Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

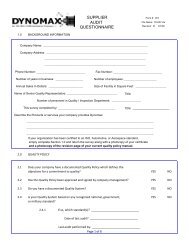

Table 4.<br />

Comparison of Contact Seals to Non-Contact Seals<br />

The table below shows the most important advantages of Non-Contact Seals compared with<br />

lip seals.<br />

Criteria Lip seal Non-Contact Seal<br />

Wear by friction none<br />

Power loss by friction none --> savings of energy<br />

--> may lead to smaller driving<br />

units<br />

Temperature<br />

increase<br />

yes none<br />

Speed limit depending on material none<br />

Live limited by wear unlimited<br />

Lubrication required at the sealing location no lubrication required for the seal<br />

Mating parts Hardening and grinding required for<br />

the shaft at higher speeds to reduce<br />

wear<br />

Temperature<br />

range<br />

Space<br />

requirement<br />

Field of<br />

applications<br />

limited due to material (plastic or<br />

rubber)<br />

Hardening and grinding not<br />

necessary<br />

from very low to very high<br />

- 40° C - 140° C (plastic material)<br />

- 40° F - 340° F (metallic material<br />

steel + aluminium)<br />

small formerly large - customer designed<br />

labyrinth seals;<br />

Grease lubrication Grease lubrication<br />

Oil lubrication Oil lubrication if oil level below<br />

sealing diameter<br />

Oil mist lubrication<br />

water - limited, as water may increase<br />

the friction at sealing location<br />

fine and coarse granular<br />

contamination not possible, as this<br />

environment causes rapid wear of the<br />

lips<br />

water - with the use of rust proof<br />

materials and level below sealing<br />

diameter<br />

fine and coarse granular<br />

contamination can be sealed<br />

reliably if applied to horizontal<br />

shaft.<br />

Because of the friction, contacting seals will raise the temperature of the system and therefore<br />

cannot be considered for the majority of machine tool <strong>spindle</strong>s. Thus, in general, contacting seals<br />

are used only where low speeds are involved<br />

dN value below 200.000<br />

- 30 -