SENSATIONAL

Read the full print edition - techlife magazine

Read the full print edition - techlife magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

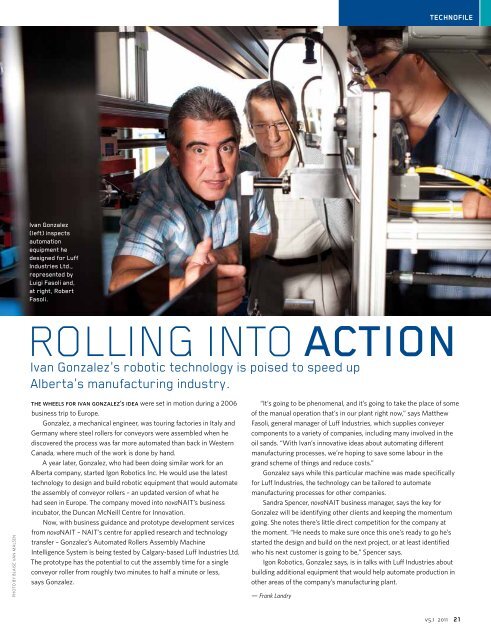

TECHNOFILEIvan Gonzalez(left) inspectsautomationequipment hedesigned for LuffIndustries Ltd.,represented byLuigi Fasoli and,at right, RobertFasoli.ROLLING INTO ACTIONIvan Gonzalez’s robotic technology is poised to speed upAlberta’s manufacturing industry.Photo by blaise van malsenthe wheels for ivan gonzalez’s idea were set in motion during a 2006business trip to Europe.Gonzalez, a mechanical engineer, was touring factories in Italy andGermany where steel rollers for conveyors were assembled when hediscovered the process was far more automated than back in WesternCanada, where much of the work is done by hand.A year later, Gonzalez, who had been doing similar work for anAlberta company, started Igon Robotics Inc. He would use the latesttechnology to design and build robotic equipment that would automatethe assembly of conveyor rollers – an updated version of what hehad seen in Europe. The company moved into novaNAIT’s businessincubator, the Duncan McNeill Centre for Innovation.Now, with business guidance and prototype development servicesfrom novaNAIT – NAIT’s centre for applied research and technologytransfer – Gonzalez’s Automated Rollers Assembly MachineIntelligence System is being tested by Calgary-based Luff Industries Ltd.The prototype has the potential to cut the assembly time for a singleconveyor roller from roughly two minutes to half a minute or less,says Gonzalez.“It’s going to be phenomenal, and it’s going to take the place of someof the manual operation that’s in our plant right now,” says MatthewFasoli, general manager of Luff Industries, which supplies conveyercomponents to a variety of companies, including many involved in theoil sands. “With Ivan’s innovative ideas about automating differentmanufacturing processes, we’re hoping to save some labour in thegrand scheme of things and reduce costs.”Gonzalez says while this particular machine was made specificallyfor Luff Industries, the technology can be tailored to automatemanufacturing processes for other companies.Sandra Spencer, novaNAIT business manager, says the key forGonzalez will be identifying other clients and keeping the momentumgoing. She notes there’s little direct competition for the company atthe moment. “He needs to make sure once this one’s ready to go he’sstarted the design and build on the next project, or at least identifiedwho his next customer is going to be,” Spencer says.Igon Robotics, Gonzalez says, is in talks with Luff Industries aboutbuilding additional equipment that would help automate production inother areas of the company’s manufacturing plant.— Frank Landryv5.1 2011 21