Lockout Tagout Machine Specific Procedure Forms

Lockout Tagout Machine Specific Procedure Forms

Lockout Tagout Machine Specific Procedure Forms

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

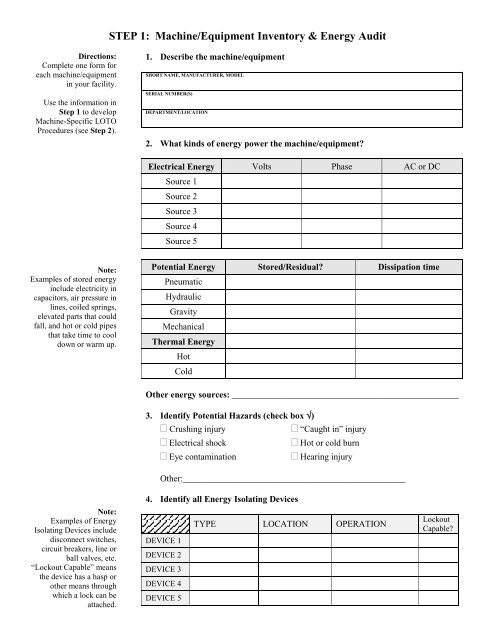

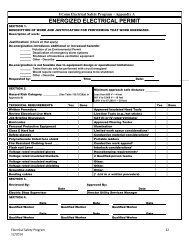

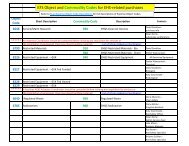

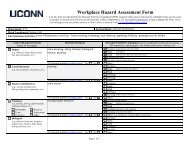

STEP 1: <strong>Machine</strong>/Equipment Inventory & Energy AuditDirections:Complete one form foreach machine/equipmentin your facility.Use the information inStep 1 to develop<strong>Machine</strong>-<strong>Specific</strong> LOTO<strong>Procedure</strong>s (see Step 2).1. Describe the machine/equipmentSHORT NAME, MANUFACTURER, MODELSERIAL NUMBER(S)DEPARTMENT/LOCATION2. What kinds of energy power the machine/equipment?Electrical Energy Volts Phase AC or DCSource 1Source 2Source 3Source 4Source 5Note:Examples of stored energyinclude electricity incapacitors, air pressure inlines, coiled springs,elevated parts that couldfall, and hot or cold pipesthat take time to cooldown or warm up.Potential Energy Stored/Residual? Dissipation timePneumaticHydraulicGravityMechanicalThermal EnergyHotColdOther energy sources: ___________________________________________________3. Identify Potential Hazards (check box √)Crushing injury“Caught in” injuryElectrical shockHot or cold burnEye contaminationHearing injuryOther:__________________________________________________Note:Examples of EnergyIsolating Devices includedisconnect switches,circuit breakers, line orball valves, etc.“<strong>Lockout</strong> Capable” meansthe device has a hasp orother means throughwhich a lock can beattached.4. Identify all Energy Isolating DevicesTYPE LOCATION OPERATIONDEVICE 1DEVICE 2DEVICE 3DEVICE 4DEVICE 5<strong>Lockout</strong>Capable?

STEP 2: <strong>Machine</strong>-<strong>Specific</strong> <strong>Lockout</strong>/<strong>Tagout</strong> <strong>Procedure</strong>s(Directions: Use the information gathered in Step 1 to complete Step 2)A. SHUTDOWN PROCEDURES -- Establishing <strong>Lockout</strong>/<strong>Tagout</strong>1. NOTIFY all affected employees that the machine or equipment will be shut down and locked/tagged out forservicing. Name who and how they will be notified:________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________2. SHUTDOWN the machine or equipment. List the steps to shut down the machine/equipment, including the typeand location of the operating controls:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________3. ISOLATE the machine/equipment from its energy sources. List types, locations, and operation procedures for allEnergy Isolating Devices.Type Location OperationDevice 1Device 2Device 3Device 44. APPLY lockout/tagout devices to the Energy Isolating Devices. List the type of lockout device that will be used oneach Energy Isolating Device.Energy Isolating Device<strong>Lockout</strong> Device DescriptionDevice 1Device 2Device 3Device 45. CONTROL all stored/residual hazardous energy. List the types of stored energy and how to dissipate or restrain.Energy TypeMethod to Dissipate or Restrain6. VERIFY that the machine/equipment has been isolated by attempting to restart it. Describe how to attempt torestart the machine/equipment.: __________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________B. RESTART PROCEDURES – Removal of Locks and Tags1. Check equipment and surrounding area to ensure all tools, etc. have been removed and equipment isoperationally intact.2. Verify that all employees are in a safe area, and controls are in a neutral position.3. Remove Locks and Tags in the reverse order they were applied, and reenergize.4. Notify affected employees when servicing is complete and equipment is ready for use.5. List any additional steps:_____________________________________________________________________________________________________________________________________________________