FILTRATION

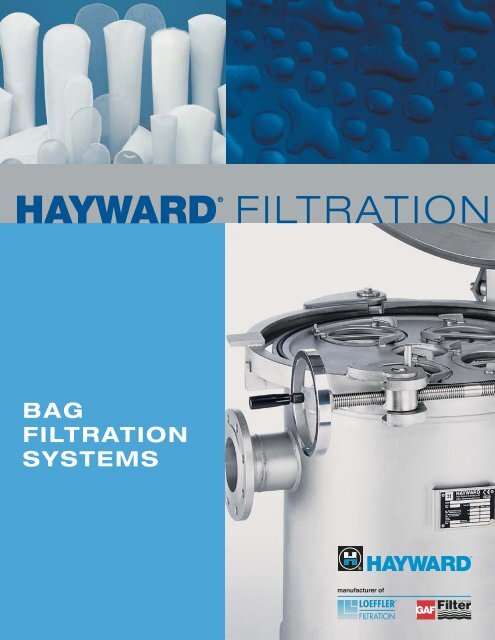

HAYWARD®

HAYWARD®

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HAYWARD®<strong>FILTRATION</strong>BAG<strong>FILTRATION</strong>SYSTEMS

<strong>FILTRATION</strong>A HISTORY OF INNOVATIONIn 1923, HAYWARD ®began manufacturingspecialty metal valves and industrial flowcontrol products. Since then, HAYWARD hasevolved through strategic acquisitions andtechnological advances.Building on more than 75 years of Strainer filterexpertise, in 1996 HAYWARD diversifiedinto Bag and Cartridge liquid filtration byacquiring American Felt and Filter’s Filtrationdivision. In 1998, HAYWARD established itselfToday, HAYWARD Filtration is a truly globalas a key supplier outside of the USA by acquiringGermany’s LOEFFLER ®Filter-Technik. Inorganization manufacturing market-leadingbrands synonymous with performance, qualityand innovation.1999, the acquisition of GAF ® Filter Systemsestablished HAYWARD as the world’s premiersupplier of liquid bag filtration products.The HAYWARD Filtration business comprises 3To understand more about HAYWARD ®Filtrationthe company, its Products, Applicationsand Customer Service, we encourage you tovisit us at:www.haywardfiltration.comcomplimentary technologies; Gas–Liquid Separators,Pipeline Strainers and Bag and Cartridgeliquid filtration systems. With 7 globalmanufacturing facilities, 26 wholly owned subsidiariesand independent distributor network,HAYWARD Filtration actively serves Customersin over 45 countries.2

LLOYD’SQUALIFICATIONSThis brochure details what is now regarded as the most comprehensive, innovative line of Filter Housings and Accessoriesavailable on the market. Over recent years HAYWARD ® Filtration has introduced new concepts to Filter Housing designencompassing the revolutionary QIC-LOCK quick opening cover-lid mechanism (see page 12/13) greatly reducing changeouttimes and a tangential outlet which lowers housing height making it easier to access the filter bags.Probably HAYWARD Filtration’s greatest achievement is the development and implementation of a single global product linemanufactured worldwide in multiple locations to a common design in compliance with local code requirements: In Europe, Asia-Pacific and South America HAYWARD Filtrationis fully qualified to provide pressure housings of Category I-IVunder the Pressure Equipment Directive (PED) (97/23/EC) whichcame into effect May 29, 2002. HAYWARD manufactures housingsto Design Code AD 2000-Merkblätter, the Notified body is TÜVRheinland-Berlin Brandenburg, Conformity Assessment up toModule H1 and G. In North America, South America and Asia, HAYWARD Filtrationis fully qualified to provide the same range of housingsaccording to ASME. Canadian registration numbers,CRN, arealso available.In every location, HAYWARD Filtration Sales and Technical Supportspecialists can review the needs of an installation and recommendthe right combination of hazard category and housing design tomeet any need.REGISTER QUALITY ASSURANCE¥ISO9001Certificate Number 14753973

TABLE OF CONTENTSApplications 1012QIC-LOCK TMConceptMulti-Bag housing with Open and Close cycles of less than 30 seconds!QIC-LOCK TM MAXILINE TM VMBF SEThe user friendly, cost effective bag filter housing for high volumeapplications and processes demanding frequent bag change-out.Ideal for batch process runs and safety filtration.1415MAXILINE TM MBF HEThe user friendly, perfect sealing bag filter housing for safe filtrationand minimized product loss. Ideal for batch processes which demandthe highest quality of filtration.MAXILINE TM MBF HDThe user friendly, perfect sealing bag filter housing for safe filtrationand minimized product loss. Features an economic davitcover design.1617Custom Designed HousingsHAYWARD ® bag filter housing are designed to accommodate a wide range ofpossible standard modifications.TOPLINE TMFilter HousingsThe best filter housing for the most demanding applications.1819SIDELINE TMFilter HousingsMid-priced filter housings for most applications.4

SERIESMAXILINEVMBF SEMAXILINEMBF HEMAXILINEMBF HDTOPLINESIDELINEDUOLINEMODULINEPOLYLINEFLOWLINEECOLINETECHNICAL DATAType*No. Of BagsBag SizeMax. Flow 2 GPMMaterial 1Max. Allowable PressureHousing WeightMax. Allowable Temperature**Housing VolumeInlet Outlet ConnectionTypeVent 4Dimensions In InchesPSI ºF GAL LBS IN A B C D E FVMBF-0402-AB10-040A-UT-11SE 4 2 400 SS 150 250 69 484 4" Flanged 1" 6.00 20.00 10.50 22.00 15.75 68.00VMBF-0602-AB10-060A-UT-11SE 6 2 900 SS 150 250 139 983 6" Flanged 1" 7.25 20.00 13.00 31.50 20.75 80.00VMBF-0802-AB10-080A-UT-11SE 8 2 1750 SS 150 250 141 1023 8" Flanged 1" 8.25 19.00 12.80 31.50 20.50 80.00MBF-0302-AB10-030A-UT-11HE 3 2 230 SS or CS 150 250 40 245 3" Flanged 1" 6.00 22.50 6.40 18.00 12.75 60.00MBF-0402-AB10-040A-UT-11HE 4 2 400 SS or CS 150 250 69 380 4" Flanged 1" 6.00 22.20 7.40 24.00 16.00 68.40MBF-0602-AB10-060A-UT-11HE 6 2 900 SS or CS 150 250 90 440 6" Flanged 1" 7.50 19.50 9.03 24.00 16.50 68.80MBF-0802-AB10-080A-UT-11HE 8 2 1750 SS or CS 150 250 116 644 8" Flanged 1" 8.25 19.00 6.48 30.00 20.50 79.50MBF-0302-AB10-030A-UT-11HD 3 2 230 SS or CS 150 250 40 255 3" Flanged 1" 6.00 22.50 6.40 18.00 12.75 66.00MBF-0402-AB10-040A-UT-11HD 4 2 400 SS or CS 150 250 54 390 4" Flanged 1" 6.00 22.20 7.80 24.00 16.00 68.00MBF-0602-AB10-060A-UT-11HD 6 2 900 SS or CS 150 250 95 460 6" Flanged 1" 7.00 20.00 9.80 26.00 18.50 68.00MBF-0802-AB10-080A-UT-11HD 8 2 1750 SS or CS 150 250 140 655 8" Flanged 1" 8.25 19.00 10.78 30.00 20.50 66.00MBF-1002-AB10-100A-UT-11HD 10 2 2600 SS or CS 150 250 215 1400 10" Flanged 1" 10.00 17.00 13.30 36.00 24.50 70.00MBF-1202-AB10-100A-UT-11HD 12 2 2600 SS or CS 150 250 245 1500 10" Flanged 1" 10.00 17.00 13.80 38.00 24.50 72.00MBF-1402-AB10-100A-UT-11HD 14 2 2600 SS or CS 150 250 311 1800 10" Flanged 1" 11.50 20.00 11.81 42.00 28.00 76.00MBF-1602-AB10-120A-UT-11HD 16 2 3500 SS or CS 150 250 317 1875 12" Flanged 1" 11.50 20.00 11.81 42.00 28.00 76.00MBF-1802-AB10-120A-UT-11HD 18 2 3500 SS or CS 150 250 446 2420 12" Flanged 1" 12.50 22.00 10.69 48.00 31.00 88.00MBF-2002-AB10-140A-UT-11HD 20 2 4500 SS or CS 150 250 454 2505 14" Flanged 1" 12.50 22.00 10.69 48.00 31.00 88.00MBF-2202-AB10-140A-UT-11HD 22 2 4500 SS or CS 150 250 570 2730 14" Flanged 1" 12.50 22.00 13.44 52.00 33.00 92.00MBF-2402-AB10-140A-UT-11HD 24 2 4500 SS or CS 150 250 570 2800 14" Flanged 1" 12.50 22.00 13.44 52.00 33.00 92.00TBF-0101-AB10-020A 1 1 90 SS or CS 150 400 3.5 80 2" Flanged 1/4" 17.70 15.50 1.93 8.62 12.08 53.50TBF-0102-AB10-020A 1 2 180 SS or CS 150 400 7.25 93 2" Flanged 1/4" 17.70 31.00 1.93 8.62 12.08 84.25TBF-0102-AB10-020R-M32B0 1 2 180 SS 150 400 7.25 93 2" Tri-Clamp 1/4" 15.80 32.78 1.93 8.62 12.83 84.25SBF-0101-AB10-020A 1 1 90 SS 150 400 4.75 84 2" Flanged 1/4" 17.70 19.50 3.15 8.62 8.66 54.70SBF-0101-AB10-030A 1 1 90 SS 150 400 4.75 84 3" Flanged 1/4" 17.70 19.50 3.15 8.62 8.66 54.70SBF-0102-AB10-020A 1 2 180 SS 150 400 8.5 102 2" Flanged 1/4" 17.70 35.00 3.15 8.62 8.66 85.50SBF-0102-AB10-030A 1 2 180 SS 150 400 8.5 102 3" Flanged 1/4" 17.70 35.00 3.15 8.62 8.66 85.50SBF-0103-AB21-015N 1 3 25 SS 300 225 0.5 26 1 1/2" NPT 1/4" na 11.77 2.95 4.50 3.50 21.80SBF-0104-AB21-015N 1 4 50 SS 300 225 0.7 29 1 1/2" NPT 1/4" na 17.87 2.95 4.50 3.50 33.90TOPLINE 2 2 180 SS or CS 150 250 16 240 2" Flanged 1/4" 17.70 24.50 1.93 8.62 37.45 84.25SIDELINE 2 2 180 SS 150 250 16 300 2" Flanged 1/4" 17.70 27.50 3.15 8.62 30.82 85.50SIDELINE 2 2 180 SS 150 250 17 330 3" Flanged 1/4" 17.70 27.50 3.15 8.62 33.32 85.50FLOWLINE 2 2 180 SS or CS 150 250 15 200 2" Flanged 1/4" 17.70 28.44 3.34 7.68 37.45 85.50TOPLINE 1+1 2 360 SS or CS 150 250 16 230 2" Flanged 1/4" 17.70 24.50 1.93 8.62 34.32 84.25SIDELINE 1+1 2 360 SS 150 250 16 230 2" Flanged 1/4" 17.70 27.50 3.15 8.62 27.44 85.50SIDLINE 1+1 2 360 SS 150 250 17 300 3" Flanged 1/4" 17.70 27.00 3.15 8.62 29.70 85.50FLOWLINE 1+1 2 360 SS or CS 150 250 15 170 2" Flanged 1/4" 17.70 28.44 3.34 7.68 26.64 85.50PBF-0101-PV/CP10-020A/N/S 1 1 50 PVC/CPVC 150 70 3.6 50 2" Flg/Skt/NPT 1/4" 7.87 13.75 9.20 6.13 10.90 32.63PBF-0102-PV/CP10-020A/N/S 1 2 100 PVC/CPVC 150 70 6.5 75 2" Flg/Skt/NPT 1/4" 7.87 29.75 9.20 6.13 10.90 74.63PBF-0101-PO10-020A 1 1 50 PPL 150 70 6.6 55 2" Flanged 1/4" 3.26 20.75 3.38 10.35 8.50 60.00PBF-0101-PO10-020N 1 1 50 PPL 150 70 6.6 51 2" NPT 1/4" 3.26 20.75 3.38 10.35 6.14 60.00PBF-0102-PO10-020A 1 2 100 PPL 150 70 9.5 68 2" Flanged 1/4" 3.26 36.75 3.38 10.35 8.50 76.00PBF-0102-PO10-020N 1 2 100 PPL 150 70 9.5 64 2" NPT 1/4" 3.26 36.75 3.38 10.35 6.14 76.00PBF-0102-PF07-020A 1 2 100 PVDF 100 80 9.5 100 2" Flanged 1/4" 3.26 36.00 3.88 10.35 8.50 75.25FBF-0101-AB10-020A 1 1 90 SS or CS 150 250 4 30 2" Flanged 1/4" 17.70 20.75 3.34 7.68 6.70 54.90FBF-0101-AB10-020N 1 1 90 SS or CS 150 250 4 30 2" NPT 1/4" 17.70 19.64 3.34 7.68 5.37 54.90FBF-0102-AB10-020A 1 2 180 SS or CS 150 250 7 43 2 Flanged 1/4" 17.70 36.31 3.34 7.68 6.70 85.70FBF-0102-AB10-020N 1 2 180 SS or CS 150 250 7 43 2" NPT 1/4" 17.70 35.19 3.34 7.68 5.37 85.70EBF-0101-AB10-020N 1 1 90 SS 100 250 4 25 2" NPT 1/4" na 19.64 3.24 7.68 5.37 37.00EBF-0102-AB10-020N 1 2 180 SS 100 250 7 38 2" NPT 1/4" na 35.19 3.24 7.68 5.37 68.00EBF-0103-AB10-015N 1 3 25 SS 150 250 0.5 9 1 1/2" NPT 1/4" na 11.77 2.78 4.50 3.50 22.45EBF-0104-AB10-015N 1 4 50 SS 150 250 0.7 11 1 1/2" NPT 1/4" na 17.87 2.78 4.50 3.50 33.84* Type number is for stainless steel construction. Change AB to CS for carbon steel. ** Depending on seal material1) SS = Austenitic Stainless Steel SS 316 and CF8M or better 2) Maximum theoretical flow based on water viscosity, bag specific3) Dimensions for reference only and approximate. Exact dimensions for installation purposes available on request. 4) For details, see available product specific data sheetProduct CodesD – MBF – 04 02 – AC 10 – 050 D5D-DUOLINEM-MODULINEVMBF-MAXILINEMBF-MAXILINETBF-TOPLINESBF-SIDELINEPBF-POLYLINEFBF-FLOWLINEEBF-ECOLINENo. of bags01, 02,04, 08,12, 16,20, 24Bag Size01-short 7"02-short 7"03-short 4"04-short 4"MaterialAB-SS316CP-CPVCCS-Carbon SteelPO-PolypropylenePF-PVDFPV-PVCPressure rating07-100 psi10-150 psi21-300 psiConnection Size050- 1 /2"010-1"012-1 1 /4"015-1 1 /2"020-2"Up to 140-14"Connection TypeA-ANSI FlangeN-NPT Female ThreadR-Tri-ClampS-Socket

APPLICATIONSECOLINEFLOWLINESIDELINETOPLINEMAXILINEPOLYLINEDUOLINEHD HE SECoarse filtration >500 µm ■ ■ ■ ■ ■ ■ ■ ■ ■Medium filtration >10 µm ■ ■ ■ ■ ■ ■Fine filtration

FILTER HOUSINGSDUOLINE TM / MODULINE TM / TOPLINE TMDual Filter HousingsDiscover the flexibility of using multiple housings together as part of a system.2021POLYLINE TMFilter HousingsAll-plastic, rugged PVC, CPVC, PPL or PVDF constructionfor superior corrosion resistance.FLOWLINE TMFilter HousingsVersatile, heavy-duty but cost-effective filter housings.2223ECOLINE TMFilter HousingsLight-weight, economical filter housings.HAYWARD ®Filter Housing AccessoriesOriginal HAYWARD Accessories, Consumables and Spare Parts for safety and reliability.2450Technical InformationPipeline Strainers &Gas Liquid SeparatorsOverview of the entire HAYWARD Strainer lineand HAYWARD Wright-Austin separator line.527

TABLE OF CONTENTS10ApplicationsAn overview of some of the thousands of filtration processes that can be improved andmade more efficient or cost effective with HAYWARD High Performance Filter Bags.26What’s Behind Every HAYWARDPrecision Filter BagA quick look at what makes a HAYWARD high performance filter bag and thetechnology behind it.PROGAF Filter Bags30A revolution in filter bags. PROGAF combines a high-efficiency media with a high capacitypre-filter for effective particulate removal down to the submicron level.34ACCUGAF “Filter BagsHighly efficient filter bags that have an extremely high particle retention efficiency. Applications thatrequire this high filtration efficiency can now take advantage of bag filtration with HAYWARD’sACCUGAF .LOFCLEAR Filter BagsHighly efficient filter bags with a special multi-layer construction that results in a better thannominal efficiency in demanding applications.3638DURAGAF Filter BagsFeatures increased media thickness with finer fibers for high pore volume. Reduced time betweenbag changings improves operating efficiencies and reduces operating costs. Discover howDURAGAF can work better in your application.84

FILTER BAGSCLEARGAF Filter Bags40For food, beverage and pharmaceutical applications, most HAYWARD filter bags can bemanufactured, packaged and stored to meet EEC and FDA requirements.41BANDSEAL Tie-on filter bags for filtration without a vessel.SENTINEL ®42All-welded construction bags for higher filtration efficiency. Patented ringseal for worry-free sealing-assurance.43SNAP-RING ®Sewn construction filter bag for less demanding appli-cations.HAYFLOW 44HAYWARD’s revolutionary new filter element.50Technical InformationPipeline Strainers &Gas Liquid SeparatorsOverview of the entire HAYWARD Strainer lineand HAYWARD Wright-Austin separator line.529

APPLICATIONSTypical Applications for HAYWARDHigh Performance Filter BagsAutomotiveFiltration of pretreatment bath, filtration of E-Coat, topcoatand clearcoat, primer, paint ring line filters, partscleaning fluids, drawing compounds, lubricants, metalworking fluids and pump intake filters.ChemicalCatalyst recovery, removal of pipe scale, polishing ofaqueous process fluids, alkalis, acids and solvents,filtration of emulsions and dispersions, gel removal fromresins. Activated carbon or catalyst removal in the finechemicals industry is a typical example of a demandingapplication in chemical processing. HAYWARD FilterBags meet these application requirements for high filtrationefficiency coupled with long service life and reliability.ElectronicsWafer and chip processing, electronic etching baths,photo-chemical polishing and high-purity water filtrationand prefiltration of various membrane filtration processesto improve their cost effectiveness. HAYWARD Filter Bagsdemonstrate the required purity, efficiency and consistentperformance.Food and BeveragePolishing filtration of wine, spirits and beer, removal ofparticles from edible oils, removal of carbon black fromcellulose, slime removal in gelatins, liquid sugar, thickjuice, corn syrup polishing, starch processing, milkprocessing and soft drinks. Many HAYWARD Filter Bagsconform to FDA and even EEC food processingstandards and can meet the unique and varied demandsof these applications.Metal WorkingFiltration of hydraulic oil, pretreatment system filtration,precious metal recovery, metal working fluids, anddrawing compounds. Parts cleaning machines use ourfilter bags for minimizing residual dirt on parts.10

PetrochemicalsFiltration of lube oils, fuel additives, enhanced oilrecovery, filtration of amine solutions, filtration of glycolfluids, gas purification processes, distillation and crackingprocesses, amine washers, off-shore filter stations,oil drilling and injection fluids.Paint and LacquerRemoval of agglomerates, removal of paint coagulates,solvent filtration, removal of storage contaminants, fillinglines, and paint mixing lines, monomer purification.PharmaceuticalRecovery of expensive active ingredients, catalyst recovery,active carbon purification and removal, filtrationof gelatins, hormones, vitamin extracts, polishing ofherbal mixtures, protein removal from plasma, filtrationof saline solutions.Resins, Plastics,Inks and CoatingsOil and polymer filtration, dispersions, polymerizationbatches, resins for can coatings, plastics compounding,printing ink, plastics processing, paper coatings, highpurity ink-jet fluid filtration.Water TreatmentWell water filtration, water treatment plants, silt removal,pipe scale removal, sand and algae removal from seawater, ion exchange resin recovery, calcium depositremoval, filtration of chemicals used for water treatment,dust removal from cooling tower installations.Surface water filtration is an area traditionally dominatedby cartridge filtration. Now, the high efficiency and longlife of HAYWARD High Performance Filter Bags are acost-effective alternative to expensive cartridges.11

QIC-LOCK ®EconomicalCONCEPTUser friendlyFast · Simple · Efficient · Economical · Safe · User friendly · DurableLow Maintenance · Cost effective · Approved design · High ProductivityTerms that reflect bag filter user expectations in the modern day production environment.SimpMULTI-BAG/MAXILINE TMHOUSINGCLOSE CYCLES IN LESS THAN 30 SEThe revolutionary QIC-LOCK opening mechanism answers all the demands of Bag Filtration usersworking in an environment where productivity and safety are the key priorities. Years of field-basedEffexperience on earlier designs such as the V-clamp “toggle” closure followed by the “ratchet” systemhave all proven the requirement for benefits of rapid opening mechanisms. QIC-LOCK is safe to use, an interlock prevents opening until the housing is entirely vented. QIC-LOCK is simple and fast to operate, standing in 1 position, the operator can rotate thehand-wheel and open the cover, there is no requirement to have full movement and accessaround the housing or the use of any tools as with conventional bolted closures.Cost QIC-LOCK has a rugged design, precision machining assures long-life and repeatable operation,and a special coating protects the spindle surface from wear and corrosion.The design is approved for all pressure housing design codes.QIC-LOCK doesn’t just make life easier for operators; there are significant cost benefits to be realizedwith greatly reduced down times and lower maintenance costs.Safe12

1Filter element change necessary, opening the safetyEasyinterlock ensures simultaneous pressure relief2Rotation of the spindle using a hand-wheelopens the V-clamp into the end positionle3Opening the cover aided byspring assisted mechanismOPEN ANDCONDS!icient4Filterelementchangeeffective5 Closing of the cover6FastClosing of the V-clamp byrotation of the spindle7Closing of the safety interlock,housing is ready to go on-line!13

MAXILINE TM VMBF SEQIC-LOCK MAXILINE VMBF SEThe user friendly, cost effective bag filter housing for high volumeapplications and processes demanding frequent bag change-out.Ideal for batch process runs and high dirt load applications. QIC-LOCK rapid opening mechanism ensures simple, operatorfriendly and safe operation with minimal downtime to increaseproductivity and decrease running costs. Unique 3-point hold down or bayonet fittings ensure high qualityof seal between each filter bag and housing body. Special tool(supplied) ensures simple effective operation. A counter-balanced spring assisted cover-lifting mechanismbalances the cover perfectly giving it a weightless feel. Openingand closing of the cover with the "little finger" is a reality. Positive O-ring sealing offers easy and safe operation. Side inlet and bottom outlet provides easy and full drainage,tangential outlet option available to reduce housing height. Available in carbon steel or Type 316 stainless steel for highcorrosion resistance. Housing volume is optimized to minimize product loss. 6 standard sizes with 4 through to 24 bag housings available(size 02).These value added features:QIC-LOCK spindle mechanismAutomatic safety interlock for venting housingLow profile design with tangential inlet/outlet.Spring assisted cover lifterSee page 5 for dimensions.Give these benefitsOperator friendly, simple, fast bag change-out.Idea for processes requiring frequent bagchanges such as batch processes.Cover cannot be opened if housing is underpressure.Reduces housing height to make bag changingeasier. No need for ladders, stools or catwalks.Quick, easy opening of even the largest sizecovers by a single person.14

MAXILINE TMMBF HEMAXILINE MBF HEThe user friendly, cost effective bag filter housingfor high volume, multiple applicationsand processes. The bag filter housing is designed with a proven swing eye-bolt orsegment clamp closure mechanism. Unique 3-point hold down or bayonet fittings ensure high quality ofseal between each filter bag and housing body. Special tool(supplied) ensures simple, effective operation. A counter-balanced spring assisted cover-lifter balances the coverperfectly giving it a weightless feel. Opening and closing of thecover with the "little finger" is a reality. Positive O-ring sealing offers easy and safe operation. Side inlet and bottom outlet provides easy and full drainage,tangential outlet option available to reduce housing height. Available in carbon steel or Type 316 stainless steel for highcorrosion resistance. Housing volume is optimized to minimize product loss. 6 standard sizes with 4 through to 24 bag housings available(size 02).These value added features:Low profile design with tangential inlet/outletPositive, 3-point bag hold downsSpring assisted cover lifterEye-bolt cover closureGive these benefitsReduces housing height to make bag changingeasier. No need for ladders, stools or catwalks.Individual, bag sealing for by-pass free filtration.Quick, easy opening and closing of even thelargest size covers.Rugged, proven design, easy to use.See page 5 for dimensions.15

MAXILINE TM MBF HDMAXILINE MBF HDThe MAXILINE HD multi-bag filter housing features a cost effective,handwheel operated, davit cover. Loosen the swing bolts,turn the davit handwheel and swing the cover aside. Standard ASME “U” Code Stamp. Tapered, electro-polished stainless steel perforated baskets. Unique 3-point hold-down or bayonet fittings ensure high qualityof seal between each filter bag and housing body. A special tool(supplied) ensures simple, effective operation. Rugged, simple handwheel-operated davit cover makes the HDperfect for cost sensitive applications. Hydraulic-assist davit cover is available as an option. Positive O-ring sealing provides easy, reliable operation. Available in carbon steel and Type 316 stainless steel for highcorrosion resistance. 7 standard sizes with 3 through to 24 bag housings are availablefor size 02 filter bags.These value added features:Hand wheel operated davit coverPositive bag hold downsUp to 24 bags per housingPositive O ring sealGive these benefitsRugged, reliable and very cost effective.Perfect bag to housing sealing for no by-passCan handle very high flow rate / high dirt loadapplicationsNo external leakageSee page 5 for dimensions.1613

CUSTOMCUSTOM DESIGNED HOUSINGSHAYWARD ® bag filter housing are designed to accommodate a wide range of possible standard modificationsMaterial of construction optimised for Chemical and Temperature compatibility:Housing - Carbon steel, Stainless steel in various grades, Hastelloy, Polypropylene and PVDFCoatings - PTFE/FEP, Polyurethane and EpoxySealings - A wide range of Gaskets and O-rings are availableEPOXY coatingProcess operating conditions:Pressure/Temperature - Depending on housing size,up to 1000 psi/750°F, Heating jackets with 200 psi/750°FFlow rates - Up to 4400 gpmQIC-LOCK Lid Closure/Lifting mechanisms:Closure - QIC-LOCK spindle, T-bolt, Swing eye-bolts,Hex-nuts, Stud-bolts,Lifting - Spring, counterbalanced,hydraulic and hand wheel DavitSurface Finish/Connections:Surface - Glass-beaded, Sand Blasted-painted, Electro-polished, Hand-polished, Acid-pickled,Coated (see above)Connections - Standardised flanges and threads (DIN, NPT, ANSI, BSP), Sanitary (Tri-clamp,Milk pipe, IDF, RJT and other sterile types)Approvals and Design Codes:ISO 9001 : 2000 CertificationPED (Pressure Equipment Directive 97/23/EC)AD 2000-Merkblätter, EN 13445, Stoomwezen, CODAP, BS5500, ASME VIII Div 1Notified body: TÜV Rheinland-Berlin Brandenburg CE 0035Modules: Up to module H1 and GSVTI and UDTASME (American Society of Mechanical Engineers)U stamp and UM stamp, CRN (Canadian Registration Number)Skid mounting and mobiles:Skids - In-house engineering capability to couple multiplehousings and or integrated control systemsMobiles - Application specific mobile units e.g. Wine PalletWine Pallet17

TOPLINE TMTOPLINE Filter HousingsThe best filter housing for the most demanding applications. TOPLINE is the finest single bag filter housing available. From itshigh-performance design to its heavy duty investment-castcomponents, everything about TOPLINE is simply the best. TOPLINE's side inlet, flow through the top design results in aminimum headroom of unfiltered liquid for easy bag change-out aswell as providing optimum sealing of the filter bag. For filter bags sizes 01 and 02. Available in carbon steel or Type 316 stainless steel constructionfor high corrosion resistance A smooth, bead-blasted finish, coupled with TOPLINE's minimum2-weld design, makes it easy to completely clean the interior of thehousing. All TOPLINE housings come with HAYWARD's exclusive Five YearWarranty, and the ASME code UM stamp. TOPLINE... for applications too demanding for ordinary bag filters.These value added features:Top inlet with liquid flow through the cover.Cover seals directly onto the filter bagFive year warrantyAdjustable mounting legsGive these benefitsReduced headroom for unfiltered liquid makesbag change-out quick and easy.Perfect sealing for the finest micron by-passfree filtration applications.Years of trouble and maintenance free service.Easier installationSee page 5 for dimensions.18

SIDELINE Filter HousingsMid-priced filter housings for most applications.SIDELINE TM A SIDELINE housing from HAYWARD is a solid, investment-castfilter in the medium cost range. SIDELINE offers a standard eye-bolt closure and a choice of 2˝or 3˝ ANSI flanged connections as standard. For filter bags sizes 01, 02, 03 and 04. SIDELINE's type 316 stainless steel construction means superiorcorrosion resistance and consistent performance, year after year.A smooth, bead-blasted finish, coupled with SIDELINE's minimum2-weld design, makes it easy to completely clean the interior of thehousing. All SIDELINE housings come with HAYWARD's exclusive Five YearWarranty and the ASME code UM stamp. SIDELINE... for all heavy duty industrial applications.These value added features:Side inlet with evacuation coverCover opening direction can be changedin the fieldCompression bag hold downIntegral cover handleGive these benefitsLess messy bag changing, no spillage ofunfiltered liquid.Easily adapts to different piping layouts.Accommodates walls, posts or otherobstructions.360 degree sealing of the filter bag tothe housing.Ergonomical and easy to openSee page 5 for dimensions.19

DUOLINE TM / MODULINE TM / TOPLINE TMDUOLINE Filter HousingsDuplex units for continuous filtration processes.The DUOLINE bag filter system consists of two bag filterhousings (SIDELINE or TOPLINE) fitted together at the inletand outlet by either a butterfly or ball valve assembly. Valveassemblies are connected together by a center post handleassembly in order to guarantee a synchronised change fromfilter A to filter B. A quick turn of the handle diverts the flowfrom one filter housing to the other. The filtration process runscontinuously during bag change-outs.DUOLINE DSBFSee page 5 for dimensions.MODULINE Filter HousingsDouble or modular multibag unit for larger flow rates.The MODULINE filter housings are multibag units assembledfrom two or more standard SIDELINE (MSBF) or TOPLINE (MTBF)housings using standard ellbows, manifolds or T-Pipe modules.The MODULINE filter concept offers greater flexibility, capacitycan be easily increased by adding further modules. MODULINEhousings are fabricated to customer specifications.MODULINE MSBF-02See page 5 for dimensions.MODULINE MTBF-02TOPLINE Dual Filter HousingsCompact 2-bag unit with single cover-lid.The TOPLINE TBF-02 filter housing combines the advantagesof the TOPLINE series with a compact 2-bag design.Features a single cover-lid, eye-bolt closure and standardadjustable leg assembly.TOPLINE TBF-02See page 5 for dimensions.20

POLYLINE Filter HousingsRugged, all plastic housings with a choice of PVC, CPVC, PPLor PVDF construction to meet the needs of all ultra-pure orcorrosive applications.POLYLINE TM POLYLINE filter housings have no metal components to rust,corrode or contaminate the process media. Housings are availablefor size 01 or 02 filter bags (PVDF 02 only).PPL/PVDF modelsfeature externalcover threads With a POLYLINE housing you get extra features at no extra costsuch as a vent/bleed valve installed on the housing cover and anintegral mounting flange for rock solid installation without the needfor support legs. The two bottom pipe connections are interchangeableas outlet or drain, allowing easy modification to in-line or looppiping arrangements to accommodate any installation design. The hand removable, no tools required, spin off cover makes filterbag changing quick and easy. Just a few turns of the cover usingthe built in handle opens and closes the housing with little effort. For applications that require continuous flow, duplex models areavailable. Here, the flow never has to be shut down for bagchange-out. For contamination sensitive or severely corrosivefiltration applications, POLYLINE is your best choice.PVC/CPVC modelsfeature true unionconnectionsDuplex modelsfor continuousflow applicationsWORKING PRESSURE (PSI)Operating Temperature/Pressurefor POLYLINE Filter HousingsTEMPERATURE °C20 30 40 50 60 70 80 90 100 110 120 1301100150100012010080604020060PVCPVDFPPL(Simplex)CPVC & PPL(Duplex)900800700600500400300200100080 100 120 140 160 180 200 220 240 260 280TEMPERATURE °FWORKING PRESSURE (kPa)These value added features:Give these benefitsPVC/CPVCPPL/PVDFAll plastic construction with smooth interiorsurfaces.Easy to clean. Will never rust, corrodeor contaminate the process media.Hand removable spin off cover.Fast bag change out, no tools neededto remove coverTwo outletsAllows either in-line or loop pipingconnections with other outlet usedas a drain.Duplex model availableUsed in applications requiringcontinuous flow.See page 5 for dimensions.21

FLOWLINE TMFLOWLINE Filter HousingsVersatile, heavy-duty cost-effective filter housings. A FLOWLINE housing from HAYWARD ® is the best choice forindustrial, commercial and OEM applications that do not require acode stamp. The standard design is available with threaded orflanged connections. FLOWLINE’s cost-effective design incorporates all of the featuresheavy duty applications demand but in a light-weight construction. FLOWLINE’s special design uses a minimum number of welds for asmooth, easy to clean interior surface. For filter bags sizes 01 and 02. Available in carbon steel and Type 316 stainless steel for highcorrosion resistance. A smooth, bead-blasted finish makes it easyto completely clean the interior of the housing.These value added features:Fabricated constructionCover opening direction can be changedin the fieldAdjustable mounting legsIntegral cover handleGive these benefitsCost effective, lighter weight than acast housing.Easily adapts to different piping layouts.Accommodates walls, posts or otherobstructionsEasier installationMakes it easier to open and close cover.See page 5 for dimensions.22

ECOLINE Filter HousingsLight-weight, economical filter housings.ECOLINE TM An ECOLINE housing from HAYWARD ® has a light-weight design forcommercial, OEM, non-hazardous, low pressure applications thatdo not require a Code Stamp. ECOLINE’s cost-effective design incorporates a handy V-clampclosure and threaded couplings. The lid is fitted with a 1/4" BSPconnection for easy fitting of a vent or gauge. For filter bags sizes 01, 02, 03 and 04. ECOLINE's type 316 stainless steel construction offers superiorcorrosion resistance and consistent performance. A smooth,bead-blasted finish makes it easy to completely clean the interiorof the housing.These value added features:Cost effective designCompression bag hold downV-clamp cover closureSide inlet with evacuation coverGive these benefitsPerfect for cost sensitive applications.360 degree sealing of the filter bag tothe housing.Easy to operate for quick cover removaland closure.Less messy bag changing, no spillage of unfilteredliquid.See page 5 for dimensions.23

ACCESSORIESHAYWARD ®FILTER HOUSING ACCESSORIESOriginal HAYWARD ® Accessories, Consumables andSpare Parts for safety and reliabilityThe wide range of filter housing Accessories from HAYWARDmakes it possible to custom design a housing to the exactrequirements of your application, no matter how complexor unique it may be.01Accessories can be used to improve processes as well asthe application requirement itself. For example, displacementballoons make bag change-out easier, LOFNETICmagnetic inserts extend filter bag life in applications wheremagnetic particles are encountered.Original HAYWARD “added value” Accessories are guaranteedto work with your HAYWARD filter housings as part ofthe system to deliver the highest performance and reliability.01 Restrainer BasketsHeavy duty, electropolished SS 316 perforated plate baskets(included with housing) allows use of filter bags andHAYFLOW elements up to differential pressures of 50 psi.Available in all standard sizes, fitting all HAYWARD bagfilter housings. Specially designed restrainer baskets,including special of construction such as HASTELLOY orEPOXY coated, are available. Standard baskets can beused in combination with adaptor rings for retrofitting othertypes of housings.111002 LOFNETIC MagnetsMagnet assemblies are inserted into the filter bag during filtration,they are a combination of bag positioner fitted in thecenter with a magnetic bar(s). Lifetime is extended byretaining magnetic particles such as chips and fines,preventing deposition onto the filter media. They also retainfiner magnetic dust when using bags of coarser micronrating. HAYWARD magnetic strainers are available in size01 and 02 using one or two SS 316 covered magnetic bars.03 Bag PositionerHighly recommended for all installations, mandatory for some,bag positioners or “bag lock’s” ensure correct positioning ofthe filter bag within the basket and eliminate any “bobbing”up and down movement of the bag caused by uncontrolledback pressure. This avoids any chance of bag bursting.ACCUGAF , PROGAF and LOFCLEAR 500 filter bagsneed to be equipped with a bag positioner. A special newcollar design firmly fixes the element inside the bag duringfiltration. They are available in sizes 01 and 02.24

020304filter bags eliminating the need for expensive pressureaideddraining systems. A special new collar design firmlypositions the balloon inside the bag. The SS 316 balloons'maximum DP is 230 psi, they are available in sizes 01 and 02.06 Manifold ModulesHAYWARD standard pipe modules are available in SS 316.90° elbows, flange reductions, flanged “T” sections andflange manifolds can be easily assembled to make DUO-LINE or MODULINE bag filter versions based on FLOW-LINE , SIDELINE or TOPLINE size 01 or 02 housings.07 Adapter Head for Open filtrationUsed in conjunction with SNAP-RING ® filter bags in gravityfeed open systems. Adapter heads are available in SS 316and polypropylene with a 1.5" NPT connection for pressuresto 20 psi.090508 Gaskets and O-ring sealsAs standard, HAYWARD metal filter housings are fitted withBuna N O-rings, plastic housings have Viton ® O-rings.Other material options such as EPDM, Viton, TFE encapsulatedViton or Silicone rubber are available as are flat gaskets.The options offer a variety of chemical and thermalresistances to meet a multitude of uses and applications.08070609 Mesh StrainersBag filter housings may be fitted with SS 316 mesh linedstrainers in place of baskets to convert them to strainer filters.Mesh strainers are available in four standard sizes: 01,02, 03 and 04, micron ratings are 25, 50, 100, 150, 250,400, 800 µm respectively.04 Leg AssemblyHeight-adjustable leg assemblies are standard for size 01and 02 TOPLINE , FLOWLINE , and SIDELINE housings,and optional for ECOLINE housings. Wall mounting bracketsare also available.05 Displacement BalloonsInserting a displacement balloon inside the filter bag minimizesthe amount of residual liquid present in the filter bagand reduces product loss. This eases the changing of the10 MiscellaneousGauges, Vents, Eye-bolts, Clamp-screws, V-clamps, Centerbolts,Butterfly and Ball Valves are available as accessories orspare parts to fit the various HAYWARD bag filter housings.11 Bag Hold-down RingsThe various ECOLINE , SIDELINE , FLOWLINE , POLYLINE and MAXILINE MBF bag filter housings are fitted with differentbag hold-down rings (included with housing). Theyhold the filter bag securely inside the restrainer basketwhich in turn is positioned correctly within the housing.25

FILTER BAGSHAYWARDPrecision inFiltration.A Whole NewWay to ThinkAbout BagFiltrationSystems26

INTRODUCTIONSetting New Technology BoundariesDemanding or critical liquid filtration applicationsrequire high performance filtration media. This mediamay have to be more efficient, stronger, longer lastingor conform to specific standards. Sometimes, aunique combination of these qualities can be required.HAYWARD has developed a line of filter bags thatmeet these stringent media requirements. The convenienceand economy of liquid bag filtration is nowfeasible for filtration applications that previouslyrequired other, more expensive systems.Change the way you’ve beenthinking about filter bags...andexplore the range of filter bagsdescribed in this catalog. Youmay find solutions to your mostdifficult filtration challengeshere. Today’s bags are capableof performing in applicationsthat, in the past, required morecomplex and expensive filtrationsystems.After you have finished reading about these special filterbags, contact us. Because demanding or criticalapplications can be complex, a HAYWARDApplications Specialist is available to perform a noobligationanalysis of your process. Learn how one ofthese high performance filter bags can work in yoursystem, whether your system already exists or is inthe design stage, and the improvements you canexpect…before you make any commitment.PROGAF , ACCUGAF , LOFCLEAR , DURAGAF , HAYFLOW CLEARGAF ,SENTINEL ® , SNAP-RING ®and BANDSEAL 27

FILTER BAG FEATURESWhat Makes a HAYWARD Filter Bag Better?State-of-the-art media...advance construction...qualitycontrol...customer service...application specialists...inshort, the entire HAYWARD organization teams up tobring you the most advanced bag filtration solutionsavailable. Hayward has applications specialists availablearound the world to help first-hand with difficult, demandingapplications. On-site trials demonstrate the best filterbag for any new application. Expert system softwaremakes system sizing and optimization simple and effective.In short, commitment to our customers packs valueaddedquality into every product we sell.Advanced Filter DesignStarting with unique element design and ending withpatented sealing technology, HAYWARD products deliverperformance in simple or complex applications. Multilayerconstructions, pleated extended surfaces, fullyweldedconstructions and pressure-activated seals areonly some of the features which make HAYWARD filterbags the most advanced in the world. This range ofdesign and construction offers filtration solutions over thefull spectrum of fine filtration applications.Advanced Filtration MediaNo other range of filtration products can bring the widerange of filtration media and construction to either simpleor demanding applications. Progressive structure mediadeliver efficiency and media life not available in any othertechnology. High-purity media styles permit filtrationwithout contamination of the fluid. Heat-stabilizedmonofilament meshes deliver absolute filtration ratings inalmost any fluid. High-quality felts deliver the most costeffectivefiltration available today for straightforwardapplications. In short, full-spectrum performance.Proprietary Fabrication TechnologyWhether sewn or welded, simple or complex, HAYWARDfilter bags are fabricated using the most advanced techniquesand equipment in the world. Highly automatedwelding systems produce consistent, dependable bagconstruction. HAYWARD’s proprietary UNIWELD systemproduces bag seals which are, at the same time, strongand flexible to conform to restrainer baskets. Food-gradeproducts are fabricated in facilities where both the environmentand materials are controlled to assure cleanliness.Repeatable, robust, cost-effective…technologyworking for our customers.Rigorous Quality StandardsEvery HAYWARD filterbag carries its ownpromise of quality toour customers. The QCtag permits full traceabilityof both materialsand processes throughoutfabrication and intoservice. Hayward ISO9001:2000 facilitiesproduce filter bags andvessels to standardsdemanded by demandingindustries. Fromthe simplest sewn filterbag to the most complexmulti-layer construction,the quality is the same. No compromise…theHAYWARD promise to its customers.28

NOMINALABSOLUTEµmgpm0.1 1 10 100 10000 45 90 135 180In this brochure, an application key appears for each bag style. You can use this key toselect a bag based on particle size range and flow rate, for size 02 bags made of standardfilter bag material.COMPASS Expert SystemSoftwareSelect a filter…size and optimize asystem…search for your application.COMPASS brings over 30 years ofapplication success to the fingertips ofeach HAYWARD Filtration Specialist.This breadth of experience is availablein a customer’s facility or over thephone, to provide rapid accurateestimates of system performance.Worldwide Customer SupportHAYWARD has manufacturing facilitiesand customer support personnel locatedin North America, South America,Europe, Asia, Africa and Australia. Thereare 26 HAYWARD Regional SalesOffices and an independent, professionaldistribution network to serve theneeds of our customers in 45 countries.Throughout the purchase, installation,and start-up of your HAYWARDFiltration System, a HAYWARD representativeis always available to insure itsperformance.THE CONTAMINANT SPECTRUM OF BAG DESIGNContaminant Particle SizeMicro Filtration Fine FiltrationCoarse Filtration0.1 micron1 micron 10 micron 100 micron 1000 micronPROGAF Bag FiltersACCUGAF Bag FiltersLOFCLEAR Bag FiltersMonofilament Bags/SNAP-RING ® BagsSENTINEL ® Felt BagsDURAGAF Felt BagsCLEARGAF Felt Bags FiltersHAYFLOW THE CONTAMINANT SPECTRUM OF MEDIAContaminant Particle SizeMicro Filtration Fine FiltrationCoarse Filtration0.1 micron1 micron 10 micron 100 micron 1000 micronMeltblown Precision Media• LOFCLEAR for purity and performance• ACCUGAF for absolute filtration• PROGAF for long life & unequaled filtrationMonofilament Mesh• Accurate, absolute• High precisionHayward Precision Felts• Standard Needlefelt• DURAGAF extended life• CLEARGAF for purity• HAYFLOW THE CONTAMINANT SPECTRUM OF FILTER SEALSContaminant Particle SizeMicro Filtration Fine Filtration Coarse Filtration0.1 micron1 micron 10 micron 100 micron 1000 micronBANDSEAL • Simple, effectiveSNAP-RING ®• Versatile, low-cost• Wide range of mediaSENTINEL ® CLICK-Seal• “The Best in the Business”• Seal improves with higher differential pressure• Wide fluid and temperature compatibilityREGISTER QUALITY ASSURANCE¥LLOYD’SISO9001Certificate Number 147539729

PROGAF The Filter Bag that Works BetterThan a Filter CartridgePROGAF filter bags bring a new, high-performance alternativeto applications requiring absolute filtration.PROGAF’s progressive density depth filtration delivershigh efficiency (up to 99.98%) and long life with all theconvenient features of a bag filter. In comparison withother filtration technologies, PROGAF delivers loweroperating costs while retaining the ease of change-outtypical of a bag filter.Welded Construction for SuperiorPerformanceAll PROGAF High Performance Filter Bags feature 100%welded construction for better filtration performance. Thisconstruction ensures that nothing bypasses the processmedia through holes in the fabric created from sewing thematerial. HAYWARD’s proprietary welding technologyproduces a super-strong seam that stands up to the mostdemanding applications.The SENTINEL plastic step-ring seal provides a sealbetween the filter vessel and the PROGAF Filter Bag.As the pressure differential rises inside the vessel,the seal becomes more efficient.PROGAF Filtration RatingsFilterModelPGF 50PGF 51PGF 55PGF 57Particle Size at Common Removal Efficiencies (µm)>60%->80@0.1518>90%-.3313>95%.15.45616>99%.45.51020>99.9%Filtration efficiency confirmed by independent test laboratory121225∆P (psi)Size 02@ 45 gpm3.62.50.90.3PROGAF Filter Bags Seal Betterin Critical ApplicationsThe patented SENTINEL provides a flexible, chemicallyresistantseal which adapts to any filter vessel. Thisunique design employs a pressure-activated sealing lipwhich responds to increases in differential pressure.As the pressure increases,the seal of the ring improves,guaranteeing bypass-freeperformance over all ranges ofpressure, temperature and micronrating. The elevated bag handlesmake removal quick and easy.Unique ProgressiveDensity Media StructurePROGAF filter bags utilize anadvanced media structure developedspecifically to deliver bothlong life and absolute filtration.PROGAF’s progressive densitydesign uses up to 12 layers ofmedia which become finer andfiner as fluid passes through. Theresult is a gradual removal of con-30

ABSOLUTEµmgpm0.1 1 10 100 10000 45 90 135 180taminant without any single layer blinding prematurely.Application and laboratory tests confirm that PROGAFbag filters deliver longer service life and lower operatingcosts than any other renewable filter element. The 100%polypropylene construction provides pure, silicone-freematerials in an economic, self-contained, easily disposablefilter bag.Filtration Efficiencies Of Up To 99.98%PROGAF High Performance Filter Bags from HAYWARDhave performance efficiencies of up to 99.98%….trueabsolute filtration. In many filtration applications of 1micron and above, PROGAF Filter Bags can replaceexpensive cartridge filtration systems and provide betterperformance while saving time and money. Ask yourHAYWARD Filtration Specialist for “real world” documentedcase histories, illustrating how PROGAF FilterBags have performed in applications similar to yours.Choose Just the Filtration EfficiencyYour Application NeedsPROGAF Filter Bags are available in efficiency codes of50, 51, 55 and 57. To select the perfect PROGAF FilterBag for your application, choose the micron retention efficiencylevel you need on the left side of the chart at particlesize in microns at the bottom. Next, locate the bagefficiency code (identified by the colored lines) that isclosest to that point. There you have it: the most costeffective filter bag for your critical filtration application.The PROGAF DifferenceOrdinary standard filter bags are made from needledfelt media that has a fiber structure that is not as fineand precise as the filtration grade melt blown media usedfor PROGAF Filter Bags. The needled fibers are muchlarger in size and spaced much further apart, yieldinga lower efficiency. PROGAFFilter Bags have beendesigned to deliver calibratedfractional efficiency onvery small particles, down toless than one micron. Thebags feature a completelywelded construction andthe unique, patented SEN-TINEL Sealing Ring For apositive by-pass free seal.And all PROGAF Filter Bagshave a round bottom shapefor increased pressure stability.Unique layeredconstruction structure31

FLOWLarge particles trapped incoarse outer layersMedia gradually becomesfiner through the depth ofthe structureSmall particles trapped infiner inner layersFiltration media made-up of many different layers ofgraded density melt-blown polypropylene. Particulatematter is removed progressively throughout the media,resulting in a more efficient removal mechanismSome Typical PROGAF ApplicationsAll materials used in the construction of PROGAF FilterBags, including the multilayer melt-blown polypropylenemedia, are FDA/EC listed materials that meet theirrequirements for food contact applications. But food orbeverages are not the only applications that can takeadvantage of PROGAF’s high filtration efficienciesand capacity retention. The pharmaceutical, microelectronics,chemical, food, ink and paint, and watertreatment industries can also use PROGAF HighPerformance Filter Bags.Chemical and Pharmaceutical IndustriesDemanding filtration in high-purity industries are theapplications PROGAF was made for. Media capable ofremoval to 2 µm absolute with long service live is essentialfor activated carbon removal or catalyst recovery. Gelremoval requires a deep matrix of fine fibers. A PROGAFbag is ideally suited for each of these applications.Available in four filtration ratings, one of the PROGAFbags will deliver just the needed performance.Water FiltrationWater filtration applications have traditionally beendominated by cartridge filtration. Following extensiveworldwide trials, PROGAF 51 has demonstrated a log 3.5reduction of impurities in these demanding applications.Micro-ElectronicsThese applications typically require chemicals that areconstantly filtered to extremely low levels of particlecontaminant. PROGAF’s special profile, with its highefficiency media and graded density structure, providesperformance characteristics superior to that of traditionalcartridge type filtration. PROGAF out-performs cartridgesin terms of dirt-holding capacity, service life, and cost.Membrane prefiltration significantly reduces the SDIvalues in water filtration.Compare PROGAF to Filter Cartridges andSee the DifferenceThe two charts on the next page graphically illustrate theadvantages of PROGAF High Performance Filter Bagsover different types of filter cartridges. PROGAF FilterBags and filter cartridges come in many shapes and sizes.Compare PROGAF Filter Bags with their cartridge equivalentin material, micron rating and industry qualifications.Progressive structure of PROGAF filter bags deliversoperating differential pressure which starts and remainslower during filter life than other comparable filters. Thechart shown here illustrates the results of actual comparisontests made against two common styles ofcartridge filters: depth-loading and pleated polypropylene.During laboratory loading tests, the PROGAFfilters remained at the lowest differential pressure of any32

of the three over the life, illustrating the effectiveness ofthe progressively structured media.OPERATIONALCONSIDERATIONSBag PositionerTo ensure proper performance, PROGAF Filter Bags mustbe used with the HAYWARD Bag Positioner. Using themtogether aids bag insertion into the filter housing andassures correct alignment of the bag inside the restrainerbasket, prevents the bag from being pushed out of therestrainer basket in case of reverse flow, and makes bagremoval easier.Pre-Wetting in Aqueous SolutionsPROGAF filter bags are fabricated from fine polypropylenefiltration media. This material is hydrophobic, whichmeans that water will not wet the surface of the fibers.Therefore, a fluid with lower surface tension must first beused to wet the fibers, as well as cartridge filters madefrom this material. Prior to installation, you must firstimmerse the bags for a few minutes in a wetting solutioncompatible with the process fluid. After the fibers are wet,water is drawn in by capillary action. Full details abouthow to install and pre-wet PROGAF Filter Bags areprovided in the installation instructions.PRODUCTCODESPROGAF PGFBag MaterialE - Mesh CoverE-PP Sentinel ®RingBag/Box Box Size (in.)04 32 x 12 x 1451 E 02 E O 04XMicron Rating µmBag Cover LayerBag Size Collar/Ring Type Bottom Shape PackagingPROGAF Range50 5155 57Code Size Area02 7 x 32 inches 5.2sqftRound Bottom33

ACCUGAF ACCUGAF , Filter Bagsfor Applications DemandingEfficiency >99%The ACCUGAF filter bag from HAYWARD pushes the boundaries of bagfiltration technology far beyond traditional designs. With efficiencies>99%, each ACCUGAF model provides cost-effective filtration solutionsfor demanding applications. The five models assure users that particlesfrom the range of 1-25 microns can be removed effectively while deliveringlong service lifeHigh-Efficiency PerformanceACCUGAF filter bags feature:• 100% welded seams• HAYWARD patented SENTINEL seal ring• Meltblown filtration media in polypropylene or polyester• No additives, such as resins, binders or surface treatmentsFDA Compliant MaterialsACCUGAF filter bags are constructed entirely of materials compliant toFDA requirements for materials in contact with food. All materialsconform to US Code of Federal Regulations 21 CFR Part 177 and ECDirective 90/128/EEC.*ApplicationsAlthough ideally suited for food and beverages, ACCUGAF filter bags willdeliver equal performance an a wide range of demanding applicationssuch as:• Beer, wine, spirits and beverage filtration• Fine particle removal in parts cleaning• Final filtration of lacquers• Final filtration of vinegar• Activated carbon removal in process systems• Final filtration of hydraulic oils and lubricantsACCUGAF Filtration RatingsPolyester Polypropylene MaterialFilterModelAGF 51AGF 53AGF 55AGF 57AGF 59AGFE 51AGFE 55AGFE 57Particle Size at Common Removal Efficiencies (µm)>60%0.20.812100.212>90%0.6124250.624>95%0.8235300.835>99%1.53510251.5510>99.9%5415253551525∆P (psi) Size 02@ 45 gpm1.303.200.730.600.441.300.730.60Max Op.Temp(°F)190190190190190320300300Filtration efficiency confirmed by independent testing laboratory.*Polypropylene only34

ABSOLUTEµmgpm0.1 1 10 100 10000 45 90 135 180OPERATIONALCONSIDERATIONSRetention EfficiencyBag PositionerACCUGAF filter bags must be used with the HAYWARDbag positioner. This eases insertion and assures correctalignment of the filter bag inside the restrainer basket. Inaddition, the filter bag will be protected against damageto inadvertent back-flow.Pre-Wetting in Aqueous SolutionsACCUGAF polypropylene filter bags are fabricated frommicrofiber filtration media. These materials are hydrophobic,indicating that water will not wet the fiber surfaces.As will all other fine polypropylene filters, a lower surfacetension fluid (wetting agent) must be used to wet themedia prior to introducing water. Prior to service, the filterbags must be immersed in a wetting solution compatiblewith the process fluid. After wetting, an aqueous fluid willbe drawn into the media through capillary action. Fulldetails about installation and wetting are provided withevery box of ACCUGAF filter bags.ACCUGAF Filter Bags, are available in retention codes of 51, 53, 55, 57, and 59.To select the perfect ACCUGAF Filter Bag for your application use the chart andchoose the retention efficiency level you need on the left side of the chart atparticle size in microns at the bottom. Next find which bag efficiency code(identified by the colored lines) is closest to that point. There you have it, themost cost effective filter bag for your critical filtration application.Flow Rate DataPRODUCTCODESAGF: polypropylene melt-blownAGFE: polyester melt-blownACCUGAF AGF: polypropylene melt-blownAGFE: polyester melt-blownAGFBag MaterialE: Polypropylene MeshR: Polyester MeshE: PP SENTINEL ® RingH: Hytrel SENTINEL ® RingBags/Box Box Size (inches)01/02 10M 19 x 12 x 1453 E 02 E O 10MMicron Rating µmAGF AGFE51 5153 -55 5557 5759 -Bag Cover LayerBag Size Collar/Ring Type Bottom Shape PackagingCode Size Area01 ø 7 x 17 inches L 2.6 sqft02 ø 7 x 32 inches L 5.2 sqftround bottom35

LOFCLEAR Cost Effective FilterBags for AbsoluteFiltration ApplicationsLOFCLEAR filter bags now make absolute filtration viablein many applications where only standard bags could beused due to cost constraints. Made from 100% purepolypropylene materials compliant with food requirements,LOFCLEAR filter bags contain no leachables orlubricants such as silicone oils. In addition, their excellentoil adsorbancy makes LOFCLEAR filter bags ideallysuited to the oil removal needs of the paint and coatingsindustries.Two Series to Match Filters to ApplicationsLOFCLEAR filter bags are available in two styles, Series100 and Series 500. These two styles make it possible tomatch the requirements of a wide range of applications,depending on the needs for efficiency and long life. TheSeries 100 filters use a multi-layer construction for applicationswhere high efficiency is of prime importance. TheSeries 500 filters utilize a patent pending pleated constructionto increase surface area for applications requiringhigh dirt capacities and long life.Perfect for Removal of Gelatinous MaterialsLOFCLEAR filter bags have proven to be highly effectivein the removal of gelatinous contaminants. The combinationof deep microfiber filtration media breaks up gels andLOFCLEAR Filtration RatingsFilterModelParticle Size at Common Removal Efficiencies (µm) ∆P (psi) Size 02@ 45 gpm>60% >90% >95% >99%113/123 0.51240.36114/124 0.75 2350.30115/125 1.5 3.58100.15116/126 2613 15

ABSOLUTEµmgpm0.1 1 10 100 10000 45 90 135 180LOFCLEAR Series 500 Filter BagsLOFCLEAR Series 500 Filter Bags have an all-weldedmulti-pleated construction for high efficiency and longlife. This series of bags has a pleated prefiltration layerand a complex design of final filtration layers, allowing theremoval of difficult-to-filter gels and deformable particleswith a high capacity of solids loading. The outer webcovering eliminates any downstream fiber migration.LOFCLEAR Series 500Filter Bags are availablein fourdifferent efficiencyratings so you canchoose your exactrequired filtration efficiency.LOFCLEARFilter Bags have filtrationefficiencies from95 to 99%, with a dirtholdingcapacity ofover 2 pounds.Among the many applications for LOFCLEAR Series 500Filter Bags are oils, slurries, dilute oil removal, re-circulatingbatch systems, and systems with heavy contamination.A pleated prefilter provides a verylarge surface (about 32 sq ft) tocollect gels and solids before itreaches the final filter layers.PRODUCTCODES100 seriesLOFCLEAR LCRBag MaterialT-Spun-bondCoverE-PolypropyleneSENTINEL ® Ring123 T 02 E 25LMicron Rating µmBag Cover LayerBag Size Collar/Ring Type PackagingLOFCLEAR Range113 123 130114 124 135115 125116 126118 128119 129Code Size01 ø 7 x 17 inches L02 ø 7 x 32 inches LBags/Box Box Size25-50 LPRODUCTCODES500 seriesLOFCLEAR LCRBag MaterialT-Spun-bondCoverZ-Santoprene ®SENTINEL ® Ring522 T 02 Z 04XMicron Rating µmBag Cover LayerBag Size Collar/Ring Type PackagingLOFCLEAR Range522 527525 529Code Size02 ø 7 x 32 inches LBags/Box Box Size4 X37

TOPLINE TMTOPLINE Filter HousingsThe best filter housing for the most demanding applications. TOPLINE is the finest single bag filter housing available. From itshigh-performance design to its heavy duty investment-castcomponents, everything about TOPLINE is simply the best. TOPLINE's side inlet, flow through the top design results in aminimum headroom of unfiltered liquid for easy bag change-out aswell as providing optimum sealing of the filter bag. For filter bags sizes 01 and 02. Available in carbon steel or Type 316 stainless steel constructionfor high corrosion resistance A smooth, bead-blasted finish, coupled with TOPLINE's minimum2-weld design, makes it easy to completely clean the interior of thehousing. All TOPLINE housings come with HAYWARD's exclusive Five YearWarranty, and the ASME code UM stamp. TOPLINE... for applications too demanding for ordinary bag filters.These value added features:Top inlet with liquid flow through the cover.Cover seals directly onto the filter bagFive year warrantyAdjustable mounting legsGive these benefitsReduced headroom for unfiltered liquid makesbag change-out quick and easy.Perfect sealing for the finest micron by-passfree filtration applications.Years of trouble and maintenance free service.Easier installationSee page 5 for dimensions.18

NOMINALµmgpm0.1 1 10 100 10000 45 90 135 180How much longer will a DURAGAF Filter Bag last in your application?Extended Life Feltfiner fibersmore poresthicker mediaSurface of Extended Life Feltno fiber releasefull flow through surface channelsPRODUCTCODESDURAGAF POXL: PolypropylenePEXL: PolyesterPOXLF: Polypropylene Food GradePEXLF: Polyester Food GradePOXLBag MaterialP: PlainE: Polypropylene SENTINEL Ring,Welded (POXL)/(POXLF)H: Hytrel SENTINEL Ring, Welded (PEXL)Z-WW: Santoprene SENTINEL Ring,Welded (PEXLF)50 P 01 E 30LMicron Rating µmBag Cover LayerBag Size Collar/Ring Type PackagingPOXL/PEXL PEXLF POXLF1 5 1 510 25 5 1050 100 10Code Size01 ø 7 x 17 inches02 ø 7 x 32 inchesBags/Box Box Size (mm)L: Large39

CLEARGAF CLEARGAF Fully Compliantand Approved for Food andBeverage ServiceCLEARGAF Features Deliver Advanced Benefits• Compliant materials assure compatibilitywith all food applications. Sewn bags usespecial lubricant-free thread• Independent verification guaranteesconformity to EC and FDA requirements• Low-migration media minimizessubstances introduced to fluids• SENTINEL ® Ring Bag Seals eliminate fluidbypass• All-welded construction eliminates fluidbypass through needle holes on felt andmulti-layer filter bags• Controlled production eliminatescontamination from handling andenvironmental conditions• Single packaging keeps bags free fromcontamination during shipping, storageand installation• Special handling & storage ensures thatthere is no contamination after packagingCLEARGAF is the first and only series of filter bags specificallydesigned for the requirements of the food, beverageand pharmaceutical industries. Comprised of several filterstyles, CLEARGAF is the only filter bag to deliver:- Fully FDA compliant materials per 21CFR177- Fully EC compliant per 90/128/EEC- Independent testing and certification- Special single packaging and warehouse controlCLEARGAF Filter Bags for DirectContact with FoodstuffsFilter Bags are widely used for the filtration of fluids thatare directly or indirectly used as foodstuffs. In most applications,these types of filters must be carefully selectedto ensure that foodstuffs are not contaminated from theiruse. Most materials used to manufacture disposablefilters, including bag filters and cartridge filters, are polymers,which are generally selected for their purity in theapplication. Many of these materials, however, containmaterials that can diffuse out of the plastic into theprocess fluid. This effect, known as migration, can lead tofoodstuff contamination. For this reason, the use of polymersis often limited to products such as CLEARGAFFilter Bags, which are made from materials that havebeen documented as safe in food applications.CLEARGAF Filter Bags conform to both US FDA andEuropean EC regulations. The difference between theFDA and EC regulations is one of degree. FDA regulationlimits on migration are proportional to weight. EC limits,however, are based on area, and must be demonstratedin tests on finished articles. For heavy material, theEC limits can be up to 50 times more restrictive thanthe FDA ones.Independent VerificationYou can be sure all CLEARGAF Filter Bags meet theserequirements, because they have been evaluated, testedand certified for EC migration performance by an independentfood research institute. CLEARGAF FilterBags are also made only from materials listed in the USCode of Federal Regulations Title 21 Part 177. No othermaterials are added during fabrication.Special Manufacturing and PackagingCLEARGAF Filter Bags are manufactured under specialconditions to ensure that they contain no contamination.Immediately after manufacture, each bag is individuallysealed in protective plastic packaging to keep themcontamination-free. HAYWARD has special warehousingfacilities for CLEARGAF Filter Bags to further protectthem during storage. No other manufacturer goes tothese lengths to ensure the quality of their food gradefilter bags. For less demanding food and beverageapplications, HAYWARD offers a line of cost effectivefilter bags that are appropriate for many applications.40

ABSOLUTE /NOMINALµmgpm0.1 1 10 100 10000 45 90 135 180SelectionChartMax.Temp(°F)SizesAvailable Grades01 02 03 04 1 5 10 25 50 80 100 150 200 250 400 600 800RingStylePEF285ZPEXLF285ZPOF*195EPOXLF*195ENMOF285ZAGF*19551 - 53 - 55 - 57 - 59EPGF*19550 - 51 - 55 - 57E*Products subject to MPQ in Europe applications. See Technical Bulletin TB990801 for full details.PRODUCTCODESPEF: polyester needlefeltPEXLF: extended life polyester needlefeltPOF: polypropylene needlefeltPOXLF: extended life polypropylene needlefeltNMOF: nylon monofilamentAGF: polypropylene meltblownPGF: polypropylene meltblownE: PO SENTINEL ® RingE: Extruded mesh (for AGF, PGF)CLEARGAF P: Plain (no cover) (for needlefelts) Z-WW: SANTOPRENE ®SENTINEL ® RingPEFBag MaterialBags/Box Box Size10-50 S, M, L25 P 01 Z-WW 40LMicron Rating µmCLEARGAF Range1, 5, 10,25, 50, etc.Bag Cover LayerBag Size Collar/Ring Type PackagingCode Size01 ø 7 x 17 inches L02 ø 7 x 32 inches L03 ø 4 x 9 inches L04 ø 4 x 15 inches LBANDSEAL NOMINALµm0.1 1 10 100 1000gpm0 45 90 135 180For simple, minimalpressurenon-criticalopen filtration applications(that is, filtrationwithout a vessel),HAYWARD’s lineof BANDSEAL FilterBags offers manycost-effective choices. These filter bags are available witha drawstring that permits them to be installed directly onthe end of a pipe, without the need of an adapter.PRODUCTCODESBANDSEAL NMO: Nylon MonofilamentNMOBag MaterialP: Plain R: without ringBags/Box Size50 S100 P 01 R R 50SMicron Rating µmBag Cover LayerBag Size Collar/Ring Type Draw String PackagingBANDSEAL Range25-800Code Size01 ø 7 x 17 inches L43 width 5.5 x 12 inches L45 width 5.5 x 20 inches LR: tie on bandnone: without band41

NOMINALµm0.1 1 10 100 1000SENTINEL gpm0 45 90 135 180®Welded Construction Filter BagsWelded Construction Filter BagsSENTINEL filter bags from HAYWARD represent theindustry standard in bypass-free filter construction.Available in polyester and polypropylene materials, allSENTINEL filter bags feature:• SENTINEL Pressure Actuated Seal Ring• Silicone Free Needled Felt• Super Strong Welded Construction• Non Migrating Media ConstructionIn its new versionthe SENTINELring is featuredwith an additionalsealing lip. Thislip snaps intoposition within aspecial groove.Now, applications requiring polypropylene or polyesterfelt filter bags can take advantage of the all-welded constructionafforded by HAYWARD patented SENTINEL ®Filter Bags. These bags, made from silicone-free materials,feature super-strong welded construction rather thansewn seams. This construction ensures that nothing bypassesthe process media through holes in sewn fabric.Proprietary ConstructionHAYWARD’s proprietary construction processes producea reliable, durable filter bag. All seams are fully welded,producing strong, reliable joints with no by-pass or loosesewing thread. Seams are both strong and flexible, allowingthe filter bag to form to the restrainer basket. The seamedges are heat sealed, eliminating possible loose fibers.This results in a filter bag with durable performance for themost demanding applications.SENTINEL ® Seal RingAll HAYWARD SENTINEL filter bags utilize the patentedSENTINEL seal. Its all-plastic construction provides aflexible, chemically resistant seal which adapts to any filterhousing. This unique design employs a pressure activatedsealing lip which responds to increases in differentialpressure. As the pressure increases, the seal of thering improves, insuring by-pass free performance over allranges of pressure, temperature and micron rating. Theelevated bag handles make removal of the bag from thevessel quick and easy. When a SENTINEL filter bag isinstalled into a HAYWARD filter vessel, the ring snaps intoplace, holding its position until the vessel is closed.PRODUCTCODESPO: Polypropylene NeedlefeltPE: PolyesterNMO: Nylon, monofil meshPOBag MaterialBags/Box Box SizeS, M, L25 P 02 E30LMicron Rating µmP: PlainBag Cover LayerE: Polypropylene SENTINEL ® Ring, weldedH: Polyester SENTINEL ® Ring, weldedZ: Santoprene SENTINEL ® Ring, sewnBag Size Collar/Ring Type Options PackagingSENTINEL ® Range1 255 50 20010 100 1250Code Size01 ø 7 x 17 inches L02 ø 7 x 32 inches L03 ø 4 x 9 inches L04 ø 4 x 15 inches LWW42

SNAP-RING ®NOMINALµm0.1 1 10 100 1000gpm0 45 90 135 180Sewn Construction Filter BagsFor over 30 years, HAYWARD SNAP-RING ® filter bagshave been critical components of filtration systemsworld-wide. The wide range of media materials, affordableprice, and reliability of construction have madethem the ideal choice for applications in nearly allprocess industries.Superior, Consistent QualitySNAP-RING filter bags are manufactured to the higheststandards of fabrication available. Materials must satisfystringent specifications for filtration performance andmedia purity. Production under 9001:2000 quality systemsresults in order to order, year to year, reliability andrepeatability. Heavy duty sewing thread and the metalseal ring are produced to HAYWARD specifications andguaranteed to be silicone free.Adaptable to Most VesselsSNAP-RING filter bags are designed and constructed to fitthe widest range of filter vessels, whether from HAYWARDor from another supplier. Special geometries are availableto fit most non-standard housings.Cut away showingSNAP-RING sewninto the bagApplication VersatilitySNAP-RING filter bags are available with four differentring plastics, six different media materials and elevenmicron ratings. SNAP-RING filter bags can handlecorrosive chemicals, aggressive solvents and evenelevated temperatures. With this many choices, the rightHAYWARD filter bag is available for every application.PRODUCTCODESMultifilament MeshPEMU: PolyesterMonofilament MeshNMO: Nylon PEMO: PolyesterPMO: Polypropylene PTMO: PTFENeedlefeltPE: Polyester HT: Nomex ®PO: Polypropylene PT: PTFENY: Nylon W: WoolSNAP-RING ®POBag MaterialP: PlainA: Stainless Steel SNAP-RING ®S: Carbon Steel SNAP-RING ® ,Zinc PlatedBags/Box Box Size30 S, M, L25 P 02 S30LMicron Rating µmSNAP-RING ® Range1 255 50 20010 100 1250Bag Cover LayerBag Size Collar/Ring Type Options PackagingCode Size01 ø 7 x 17 inches L02 ø 7 x 32 inches L03 ø 4 x 9 inches L04 ø 4 x 15 inches L43

HAYFLOW HAYWARD’s Revolutionary New Filter ElementHAYFLOW – The Next Generation ofFiltration SystemsWith this new, patent pending filter element HAYWARDtechnology has combined the best of both bag andcartridge filters into one single filtration element foroutstanding filtration performance. Because HAYFLOW’ssurface area is up to 70% greater than a similar size filterbag, existing systems that use HAYFLOW experiencelonger filter element life and less changing, resulting inreduced running costs. With HAYFLOW, designers ofnew bag filtration systems can opt for reduced runningcosts or, because of the high flow rates possible withHAYFLOW, reduce filter housing size by up to 50% thuslowering the initial cost of the system.What Makes the HAYFLOW ElementBetterThe heart of HAYWARD’s HAYFLOW filter element is twoconcentric cylinders of high-quality extended lifeHAYWARD filter media. These cylinders are formedusing unique welding technology to create a no by-passseam. The diameter of the cylinder is the same size as astandard filter bag, so retrofitting into existing systems iseasy. The HAYFLOW element is fitted with HAYWARD’spatented SENTINEL ® sealing ring, ensuring a positiveseal with the filter vessel to protect against bypass of theprocess media.How the HAYFLOW Element WorksThe process fluid enters the inside of the element,passes through it, and exits through the vessel outlet.Like a filter bag, the filtered-out material stays insidethe HAYFLOW element. The HAYFLOW element is unlikea filter cartridge, where the residue of the filtered materialremains on the outside of the cartridge, complicatingthe changing process.The concentricmedia layers arewelded onto a topand a bottom ringAn All-Around Better ChoiceChanging a HAYFLOW filter element can actually beeasier than changing a filter bag, because HAYFLOW’srevolutionary design only retains 25% of the residual liquidvolume of a similarly sized filter bag. When you need tochange the element, it weighs up to 75% less than afilter bag. A full bag can weigh up to 33 lbs, so weightis an important consideration for the system operator.44

NOMINALRATEDµmgpm0.1 1 10 100 10000 45 110 175 220Easy installationof HAYFLOW’sinto existing bagfilter housingsThe lower retention volume of HAYFLOW means less saleableproduct has to be thrown away. This importantHAYFLOW feature can provide considerable savings overtime. HAYFLOW’S cylindrical construction offers strengthunrivaled in other similar products. The all-welded filterelement is fit to a matching restrainer basket, allowing thefiltration media to be replaced easily and quickly. Theclose-tolerance fit of the filter and the restrainer basketprovide ease of installation and worry-free performance.This combination of fully-welded seams and a rigid, cylindricalgeometry provides strength over a full range of operatingdifferential pressure. The HAYFLOW element is alwayssmooth and fits to the basket walls without crimps orpleats, guaranteeing a quick and easy installation. Batchsystem operators often do not want to stop a batchprocess and change a filter bag. Using HAYFLOW, systemoperators have found up to 5 times the life over a similarsize filter bag and experienced reduced operating costs.Usually, bag filters are bigger than cartridge filters butare easier to handle and more cost effective. HAYFLOWbrings the best of both systems together...high flow ratesin compact vessels, or a longer lifetime and extendedchanging cycles. HAYFLOW combines highly efficientfilter media, enlarged surface area, better dirt-holdingcapabilities and a reduction of the residual liquid volumeretained in the element. All of these advantages result insuperior filtration performance.The Choice is YoursHAYWARD’s HAYFLOW filter elementcan be adapted to a wide rangeof applications through the use of differentfilter media. Basically, any weldable filtrationmedia can be used to construct aHAYFLOW element. Multilayered construction isalso possible for applications that require it. Usingmelt-blown polypropylene media, HAYFLOW elementsare available with high micron retention ratings, and withselective absorption characteristics as well. StandardHAYFLOW filter elements are available in both polypropyleneand polyester construction. These two materials arevery versatile and will perform in a majority of applicationsover a wide range of temperatures. HAYWARD uses ahigh-quality, extended life DURAGAF needle felt mediawith extremely fine fibers and higher pore volumes forsuperior performance. Both feature either polypropylene orpolyester SENTINEL sealing rings.Cut away of the element from anE-coat tank filtration after beingin service for eleven weeks• Higher flow rates - smaller,less costlyvessels can be used• Up to five times greaterlife over filter bags• Liquid losses are 25% ofsimilar sizefilter bag• SENTINEL sealing ringMetal fines collectedfrom parts washer45

HAYFLOW The HAYFLOWEffectFeatures:• Higher flow rates - smaller, less costlyhousings can be used• Up to five times greater life over filter bags• Liquid losses are 25% of similar sizefilter bag• SENTINEL sealing ring and 100%welded construction for no by-pass• Up to 35 times more effective thanstandard filter cartridges• Low pressure differential results inless energy consumption of pumps• Very cost-effective in comparisonto similar systems• Rugged cylindrical construction• Easier maintenance with reduced costs• Easy retro fit to existing filter housingsAnd….HAYWARD’s superior support,before, during and after system installation.Take Advantage of HAYFLOW NowYou can easily change over from ordinary bag filtration tothe revolutionary new HAYFLOW filter element. Existing bagfilter housings need only to be fitted with a new HAYFLOWrestrainer basket for instant compatibility with theHAYFLOW element. No tools, special equipment or modificationto the vessel are required. Just drop in the newbasket, and you are ready to take advantage of all the benefitsoffered by a HAYFLOW filtration system.Still Not Sure if HAYFLOW is Right for You?Contact us. We can show you how you can save moneyand improve your filtration process using HAYFLOW filterelements.Turbo effect in solidscollection helps to extendlife of filter element46

Application:✓Automotive✓Sugar Processing✓Paints, Coatings, Inks, Dispersions✓Resins✓Water and Waste Water Treatment✓Solvents✓Lubricants and Metalworking Fluids✓Aqueous and Solvent Based Cleaners inParts Washing Equipment✓Pulp and Paper✓Oil and Gas Exploration and Processing✓Pharmaceutical✓Food Processing✓Chemical Process Industries✓Potable Water, Beer, and Wine✓Edible OilsRemember “Filter Cost” and “Filtration Cost”are Not the Same ThingWe can explain the difference and demonstrate theHAYFLOW advantage in your application.PRODUCTCODESHAYFLOW Filter ElementPOXL: Polypropylene Extended Life NeedlefeltLCR: LOFCLEAR 7 x 28 inchesPEXL: Polyester Extended Life NeedlefeltHAYFLOWPOXL 1 HAY 08LMaterialMicron Rating µm1, 5, 10, 25, 50,100 (POXL/PEXL)128 (LCR)PackagingPackagingElements/BoxBox Size8 L (large)47

HAYWARD PRECISIONPRODUCT LINEMediaµ-Ratings151025508010012515020025030040060080010001250PROGAF PGF50515557SEE EFFICIENCY CHART ON PAGE 11ACCUGAF AGFAGFE5151535555575759SEE EFFICIENCY CHART ON PAGE 15LOFCLEAR LCR123130522124135125525126527128129529SEE EFFICIENCY CHART ON PAGE 16CLEARGAF POFPEFPOXLFPEXLFNMOFxxxxxxxxxxxxxxxxxxxxxxxxxxxDURAGAF POXLPEXLxxxxxxxxxxxxSENTINEL ®POPENMOxxxxxxxxxxxxxxxxxxxxxxxxxxxxSNAP-RING ®POPENYHTPTWNMOPMOPEMOPTMOPEMUxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxBANDSEAL NMOxxxxxxxxxxxxxxxxxxxxxxxxHAYFLOW (special basket required)POXLPEXLLCR128xxxxxxxxxxxx48

FILTER BAGSMediaAvailable Size / Maximum Flow (gpm)SNAP-RINGSENTINELBandRingSideBottomMaterialTypeSurfaceFinishMax op.Temp (°F)35353590907575907575909090909090909090909090909090456666665318018013513518013513518018018018018018018018018018018018018018018018018001 02 03 04 43 4526262626262626535353535353536 12EEHEEZEZEZZEHEHZEHESSSAASSASASRWWWWWWWWWWSWWWWSSSSSSSSSSSSSSWWWWWWSSWWWWWSWWWWSSWSSSSSSSSSSSWWSWWWSSWWWWWSWWWWSSSSSSSSSSSSSSWWWPolypropylenePolypropylenePolyesterPolypropylenePolypropylenePolypropylenePolypropylenePolyesterPolypropylenePolyesterNylonPolypropylenePolyesterPolypropylenePolyesterNylonPolypropylenePolyesterNylonNomex ®PTFEWoolNylonPolypropylenePolyesterPTFEPolyesterNylonNylonPolypropylenePolyesterPolypropyleneMeltblownMeltblownMeltblownMeltblownMeltblownMeltblownFeltFeltFeltFeltMeshFeltFeltFeltFeltMeshFeltFeltFeltFeltFeltFeltMeshMeshMeshMeshMeshMeshMeshFeltFeltMeltblownsingedsingedglazedglazedglazedglazedsingedsingedsingedsingedsingedglazedglazed194194302194194194194284194284284194302194302257230374374473500275374230374500293374374194302194RingsWeld/Sewn49