PSF Power Strap Feeder

PSF Power Strap Feeder - Signode

PSF Power Strap Feeder - Signode

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

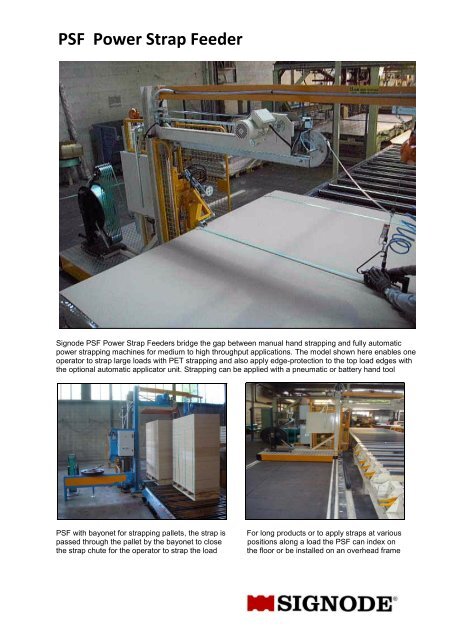

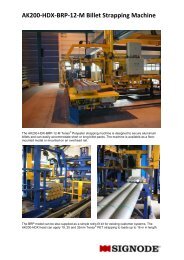

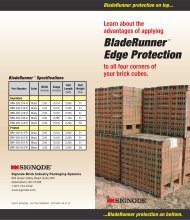

<strong>PSF</strong> <strong>Power</strong> <strong>Strap</strong> <strong>Feeder</strong>Signode <strong>PSF</strong> <strong>Power</strong> <strong>Strap</strong> <strong>Feeder</strong>s bridge the gap between manual hand strapping and fully automaticpower strapping machines for medium to high throughput applications. The model shown here enables oneoperator to strap large loads with PET strapping and also apply edge-protection to the top load edges withthe optional automatic applicator unit. <strong>Strap</strong>ping can be applied with a pneumatic or battery hand tool<strong>PSF</strong> with bayonet for strapping pallets, the strap ispassed through the pallet by the bayonet to closethe strap chute for the operator to strap the loadFor long products or to apply straps at variouspositions along a load the <strong>PSF</strong> can index onthe floor or be installed on an overhead frame

<strong>PSF</strong> <strong>Power</strong> <strong>Strap</strong> <strong>Feeder</strong>The Signode <strong>PSF</strong> range is very flexible operator controlled system and has a large number of optionsavailable for pallet and pallet less load strapping. This enables most customer applications for medium tohigh throughput strapping and packaging to be satisfied. The <strong>PSF</strong> as a single operator station reducesmanpower needs, enables efficiency to be improved and raises packaging consistency. The <strong>PSF</strong>s can bedelivered for use with Signode’s high performance Tenax ® PET or Steel strapping materials .Medium production throughputs – to cater for production lines of up to 40 pallets/hour .Maximum machine up-time - due to simple <strong>PSF</strong> head strap feeder designEasy strap feed up around the load - increases machine and operator efficiencyErgonomic design- reduces operator fatigue and effort – higher quality packagingImproved load securement & package stability - consistent strap tension using Signode hand toolsLower cost of ownership - easy service & low maintenance needsThe machine is built as standard with heavy-duty framework to suit the customer plant location. The unit hasa heavy-duty strap chute with full-length or telescopic strap chutes for high-speed strap feeding and accurateand importantly vertical strap positioning onto the load. The standard strap feeder is the <strong>PSF</strong>-1 Modular headfor heavy-duty 12-19 mm Tenax ® PET polyester or 13-19 mm steel strapping.<strong>PSF</strong> OptionsTechnical SpecificationsBayonet for through pallet void strappingFixed strap chute for pallet-less loadsManual wooden batten feeder and lifterEntry and exit roller conveyor sectionsPET Jumbo coil strap dispenser 73 kgPET Superjumbo coil strap dispenser 135 kgCombi model for Steel & PET strap useAutomatic top edge applicator unitIndexing model on floor based or onoverhead frameworkOther RAL colour finishes available.Pack Width Min 500 mmPack Width Max 2.500 mmPack Height min 100 mmPack Height max 2.000 mm<strong>Strap</strong> feedLoop auto. re-feed<strong>Strap</strong> Sizes9 - 19 mm<strong>Strap</strong> TypesPET and Steel<strong>Strap</strong> Feed Speed 3 m /sec.Controller Siemens S7-200Pneumatic connection 6 Bar, 20L / cycle<strong>Power</strong>. Connection 400 V 3Ph 50Hz<strong>Power</strong> Consumption 0,7 kWControl Voltage 24 V DC<strong>Strap</strong> Dispenser 406mm core std.Machine weight 500 kg approx.<strong>PSF</strong> loop for auto strap re-feed to reduce operatoreffort model with VT pneumatic hand tool for PETSimple overview showing <strong>PSF</strong> with strap bayonet,strap dispenser, tool suspension system and controlsThe company reserves the right to make technical changes without prior notification E-010929