Sto RFP

Sto RFP

Sto RFP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

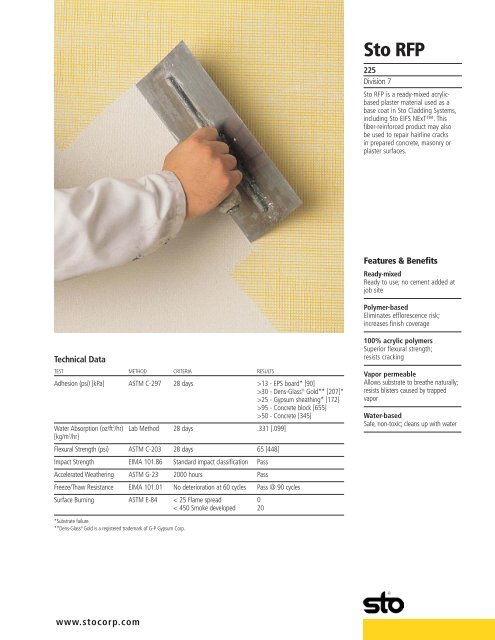

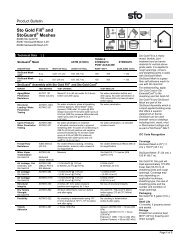

<strong>Sto</strong> <strong>RFP</strong>225Division 7<strong>Sto</strong> <strong>RFP</strong> is a ready-mixed acrylicbasedplaster material used as abase coat in <strong>Sto</strong> Cladding Systems,including <strong>Sto</strong> EIFS NExT. Thisfiber-reinforced product may alsobe used to repair hairline cracksin prepared concrete, masonry orplaster surfaces.Features & BenefitsReady-mixedReady to use; no cement added atjob sitePolymer-basedEliminates efflorescence risk;increases finish coverageTechnical DataTEST METHOD CRITERIA RESULTSAdhesion (psi) [kPa] ASTM C-297 28 days >13 - EPS board* [90]>30 - Dens-Glass ® Gold** [207]*>25 - Gypsum sheathing* [172]>95 - Concrete block [655]>50 - Concrete [345]Water Absorption (oz/ft 2 /hr) Lab Method 28 days .331 [.099][kg/m 2 /hr]Flexural Strength (psi) ASTM C-203 28 days 65 [448]Impact Strength EIMA 101.86 Standard impact classification PassAccelerated Weathering ASTM G-23 2000 hours PassFreeze/Thaw Resistance EIMA 101.01 No deterioration at 60 cycles Pass @ 90 cyclesSurface Burning ASTM E-84 < 25 Flame spread 0< 450 Smoke developed 20100% acrylic polymersSuperior flexural strength;resists crackingVapor permeableAllows substrate to breathe naturally;resists blisters caused by trappedvaporWater-basedSafe, non-toxic; cleans up with water*Substrate failure**Dens-Glass ® Gold is a registered trademark of G-P Gypsum Corp.www.stocorp.com

<strong>Sto</strong> <strong>RFP</strong>225Coverage85-100 ft 2 (7.9-9.3 m 2 ) at the recommendeddry thickness of 1 ⁄ 16" (1.6 mm) over properlyrasped <strong>Sto</strong> Insulation Board. Coverages mayvary depending on application technique andsurface conditions.Packaging5 gal pail (19 L)Shelf Life12 months, if properly stored and sealed.<strong>Sto</strong>rageProtect from extreme heat [90º F (32º C)],freezing and direct sunlight.Surface PreparationConcrete and masonry surfaces: Surfacesmust be free of all bond-inhibiting materials,including dirt, efflorescence, form oil and otherforeign matter. Loose or damaged material mustbe removed by waterblasting, sandblasting ormechanical wire brushing and repaired. Avoidapplication over irregular surfaces. Refer toASTM D- 4258 and ASTM D-4261 for completedetails on methods of preparing cementitioussubstrates for coatings.<strong>Sto</strong> Exterior Insulation and Finish Systems(EIFS): Insulation board must be rasped andfree of all bond-inhibiting materials.<strong>Sto</strong> Quik Gold Soffit System:Sheathing surface must be free of all bondinhibitingmaterials, damage or deterioration.MixingMix with a clean, rust-free electric drill and paddle.A small amount of clean, potable water maybe added to aid workability.ApplicationApply only to sound and clean, dry, properly prepared,frost-free surfaces.<strong>Sto</strong> Exterior Insulation and Finish System/<strong>Sto</strong> Quik Gold Soffit System: Apply <strong>Sto</strong> <strong>RFP</strong>with spray equipment such as the <strong>Sto</strong>Silo Systemor <strong>Sto</strong>’s M-8 Spray Pump, or using a stainlesssteel trowel, to an approximate thickness of 1 ⁄ 8"(3 mm). Work horizontally or vertically in stripsof 40" (1016 mm), and immediately embed <strong>Sto</strong>Mesh into the wet <strong>Sto</strong> <strong>RFP</strong> by troweling fromthe center to the edges of the mesh. Avoid wrinklesin the mesh and smooth the base coat toeliminate trowel marks. <strong>Sto</strong> <strong>RFP</strong> must completelyhide the reinforcing mesh when dry. Reapplyadditional base coat, if necessary, to hide thereinforcing mesh as soon as first application isdry. Once applied, the working time is up to 25minutes depending upon material, ambient temperaturesand surface conditions.Crack Repair: Embed 6" (152 mm) wide <strong>Sto</strong>Mesh centered over the crack in <strong>Sto</strong> <strong>RFP</strong> andfeather along edges.Protect from rain, freezing and continuous highhumidity until completely dry.Curing/Drying<strong>Sto</strong> <strong>RFP</strong> dries within 24 hours under normal[70º F (21º C), 50% RH] conditions. Full dryingvaries depending on temperature/ humidityand surface conditions.Cool damp conditions retard drying and mayrequire extended periods of protection from rainand freezing.Clean UpClean tools and equipment with water immediatelyafter use. Dried material can only beremoved mechanically.LimitationsUse <strong>Sto</strong> <strong>RFP</strong> only when surface and ambienttemperatures are above 40° F (4° C) and below100º F (38º C) during application and dryingperiod. <strong>Sto</strong> <strong>RFP</strong> should not be used on weatherexposedhorizontal or below grade surfaces orwhere immersion in water may occur.Sloped surfaces: minimum required slope is 1:2(27°) and maximum width is 12" (300 mm).<strong>Sto</strong> Mesh embedded in <strong>Sto</strong> Flexyl, not <strong>Sto</strong> <strong>RFP</strong>, isrequired beneath finish coating. Increase slopefor northern climates to prevent accumulation ofice/snow and water on surface. Periodic inspectionand increased maintenance of coating maybe required.<strong>Sto</strong> <strong>RFP</strong> should not be used as a finish coat.Health & SafetyHealth PrecautionsProduct is water-based. As with any chemicalconstruction product, exercise care when handling.Safety PrecautionsUse adequate ventilation. Safety goggles andprotective gloves are recommended. Removecontaminated clothing immediately.First AidSKIN CONTACT: Wash thoroughly with soap andwater.EYE CONTACT: Flush immediately with water for10-15 minutes and contact a physician.RESPIRATORY PROBLEMS: Remove affectedperson to fresh air immediately and contact aphysician.HYGIENE: Wash hands immediately after use.Wash clothing before re-use.SpillsCollect with suitable absorbent material such ascotton rags.DisposalDispose in accordance with local, state orfederal regulations.WarningKEEP CONTAINER CLOSED WHEN NOT IN USE.KEEP OUT OF REACH OF CHILDREN. NOT FORINTERNAL CONSUMPTION. FOR INDUSTRIALUSE ONLY. Consult the Material Safety DataSheet for further health and safety information.LIMITED WARRANTYTHIS PRODUCT IS SUBJECT TO A WRITTENLIMITED WARRANTY WHICH CAN BE OBTAINEDFREE OF CHARGE FROM: <strong>Sto</strong> Corp., 3800 CampCreek Parkway, Building 1400, Suite 120,Atlanta, GA 30331; Tel: 404-346-3666;Fax: 404-346-3119.<strong>Sto</strong> Corp.3800 Camp Creek ParkwayBuilding 1400, Suite 120Atlanta, GA 30331Tel: 404-346-3666Toll Free: 1-800-221-2397Fax: 404-346-3119www.stocorp.comS155-225 01/03 VEN 5609100% ACRYLICPOLYMERS