HEUI Fuel Systems

PEHP9526 - HEUI Fuel Systems - Caterpillar

PEHP9526 - HEUI Fuel Systems - Caterpillar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

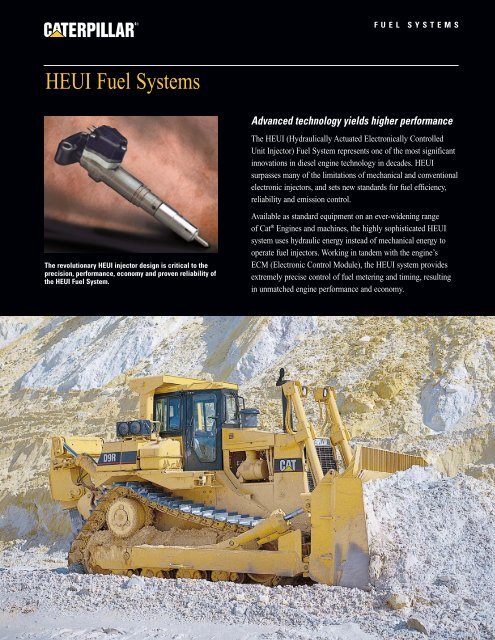

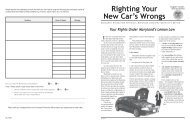

®FUEL SYSTEMS<strong>HEUI</strong> <strong>Fuel</strong> <strong>Systems</strong>The revolutionary <strong>HEUI</strong> injector design is critical to theprecision, performance, economy and proven reliability ofthe <strong>HEUI</strong> <strong>Fuel</strong> System.Advanced technology yields higher performanceThe <strong>HEUI</strong> (Hydraulically Actuated Electronically ControlledUnit Injector) <strong>Fuel</strong> System represents one of the most significantinnovations in diesel engine technology in decades. <strong>HEUI</strong>surpasses many of the limitations of mechanical and conventionalelectronic injectors, and sets new standards for fuel efficiency,reliability and emission control.Available as standard equipment on an ever-widening rangeof Cat ® Engines and machines, the highly sophisticated <strong>HEUI</strong>system uses hydraulic energy instead of mechanical energy tooperate fuel injectors. Working in tandem with the engine’sECM (Electronic Control Module), the <strong>HEUI</strong> system providesextremely precise control of fuel metering and timing, resultingin unmatched engine performance and economy.

®Meeting the demand for loweremissions, better fuel economyand higher performance.<strong>HEUI</strong> injector technology is changingthe way equipment owners, techniciansand operators think about diesel engineperformance. <strong>HEUI</strong> performance surpassesmechanical unit injectors and conventionalelectronic unit injectors, bringing newvalue to your investment in Cat Enginesand machines.3. High Pressure Oil Pump 4. Injector ActuationPressure Control Valve1. InjectorsPrecise injection pressureat any engine speedIn the traditional common rail fuel system,the entire fuel line is under high pressure.With the <strong>HEUI</strong> system, fuel remains at lowpressure until it is injected into the cylinder.<strong>Fuel</strong> pressure is created hydraulically inresponse to a signal from the ElectronicControl Module (ECM).2. ECMFour basic components work together to bring precision, reliability and simplifiedmaintenance to the <strong>HEUI</strong> fuel system.weindex.infoInjection pressure in a <strong>HEUI</strong> fuel systemis independent of engine speed.<strong>HEUI</strong> controls injection pressureelectronically. This unique capabilitymeans the regulation of injection pressureis completely independent of crankshaftspeed. Peak injection pressure can beachieved under acceleration and lugconditions, providing better fuel economy,better response and reduced smoke.A close look at the <strong>HEUI</strong> SystemThe <strong>HEUI</strong> fuel system consists of four basiccomponents:1. <strong>HEUI</strong> Injector Uses hydraulic energy(as opposed to mechanical energy fromthe engine camshaft) from pressurizedengine lube oil for injection. The pressureof the incoming oil (800 to 3300 psi)controls the rate of injection, while theamount of fuel injected is determinedby the ECM.2. Electronic Control Module (ECM)This sophisticated on-board computerprecisely manages fuel injection and otherengine systems. The <strong>HEUI</strong> injector solenoidis energized by an electronic signal generatedin the ECM. Using input from multiplesensors, the ECM’s dual microprocessorsuse proprietary software and customersuppliedperformance parameters toproduce maximum engine performanceunder any conditions.3. High Pressure Oil Pump Thevariable displacement axial pump featuresa built-in reservoir to immediately supplyoil at cold starts.4. Injector Actuation PressureControl Valve This electronicallyoperated valve controls oil pump outputand injection pressure.

FUEL SYSTEMS<strong>HEUI</strong> brings newvalue to your engine andequipment investment.Improved response Engines equippedwith <strong>HEUI</strong> injectors have outstandingresponse and improved highaltitude operation.Improved fuel economy The abilityto inject fuel at any crank angle resultsin up to 2.7 percent better fuel economycompared to scroll mechanical injectors.Optimum fuel economy also meansreduced gaseous emissions and lesswhite smoke during cold engine starts.Optimum performance The control offuel delivered during ignition delay andmain injection, known as rate shaping,is made possible by the <strong>HEUI</strong>’s abilityto operate independent of engine speed.Rate shaping modifies engine heat releasecharacteristics, which also helps reduceemission and noise levels. Rate shapingoptimizes engine performance by varyingthe idle and light load rate characteristicsindependent of rated and high load conditions.Reduced smoke and particulate emissionsSince the <strong>HEUI</strong> injector’s performancedoes not depend on engine speed, it canmaintain high injection pressures througha wide operating range. Electronic controlof these pressures helps improve emissionsand low-speed engine response.Reduced engine noise A split injectionfeature leads to a more controlled fuel burnand lower noise levels. Additional benefitsinclude reduced shock loads as well as lesswear and tear on drive train components.PoppetValveIntensifierPistonNozzleAssemblyHIA450 <strong>HEUI</strong> InjectorElectronicSolenoidPlungerNozzleValveReman <strong>HEUI</strong> injectors are as goodas new, as strong as everCaterpillar’s remanufacturing process returnsused injector components to their originalperformance specifications using state-ofthe-artsalvage techniques, strict reuseguidelines, advanced manufacturing systemsand unequaled quality control. Testing is animportant part of the process. Qualifiedtechnicians utilize the same kinds ofsophisticated equipment used to audit thequality of new components. Caterpillar’ssubstantial investment in state-of-the-artmeasuring technology ensures that themost exacting standards are met.Protect your <strong>HEUI</strong> <strong>Fuel</strong> Systemwith Cat High Efficiency<strong>Fuel</strong> FiltersExclusive features like spiral roving,acrylic beads and a non-metallic centertube help Cat High Efficiency <strong>Fuel</strong>Filters protect your engine againstdamaging fuel contamination.Today’s Cat Engines deliver morehorsepower, quicker response andbetter fuel economy than ever. Butthese precision components are alsomore susceptible to wear and damagefrom fuel system contaminants. In fact,the number one cause of prematurefuel system wear is abrasive particlessmaller than 10 microns.Cat High Efficiency <strong>Fuel</strong> Filtersare designed with a super-finefiltration media that removes morethan 98 percent of particles 2 micronsand larger. More contaminants areremoved, which maximizes protectionof injectors, pumps and other fuelsystem components.Damagesfuel systems(5-10 microns)Human hair(80 microns)High Efficiencyfiltration(2 microns)Standardfiltration(15 microns)weindex.info

WE’RE COMMITTED TOSERVICE AND SUPPORTWhen your Cat engine needs service,our professional technicians have thetraining and tools to get you back to workfast. Off-the-shelf component availabilityis backed by the Caterpillar worldwideparts network.Give us a call or stop by our parts counter.We’ll show you how we canhelp lower your owning and operatingcosts with the highest quality enginecomponents, a wide range of Cat Remancomponents, and the most comprehensiveservice and support available.weindex.infoPEHP9526 For more information, see us today or visit our web site at www.CAT.com © 1999 CaterpillarPrinted in U.S.A.