Particulate structure of L10 ordered ultrathin FePt films for ...

Particulate structure of L10 ordered ultrathin FePt films for ...

Particulate structure of L10 ordered ultrathin FePt films for ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

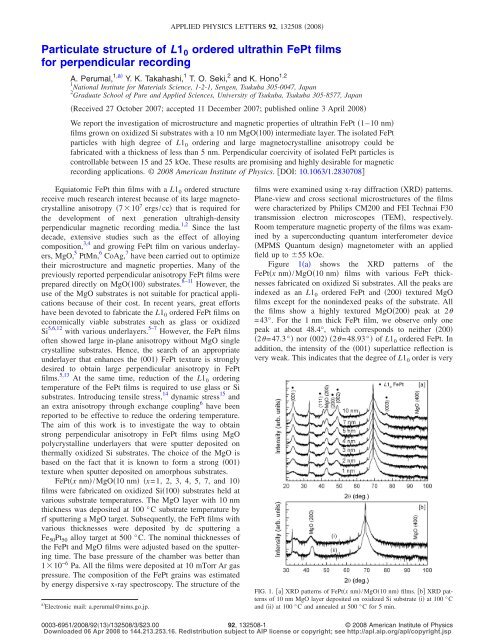

APPLIED PHYSICS LETTERS 92, 132508 2008<strong>Particulate</strong> <strong>structure</strong> <strong>of</strong> L1 0 <strong>ordered</strong> <strong>ultrathin</strong> <strong>FePt</strong> <strong>films</strong><strong>for</strong> perpendicular recordingA. Perumal, 1,a Y. K. Takahashi, 1 T. O. Seki, 2 and K. Hono 1,21 National Institute <strong>for</strong> Materials Science, 1-2-1, Sengen, Tsukuba 305-0047, Japan2 Graduate School <strong>of</strong> Pure and Applied Sciences, University <strong>of</strong> Tsukuba, Tsukuba 305-8577, JapanReceived 27 October 2007; accepted 11 December 2007; published online 3 April 2008We report the investigation <strong>of</strong> micro<strong>structure</strong> and magnetic properties <strong>of</strong> <strong>ultrathin</strong> <strong>FePt</strong> 1–10 nm<strong>films</strong> grown on oxidized Si substrates with a 10 nm MgO100 intermediate layer. The isolated <strong>FePt</strong>particles with high degree <strong>of</strong> L1 0 ordering and large magnetocrystalline anisotropy could befabricated with a thickness <strong>of</strong> less than 5 nm. Perpendicular coercivity <strong>of</strong> isolated <strong>FePt</strong> particles iscontrollable between 15 and 25 kOe. These results are promising and highly desirable <strong>for</strong> magneticrecording applications. © 2008 American Institute <strong>of</strong> Physics. DOI: 10.1063/1.2830708Equiatomic <strong>FePt</strong> thin <strong>films</strong> with a L1 0 <strong>ordered</strong> <strong>structure</strong>receive much research interest because <strong>of</strong> its large magnetocrystallineanisotropy 710 7 ergs/cc that is required <strong>for</strong>the development <strong>of</strong> next generation ultrahigh-densityperpendicular magnetic recording media. 1,2 Since the lastdecade, extensive studies such as the effect <strong>of</strong> alloyingcomposition, 3,4 and growing <strong>FePt</strong> film on various underlayers,MgO, 5 PtMn, 6 CoAg, 7 have been carried out to optimizetheir micro<strong>structure</strong> and magnetic properties. Many <strong>of</strong> thepreviously reported perpendicular anisotropy <strong>FePt</strong> <strong>films</strong> wereprepared directly on MgO100 substrates. 8–11 However, theuse <strong>of</strong> the MgO substrates is not suitable <strong>for</strong> practical applicationsbecause <strong>of</strong> their cost. In recent years, great ef<strong>for</strong>tshave been devoted to fabricate the L1 0 <strong>ordered</strong> <strong>FePt</strong> <strong>films</strong> oneconomically viable substrates such as glass or oxidizedSi 5,6,12 with various underlayers. 5–7 However, the <strong>FePt</strong> <strong>films</strong><strong>of</strong>ten showed large in-plane anisotropy without MgO singlecrystalline substrates. Hence, the search <strong>of</strong> an appropriateunderlayer that enhances the 001 <strong>FePt</strong> texture is stronglydesired to obtain large perpendicular anisotropy in <strong>FePt</strong><strong>films</strong>. 5,13 At the same time, reduction <strong>of</strong> the L1 0 orderingtemperature <strong>of</strong> the <strong>FePt</strong> <strong>films</strong> is required to use glass or Sisubstrates. Introducing tensile stress, 14 dynamic stress 15 andan extra anisotropy through exchange coupling 6 have beenreported to be effective to reduce the ordering temperature.The aim <strong>of</strong> this work is to investigate the way to obtainstrong perpendicular anisotropy in <strong>FePt</strong> <strong>films</strong> using MgOpolycrystalline underlayers that were sputter deposited onthermally oxidized Si substrates. The choice <strong>of</strong> the MgO isbased on the fact that it is known to <strong>for</strong>m a strong 001texture when sputter deposited on amorphous substrates.<strong>FePt</strong>x nm/MgO10 nm x=1,2,3,4,5,7,and10<strong>films</strong> were fabricated on oxidized Si100 substrates held atvarious substrate temperatures. The MgO layer with 10 nmthickness was deposited at 100 °C substrate temperature byrf sputtering a MgO target. Subsequently, the <strong>FePt</strong> <strong>films</strong> withvarious thicknesses were deposited by dc sputtering aFe 50 Pt 50 alloy target at 500 °C. The nominal thicknesses <strong>of</strong>the <strong>FePt</strong> and MgO <strong>films</strong> were adjusted based on the sputteringtime. The base pressure <strong>of</strong> the chamber was better than110 −6 Pa. All the <strong>films</strong> were deposited at 10 mTorr Ar gaspressure. The composition <strong>of</strong> the <strong>FePt</strong> grains was estimatedby energy dispersive x-ray spectroscopy. The <strong>structure</strong> <strong>of</strong> thea Electronic mail: a.perumal@nims.go.jp.<strong>films</strong> were examined using x-ray diffraction XRD patterns.Plane-view and cross sectional micro<strong>structure</strong>s <strong>of</strong> the <strong>films</strong>were characterized by Philips CM200 and FEI Technai F30transmission electron microscopes TEM, respectively.Room temperature magnetic property <strong>of</strong> the <strong>films</strong> was examinedby a superconducting quantum interferometer deviceMPMS Quantum design magnetometer with an appliedfield up to 55 kOe.Figure 1a shows the XRD patterns <strong>of</strong> the<strong>FePt</strong>x nm/MgO10 nm <strong>films</strong> with various <strong>FePt</strong> thicknessesfabricated on oxidized Si substrates. All the peaks areindexed as an L1 0 <strong>ordered</strong> <strong>FePt</strong> and 200 textured MgO<strong>films</strong> except <strong>for</strong> the nonindexed peaks <strong>of</strong> the substrate. Allthe <strong>films</strong> show a highly textured MgO200 peak at 2=43°. For the 1 nm thick <strong>FePt</strong> film, we observe only onepeak at about 48.4°, which corresponds to neither 2002=47.3° nor 002 2=48.93° <strong>of</strong> L1 0 <strong>ordered</strong> <strong>FePt</strong>. Inaddition, the intensity <strong>of</strong> the 001 superlattice reflection isvery weak. This indicates that the degree <strong>of</strong> L1 0 order is veryFIG. 1. a XRD patterns <strong>of</strong> <strong>FePt</strong>x nm/MgO10 nm <strong>films</strong>. b XRD patterns<strong>of</strong> 10 nm MgO layer deposited on oxidized Si substrate i at 100 °Cand ii at 100 °C and annealed at 500 °C <strong>for</strong> 5 min.0003-6951/2008/9213/132508/3/$23.0092, 132508-1© 2008 American Institute <strong>of</strong> PhysicsDownloaded 06 Apr 2008 to 144.213.253.16. Redistribution subject to AIP license or copyright; see http://apl.aip.org/apl/copyright.jsp

132508-3 Perumal et al. Appl. Phys. Lett. 92, 132508 2008FIG. 4. Out-<strong>of</strong>-plane line with closed circles and in-plane line with opencircles magnetic hysteresis loops <strong>of</strong> <strong>FePt</strong>x nm/MgO10 nm <strong>films</strong> withvarious <strong>FePt</strong> thicknesses.4 nm show a linear variation with the applied field at a highfield region, but exhibit a tiny hysteresis around zero fieldswith a coercivity <strong>of</strong> 1.4 kOe. This might arise from the presence<strong>of</strong> a small c-axis distribution <strong>of</strong> about 5 to 10% in theperpendicular direction. By increasing the film thicknessfrom 3 to 10 nm, the in-plane M-H loops show larger hysteresisand the in-plane coercivity increases dramaticallyfrom 1.4 to 15 kOe, respectively. As described earlier, thisrapid increase in in-plane coercivity might result from theincrease in either the fct <strong>FePt</strong>200 or the <strong>FePt</strong>111 orientationswith increasing <strong>FePt</strong> thickness. However, the exactamount <strong>of</strong> contribution <strong>of</strong> the <strong>FePt</strong> orientation to thelarge in-plane coercivity is not clear at this moment. Theanisotropy field H k <strong>for</strong> each <strong>FePt</strong> film was calculated byextrapolating the in-plane hysteresis loops. Subsequently,the magnetocrystalline anisotropy was calculated usingK u =M S H k /2 and listed in Table I. The <strong>FePt</strong> 4 nmfilm has a large K u value <strong>of</strong> 3.910 7 =84092 000/2 ergs/cc. The drastic increase in the perpendicularcoercivity and magnetocrystalline anisotropy can be attributedto the high degree <strong>of</strong> L1 0 ordering in <strong>FePt</strong> by varyingits thickness. The initial magnetization curves <strong>of</strong> all the<strong>films</strong> were difficult to saturate except <strong>for</strong> the 10 nm thick<strong>FePt</strong> film. This is due to the change in the morphology <strong>of</strong> thefilm from a particulate to an interconnected island <strong>structure</strong>.However, the magnetic field necessary to saturate the film isstill larger than 30 kOe. The dependence <strong>of</strong> magnetic propertieson the <strong>FePt</strong> film thickness is supported well from ourmicrostructural results.We have also fabricated the <strong>FePt</strong> <strong>films</strong> with the samethicknesses directly on the single crystal MgO100 substratesunder similar experimental conditions to understandthe development <strong>of</strong> additional <strong>FePt</strong>200 and <strong>FePt</strong>111 grainorientations with increasing <strong>FePt</strong> thickness in <strong>FePt</strong>x4 nm/MgO10 nm <strong>films</strong>. The XRD patterns <strong>of</strong> the <strong>FePt</strong>1–10 nm <strong>films</strong> on the MgO100 substrate showed strong001 and 003 superlattice reflections without any additional<strong>FePt</strong> grain orientations. Thus, the <strong>for</strong>mation <strong>of</strong>additional fct <strong>FePt</strong>200 and <strong>FePt</strong>111 grain orientationsin the <strong>FePt</strong>x5 nm/MgO10 nm <strong>films</strong> deposited on anoxidized Si substrate can be attributed to the inadequate texturing<strong>of</strong> the 10 nm MgO underlayer, as shown in Fig. 1b.Note that such grain orientations may also result from theexistence <strong>of</strong> the small grain size in the MgO underlayer.Nevertheless, we could fabricate the particulate <strong>structure</strong>d<strong>FePt</strong> 1–5 nm <strong>films</strong> on the 10 nm MgO200 underlayerwith high degree <strong>of</strong> L1 0 ordering, large magnetocrystallineanisotropy and controllable perpendicular coercivity.In summary, this work has demonstrated the possibility<strong>of</strong> fabricating particulate <strong>ultrathin</strong> <strong>FePt</strong> <strong>films</strong> on 10 nm thinMgO100 underlayer with controllable magnetic propertiesat a substrate temperature <strong>of</strong> 500 °C on economically viablesubstrates <strong>for</strong> the practical application <strong>of</strong> perpendicular recording.The increase in <strong>FePt</strong> thickness over 5 nm in<strong>FePt</strong>/MgO <strong>films</strong> results in the development <strong>of</strong> various <strong>FePt</strong>grain orientations, in contrast to the <strong>FePt</strong> <strong>films</strong> prepared onMgO 100 substrates.One <strong>of</strong> the authors A.P. acknowledges financial supportfrom the Japan Society <strong>for</strong> the Promotion <strong>of</strong> Science JSPSin the <strong>for</strong>m <strong>of</strong> JSPS postdoctoral fellowship. This work wasin part supported by the Ministry <strong>of</strong> Education, Science,Sports and Culture, Japan, Grant-in-Aid <strong>for</strong> Scientific ResearchB 198574, 2007. This work was in part supported byWorld Premier International Research Center Initiative WPIInitiative on Materials Nanoarchitronics, MENT, Japan.1 S. N. Piramanayagam, J. Appl. Phys. 102, 0113012007.2 S. Khizroev and D. Litvinov, J. Appl. Phys. 95, 4521 2004.3 D. C. Berry and K. Barmak, J. Appl. Phys. 102, 024912 2007.4 C. Y. You, Y. K. Takahashi, and H. Kono, J. Appl. Phys. 100, 0561052006.5 J. S. Chen, B. C. Lim, J. F. Hu, Y. K. Kim, B. Liu, and G. M. Chow, Appl.Phys. Lett. 90, 042508 2007.6 C. C. Chiang, C.-H. Lai, and Y. C. Wu, Appl. Phys. Lett. 88, 1525082006.7 Y. C. Lai, Y. H. Chang, Y. C. Chen, C. H. Liang, W. C. Chang, C. M.Chiou, and G. J. Chen, J. Appl. Phys. 101, 053913 2007.8 T. Shima, K. Takanashi, Y. K. Takahashi, and K. Hono, Appl. Phys. Lett.85, 2571 2004.9 Z. L. Zhao, J. S. Chen, J. Ding, J. B. Yi, B. H. Liu, and J. P. Wang, Appl.Phys. Lett. 88, 052503 2006.10 R. Maab, M. Weisheit, S. Fahler, and L. Schultz, J. Appl. Phys. 100,073910 2006.11 J. Buschbeck, S. Fahler, M. Weisheit, K. Leistner, J. McCord, B.Rellinghaus, and L. Schultz, J. Appl. Phys. 100, 123901 2006.12 Y. C. Wu, L. W. Wang, and C. H. Lai, Appl. Phys. Lett. 91, 0725022007.13 I. Fujii, T. Shima, and K. Takanashi, Mater. Trans. 47, 472006.14 Y. Xu, J. S. Chen, and P. J. Wang, Appl. Phys. Lett. 80, 3325 2002.15 C. H. Lai, C. H. Yang, C. C. Chiang, T. Balaji, and T. K. Tseng, Appl.Phys. Lett. 85, 4430 2004.Downloaded 06 Apr 2008 to 144.213.253.16. Redistribution subject to AIP license or copyright; see http://apl.aip.org/apl/copyright.jsp