Premier spherical roller bearings our vast experience

Premier spherical roller bearings: our vast experience - NTN Bearing

Premier spherical roller bearings: our vast experience - NTN Bearing

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

From casting to surface treatment:<br />

total steel control<br />

Cast quality,<br />

alloy purity<br />

To sustain extreme stress loads, <strong>spherical</strong> <strong>roller</strong><br />

<strong>bearings</strong> require a steel quality beyond reproach.<br />

Two main considerations: strictly observed casting<br />

process and inclusion cleanliness. The SNR steel<br />

suppliers are selected worldwide, in line with these<br />

two criteria. The corporate agreements implemented<br />

with them guarantees reliable availability and<br />

perfect traceability.<br />

While continuously improving measurement accuracy,<br />

SNR has maintained the same test principles<br />

for thirty-five years! These constant principles are<br />

valuable, having allowed us to assess and control<br />

the evolution of the steels for several decades.<br />

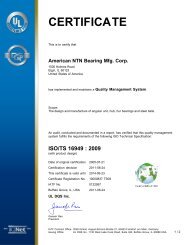

Service life is<br />

almost doubled<br />

in h<strong>our</strong>s<br />

1 000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

88<br />

Corrected nominal service life (L na )<br />

L na = a 1 .a 2 .a 3 .L 10<br />

a 1 = correction coefficient for a different reliability from<br />

a 2 =<br />

a 3 =<br />

L 10 =<br />

Service life of the steels used by SNR<br />

Before 1991: 100 h<strong>our</strong>s<br />

89 90 91 92 93 94 95 96 97 98 99 00 01 02 03 04 05<br />

Average service life<br />

SNR's acceptance limit<br />

90%.<br />

Since 1993: 450 h<strong>our</strong>s<br />

Before 1993: 250 h<strong>our</strong>s<br />

x 1,75<br />

correction coefficient according to material used,<br />

internal geometry and bearing manufacture.<br />

correction coefficient according to operating<br />

conditions (considered equal to 1 in normal<br />

operating conditions).<br />

basic nominal life.<br />

Years<br />

Some 15 years ago, the best steelworks in the<br />

world used to reach a minimum performance criterion<br />

of 250 h<strong>our</strong>s for 100 Cr6 steel in SNR's severe<br />

testing conditions. The cooperative work with <strong>our</strong><br />

suppliers allowed us to achieve the new steel<br />

quality, raising the performance criteria to more<br />

than 450 h<strong>our</strong>s: below this threshold, SNR refuses<br />

any steel production.<br />

With both rings manufactured from this new quality<br />

steel, an a 2 coefficient equal to 1.75 could be<br />

integrated in the corrected service life calculation.<br />

This is the minimum guaranteed value. In fact, this<br />

rate is regularly exceeded: the average of the steel<br />

batches used would allow a factor 3 or 4 to be<br />

applied by adopting this minimum value.<br />

SNR focuses on safety, for all types of applications.<br />

6