thirteen

COVER HEAT INS FRONT.ai - Trigraha Sealisindo

COVER HEAT INS FRONT.ai - Trigraha Sealisindo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

JIC 8000<br />

CERAMIC FIBER BLANKET<br />

Ceramic fiber product are made from exceptionally pure<br />

alumina, silica and refactory oxides. This assures that all<br />

ceramics fiber have excellent temperature resistance,<br />

outstanding thermal stability, and good resistance to<br />

devitrification.<br />

Technical Characteristic and Application :<br />

• Excellent thermal stability<br />

The high purity fibers have good resistance to devitrification and are suitable or use up to 1260 0 C<br />

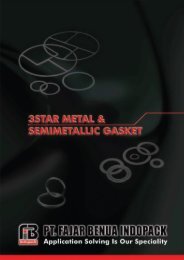

• Low thermal conductivity<br />

Ceramic fiber is an excellent insulator, having lower thermal conductivity than normal refacton lining material<br />

• Low heat storage<br />

Heat up and cooldown times are reduced substantially, and the productivity of a furnace or kiln can be increased<br />

in cyclical operations.<br />

• Light Weight<br />

Structural strength requirement are reduced with considerable saving as result.<br />

• Resistant to thermal shock<br />

A furnace or kiln can be rapidly heated and cooled.<br />

• Chemically stable<br />

Ceramic fiber product are essentially unaffected by all chemicals except hydrofluoric and phosphoric acid, and<br />

strong alkalis. If wet by oil or water, their thermal and physical properties will be fully restored after drying.<br />

• Resilient and resistant to physical abuse<br />

• They provide acoustic insulation resulting in a quiter working environment<br />

Properties<br />

: 1260 0 C<br />

Melting Point<br />

: