Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

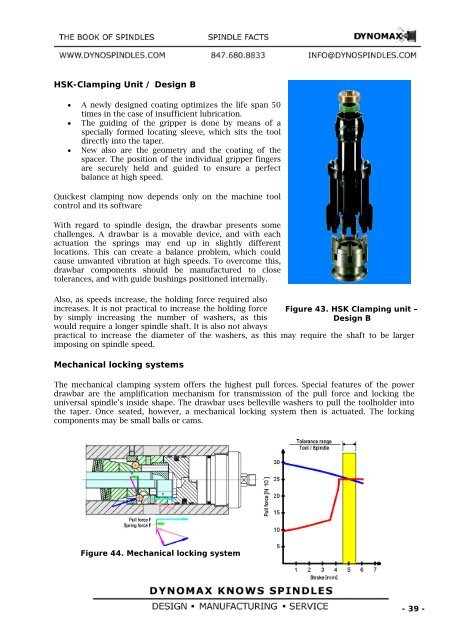

HSK-Clamping Unit / Design B<br />

• A newly designed coating optimizes the life span 50<br />

times in the case of insufficient lubrication.<br />

• The guiding of the gripper is done by means of a<br />

specially formed locating sleeve, which sits the tool<br />

directly into the taper.<br />

• New also are the geometry and the coating of the<br />

spacer. The position of the individual gripper fingers<br />

are securely held and guided to ensure a perfect<br />

balance at high speed.<br />

Quickest clamping now depends only on the machine tool<br />

control and its software<br />

With regard to <strong>spindle</strong> design, the drawbar presents some<br />

challenges. A drawbar is a movable device, and with each<br />

actuation the springs may end up in slightly different<br />

locations. This can create a balance problem, which could<br />

cause unwanted vibration at high speeds. To overcome this,<br />

drawbar components should be manufactured to close<br />

tolerances, and with guide bushings positioned internally.<br />

Also, as speeds increase, the holding force required also<br />

increases. It is not practical to increase the holding force<br />

by simply increasing the number of washers, as this<br />

would require a longer <strong>spindle</strong> shaft. It is also not always<br />

practical to increase the diameter of the washers, as this may require the shaft to be larger<br />

imposing on <strong>spindle</strong> speed.<br />

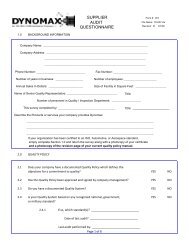

Mechanical locking systems<br />

Figure 43. HSK Clamping unit –<br />

Design B<br />

The mechanical clamping system offers the highest pull forces. Special features of the power<br />

drawbar are the amplification mechanism for transmission of the pull force and locking the<br />

universal <strong>spindle</strong>’s inside shape. The drawbar uses belleville washers to pull the toolholder into<br />

the taper. Once seated, however, a mechanical locking system then is actuated. The locking<br />

components may be small balls or cams.<br />

Figure 44. Mechanical locking system<br />

- 39 -