Multimedia

Download A3 poster (filesize approx 4MB) - OPERC

Download A3 poster (filesize approx 4MB) - OPERC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

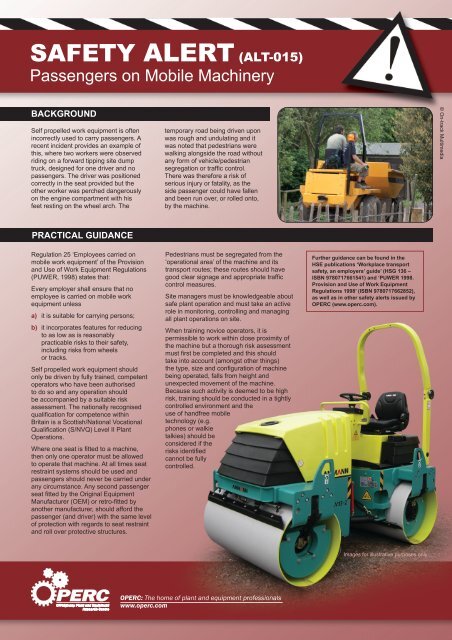

SAFETY ALERT (ALT-015)<br />

Passengers on Mobile Machinery<br />

BACKGROUND<br />

Self propelled work equipment is often<br />

incorrectly used to carry passengers. A<br />

recent incident provides an example of<br />

this, where two workers were observed<br />

riding on a forward tipping site dump<br />

truck, designed for one driver and no<br />

passengers. The driver was positioned<br />

correctly in the seat provided but the<br />

other worker was perched dangerously<br />

on the engine compartment with his<br />

feet resting on the wheel arch. The<br />

temporary road being driven upon<br />

was rough and undulating and it<br />

was noted that pedestrians were<br />

walking alongside the road without<br />

any form of vehicle/pedestrian<br />

segregation or traffic control.<br />

There was therefore a risk of<br />

serious injury or fatality, as the<br />

side passenger could have fallen<br />

and been run over, or rolled onto,<br />

by the machine.<br />

© On-track <strong>Multimedia</strong><br />

PRACTICAL GUIDANCE<br />

Regulation 25 ‘Employees carried on<br />

mobile work equipment’ of the Provision<br />

and Use of Work Equipment Regulations<br />

(PUWER, 1998) states that:<br />

Every employer shall ensure that no<br />

employee is carried on mobile work<br />

equipment unless<br />

a) it is suitable for carrying persons;<br />

b) it incorporates features for reducing<br />

to as low as is reasonably<br />

practicable risks to their safety,<br />

including risks from wheels<br />

or tracks.<br />

Self propelled work equipment should<br />

only be driven by fully trained, competent<br />

operators who have been authorised<br />

to do so and any operation should<br />

be accompanied by a suitable risk<br />

assessment. The nationally recognised<br />

qualification for competence within<br />

Britain is a Scottish/National Vocational<br />

Qualification (S/NVQ) Level II Plant<br />

Operations.<br />

Where one seat is fitted to a machine,<br />

then only one operator must be allowed<br />

to operate that machine. At all times seat<br />

restraint systems should be used and<br />

passengers should never be carried under<br />

any circumstance. Any second passenger<br />

seat fitted by the Original Equipment<br />

Manufacturer (OEM) or retro-fitted by<br />

another manufacturer, should afford the<br />

passenger (and driver) with the same level<br />

of protection with regards to seat restraint<br />

and roll over protective structures.<br />

Pedestrians must be segregated from the<br />

‘operational area’ of the machine and its<br />

transport routes; these routes should have<br />

good clear signage and appropriate traffic<br />

control measures.<br />

Site managers must be knowledgeable about<br />

safe plant operation and must take an active<br />

role in monitoring, controlling and managing<br />

all plant operations on site.<br />

When training novice operators, it is<br />

permissible to work within close proximity of<br />

the machine but a thorough risk assessment<br />

must first be completed and this should<br />

take into account (amongst other things)<br />

the type, size and configuration of machine<br />

being operated, falls from height and<br />

unexpected movement of the machine.<br />

Because such activity is deemed to be high<br />

risk, training should be conducted in a tightly<br />

controlled environment and the<br />

use of handfree mobile<br />

technology (e.g.<br />

phones or walkie<br />

talkies) should be<br />

considered if the<br />

risks identified<br />

cannot be fully<br />

controlled.<br />

Further guidance can be found in the<br />

HSE publications ‘Workplace transport<br />

safety, an employers’ guide’ (HSG 136 –<br />

ISBN 9780717661541) and ‘PUWER 1998.<br />

Provision and Use of Work Equipment<br />

Regulations 1998’ (ISBN 9780717662852),<br />

as well as in other safety alerts issued by<br />

OPERC (www.operc.com).<br />

Images for illustrative purposes only<br />

OPERC: The home of plant and equipment professionals<br />

www.operc.com

SAFETY ALERT (ALT-015)<br />

Passengers on Mobile Machinery<br />

BACKGROUND<br />

Self propelled work equipment is often<br />

incorrectly used to carry passengers. A<br />

recent incident provides an example of<br />

this, where two workers were observed<br />

riding on a forward tipping site dump<br />

truck, designed for one driver and no<br />

passengers. The driver was positioned<br />

correctly in the seat provided but the<br />

other worker was perched dangerously<br />

on the engine compartment with his<br />

feet resting on the wheel arch. The<br />

temporary road being driven upon<br />

was rough and undulating and it<br />

was noted that pedestrians were<br />

walking alongside the road without<br />

any form of vehicle/pedestrian<br />

segregation or traffic control.<br />

There was therefore a risk of<br />

serious injury or fatality, as the<br />

side passenger could have fallen<br />

and been run over, or rolled onto,<br />

by the machine.<br />

© On-track <strong>Multimedia</strong><br />

PRACTICAL GUIDANCE<br />

Regulation 25 ‘Employees carried on<br />

mobile work equipment’ of the Provision<br />

and Use of Work Equipment Regulations<br />

(PUWER, 1998) states that:<br />

Every employer shall ensure that no<br />

employee is carried on mobile work<br />

equipment unless<br />

a) it is suitable for carrying persons;<br />

b) it incorporates features for reducing<br />

to as low as is reasonably<br />

practicable risks to their safety,<br />

including risks from wheels<br />

or tracks.<br />

Self propelled work equipment should<br />

only be driven by fully trained, competent<br />

operators who have been authorised<br />

to do so and any operation should<br />

be accompanied by a suitable risk<br />

assessment. The nationally recognised<br />

qualification for competence within<br />

Britain is a Scottish/National Vocational<br />

Qualification (S/NVQ) Level II Plant<br />

Operations.<br />

Where one seat is fitted to a machine,<br />

then only one operator must be allowed<br />

to operate that machine. At all times seat<br />

restraint systems should be used and<br />

passengers should never be carried under<br />

any circumstance. Any second passenger<br />

seat fitted by the Original Equipment<br />

Manufacturer (OEM) or retro-fitted by<br />

another manufacturer, should afford the<br />

passenger (and driver) with the same level<br />

of protection with regards to seat restraint<br />

and roll over protective structures.<br />

Pedestrians must be segregated from the<br />

‘operational area’ of the machine and its<br />

transport routes; these routes should have<br />

good clear signage and appropriate traffic<br />

control measures.<br />

Site managers must be knowledgeable about<br />

safe plant operation and must take an active<br />

role in monitoring, controlling and managing<br />

all plant operations on site.<br />

When training novice operators, it is<br />

permissible to work within close proximity of<br />

the machine but a thorough risk assessment<br />

must first be completed and this should<br />

take into account (amongst other things)<br />

the type, size and configuration of machine<br />

being operated, falls from height and<br />

unexpected movement of the machine.<br />

Because such activity is deemed to be high<br />

risk, training should be conducted in a tightly<br />

controlled environment and the<br />

use of handfree mobile<br />

technology (e.g.<br />

phones or walkie<br />

talkies) should be<br />

considered if the<br />

risks identified<br />

cannot be fully<br />

controlled.<br />

Further guidance can be found in the<br />

HSE publications ‘Workplace transport<br />

safety, an employers’ guide’ (HSG 136 –<br />

ISBN 9780717661541) and ‘PUWER 1998.<br />

Provision and Use of Work Equipment<br />

Regulations 1998’ (ISBN 9780717662852),<br />

as well as in other safety alerts issued by<br />

OPERC (www.operc.com).<br />

Images for illustrative purposes only<br />

OPERC: The home of plant and equipment professionals<br />

www.operc.com