27487 MD-VRB 4pp - Signode

27487 MD-VRB 4pp - Signode

27487 MD-VRB 4pp - Signode

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

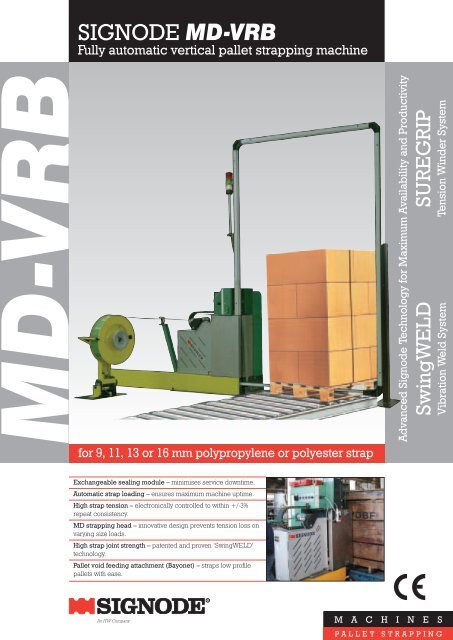

SIGNODE <strong>MD</strong>-<strong>VRB</strong>Fully automatic vertical pallet strapping machine<strong>MD</strong>-<strong>VRB</strong>Features and Benefitsfor 9, 11, 13 or 16 mm polypropylene or polyester strapAdvanced <strong>Signode</strong> Technology for Maximum Availability and ProductivitySUREGRIPTension Winder SystemSwingWELDVibration Weld SystemExchangeable sealing module – minimises service downtime.Automatic strap loading – ensures maximum machine uptime.High strap tension – electronically controlled to within +/-3%repeat consistency.<strong>MD</strong> strapping head – innovative design prevents tension loss onvarying size loads.High strap joint strength – patented and proven ‘SwingWELD’technology.Pallet void feeding attachment (Bayonet) – straps low profilepallets with ease.An ITW CompanyHM A NC DH TI ON OE SLAPALLETC C E SSTRAPPINGS O R I E S

SIGNODE <strong>MD</strong>-<strong>VRB</strong>Fully automatic vertical pallet strapping machineMaximum productivity and availability in a complete packageThe <strong>MD</strong>-<strong>VRB</strong> has been specifically developed for the vertical strapping ofpalletised loads and combines advanced features with proventechnology to deliver industry standard levels of reliability and availability.Suitable for use with polypropylene or polyester strapping in 9, 11, 13 or16 mm widths, it offers total operational flexibility to strap and secure a widevariety of palletised loads, including cartons, appliances, timber products,metal and glass components, bales and bundled products. Thecombination of <strong>Signode</strong>’s clutch free technology, multi-motor design andconsistent (+/- 3%) strap tension from 80 to 2100 Newtons, provides atechnologically advanced machine that is exceptionally reliable and can bespecified to suit specific productivity targets.High Strap TensionThe <strong>MD</strong> Strapping HeadThe side-mounted design of the <strong>MD</strong> strapping headenables it to securely strap pallet loads of differingwidths without any loss of tension. The pallet side isdetected via a sensor and the <strong>MD</strong> head movestowards the pack at the optimum approach speed toprevent any damage to the pallet.For maintenance, the <strong>MD</strong> head rotates through a full90º providing complete access to both sides, enablingoperators to service or clean the head without theneed of removal from the machine.The patented tension winder system iselectronically controlled to ensure consistentstrap tension of between +/-3% from strap tostrap. Tension levels from 80 to 2100 Newtonsare available to suit a wide variety of productapplications.Exchangeable Sealing ModuleThe sealing module is easilyexchanged and, when used with theoptional spare module, enablesoperation to continue, minimisingdowntime when service is required.

Automatic Strap LoadingAll <strong>Signode</strong> <strong>MD</strong> machines areequipped with a fully automatic, highspeed strap feed system to maximisemachine availability.High Strap Joint StrengthInnovative yet proven <strong>Signode</strong>technology in the form of the patentedSwingWELD vibration systemguarantees consistently high jointstrength, yet is sensitive to theenvironment as it produces no heat,fumes or smoke.Low Strap IndicatorA photo-cell, located on the dispenseritself detects low strap conditions andactivates a warning light signal to theoperator to prepare a new strap coil.Quick Change Coil Dispenser(optional)The <strong>MD</strong>-<strong>VRB</strong> features a novel strapdispenser which enables coils to beloaded from either horizontal or 45ºpositions and is hinged to lay down foreasy loading. Its design minimisesoperator lifting effort when moving thedispenser back to the upright position.The whole process is extremely fastensuring full productivity is quicklyrestored.Pallet Void Feeding Attachment(bayonet)At just 33 mm, the <strong>MD</strong>-<strong>VRB</strong>’s PVFAensures low profile pallets are strappedeasily and safely.<strong>MD</strong>-<strong>VRB</strong> models with top compressionTwo further developments of the modular <strong>MD</strong> side-sealstrapping system, both featuring an additionalcompression device, have been specially developed forpalletised bottle and can applications.Can applications – supplied with a compression force of5,000 Newtons, adjustable in 5 steps.Bottle applications – supplied with a compression force of20,000 Newtons, adjustable in 17 steps.Electrically driven and controlled, the compressiondevice features:a single power source for clean, efficient and fast operation,plus ease of control, high machine availability, with lowmaintenance costs and precise compression force with highrepeatability.

SIGNODE <strong>MD</strong>-<strong>VRB</strong> Fully automatic, vertical strapping machineInnovation and total reliability for pallet strapping<strong>MD</strong>-<strong>VRB</strong>Construction, operation and serviceThe <strong>MD</strong>-<strong>VRB</strong> is designed for the vertical strapping of palletloads with polypropylene or polyester strapping of 9, 11, 13 or16 mm width. The strapping head, mounted at the side of themachine, can travel up to 500 mm towards the pack toaccommodate packs of different widths. The side of the packis detected by a sensor that guarantees an optimumapproach speed to prevent the strapping head fromOptionsSpare sealing moduleNon standard chute dimensionsAdditional spare strap dispenserRiser kitPhotocell for low strap detection and machine status beaconFoot cycle switchBayonet lengths exceeding 2000 mmAllen Bradley MicroLogix PLCAutomatic strap rewind. (Automatically rewinds the strap during long periods ofinactivity, ensuring greater efficiency when re-starting).Machine DesignThe <strong>MD</strong>-<strong>VRB</strong> is available in a wide range of chute sizes with aluminiumconstruction.The height of the strap chutes varies between 1400 mm and 3000 mm, in200 mm increments.Bayonets are available in lengths of 1250 mm to 2000 mm in 250 mmincrements.Bayonet lengths exceeding 2000 mm are available for special order only.Strapping Materials<strong>Signode</strong> Dylastic ® <strong>Signode</strong> Tenax ®PolypropylenePolyester654 series 9 mm 1616 series 9 mm714 series 11 mm 1716 series 11 mm716 series 11 mm 1718 series 11 mm718 series 11 mm 1816 series 13 mm816 series 13 mm 1818 series 13 mm818 series 13 mm 1822 series 13 mm935 series 15 mm 2030 series 16 mm936 series 15 mm 2040 series 16 mm816 series 13 mm 2080 series 16 mmWorldwide Service Back-upAs a global product, consumables, service and parts back-up is availablefrom <strong>Signode</strong> distributors and partners, worldwide.<strong>MD</strong>-VR and <strong>MD</strong>-VFor applications where a bayonet is not required, the <strong>MD</strong>-VR and <strong>MD</strong>-Vmodels are also available.damaging the load. The strap chute and bayonet aremanufactured from extruded aluminium profile to ensurepositive transfer through the machine. The <strong>MD</strong>-<strong>VRB</strong> carriesCE safety certification to guarantee the highest level of userprotection. The electrical power circuit is designed to shutdown immediately when the safety chain is broken i.e. doorsopened or other emergency stop facilities activated.Technical DataStrapping Head<strong>MD</strong> with patented new technologySealing MethodSwingWELD – vibration sealStrap TensionAdjustable from 80 to 2100 Newtons(alternative 2400 N) with high repeat accuracyStrap CycleInitiated by means of photo cellsPower Supply400/415 volts, 3 phase, 50Hz or460 volts, 3 phase, 60HzPower Consumption 2.15 kW without conveyorControl Voltage24 volts DCControl Siemens S7-200Max Noise Level79 dB (A)Max Chute Size2000 x 3000 mm (width x height)Min Load Height700 mm including palletMachine WeightApprox 520 kgMachine Finish:Bayonet and HeadTracking Housing RAL 1003 yellowStrap ChuteAluminiumFrame and BaseRAL 7021 black + RAL 6000 greenMax Head Stroke500 mmF U L L Y A U T O M A T I C S T R A P P I N Gwww.signodeeurope.comAn ITW Company P319 E 1/05© <strong>Signode</strong> 2004 Printed in the U.K.<strong>Signode</strong> has a policy of continuous product development and reserves the right to alterspecifications at any time without prior notice.Designed and Produced by SEL Ltd. Birmingham.