,9 93.0 225.0 83762 50 c 1,5 16 31,883735 12 G 0.75 18 14,2 155.0 326.0 83763 61 G 1.5 16 34,683736 18 G 0.75 18 16.6 211.0 457.083737 25 G 0.75 18 20.0 278.0 635.0 83713 2 X 2.5 14 11,183738 34 G 0.75 18 22.4 360.0 805.0 83764 3 c 2.5 14 12,083739 41 c 0,75 18 24.0 454.0 908.0 83765 4G2.5 14 13.483740 50 G 0.75 18 26.2 541.0 1155.0 83766 SC2.5 14 14.683741 61 G 0.75 18 30.0 628,0 1400,0 83767 7 G 2.5 14 17.283768 12 G 2.5 14 21,283711 2x1 17 8.5 48,0 113,0 83769 18 G 2,5 14 24,883742 3G1 17 9.2 61.0 144,0 83770 25 G2.5 14 29.883743 4 G 1 17 9.8 76.0 178.0 83771 34 c 2.5 14 34,483744 5 G1 17 10.7 85.0 205,0 83772 soc 2,5 14 39,083745 7G1 17 12.5 113.0 263.0 83773 61 G 2,5 14 41,083746 12 G 1 17 15,1 195.0 424.0Dimensions and specifications may be changed without prior notice. (RN01lCop. w eightweight ca. kg 1kg/km km256,0 560,0342,0 760,0447.0 945,0575,0 1151,0666,0 1300.0780,0 1500,069.0 144,080,0 160,094,0 210,0114.0 240.0143,0 305,0254,0 482.0314,0 611,0477.0 950,0671.0 1200,0777.0 1400.0911,0 1665.01079,0 1852.081,0 189.0115,0 244,0141.0 296.0188,0 367,0241.0 478,0397,0 622.0556.0 1010,0790.0 1375.01007,0 1893.01498.0 2666,01794.0 3077.0!: NCLUKA...a.

~ HI·TECH~ CONTROLS, INC.(800) 677-8942 I (303) 680-5159Click or Call for a Quotelwww. h itech controls .comJZ-600-Y-CY UL/CSA flexible, number coded, 0,6/1kV,EMC-preferred typeI Rol-lS ITechnical data• Special PVC control cables• Adapted <strong>to</strong> DIN VDE 0276 part 627,DIN VDE 0281 part 13, with insulationthickness for 1 kV type and UL-Std. 758Style 21179• Temperature rangeflexing -soc <strong>to</strong> +80°Cfixed installat ion -40°C <strong>to</strong> +90°C• Nominal voltage u 1000 v• Test voltage 4000 v• Breakdown voltage m in. 8000 V• Insulation resistancem in. 20 MOhm x km• Power rating<strong>according</strong> <strong>to</strong> DIN VDE 0298• Minimum bending radiusflexing 10x cable 0fixed installation Sx cable 0• Radiation resistanceup <strong>to</strong> 80x106 cJ/kg • Coupling resistancemax. 250 Ohm/kmCable structure• Bare copper. fine wire conduc<strong>to</strong>rs.<strong>according</strong> <strong>to</strong> DIN VDE 0295 cl. 5, BS 6360cl. 5 and IEC 60228 cl. 5• Special PVC core insulation Tl2, <strong>to</strong>DIN VDE 0281 part 1, class 43 UL-Std. 1581• Black cores with sequential numberingimprinted in white, <strong>according</strong> <strong>to</strong>DIN VDE 0293• Green-yellow earth core in the outer layer(3 cores and above>• Cores stranded in layers with optimallay-length• PVC-insulated inner sheath TM2, <strong>to</strong>DIN VDE 0281 part 1, class 43 UL-Std. 1581• Braided screen of tinned Cu wires. coverageapprox. 85%• Special PVC outer sheath TM2, <strong>to</strong>DIN VDE 0281 part 1 class 43 UL -Std. 1581• Colour black (RAL 9005) or grey Properties• Extensively oil resistantChemical Resistance - see table TechnicalInformations• Resistant <strong>to</strong> ultra vio let rays • PVC self-extinguishing and flame retardant<strong>according</strong> <strong>to</strong> VDE 0482-332-1-2, DIN EN60332-1-2/ IEC 60332-1 (equivalentDIN VDE 0472 part 804 test method Bl VW1,FT1• The materials used in manufacture arecadmium-free and contain no silicone andfree f rom substances harmful <strong>to</strong> thewetting properties of lacquersNote• G = with green-yellow earth core;x =without green-yellow earth core .• AWG sizes are approximate equivalentvalues. The actual cross-section is in m m 2 •• unscreened analogue type:JZ-600 UL/CSAApplicationWiring cable for measuring and controlling purposes in <strong>to</strong>ol machinery, conveyor belts and production lines. for plant installations. airconditioning and in steel production plants and rolling mills. Suitable for installation for flexible use for medium mechanical stresses withfree movement without tensile stress or forced movements in dry, moist and wet rooms as well as outside

* HI·TECH (800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelJZ-600· Y ·CY UL/CSA flexible, number coded, 0,6/1kV,EMC-preferred typePart No. No. cores x AWC·no. outer o Cop. Weight Part No. No.cores x AWC·no. Outer a Cop. WeightJacket cross-sec. ca. mm weight ca. kg 1 Jacket cr1)ss·sec. ca.mm weight ca. kg 1colour mm 2 kglkm km colour mm 2 kglkm kmblackgrey12369 2 X 1,5 16 10.2 68,0 162,0 12434 2 X 1,5 16 10,2 68.0 162.012370 3 G 1.5 16 10,9 84,0 187,0 12435 3G1,5 16 10,9 84.0 187,012371 4G 1,5 16 12,2 104,0 240,0 12436 4 G 1.5 16 12,2 104,0 240,012372 5 G 1,5 16 13,3 123,0 289,0 12437 5G 1.5 16 13,3 123,0 289.012373 7 G 1.5 16 16,0 180,0 383,0 12438 7 G 1,5 16 16,0 180,0 383,012374 12 G 1,5 16 19.6 284,0 592,0 12439 12 G 1,5 16 19,6 284.0 592,012375 18 G 1.5 16 23.4 390,0 806.0 12440 18 G 1,5 16 23,4 390,0 806,012376 25 G 1,5 16 28.2 521,0 1241,0 12441 25 G 1,5 16 28,2 521,0 1241,012377 2 X 2,5 14 11,5 99,0 272.0 12442 2 X 2,5 14 11,5 99,0 272.012378 3 G 2,5 14 12.2 124,0 298.0 12443 3G2,5 14 12.2 124.0 298.012379 4 G 2,5 14 13.4 170,0 345,0 12444 4 G2,5 14 13.4 170,0 345.012380 5 G 2,5 14 14,9 202,0 427,0 12445 5G2.5 14 14,9 202.0 427.012381 7 G2.5 14 17,9 268,0 561,0 12446 7 G2,5 14 17,9 268,0 561,012382 12 G 2.5 14 21,9 423,0 857,0 12447 12 G 2,5 14 21,9 423,0 857,012383 18 G 2.5 14 26.1 572,0 1355,0 12448 18 G 2,5 14 26,1 572.0 1355.012384 25 G 2.5 14 31.9 740,0 1995,0 12449 25 G 2,5 14 31,9 740,0 1995,012385 2x4 12 14.3 156,0 306.0 12450 2x4 12 14,3 156.0 306,012386 3G4 12 15,1 191,0 391.0 12451 3G4 12 15.1 191,0 391,012387 4G4 12 16,7 236,0 527,0 12452 4 G4 12 16,7 236,0 527.012388 5G4 12 18.6 303,0 700,0 12453 5G4 12 18,6 303,0 700.012389 7G4 12 20.0 394,0 920,0 12454 7G4 12 20,0 394,0 920.012390 3G6 10 17,0 251,0 629,0 12455 3G6 10 17,0 251,0 629,012391 4G6 10 18.7 319,0 731,0 12456 4G6 10 18,7 319,0 731,012392 5G6 10 20,7 421,0 1105,0 12457 5G6 10 20,7 421,0 1105.012393 7G6 10 23,0 561.0 1465,0 12458 7G6 10 23.0 561.0 1465,012394 3 G 10 8 19,6 371,0 1125.0 12459 3G 10 8 19.6 371,0 1125.012395 4 G 10 8 21,9 576,0 1345,0 12460 4 G 10 8 21,9 576,0 1345.012396 5 G 10 8 24.1 620.0 1635,0 12461 5G10 8 24.1 620,0 1635.012397 7 G 10 8 26,8 842,0 2210.0 12462 7 G 10 8 26,8 842,0 2210.012398 3 G 16 6 23.5 540,0 1395,0 12463 3G16 6 23.5 540,0 1395.012399 4 G 16 6 26.4 807,0 1870,0 12464 4G 16 6 26.4 807,0 1870.012400 5 G 16 6 28,8 1394,0 2720,0 12465 SG 16 6 28.8 1394,0 2720,012401 7 G 16 6 31,9 1605,0 3213,0 12466 7 G 16 6 31 ,9 1605,0 3213.012402 3 G 25 4 28.0 820,0 2465,0 12467 3 G 25 4 28,0 820.0 2465.012403 4 G 25 4 32,5 1169,0 2750,0 12468 4 G 25 4 32,5 1169.0 2750.012404 5 G 25 4 35,7 1850,0 3490,0 12469 5G25 4 35,7 1850,0 3490,012405 7 G 25 4 39.0 2140,0 4980,0 12470 7 G25 4 39,0 2140.0 4980.0Dimensions and specifications mav be changed without prior notice. !RN01 1~ 1•1

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ 604-FCY TC TRAY CABLE PVC power cable, exposed run.screened, gooc, GOOV. EMC·preferred type,~~ HELUKABEL JZ-604 FCY TC-ER UL 1277 18AWG I 1 OMM 7C 600V 90C DRY 75C WET SUN RES ( (~ OIL RES 1 DIR BUR FT4 OR 'iU AWN STYLE 2587 CSA AWM 1111 AlB 90C FT-1600V LL 113926Technical data• PVC power cable. screened<strong>to</strong>U L -standard 1277 TRAY CABLE• MultinormAWM-Style 2587 <strong>to</strong> UL-Std. 758 andCSA C22.2 No 210.2 1/11 AlB 9o•c 600 V• Temperature rangedry environmentf lexing -5•c <strong>to</strong> +9o•cf ixed installation -25•c <strong>to</strong> +9o•cwet environmentf lexing -5•c <strong>to</strong> +75•cf ixed installation -25•c <strong>to</strong> +75•c• Nominal voltage <strong>to</strong> UL 600 v• Test voltage 3000 V• Breakdown voltage m in. 6000 V• Insulation resistancemin. 20 MOhm x km• Minimum bending radius10x cable 0• Radiation resistanceup <strong>to</strong> 80x10 6 cJ/kg (up <strong>to</strong> 80 Mradl• coupling resistancemax. 250 Ohm/kmCable structure• Bare copper. fine wire conduc<strong>to</strong>rs.<strong>according</strong> <strong>to</strong> DIN VDE 0295 cl. 5, BS 6360cl. 5 and IEC 60228 cl. 5• Spezial PVC core insulation class 12 B <strong>to</strong>table 50.155 UL-standard 1581,type TFF <strong>to</strong> UL-Std. 62 table 6.2

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ 604-YCY TC TRAY CABLE PVC power cable, exposed run,screened, 90°C, 600V, EMC·preferred typeTechnical data• PVC power cable, screened <strong>to</strong>UL-standard 1277 TRAY CABLE• Multinormalso conforms <strong>to</strong> the following standards:AWM-Stvle 2587 <strong>to</strong> UL-Std. 758lcUU and CSA type TC FT4 <strong>to</strong> C22.2 no 230,CSA C22.2 No 210.2 1/11 AlB 90°C 600 V FT4• Temperature rangedry environmentf lexing -soc <strong>to</strong> +90°Cf ixed installation -25°C <strong>to</strong> +90°Cwet environmentf lexing -soc <strong>to</strong> +75°Cfixed installation -25°C <strong>to</strong> +75°C• Nominal voltage <strong>to</strong> UL 600 v• Test voltage 3000 v• Breakdown voltage min. 6000 v• Insulation resistancem in. 20 MOhm x km• Minimum bending radius10x cable 0• Radiation resistanceup <strong>to</strong> 80x10 6 cJ/kg

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ•602•PUR 80°C, 600V, two approvals control cable~~---iii~=~HEL ~~UKABEL JZ-802-PUR"' AWII14 AWG12.5 QWI 4C E170815 CSA AWIIIII AlB 80"C 800V FT 1 c ETechnical data• Control cable of special-PUR <strong>to</strong> UL CSA AWM1/11 AlB Style 20939 (jacket insulation) andCSA• Temperature rangef lexing -soc <strong>to</strong> +80°Cf ixed installation -40°C <strong>to</strong> +80°C• Nominal voltage <strong>according</strong> <strong>to</strong>UL + CSA 600 V• Test voltage 3000 v• Breakdown voltage m in. 6000 v• Insulation resistancemin 20 MOhm x km• Minimum bending radiusf lexing 7 .sx cable 0f ixed installation 4x cable 0• Radiation resistanceup <strong>to</strong> 100x1os cJ/kg

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a QuotelJZ·602·PUR sooc. GOOV, two approvals control cablePart No. No.cores x AWG·no. outer o Cop. Weight Part No. No.cores xcross-sec. ca. mm weight ca. kg 1 cross-sec.mm 2 kg/km km mm 212537 3 G 35 2 28.6 1008.0 1590.0 12541 4 G 7012538 4 G 35 2 31.7 1344,0 2123.012539 5 G 35 2 35,5 1680,0 2612,0 12542 4G9512540 4 G 50 35,8 1920.0 3058,0 12543 4 G 120Dimensions and specifications may be changed without prior notice. (RN01 lwww. h itech controls .comAWG·no. Outer o Cop. Weightca. mm weight ca. kg 1kg/ km km2/0 41.6 2688,0 4254.03/0 46,0 3648,0 5762,04/0 52,8 4608,0 7280,0.el•l

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ·602·PUR DC/AC sooc. 600V, two approvalscontrol cableIRoHSITechnical data• Control cable of special-PUR <strong>to</strong> UL CSA AWM1/11 A/B Style 20939 (jacket insulation) andCSA• Temperature rangeflexing -soc <strong>to</strong> +80°Cfixed installation -40°C <strong>to</strong> +80°C• Nominal voltage <strong>according</strong> <strong>to</strong>UL + CSA 600 V• Test voltage 3000 V• Breakdown voltage min. 6000 V• Insulation resistancemin 20 MOhm x km• Minimum bending radiusflexing 7 ,Sx cable 0fixed installation 4x cable 0• Radiation resistanceup <strong>to</strong> 100x106 cJ/kg

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ•600 PUR tear and coolant resistant. 0.611kV-= ...-. • '....., ..-. HElUKABEL JZ 600-PUR 4 G 0 5 QM M/.20 AWG cYUus AWM STYLE 20234 1000 V eo•c VW 1 ,·~ .~ __., , ,.._. CSALL113926AWM I/11AI81000V80• CFT1HELUKABEL JZ.IOI...UR 4 G 0,1 QIIIIII20 AWG ~· AWII STYLE 202M 1000 V • •c VW· 1CIA U 113121 AWII 1/11 AlB 1100 V ..-c n1((Technical data• Special PUR control cables Adapted <strong>to</strong>DIN VDE 0276 part 627, DIN VDE 0281part 13, with insulation thickness for 1 kVtype and UL-Std. 758 Style 20234• Temperature rangef lexing -soc <strong>to</strong> +80°Cf ixed installation -40°C <strong>to</strong> +80°C• Nominal voltage Uo/U 0,6/1 kV• Test voltage 4000 v• Breakdown voltage min. 8000 v• Insulation resistancemin. 20 MOhm x km• Power ratingas per DIN VDE 0298• Minimum bending radiusf lexing 7 ,Sx cable 0f ixed installation 4x cable 0• Radiation resistanceup <strong>to</strong> 100x1os cJ/kg • cores stranded in layers with optimallay-length• Outer jacket, special full-polyurethaneadapted <strong>to</strong> DIN VDE 0282 part 10,appendix A, flame retardant <strong>to</strong> UL-Std. 758• Colour black or g rey

* HI·TECH(800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelJZ-600 PUR tear and coolant resistant, 0,6/1kV ~ 1•1Part No. No.cores x AWC·no. Outer e Cop. Weight Part No. No.cores x AWC·no. outer e Cop. WeightJacket cross-sec. ca.mm weight ca. kg 1 Jacket cross· sec. ca.mm weight ca. kg 1colour mm 2 kglkm k.m colour mm 2 kglkm kmblackgrey28272 2 X 2,5 14 9.5 48,0 170,0 28337 2 X 2,5 14 9.5 48,0 170.028273 3 G 2,5 14 10.0 72,0 181,0 28338 3 G 2,5 14 10,0 72.0 181,028274 4 G 2.5 14 11,1 96.0 203.0 28339 4 G 2,5 14 11,1 96.0 203,028275 5 G 2,5 14 12.4 120,0 251,0 28340 5 G 2.5 14 12.4 120,0 251.028276 7 G 2,5 14 15,0 168.0 330,0 28341 7 G 2,5 14 15.0 168,0 330,028277 12 G 2.5 14 18.4 288.0 553,0 28342 12 G 2.5 14 18.4 288.0 553,028278 18 G 2.5 14 22,0 432,0 795,0 28343 18 G 2,5 14 22,0 432.0 795,028279 25 G 2,5 14 26.9 600,0 1110,0 28344 25 G 2,5 14 26.9 600,0 1110.028280 2X4 12 11.4 77,0 190,0 28345 2X4 12 11.4 77,0 190.028281 3G4 12 12.3 115,0 235.0 28346 3G4 12 12.3 115,0 235.028282 4G4 12 13,8 154,0 310,0 28347 4G4 12 13,8 154.0 310.028283 5G4 12 15,3 192.0 410,0 28348 5G4 12 15,3 192.0 410,028284 7G4 12 16,8 269.0 540.0 28349 7G4 12 16,8 269,0 540,028285 12 G 4 12 22.9 461,0 860,0 28350 12 G4 12 22.9 461,0 860.028286 3G6 10 14,1 173,0 370.0 28351 3G6 10 14,1 173,0 370,028287 4G6 10 15,6 230,0 430,0 28352 4G6 10 15,6 230,0 430,028288 SG6 10 17,3 288.0 650,0 28353 5G6 10 17,3 288.0 650.028289 7G6 10 19,3 403,0 860,0 28354 7G6 10 19,3 403,0 860,028290 3 G 10 8 16,5 288,0 660,0 28355 3 G 10 8 16,5 288,0 660,028291 4 G 10 8 18.4 384,0 790,0 28356 4 G 10 8 18.4 384.0 790.028292 5 G 10 8 20.5 480.0 960,0 28357 5 G 10 8 20.5 480,0 960,028293 7 G 10 8 22.5 672.0 1300,0 28358 7 G 10 8 22,5 672.0 1300.028294 3 G 16 6 19,6 461.0 709.0 28359 3 G 16 6 19,6 461.0 709.028295 4 G 16 6 21.7 614,0 1114,0 28360 4 G 16 6 21.7 614,0 1114,028296 5 G 16 6 24.2 768,0 1620.0 28361 5 G 16 6 24,2 768.0 1620,028297 7 G 16 6 25,8 1075,0 1900,0 28362 7 G 16 6 25,8 1075,0 1900,028298 3 G 25 4 24,0 720.0 1450.0 28363 3 G 25 4 24,0 720,0 1450.028299 4 G 25 4 26,9 960.0 1600.0 28364 4 G 25 4 26,9 960,0 1600,028300 5 G 25 4 29.3 1200.0 2050,0 28365 5 G 25 4 29.3 1200,0 2050.028301 7 G 25 4 32.6 1680.0 2900,0 28366 7 G 25 4 32.6 1680.0 2900,0Dimensions and specifications may be changed without prior notice. IRN01 l

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .com08·602 PUR YELLOW sooc. GOOV, two approvals control cableIRoHSIHEWKABEL 08-602 PUR YELLOW 4G2,5 QMM /12548 600 V 001044489 c (Technical data• Control cable of special-PUR <strong>to</strong>Ul Style 21127 and CSA AWM 1111 AlB• Temperature rangeDIN VDEflexing -40°C <strong>to</strong> +90°Cfixed installation -50°C <strong>to</strong> +90°CULflexing <strong>to</strong> +75°Cfixed installation <strong>to</strong> +75°CCSAflexing <strong>to</strong> +80°Cfixed installation <strong>to</strong> +80°C• Nominal voltageDIN VDE Uo/U 3001500 VULICSA U 600 V• Test voltage 3000 v• Minimum bending radiusflexing 6x cable 0fixed installation 4x cable 0• Radiation resistanceup <strong>to</strong> 100x10 6 cJikg (up <strong>to</strong> 100 MradlCable structure• Bare copper, fine wire stranded <strong>to</strong>DIN VDE 0295 cl. 5. BS 6360 cl. 5 andIEC 60228 cl. 5• Core insulation of special thermoplast• Cores colour <strong>to</strong> UL colour code• Colour code1 cores: black2 cores: white3 cores: red4 cores: green5 cores: brown• Cores stranded in layers with optimallay-length• Core wrapping with fleece• PUR outer jacket TMPU <strong>to</strong> DIN VDE 0282part 10, attachment A• Jacket colour yellow (RAL1021 lProperties• Resistant <strong>to</strong> mineral oils, synthetic oils andrefrigerants. UV-radiation. ozon and oxygen• High abrasion resistance• Tear and cut-resistant• Notch resistant• The materials used in manufacturing arecadmium-free and do not contain nosilicone any silicone and free fromsubstances harmful <strong>to</strong> the wettingproperties of lacquersTests• Flame test <strong>to</strong> VDE 0482-332-1-2, DIN EN60332-1-21 IEC 60332-1 (equivalentDIN VDE 0472 part 804 test method Bl, UlVW-1, CSA FT1• Halogen-free <strong>according</strong> <strong>to</strong> DIN VDE 0482part 267 I EN 50267-2-11 IEC 60754-1(eQuivalent DIN VDE 0472 part 815)• corrosiveness of combustion gases<strong>according</strong> <strong>to</strong> VDE 0482 part 267 IDIN EN 50267-2-21 IEC 60754-2 (equivalentDIN VDE 0472 part 813)ApplicationExtremely robust duo-standard flexible control cable up <strong>to</strong> 600V. used in nearly all machines, plants and devices for u.s. and canadianmarkets. Suitable for dry moist and wet areas and outdoor applications with medium mechanical stresses for flexible applications with freemovement without tensile stresses. This PUR control cable is used in <strong>to</strong>ol making machinery, conveyor systems and production lines. in airconditioning, iron. steel and chemical industries.C E= The product is conformed with the EC Low-Voltage Directive 73/231EEC and 931681EEC.Part No. No.cores x AWC·no. Outer e Cop. Weight Part No. No.cores x AWC·no. outer e Cop. Weightcross-sec. ca. mm weight ca. kg 1 cross-sec. ca. mm weight ca. kg 1mm 2 kglkm km mm 2 kg l km km12544 3 X 1,5 16 8,0 43,0 89,0 12547 3 x2.5 14 9,0 72.0 124,012545 4 X 1,5 16 8.6 58,0 108,0 12548 4 X 2,5 14 9.9 96.0 150.012546 5 X 1,5 16 9,3 72.0 130,0 12549 5 X2,5 14 10,9 120.0 184,0Dimensions and specifications may be changed without prior notice. (RN01l

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ-602-C·PUR screened two approvals control cable, 80°C, GOOV.EMC·preferred typeHELUKABEL JZ-802oC-PUR"' AWM 11 AWG/1,1 QMM 4C E170315 C8A AWM 1111 AlB 80"C IOOV FT 1c ETechnical data• Special PUR-insulated <strong>to</strong> UL CSA AWM 1/ 11A/B Style 20939 and CSA• Temperature rangef lexing -soc <strong>to</strong> +80°Cfixed installation -40°C <strong>to</strong> +80°C• Nominal voltage<strong>according</strong> <strong>to</strong> UL+CSA 600 v• Test voltage 3000 v• Breakdown voltage min. 6000 v• Insulation resistancem in. 20 MOhm x km• Minimum bending radiusflexing 10x cable 0fixed installation sx cable 0• Radiation resistanceup <strong>to</strong> 100x10 6 cJ/kg • coupling resistancemax. 2SO Ohm/kmCable structure• Bare copper, fine wire stranded <strong>to</strong>DIN VDE 029S cl. S, BS 6360 cl. 5 andIEC 60228 cl. 5• Special PVC core insulation Tl3, <strong>to</strong>DIN VDE 0281 part 1 and UL-Style 10012• Black cores with continuous whitenumbering <strong>according</strong> <strong>to</strong> DIN VDE 0293• Green-yellow earth core in the outer layer• cores stranded in layers with optimallay-length• PVC-insulated inner sheath VMS <strong>to</strong>DIN VDE 0207 part S• Braided screen of tinned cu wires approx.85% coverage• Full-polyurethaneouter jacket grey Properties• Resistant <strong>to</strong> mineral oils. synthetic oils andrefrigerants, uv-radiation, osygene, ozonand hydrolysis. Conditionally resistant <strong>to</strong>microbes.• The materials used in manufacture arecadmium-free and contain no silicone andfree from substances harmful <strong>to</strong> thewetting properties of lacquersNote• G =with green-yellow earth core;x = without green-yellow earth core .• AWG sizes are approximate equivalentvalues. The actual cross-section is in mm 2 •• unscreened analogue type:JZ-602 PURApplicationULand CSA approved f lexible control cables up <strong>to</strong> 600 V, for all machinery in <strong>to</strong>oling and plant construction, suitable for installation in dry,moist, wet and outdoor environments for medium mechanical loads. Designed for the export-orientated machinery manufacturer, specificallyfor USA and Canada.EMC = Electromagnetic compatibilityTo optimise the EMC features we recommend a large round contact of the copper braiding on both ends.C E= The product is conformed with the EC Low-Voltage Directive 73/23/EEC and 93/68/EEC.Part No. No.cores x AWC•no. Outer o cop. Weight Part No. No.cores x AWC·no. outer ecross-sec. ca. mm weight ca. kg 1 cross-sec. ca. mmmm 2 kglkm km mm 212550 2 x0,5 20 7,7 40,0 93,0 12583 2 X 2,5 14 10,312551 3 G 0,5 20 8,0 45,0 124.0 12584 3 G 2,5 14 10,812552 4G 0.5 20 8.6 52.0 133.0 12585 4 G 2.5 14 11 .812553 5 G 0.5 20 9.2 68,0 153,0 12586 5 G 2,5 14 13.212554 7 G 0,5 20 10,5 93,0 191,0 12587 7 G 2.5 14 15,612555 9G 0.5 20 12,3 134.0 243,0 12588 9 G 2,5 14 18.112556 12 G 0.5 20 13,0 163,0 322,0 12589 12 G 2.5 14 19,2'12557 18 G 0,5 20 15,6 191,0 374,0 12590 18 G 2.5 14 23,012558 25 G 0,5 20 18,2 223,0 436,0 12591 25 G 2,5 14 28.312559 34 G 0,5 20 20,1 284,0 560,()12560 41 G 0.5 20 22,4 336.0 663,0 12592 2 X4 12 12,512593 3G4 12 13,112561 2 X 1 17 8,1 51,0 107,0 12594 4G4 12 14,512562 3G1 17 8.4 56,0 130,0 12595 5G4 12 15,812563 4G1 17 9,1 81,0 155.0 12596 7G4 12 19,012564 5 G1 17 10,0 90.0 181,012565 7G1 17 11.3 101.0 209.0 12597 2x6 10 14,212566 9 G1 17 13,3 161,0 321,0 12598 3G6 10 15,212567 12 G 1 17 13,8 175.0 341.0 12599 4G6 10 16,612568 18 G 1 17 16,2 241,0 473,0 12600 5G6 10 18.412569 25 G 1 17 19,5 342,0 650,0 12601 7G6 10 22.212570 34 G 1 17 22,5 434,0 781,012571 41 G 1 17 24.2 499,0 892,0 12602 3 G 10 8 19.112603 4 G 10 8 21,112572 2 X 1,5 16 8.7 70,0 136,0 12604 5 G 10 8 23,7'12573 3 G 1,5 16 9,2 89,0 165,0 12605 7 G 10 8 26,512574 4 G 1.5 16 10,0 97,0 192,012575 5 G 1.5 16 10,8 111,0 224,0 12606 3 G 16 6 24,212576 7 G 1.5 16 12.9 147,0 273,0 12607 4 G 16 6 27.212577 9 G 1,5 16 14.8 193.0 340.0 12608 5 G 16 6 30,612578 12 G 1,5 16 15,6 256,0 461 ,0 12609 7 G 16 6 33,612579 18 c 1,5 16 18.3 380,0 674,012580 25 G 1,5 16 22,5 544,0 950.012581 34 c 1,5 16 25.1 674,0 1203.012582 41 G 1,5 16 27,3 881,0 1588,0Dimensions and specifications may be changed without prior notice. IRN01)Cop. Weightweight ca. kg 1kglkm km73,0 173,0111.0 220.0141.0 270.0169,0 329.0251.0 428,0326,0 580.0430.0 761.0639,0 1140,0892,0 1551,0116.0 209.0198,0 310,0232,0 456.0275,0 532,0395.0 737,0183,0 318,0242,0 411,0316,0 572,0411,0 732,0570,0 961,0416,0 741,0571,0 988,0690,0 1202,0971,0 1743,0660,0 1088.0821,0 1662,01127.0 2021,01512.0 2720,0Continuation ~!: NCLUII:Aalla.

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comJZ·602·C·PUR screened two approvals control cable, sooc. 600V,EMC-preferred typePart No. No.eores x AWC·no. Outer a Cop. Weight Part No. No.cores x AWC·no. Outer a Cop. Weightcross-see. ca.mm weight ea. kg 1 cross-sec. ea.mm weight ea. kg 1mm 2 kg l km km mm 2 kg l km km12610 3 G 25 4 30.2 830,0 1947,0 12616 5G35 2 41,5 2104.0 4530.012611 4G 25 4 33.3 1170.0 2591.012612 5G25 4 36,8 1430,0 3197,0 12617 4G50 41,8 2210.0 3370,012613 7 G25 4 40.6 2150.0 4530.012618 4 G 70 2/0 47,0 2915,0 4630,012614 3G35 2 33,8 1345,0 2701,012615 4 G35 2 37.7 1690,0 3277.0 12619 4G95 3/0 51,0 3920,0 6114,0Dimensions and specifications may be changed without prior notice. (RN01 l12620 4 G 120 4/0 58,0 5097,0 7417,0

~ HI·TECH~ CONTROLS, INC.JZ-600· YC·PUREMC·preferred typeI Rol-lS!(800) 677·8942 I (303) 680·5159Click or Call for a Quoteltear and coolant resistant. 0,6/1kV, cu-screened,...www. h itech controls .comHElUKABEL JZ-&00 YC-PUR 4 G 0 5 QMM c\\lus AWM STYLE 202ld 1000 V SO" C VW 1·- - CSA ll,l92& AWM 1111 AlB 1000 V 80 C FT1 'HILUKAIIB. JZ.III.Yc-PUR • 8 1,1 Qllll 4:Wua AR I1YI.a .aM tiNY WC VW.t C (CMU.ttaat AR Ill Nil tiNY wcmTechnical data• Special PUR control cables Adapted <strong>to</strong>DIN VDE 0276 part 627, DIN VDE 0281part 13, with insulation thickness for 1 kVtype and UL-Std. 758 Style 20234• Temperature rangeflexing -soc <strong>to</strong> +80°Cf ixed installation -40°C <strong>to</strong> +80°C• Nominal voltage Uo/U 0,6/1 kV• Test voltage 4000 V• Breakdown voltage min. 8000 v• Insulation resistancemin. 20 MOhm x km• Power ratingas per DIN VDE 0298• Minimum bending radiusf lexing 10x cable 0f ixed installation 5x cable 0• Radiation resistanceup <strong>to</strong> 100X10 6 cJ/kg • Coupling resistancemax. 250 Ohm/kmCable structure• Bare copper, fine wire conduc<strong>to</strong>rs, as perDIN VDE 0295 cl. 5, BS 6360 cl. 5 andIEC 60228 cl. 5• Special PVC core insulation Tl2, <strong>to</strong>DIN VDE 0281 part 1, class 43 UL-Std. 1581UL-Style 10012• Black cores with white figure imprints <strong>to</strong>DIN VDE 0293• Green-yellow earth core in the outer layer• Cores stranded in layers with optimallay-length• Oil resistant PVC inner jacket, TM5 <strong>to</strong>DIN VDE 0281 part 1 and class 43 gem.UL-Std. 1581• Tinned copper braided screening, approx.85% coverage• Outer jacket, special full-polyurethaneadapted <strong>to</strong> DIN VDE 0282 part 10,appendix A, flame retardant <strong>to</strong> UL-Std. 758• Colour black (RAL 9005> or grey Properties• High abrasion resistance• High f lexibility• Resistant <strong>to</strong> ultra violet rays• Wear resistant• The materials used in manufacture arecadmium-free and contain no silicone andf ree from substances harmful <strong>to</strong> thewetting properties of lacquersNote• G = with green-yellow earth core;x =without green-yellow earth core.• AWG sizes are approximate equivalentvalues. The actual cross-section is in mm 2 •• unscreened analogue type:JZ-600 PURApplicationExtremely robust. control cable resistant <strong>to</strong> mineral oils and <strong>to</strong> coolant emulsions. In <strong>to</strong>ol machinery, conveyor belts and production lines,for plant installations, air conditioning and in steel production plants and rolling mills. Suitable for installation for f lexible use for mediummechanical stresses with free movement without tensile stress or forced movements in dry, moist and wet rooms as well as outside.Interesting for t he export-oriented machinery plants.EMC = Electromagnetic compatibillityTo optimise t he EMC features we recommend a large round contact of the copper braiding on both ends.C €= The product is conformed with the EC Low-Voltage Directive 73/23/EEC and 93/68/EEC.Part No. No.cores x AWC·no. Outer o cop. Weight Part No. No.cores x AWC·no. outer oJacket cross-sec. ca.mm weight ca. kg 1 Jacket cross-sec. ca.mmcolour mm• kglkm km colour mm•blackgrey28370 2 X 0,5 20 9.0 30.0 131.0 28430 2 X 0,5 20 9,028371 3 G0,5 20 9,3 39,0 154,0 28431 3G0.5 20 9,328372 4 G0.5 20 9,9 52,0 176.0 28432 4G0.5 20 9,928373 5 G 0.5 20 10.6 61,0 204.0 28433 5G0,5 20 10.628374 7 G 0,5 20 12.2 75,0 237.0 28434 7 G 0,5 20 12,228375 12 G 0,5 20 14,7 130,0 323.0 28435 12 G 0.5 20 14,728376 18 G 0.5 20 17.3 170.0 431,0 28436 18 G 0.5 20 17,328377 25 G 0.5 20 20,6 230,0 507,0 28437 25 G 0,5 20 20.628378 2 X 0,75 18 9.4 39.0 143.0 28438 2 X 0,75 18 9,428379 3 G 0,75 18 9,8 57.0 158,0 28439 3 G 0,75 18 9,828380 4 G 0,75 18 10.4 68.0 193.0 28440 4 G 0.75 18 10.428381 5 G 0.75 18 11,1 79,0 231.0 28441 5 G 0.75 18 11,128382 7 G 0,75 18 13,0 96,0 337,0 28442 7 G 0,75 18 13,028383 12 G 0.75 18 15,8 169,0 424.0 28443 12 G 0.75 18 15,828384 18 G 0.75 18 17.9 224.0 568.0 28444 18 G 0,75 18 17,928385 25 G 0,75 18 22,8 292,0 741,0 28445 25 G 0.75 18 22.828386 2 X 1 17 9.9 51.8 158.0 28446 2x1 17 9.928387 3 G 1 17 10,3 67.0 169,0 28447 3G1 17 10,328388 4G1 17 11 ,1 78,0 207.0 28448 4G1 17 11,128389 5G1 17 12,2 94.0 244.0 28449 SC1 17 12.228390 7 G 1 17 14,5 122.0 292.0 28450 7G1 17 14,528391 12 G 1 17 17.4 201.0 472.0 28451 12 G 1 17 17,428392 18 G 1 17 20.7 275.0 634.0 28452 18 G 1 17 20.728393 25 G 1 17 24,8 364,0 861,0 28453 25G1 17 24,8Dimensions and specifications may be changed without prior notice.

* HI·TECH (800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelJZ·600·YC·PUR tear and coolant resistant, 0,6/1 kV. cu-screened.EMC-preferred typePart No. No. cores x AWC·no. Outer o Cop. Weight Part No. No.cores x AWC•no. outer o cop. WeightJacket cross-sec. ca.mm weight ca. kg 1 Jacket cross-sec. ca.mm weight ca. kg 1colour mm 2 kg l km km colour mm 2 kglkm kmblackgrey28394 2 X 1,5 16 10.7 68,0 166.0 28454 2 X 1.5 16 10.7 68,0 166.028395 3 G 1,5 16 11.2 84,0 192.0 28455 3 G 1,5 16 11.2 84.0 192.028396 4 G 1,5 16 12,3 104,0 246,0 28456 4 G 1,5 16 12,3 104,0 246,028397 5 G 1,5 16 13.3 123,0 294,0 28457 5 G 1.5 16 13,3 123.0 294,028398 7 G 1,5 16 16.0 180,0 392,0 28458 7 G 1,5 16 16,0 180,0 392,028399 12 G 1,5 16 19.6 284,0 599,0 28459 12 G 1,5 16 19,6 284,0 599,028400 18 G 1,5 16 23.4 390,0 817,0 28460 18 G 1,5 16 23.4 390,0 817,028401 25 G 1.5 16 28,2 521,0 1261.0 28461 25 G 1,5 16 28,2 521,0 1261,028402 2X2,5 14 11,8 99,0 280,0 28462 2 X 2,5 14 11,8 99,0 280,028403 3 G 2,5 14 12,3 124,0 301,0 28463 3 G 2,5 14 12,3 124,0 301,028404 4 G 2,5 14 13.4 170,0 352,0 28464 4G2,5 14 13.4 170.0 352.028405 5 G 2.5 14 14,9 202.0 433,0 28465 5 G 2.5 14 14,9 202,0 433,028406 7 G 2,5 14 17,9 268,0 569,0 28466 7 G 2,5 14 17,9 268,0 569,028407 12 G 2.5 14 21,9 423,0 864.0 28467 12 G 2.5 14 21,9 423,0 864,028408 18 G 2,5 14 26,1 572,0 1365,0 28468 18 G 2,5 14 26,1 572,0 1365,028409 25 G 2.5 14 31.9 740,0 1997,0 28469 25 G 2.5 14 31,9 740,0 1997,028410 2x4 12 14.3 156,0 310.0 28470 2x4 12 14,3 156.0 310.028411 3G4 12 15.1 191,0 396,0 28471 3G4 12 15,1 191,0 396,028412 4G4 12 16.7 236,0 531,0 28472 4G4 12 16,7 236,0 531.028413 5G4 12 18,6 303,0 704,0 28473 5G4 12 18,6 303.0 704,028414 7G4 12 20.0 394,0 932,0 28474 7G4 12 20,0 394.0 932,028415 3G6 10 17,0 251,0 633,0 28475 3G6 10 17,0 251,0 633,028416 4G6 10 18.7 319,0 742,0 28476 4G6 10 18.7 319,0 742,028417 5G6 10 20,7 421,0 1117,0 28477 5G6 10 20,7 421,0 1117,028418 3 G 10 8 19,6 371,0 1131,0 28478 3 G 10 8 19,6 371,0 1131,028419 4 G 10 8 21,9 576,0 1357,0 28479 4 G 10 8 21,9 576,0 1357,028420 5 G 10 8 24.1 620,0 1646,0 28480 5 G 10 8 24,1 620.0 1646,028421 3 G 16 6 23.5 540,0 1397,0 28481 3 G 16 6 23.5 540.0 1397,028422 4 G 16 6 26.4 807,0 1880,0 28482 4 G 16 6 26.4 807.0 1880.028423 5 G 16 6 28.8 1394,0 2721,0 28483 5 G 16 6 28.8 1394,0 2721,0Dimensions and specifications may be changed without prior notice. IRN01 l~ 1•1

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comMECAFLEX® 500 halogen-free, flame retardant, oil-resistant,uv-resistant, flexible_ ..-·-- _ _....HELUKABEL MEGAFLEx- 500 25 G 1,5 QMM /13427 3001500V E170315 'M AWM STYLE ((20939 c'M AWM 1111 AlB ao·c eoov FT1 halogen-tree FRNC oil resistent 001081280Technical data• Halogen-free flexible control cable, adapted<strong>to</strong>E DIN VDE 0281 part 14, <strong>according</strong> <strong>to</strong>UL-Style 20939, UL-Std. 758• Temperature rangeflexing -3o·c <strong>to</strong> +9o·cf ixed installation -4o·c <strong>to</strong> +9o·c• Nominal voltage Uo/U 3001500 v• Test voltage 3000 v• Minimum bending radiusflexing approx. 10x cable 0fixed installation approx. 4x cable 0• FlexibleAlternate bending test <strong>according</strong> <strong>to</strong> DINVDE 0281 ·2Cable structure• Bare copper, fine wire conduc<strong>to</strong>rs, <strong>to</strong>DIN VDE 0295 cl. 5, BS 6360 cl. 5 andIEC 60228 cl. 5• Core insulation of halogen-free specialpolymer• Black cores with white continuousnumbering <strong>to</strong> DIN VDE 0293• Green-yellow earth core in the outer layer• Cores stranded in layer with optimallay-length• Outer sheath, halogen-free special polymer• Outer jacket colour grey

* HI·TECH (800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelMECAFLEX® 500 halogen-free. flame retardant. oil-resistant.uv-resistant, flexible11§1•1Part No. No.cores x Outer a Cop. Weight AWC·NO. Part No. No.cores x outer e Cop. Weight AWC·NO.cross-sec. ca.mm weight ca. kg 1 km cross-sec. ca.mm weight ca. kg 1 kmmm 2 kg / km mm 2 kg / km13361 34 G 0.5 14,5 163.0 367,0 20 13433 2 X 2,5 7,6 48.0 118.0 1413362 37C0.5 15,0 178.0 381.0 20 13434 3C 2.5 8.3 72.0 151.0 1413363 41 G 0.5 15.8 197.0 417,0 20 13435 4G2.5 9.1 96.0 181.0 1413364 42 G 0,5 15,8 202.0 454.0 20 13436 5 G 2,5 10.2 120.0 224.0 1413365 50G0.5 17.3 240.0 519,0 20 13437 7 G 2.5 12,1 168.0 316.0 1413366 61 G 0,5 19.4 293,0 635,0 20 13438 8G2,5 13,2 192,0 370,0 1413367 65G0.5 19,4 312,0 694,0 20 13439 10 G 2,5 14.7 240,0 451.0 1413440 12 G 2,5 15.2 288,0 499,0 1413368 2 X 0.75 5.2 14.4 47,0 19 13441 16 G 2,5 17.5 384.0 720,0 1413369 3 G 0.75 5,5 21,6 56,0 19 13442 18 G 2,5 18,1 432.0 769,0 1413370 3 X 0,75 5.5 21 ,6 56,0 19 13443 20 G 2,5 18.7 480,0 911 ,0 1413371 4 G 0.75 6,2 29,0 69,0 19 13444 25 G 2.5 22.2 600,0 1047,0 1413372 4 X 0,75 6,2 29,0 69,0 19 13445 30 G 2.5 23.7 720.0 1280.0 1413373 5 G 0.75 6.8 36.0 83.0 1913374 5 X 0,75 6.8 36.0 83,0 19 13446 2X4 9,2 77.0 199.0 1213375 7 G 0.75 8,1 50,0 114.0 19 13447 3G4 9,9 115.0 247,0 1213376 7 X 0.75 8.1 50,0 114,0 19 13448 4G4 11,0 154.0 299.0 1213377 8C0.75 8.9 58.0 136.0 19 13449 5G4 12.1 192,0 369.0 1213378 10 G 0,75 9.6 72,0 172,0 19 13450 7G4 13,3 269.0 463,0 1213379 12 G 0.75 9.9 86.0 183.0 19 13451 8G4 15.9 307.0 601.0 1213380 16 G 0,75 11,5 115,0 241.0 19 13452 10G4 17,3 384.0 698,0 1213381 18 c 0.75 11.9 130.0 266.0 19 13453 12 c 4 18.3 461.0 790.0 1213382 20 G 0.75 12.6 144,0 291,0 19 13454 16G4 20,2 614,0 1130,0 1213383 25 c 0.75 14.1 180.0 374,0 19 13455 18G4 21.8 691,0 1280.0 1213384 30 G 0.75 15,4 216.0 450,0 1913385 34 c 0.75 16.4 245.0 517.0 19 13456 2x6 10.8 115.0 266.0 1013386 37 G 0.75 17.2 260,0 541,0 19 13457 3G6 11.7 173.0 360,0 1013387 41 G 0.75 17,6 296.0 611,0 19 13458 4G6 13.0 230.0 429.0 1013388 42 G0,75 17,6 302,0 621,0 19 13459 5G6 14.5 288.0 529.0 1013389 50 c 0.75 19.8 360.0 742,0 19 13460 7G6 16.0 403.0 631,0 1013390 61 G 0,75 20.9 439.0 853,0 1913392 65 c 0.75 21.5 468,0 909.0 19 13461 2 X 10 14,0 192.0 440,0 813462 3 G10 15,0 288,0 550,0 813393 2x1 5.5 19.2 63.0 18 13463 4 G 10 16.8 384.0 708.0 813394 3G1 6.0 29.0 74,0 18 13464 5G10 18.7 480,0 862.0 813395 3x1 6.0 29.0 74,0 18 13465 7 c 10 20.6 672.0 1124.0 813396 4G1 6,6 38.4 90,0 1813397 4X1 6,6 38.4 90.0 18 13466 2 X 16 16,5 307.0 642.0 613398 5 G1 7.2 48,0 109,0 18 13467 3 G 16 17,6 461,0 830,0 613399 7G1 8.6 67.0 151.0 18 13468 4 G 16 19,7 641 ,0 1060.0 613400 8G1 9.4 77,0 184,0 18 13469 5G 16 21 .9 768,0 1270,0 613401 10G 1 10.4 96.0 224.0 18 13470 7 C16 24.4 1075,0 1794,0 613402 12 G 1 10.7 115.0 243,0 1813403 16 G 1 12.0 154.0 314,0 18 13471 3 G 25 22.5 720.0 1190.0 413404 18 G 1 12.7 173.0 361,0 18 13472 4 G25 25,2 960.0 1594,0 413405 20G 1 13,5 192.0 387,0 18 13473 SG25 27.9 1200.0 2014.0 413406 25 G 1 15.2 240.0 496,0 1813407 34 G 1 17,4 326.0 670.0 18 13474 3G35 25.2 1008.0 1590.0 213408 37 G 1 18.4 355,0 713,0 18 13475 4G35 28,0 1344,0 2200,0 213409 41 c 1 18.9 394.0 784,0 18 13476 5G35 31,0 1680.0 2693.0 213410 42 G 1 18,9 403.0 824,0 1813411 50G1 21.0 480.0 952.0 18 13477 3 G SO 29.5 1440.0 2571,013412 61 G 1 22.2 586.0 1140,0 18 13478 4 G 50 33.4 1920.0 3087.013413 65G1 22.8 628.0 1201.0 18 13479 5GSO 37.2 2400.0 3980.013414 2 x 1,5 6.3 29.0 70,0 16 13480 3G70 37,0 2016.0 3207.0 2/013415 3 G 1,5 6.7 43,0 94,0 16 13481 4G 70 41.2 2688.0 4077.0 2/013416 3 X 1,5 6.7 43.0 94.0 16 13482 5G70 46,0 3360,0 5501,0 2/013417 4 G 1,5 7.3 58.0 112,0 1613418 5G 1,5 8.2 72.0 141,0 16 13483 3G95 41.0 2736.0 4708.0 3/013419 7 G 1,5 9.8 101.0 191,0 16 13484 4G95 46,0 3648.0 5590.0 3/013420 8 G 1,5 10.6 115,0 224,0 16 13485 5G95 50.5 4560.0 6972.0 3/013421 10 G 1,5 11,7 144.0 282,0 1613422 12 G 1,5 12:1 173,0 311,0 16 13486 3 G 120 45,7 3456.0 5515,0 41013423 16 G 1,5 13.6 230.0 392,0 16 13487 4 G 120 50,3 4608,0 7100.0 4/013425 18 G 1,5 14,5 259.0 450,0 1613426 20 G 1,5 15.2 288,0 497,0 16 13488 3 G 150 52.2 4320.0 6279,0 300 kcmil13427 25 G 1.5 17.8 360.0 630.0 16 13489 4 G 150 57.0 5760.0 7781.0 300 kcmil13428 34 G 1,5 19.8 490.0 842,0 1613429 37 G 1.5 20.2 533.0 897.0 1613430 50 G 1,5 23.7 720.0 1277,0 1613431 61 G 1,5 25.3 878.0 1460,0 1613432 65 G 1.5 26.0 936.0 1612,0 16Dimensions and specifications mav be changed without prior notice. (RA031

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comMECAFLEX® 500-C halogen-free, flame retardant, oil-resistant,uv-resistant, flexible, screened, EMC-preferred types- -· c--.lI·HEUIKABEL MEGAFLEX- 500-C 7 G 1.5 QMM / 13552 80GISOOV E170315 - AWM STYLE ( (20838 c'M AWM 1111 AlB eo·c eoov FT1 hlllogan-fnle FRNC o11 ...a.tant 001070281Technical data• Halogen-free f lexible control cable, adapted<strong>to</strong> E DIN VDE 0281 part 14 <strong>according</strong> <strong>to</strong>UL·Style 20939, UL·Std. 758• Temperature rangeflexing -30°C <strong>to</strong> +90°Cfixed installation -40°C <strong>to</strong> +90°C• Nominal voltage Uo/U 300/500 v• Test voltage 3000 V• Minimum bending radiusflexing approx. 10x cable 0fixed installation approx. 4x cable 0• FlexibleAlternate bending test <strong>according</strong> <strong>to</strong> DINVDE 0281-2• coupling resistancemax. 250 Ohm /kmCable structure• Bare copper, f ine wire conduc<strong>to</strong>rs. <strong>to</strong>DIN VDE 0295 cl. 5, BS 6360 cl. 5 andIEC 60228 cl. 5• Core insulation of halogen-free specialpolymer• Black cores with white continuousnumbering <strong>to</strong> DIN VDE 0293• Green-yellow earth core in the outer layer• Cores stranded in layer with optimallay-length• Separating foil• Tinned copper braided screening, coverageapprox. 85%• o uter sheath, halogen-free special polymer• outer jacket colour grey • The materials used in manufacture arecadmium -free and contain no silicone andare free from substances harmful <strong>to</strong> thewetting propert ies of lacquers• LSOH = Low sm oke zero Halogen-free.Properties• Halogen-free• Highly f lame-retardant• Resistant <strong>to</strong> o ils and greases• Resistant <strong>to</strong> UV and weathering• Flexible. abrasion- and wear-resistant• ozone-resistant• Recycleable• Flam e test <strong>to</strong> VDE 0482 part 266-2-4/BS 4066 part 31 EN 50266-2/IEC 60332-3-24• Self -exting uishing and f lame retardant<strong>according</strong> <strong>to</strong> DIN VDE 0482-332-1-2, DINEN/IEC 60332-1 (previously DIN VDE 0472part 804 test method B>• corrosiveness of combustion gases<strong>according</strong> <strong>to</strong> NF X 10-702Halogen-free <strong>according</strong> <strong>to</strong> DIN VDE 0482part 267/ EN 50267-2-1/IEC 60754-1• Sm oke density <strong>according</strong> <strong>to</strong> DIN VDE 0482part 1034-1+2, DIN EN 61034-1+21IEC 61034-1+2, BS 7622 part 1+2 • Oil-resistant <strong>to</strong> VDE 0473 part 811-2-1• hydrolysebestandig nach DIN EN 61234-1• ozone-resistant<strong>to</strong>DIN EN 60811-2-1 /DINVDE 0281-2Note• G = wit h green-yellow earth core;x = wit hout green-yellow earth core .• Also available as a 0,6/1 kV cable underconsideration of economical m inim umquantities. MEGAFLEX® 600• unscreened analogue type:MEGAFLEX® 500ApplicationFor fixed installation or f lexible application, with free movements without forcing which do not constantly recur and without tensile stress.for high m echanical strain.An interference-free t ransmission of signals and pulse in assured by the high degree of screening.As a measuring and control cable primarily in machinery and plant contruction, in building and air-condi<strong>to</strong>ning systems, in warehousing andconverying systems. in ship-building and for regenerative types of energy such as in the construction of wind power stations.Especially well-suited for use in public buildings, such as airports and train stations. where personal injuries and subsequent dam age m ustbe prevented in the event of a fire.EMC = Electromagnetic compatibillityTo optimise the EMC features we recommend a large round contact of the copper braiding on both ends.CE= The product is conformed with t he EC Low-Voltage Directive 73/23/EEC and 93/68/EEC.Part No. No.cores x outer o Cop. Weight AWC·No. Part No. No.cores x outer o cop.cross-sec. ca.mm weight ca. kg 1 km cross-sec. ca. mm weightmm• kglkm mm• kglkm13500 2 X 0.5 5.7 32,1 46.0 20 13508 8 G 0,5 8.5 80,013501 3 G 0.5 6.0 39,2 56,0 20 13509 10 G 0,5 9,3 93,013502 3 G 0,5 6.0 39,2 56,0 20 13510 12 G 0,5 9,6 117,013503 4 G 0,5 6.5 46,1 62.0 20 13511 16 G 0,5 10,7 129.013504 4 G 0.5 6.5 46,1 62.0 20 13512 18 G 0.5 11,2 156.213505 5 G 0,5 7,0 52,1 75.0 20 13514 20 G 0.5 11 ,9 173,013506 5 X 0,5 7,0 52,1 75,0 20 13515 25 G 0,5 13,4 205,513507 7 G 0,5 7,9 68,3 98,0 20Dimensions and specifications mav be changed without prior no tice .

* HI·TECH (800) 677·8942 I (303) 680·5159 www. h itech controls .comCONTROLS, INC.Click or Call for a QuotelMECAFLEX® SOO·C halogen-free, flame retardant, oil-resistant,uv-resistant, flexible, screened, EMC-preferred types11§1•1Part No. No.cores x Outer a Cop. Weight AWC·NO. Part No. No.cores x Outer e Cop. Weight AWC·NO.cross-sec. ca.mm weight ca. kg 1 km cross-sec. ca.mm weight ca. kg / kmmm 2 kg / km mm 2 kg / km13516 2 X 0.75 6,1 39,3 60,0 19 13562 2 X 2,5 8,3 96,4 132,0 1413517 3 G 0,75 6,4 49.4 68,0 19 113563 3 G 2,5 9,0 148,5 168,0 1413518 3 X 0,75 6,4 49.4 68,0 19 13565 4G 2.5 9,8 174,2 195,0 1413519 4G0.75 6,9 57.2 78,0 19 13566 5 X 2,5 10,9 200,8 256.0 1413520 4 X 0,75 6,9 57,2 78,0 19 13567 7 G 2,5 12,9 235,6 345,0 1413521 5 G 0,75 7.4 69,0 95,0 19 13568 8G2,5 13,1 260,0 390,0 1713522 5 X 0,75 7,4 69,0 95,0 19 13569 10 G 2,5 15,2 335,1 482,0 1413523 7 G 0.75 8.6 87,1 130,0 19 13570 12 G 2,5 15.9 441,0 572,0 1413524 7 X 0,75 8,6 87,1 130,0 1913525 8G0,75 9,4 110.0 145,0 19 ~3571 2x4 9,8 135,5 220.0 1213526 10 G 0.75 10,0 140,0 180,0 19 13572 3G4 10,6 178,1 251,0 1213527 12 G 0.75 10.4 151,2 203,0 19 13573 4G4 11,5 220.3 305,0 1213528 16 G 0.75 11,6 183.0 275,0 19 13574 5G4 12.7 328,0 388,0 1213529 18 G 0.75 12,4 207,5 290,0 19 13575 7G4 14,0 355.2 504,0 1213530 20 G 0,75 12,9 238,0 320.0 2013531 25 G 0.75 14.8 275,8 413,0 20 13576 2x6 11,5 175,3 270,0 1013577 3G6 12.4 240,0 351.0 1013532 2x1 6,4 46,3 66,0 17 13578 4G6 13,8 305.7 464,0 1013533 3G1 6,7 56.4 80,0 17 13579 5G6 15.7 441,8 546,0 1013534 3x1 6.7 56.4 80.0 17 13580 7G6 16.6 506.0 670.0 1013535 4G1 7,3 69.7 100.0 1713537 5G1 7,8 85.4 130,0 17 13581 2 X 10 14,9 265,2 461,0 813536 7G1 7,3 69,7 100,0 17 13582 3 G 10 15.9 370.5 574,0 813538 7G1 9.1 107,3 160,0 17 13583 4 G10 17.8 486,0 785.0 813539 8G1 9,9 130,0 197,0 17 13584 5 G 10 19,6 611,2 914.0 813540 10G 1 10,8 140,0 232,0 17 13585 7 G10 21,6 820,5 1308,0 813541 12 G 1 11,2 187,0 260,0 1713542 16 G 1 12,3 218,0 346,0 17 13586 2 X 16 17.2 331,0 670.0 613543 18 G 1 13.2 253,5 382,0 17 13587 3 G16 19,0 497.0 911,0 613544 20G 1 13.8 267,0 440,0 17 13588 4 G 16 20,8 810,0 1105.0 613545 25 G 1 15,8 342,6 540.0 17 13589 5G16 22,9 1050,7 1293,0 613590 7 G 16 25,0 1183,0 2149.0 613546 2 X 1,5 6,6 63,3 88,0 1613547 3G 1.5 6,9 76.2 100,0 16 13591 4 G25 26,2 1280,0 1911,0 413548 3 X 1,5 6,9 76,2 100,0 1613549 4 G 1.5 7,5 96,2 125.0 16 13592 4 X 35 30.4 1690,0 2542.0 213550 5G 1,5 8,4 111,5 158.0 1613552 7 G 1.5 10,0 148,0 210,0 16 13593 4G50 34,6 2315,0 3550.013554 8G 1,5 11 '1 172,0 244,0 1613556 10 G 1,5 12,0 193.0 315,0 16 13594 4G70 41,3 3020,0 4939.0 2/013557 12 G 1,5 12.1 254,5 340,0 1613558 16 G 1,5 14,3 285,1 424,0 16 13595 4G95 46.2 4013,0 6690,0 3/013559 18 G 1,5 14,6 367,7 480,0 1613560 20 G 1.5 15,9 407,1 545,0 16 13596 4 G 120 51.0 5067,0 8453.0 4/013561 25 G 1,5 17,6 492.4 702,0 1613597 4 G 150 59.2 5792,0 9104,0 300 kcmilDimensions and specifications may be changed without prior notice. (RA03)

~ HI·TECH~ CONTROLS, INC.(800) 677·8942 I (303) 680·5159Click or Call for a Quotelwww. h itech controls .comcommand Cable UL (LiYY)command Cable UL (LiYY)Command Cable UL (LiYY·TPHCommand Cable UL (LiYCY)Command Cable UL (LiYCY)Command Cable UL (LiYCY·TP)UL/CSA Data <strong>Cables</strong>Pho<strong>to</strong>: HELUKABEL"