Dixon Sanitary 2010 Catalog

Dixon Bradford Sanitary Division - Goodyear

Dixon Bradford Sanitary Division - Goodyear

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Information<br />

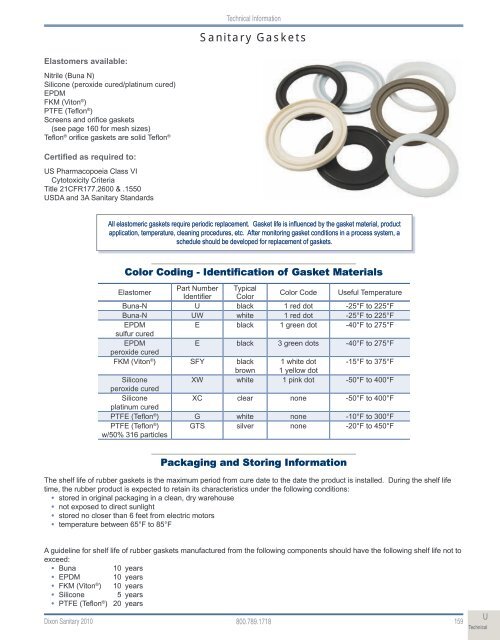

<strong>Sanitary</strong> Gaskets<br />

Elastomers available:<br />

Nitrile (Buna N)<br />

Silicone (peroxide cured/platinum cured)<br />

EPDM<br />

FKM (Viton ® )<br />

PTFE (Teflon ® )<br />

Screens and orifice gaskets<br />

(see page 160 for mesh sizes)<br />

Teflon ® orifice gaskets are solid Teflon ®<br />

Certified as required to:<br />

US Pharmacopoeia Class VI<br />

Cytotoxicity Criteria<br />

Title 21CFR177.2600 & .1550<br />

USDA and 3A <strong>Sanitary</strong> Standards<br />

All elastomeric gaskets require periodic replacement. Gasket life is influenced by the gasket material, product<br />

application, temperature, cleaning procedures, etc. After monitoring gasket conditions in a process system, a<br />

schedule should be developed for replacement of gaskets.<br />

Color Coding - Identification of Gasket Materials<br />

Elastomer<br />

Part Number Typical<br />

Identifier Color<br />

Color Code Useful Temperature<br />

Buna-N U black 1 red dot -25°F to 225°F<br />

Buna-N UW white 1 red dot -25°F to 225°F<br />

EPDM<br />

E black 1 green dot -40°F to 275°F<br />

sulfur cured<br />

EPDM<br />

E black 3 green dots -40°F to 275°F<br />

peroxide cured<br />

FKM (Viton ® ) SFY black 1 white dot -15°F to 375°F<br />

brown 1 yellow dot<br />

Silicone<br />

XW white 1 pink dot -50°F to 400°F<br />

peroxide cured<br />

Silicone<br />

XC clear none -50°F to 400°F<br />

platinum cured<br />

PTFE (Teflon ® ) G white none -10°F to 300°F<br />

PTFE (Teflon ® )<br />

w/50% 316 particles<br />

GTS silver none -20°F to 450°F<br />

Packaging and Storing Information<br />

The shelf life of rubber gaskets is the maximum period from cure date to the date the product is installed. During the shelf life<br />

time, the rubber product is expected to retain its characteristics under the following conditions:<br />

• stored in original packaging in a clean, dry warehouse<br />

• not exposed to direct sunlight<br />

• stored no closer than 6 feet from electric motors<br />

• temperature between 65°F to 85°F<br />

A guideline for shelf life of rubber gaskets manufactured from the following components should have the following shelf life not to<br />

exceed:<br />

• Buna<br />

10 years<br />

• EPDM 10 years<br />

• FKM (Viton ® ) 10 years<br />

• Silicone 5 years<br />

• PTFE (Teflon ® ) 20 years<br />

<strong>Dixon</strong> <strong>Sanitary</strong> <strong>2010</strong> 800.789.1718<br />

159<br />

U<br />

Technical