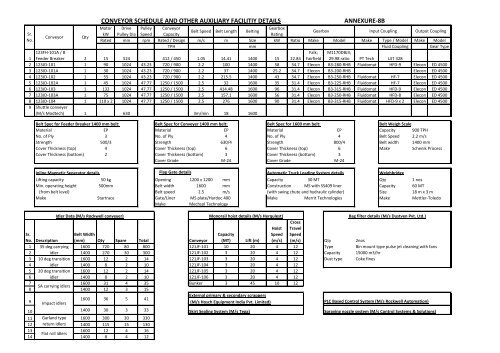

CONVEYOR SCHEDULE AND OTHER AUXILIARY FACILITIY DETAILS ANNEXURE-8B

conveyor schedule and other auxiliary facilitiy details ... - Essar

conveyor schedule and other auxiliary facilitiy details ... - Essar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Motor Drive Pulley ConveyorGearboxBelt Speed Belt Length BeltingGearbox Input Coupling Output CouplingSr.kW Pulley Dia Speed CapacityRatingConveyor QtyNo.Rated mm rpm Rated / Design m/s m Size kW Ratio Make Model Make Type / Model Make ModelTPH mm Fluid Coupling Gear Type1123FH-101A / BFeeder Breaker 2 15 524 412 / 450 1.05 14.41 1400 15 22.84Falk;FairfieldM1170DBJ3;29.98 ratio PT Tech UJT 3282 123JD-101 1 90 1024 43.23 720 / 900 2.2 100 1400 58 34.7 Elecon B3-280-RHB Fluidomat HFD-9 Elecon ED 45003 123JD-101A 1 30 1024 43.23 720 / 900 2.2 37 1400 25.2 34.7 Elecon B3-200-RHB Elecon ED 45004 123JD-102 1 55 1024 43.23 720 / 900 2.2 215.5 1400 43 34.7 Elecon B3-250-RHB Fluidomat HF-7 Elecon ED 45005 123JD-102A 1 45 1024 47.77 1250 / 1500 2.5 32 1600 35 31.4 Elecon B3-225-RHB Fluidomat HF-7 Elecon ED 45006 123JD-103 1 132 1024 47.77 1250 / 1500 2.5 414.48 1600 96 31.4 Elecon B3-315-RHB Fluidomat HFD-9 Elecon ED 45007 123JD-103A 1 75 1024 47.77 1250 / 1500 2.5 157.1 1600 56 31.4 Elecon B3-250-RHB Fluidomat HFD-8 Elecon ED 45008 123JD-104 1 110 x 2 1024 47.77 1250 / 1500 2.5 276 1600 90 31.4 Elecon B3-315-RHB Fluidomat HFD-9 x 2 Elecon ED 45009 Shuttle conveyer(M/s Modtech) 1 630 3m/min 18 1600Belt Spec for Feeder Breaker 1400 mm belt: Belt Spec for Conveyer 1400 mm belt: Belt Spec for 1600 mm belt: Belt Weigh ScaleMaterial EP Material EP Material EP Capacity 900 TPHNo. of Ply 3 No. of Ply 4 No. of Ply 4 Belt Speed 2.2 m/sStrength 500/3 Strength 630/4 Strength 800/4 Belt width 1400 mmCover Thickness (top) 4 Cover Thickness (top) 6 Cover Thickness (top) 6 Make Schenik ProcessCover Thickness (bottom) 2 Cover Thickness (bottom) 3 Cover Thickness (bottom) 3Cover Grade M-24 Cover Grade M-24Inline Magnetic Seperator details Flap Gate details Automatic Truck Loading System details WeighbridgeLifting capacity 50 kg Opening 1200 x 1200 mm Capacity 30 MT Qty 1 nosMin. operating height 500mm Belt width 1600 mm Construction MS with SS409 liner Capacity 60 MT(from belt level) Belt speed 2.5 m/s (with swing chute and hydraulic cylinder) Size 18 m x 3 mMake Startrace Gate/Liner MS plate/Hardoc 400 Make Merrit Technologies Make Mettler-ToledoMakeMechsol TechnologyIdler Data (M/s Rockwell conveyer)Monorail hoist details (M/s Herqulest)Bag filter details (M/s Dustven Pvt. Ltd.)CrossSr.No. DescriptionBelt Width(mm) Qty Spare Total ConveyorCapacity(MT) Lift (m)HoistSpeed(m/s)TravelSpeed(m/s) Qty 2nos1 35 deg carrying 1600 720 80 800 121JF-101 10 20 4 12 Type Bin mount type pulse jet cleaning with fans2 idler1400 270 30 300 121JF-102 3 20 4 12 Capacity 15000 m3/hr3 10 deg transition 1600 12 2 14 121JF-103 3 20 4 12 Dust type Coke fines4 idler1400 8 2 10 121JF-104 3 20 4 125 20 deg transition 1600 12 2 14 121JF-105 3 20 4 126 idler1400 8 2 10 121JF-106 3 20 4 127 1600 31 4 35 Bunker 3 45 10 12SA carrying idlers8 1400 12 3 159External primary & secondary scrappers1600 36 5 41Impact idlers(M/s Hosch Equipment India Pvt. Limited)PLC Based Control System (M/s Rockwell Automation)10 1400 30 3 3311 Garland type 1600 300 30 33012 return idlers 1400 115 15 13013 1600 12 4 16Flat roll idlers14 1400 8 4 12<strong>CONVEYOR</strong> <strong>SCHEDULE</strong> <strong>AND</strong> <strong>OTHER</strong> <strong>AUXILIARY</strong> <strong>FACILITIY</strong> <strong>DETAILS</strong>Skirt Sealing System (M/s Tega)<strong>ANNEXURE</strong>-<strong>8B</strong>Spraying nozzle system (M/s Control Systems & Solutions)

ELECTRICAL ITEMS IN <strong>CONVEYOR</strong> AREASr. No. Tag No. Description Motor RATING1 NT-123141A 2 MVA, Transformer 6.6/0.433KV, DYn11, Z=6.5%2 NB-123141A 3200A Bus-duct3 NS-1213141 415V, 50A, 1sec, 3200A, TPN4 Electric Hoist/ Tripper magnetic separator5 NA-123141 AC UPS I/C 16 NT-123141A Lighting Transformer 60KVA, 0.415/0.425 KV7 NK-123141A APFC Panel8 NT-123141B 2 MVA, Transformer 6.6/0.433KV, DYn11, Z=6.5%9 NB-123141B 3200A Bus-duct10 PDB 415V,50 Hz, 50kA, 1 sec, Al Bus.11 NK-123141B APFC Panel12 ND-123141 DC UPS13 PDB 415V,50 Hz, 50kA, 1 sec, Al Bus.14 Electric Hoist/Flap gate15 NW-121141 Welding Socket DB 415V,50 Hz, 50kA, 1 sec, Al Bus.16 NP-123011 AUX. POWER DISTIBUTION BOARD17 NP-123012 AUX. POWER DISTIBUTION BOARD18 NK-123011A/B. APFC PANEL19 Conveyor JD 101 LT MOTOR 9020 Conveyor JD 101A LT MOTOR 3021 Conveyor JD 102 LT MOTOR 5522 Conveyor JD 103A LT MOTOR 7523 Conveyor JD 104A LT MOTOR 11024 ID Fan for DES System-2 LT MOTOR 18.525 Shuttle Conveyor LT MOTOR 5526 Conveyor JD 102A LT MOTOR 4527 Conveyor JD 103 LT MOTOR 13228 Conveyor JD 104A LT MOTOR 11029 Conveyor JD 201 (Future) LT MOTOR 9030 ID Fan for DES System-1 LT MOTOR 18.531 ID Fan for DES System-3 LT MOTOR 18.532 Electrical Hoist (3T)-1 (JF-01) LT MOTOR 5.533 Electrical Hoist (3T)-3 (JF-03) LT MOTOR 5.534 Electrical Hoist (3T)-5 (JF-05) LT MOTOR 5.535 Electrical Hoist (3T)-7 ( MS JF-101) LT MOTOR 1136 Magnetic Separator-1 LT MOTOR 1037 Shuttle Conveyor LT MOTOR 55