Sto Leveler

244 Sto Leveler (Page 1)

244 Sto Leveler (Page 1)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

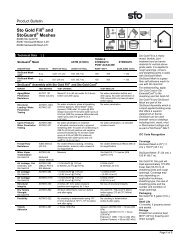

<strong>Sto</strong> <strong>Leveler</strong>244Division 7<strong>Sto</strong> <strong>Leveler</strong> is a polymer-modified,cement-based, glass fiber-reinforcedproduct used to patch or level irregularmasonry, concrete or plaster/stuccowall surfaces. Apply the product from1 ⁄8" to 1 ⁄4" (3-6 mm) thick.Features & BenefitsOne-componentReady to use; easily mixed with wateron the job site.Fiber-reinforcedImproves flexural strength; resistsshrinkage cracksTechnical DataTEST METHOD CRITERIA RESULTSCompressive Strength (psi) ASTM C-109 7 days 2,27028 days 2,710Flexural Strength (psi) ASTM C-293 7 days 80028 days 950Tensile Strength (psi) ASTM C-190 7 days 35528 days 310Tensile Bond Strength (psi) ASTM C-297 7 days 87Modified 28 days 169Cold Water Absorption ASTM C-642 7 days 6.42(% by weight) 28 days 5.51Shrinkage ASTM C-157 Air Cure 7 days .08928 days .098Water Cure 7 days .00828 days .011Creamy smooth consistencyTrowels on easily; increases job siteproductivityPolymer-modifiedIncreases durability; excellentadhesionwww.stocorp.com

<strong>Sto</strong> <strong>Leveler</strong>244Coverage30-35 ft 2 (2.8-3.3 m 2 ) per bag applied at 1 ⁄ 4"(6 mm) thick60-70 ft 2 (5.6-6.5 m 2 ) per bag applied at 1 ⁄ 8"(3 mm) thickCoverages may vary depending on applicationtechnique and surface conditions.Packaging60 lb. bag (27 kg)Shelf Life12 months, if sealed and properly stored.<strong>Sto</strong>rage<strong>Sto</strong>re off the ground in a dry area. Protect fromextreme heat [90º F (32º C)], moisture anddirect sunlight.Surface PreparationConcrete and masonry surfaces: Surfacesmust be free of all bond-inhibiting materials,including dirt, efflorescence, form oil and otherforeign matter. Loose or damaged material mustbe removed by waterblasting, sandblasting ormechanical wire brushing. Dampen surface priorto application of <strong>Sto</strong> <strong>Leveler</strong>. Refer to ASTMD-4258 and ASTM D-4261 for complete detailson methods of preparing cementitious substratesfor coatings.MixingUse 3.5-5 quarts (3.3-4.7 L) of water per 60 lb.bag (27 kg). Mix 1 ⁄ 2 bag at a time by adding <strong>Sto</strong><strong>Leveler</strong> to 3.5-5 pints (1.7-2.4 L) of clean,potable water in a clean mixing pail. Mix with aclean, rust-free electric drill and paddle. Allow toset approximately five minutes, adjust mix if necessaryby adding up to 1 ⁄ 2 pint (.24 L) of water,remix to a uniform consistency. Avoid retemperingafter mixing of product.ApplicationApply only to sound and clean, dry, properly prepared,frost-free surfaces.Dampen surfaces thoroughly with clean waterwhen applying <strong>Sto</strong> <strong>Leveler</strong> to porous surfaces orduring hot weather conditions. Apply <strong>Sto</strong> <strong>Leveler</strong>by hand troweling to a minimum 1 ⁄ 8" (3 mm) ormaximum 1 ⁄ 4" (6 mm) thickness in one application.Working time can be affected by temperatureand humidity (low humidity and high temperatureshorten working time). Once applied,the working time is up to 45 minutes dependingupon material, ambient temperatures and surfaceconditions.Protect from rain, freezing and continuous highhumidity until completely dry.Curing/Drying<strong>Sto</strong> <strong>Leveler</strong> sets in 1 to 3 hours, dependingupon ambient temperature and surface conditions.High temperatures, direct sun and windwill cause rapid drying. Under these conditions,the use of light water fogging for 48 hours isrecommended. Do not commence fogging untilinitial material sets (1-3 hours under normalconditions).Clean UpClean tools and equipment with water immediatelyafter use. Dried material can only beremoved mechanically.LimitationsUse <strong>Sto</strong> <strong>Leveler</strong> only when surface and ambienttemperatures are above 40° F (4° C) duringapplication and drying period. <strong>Sto</strong> <strong>Leveler</strong> is notrecommended for use on painted or wood surfaces.Sloped surfaces: minimum required slope is1:2 (27°) and maximum width is 12" (300 mm).<strong>Sto</strong> Mesh embedded in <strong>Sto</strong> Flexyl is requiredbeneath finish coating. Increase slope fornorthern climates to prevent accumulationof ice/snow and water on surface. Periodicinspection and increased maintenance ofcoating may be required.<strong>Sto</strong> <strong>Leveler</strong> should not be used as a finish coat.Health & SafetyHealth PrecautionsContains Portland cement and crystalline-freesilica. Avoid breathing dust. As with any chemicalconstruction product, exercise care whenhandling.Safety PrecautionsUse adequate ventilation. Use of a NIOSH/MSAapproveddust respirator, safety goggles andprotective gloves is recommended.First AidSKIN CONTACT: Wash thoroughly with soap andwater.EYE CONTACT: Flush immediately with water for10-15 minutes and contact a physician.RESPIRATORY PROBLEMS: Remove affectedperson to fresh air immediately and contact aphysician.HYGIENE: Wash hands immediately after use.Wash clothing before re-use.SpillsCollect in an appropriate container. Uncuredmaterial may be removed with water.DisposalDispose of in accordance with local, state orfederal regulations.WarningKEEP CONTAINER CLOSED WHEN NOT IN USE.KEEP OUT OF REACH OF CHILDREN. NOT FORINTERNAL CONSUMPTION. FOR INDUSTRIALUSE ONLY. Consult the Material Safety DataSheet for further health and safety information.LIMITED WARRANTYTHIS PRODUCT IS SUBJECT TO A WRITTENLIMITED WARRANTY WHICH CAN BE OBTAINEDFREE OF CHARGE FROM: <strong>Sto</strong> Corp., 3800 CampCreek Parkway, Building 1400, Suite 120,Atlanta, GA 30331; Tel: 404-346-3666;Fax: 404-346-3119<strong>Sto</strong> Corp.3800 Camp Creek ParkwayBuilding 1400, Suite 120Atlanta, GA 30331Tel: 404-346-3666Toll Free: 1-800-221-2397Fax: 404-346-3119www.stocorp.comS155-244 01/03 VEN 5609