Development of injection of reduction gas into the blast ... - klimazwei

Development of injection of reduction gas into the blast ... - klimazwei

Development of injection of reduction gas into the blast ... - klimazwei

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

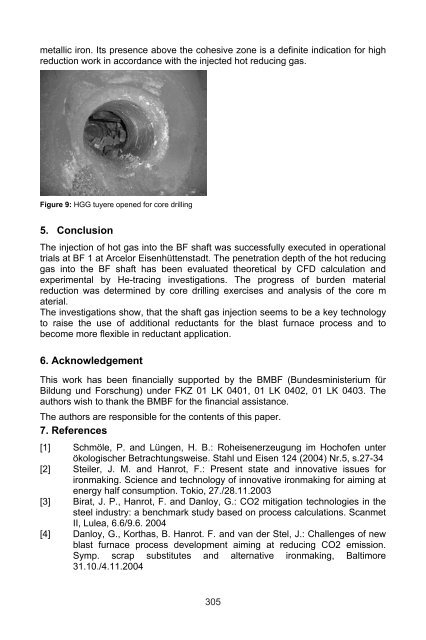

metallic iron. Its presence above <strong>the</strong> cohesive zone is a definite indication for high<br />

<strong>reduction</strong> work in accordance with <strong>the</strong> injected hot reducing <strong>gas</strong>.<br />

Figure 9: HGG tuyere opened for core drilling<br />

5. Conclusion<br />

The <strong>injection</strong> <strong>of</strong> hot <strong>gas</strong> <strong>into</strong> <strong>the</strong> BF shaft was successfully executed in operational<br />

trials at BF 1 at Arcelor Eisenhüttenstadt. The penetration depth <strong>of</strong> <strong>the</strong> hot reducing<br />

<strong>gas</strong> <strong>into</strong> <strong>the</strong> BF shaft has been evaluated <strong>the</strong>oretical by CFD calculation and<br />

experimental by He-tracing investigations. The progress <strong>of</strong> burden material<br />

<strong>reduction</strong> was determined by core drilling exercises and analysis <strong>of</strong> <strong>the</strong> core m<br />

aterial.<br />

The investigations show, that <strong>the</strong> shaft <strong>gas</strong> <strong>injection</strong> seems to be a key technology<br />

to raise <strong>the</strong> use <strong>of</strong> additional reductants for <strong>the</strong> <strong>blast</strong> furnace process and to<br />

become more flexible in reductant application.<br />

6. Acknowledgement<br />

This work has been financially supported by <strong>the</strong> BMBF (Bundesministerium für<br />

Bildung und Forschung) under FKZ 01 LK 0401, 01 LK 0402, 01 LK 0403. The<br />

authors wish to thank <strong>the</strong> BMBF for <strong>the</strong> financial assistance.<br />

The authors are responsible for <strong>the</strong> contents <strong>of</strong> this paper.<br />

7. References<br />

[1] Schmöle, P. and Lüngen, H. B.: Roheisenerzeugung im Hoch<strong>of</strong>en unter<br />

ökologischer Betrachtungsweise. Stahl und Eisen 124 (2004) Nr.5, s.27-34<br />

[2] Steiler, J. M. and Hanrot, F.: Present state and innovative issues for<br />

ironmaking. Science and technology <strong>of</strong> innovative ironmaking for aiming at<br />

energy half consumption. Tokio, 27./28.11.2003<br />

[3] Birat, J. P., Hanrot, F. and Danloy, G.: CO2 mitigation technologies in <strong>the</strong><br />

steel industry: a benchmark study based on process calculations. Scanmet<br />

II, Lulea, 6.6/9.6. 2004<br />

[4] Danloy, G., Korthas, B. Hanrot. F. and van der Stel, J.: Challenges <strong>of</strong> new<br />

<strong>blast</strong> furnace process development aiming at reducing CO2 emission.<br />

Symp. scrap substitutes and alternative ironmaking, Baltimore<br />

31.10./4.11.2004<br />

305