You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Bearing Preload<br />

Angular contact ball bearings are available with a choice of pre-loading magnitude, typically<br />

designated as light, medium and heavy.<br />

Light pre-loaded bearings are designed to allow maximum speed and less stiffness. Light<br />

pre-loaded bearings are often used for very high speed applications, where cutting loads are also<br />

light, and top RPM is needed.<br />

Heavy pre-loading allows less speed, but higher stiffness.<br />

In order to provide the required load carrying capacity for a metal cutting machine tool <strong>spindle</strong>,<br />

several angular contact ball bearings are used together. This way, the bearings can share the<br />

applied loads, and increase the overall <strong>spindle</strong> stiffness. The bearings can be installed several<br />

ways, depending upon the desired characteristics.<br />

Angular contact ball bearings must be pre-loaded in order to provide axial and radial capabilities.<br />

One simple way to do this is to mount the bearings in groups of two or three, such that the preload<br />

is correctly applied to the bearings. This is possible by using duplex bearings, which are<br />

manufactured for this purpose. The inner or outer bearing races are ground, such that when<br />

clamped together the bearings will have the proper amount of pre-load.<br />

Bearing Mounting Configurations<br />

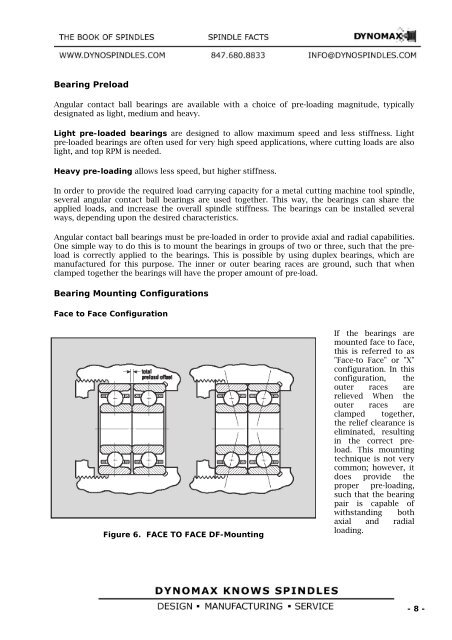

Face to Face Configuration<br />

Figure 6. FACE TO FACE DF-Mounting<br />

If the bearings are<br />

mounted face to face,<br />

this is referred to as<br />

"Face-to Face" or "X"<br />

configuration. In this<br />

configuration, the<br />

outer races are<br />

relieved When the<br />

outer races are<br />

clamped together,<br />

the relief clearance is<br />

eliminated, resulting<br />

in the correct preload.<br />

This mounting<br />

technique is not very<br />

common; however, it<br />

does provide the<br />

proper pre-loading,<br />

such that the bearing<br />

pair is capable of<br />

withstanding both<br />

axial and radial<br />

loading.<br />

- 8 -