am..Brew

T'JTJ~~~ - Free and Open Source Software

T'JTJ~~~ - Free and Open Source Software

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Continuedfrom page /6<br />

LpREPARED<br />

I+AROLIN E<br />

I'<br />

CENT ER CO ~ lACT -<br />

CE~TE R<br />

C~OR<br />

- 9/32 CE ~T E R<br />

CONOUC TOIl<br />

7LW<br />

•<br />

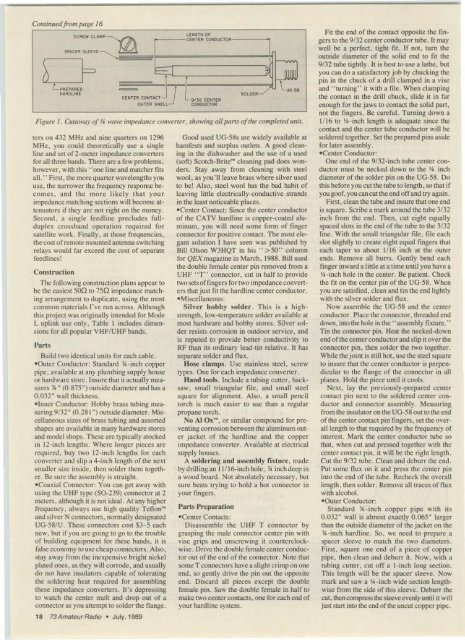

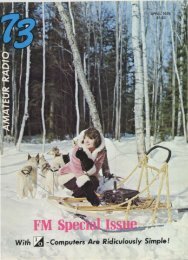

Figurt.' J. Cutawayof*wavt.' impedance con\'t.'r1er. showing allparts ofthe completed unit.<br />

rers on 432 MH z and nine quarters on 1296<br />

MHz. you could theoretically use a single<br />

line and set of 2-meter impedance conveners<br />

for all three bands . There are a few problems.<br />

however. with this " one line and matcher fits<br />

all." First. the more quarter wavelengths you<br />

use. the narrower the frequency respon se becomes.<br />

a nd th e more likel y that you r<br />

impedance matching sections will become attenuators<br />

if they are not right on the money .<br />

Second. a single feedline precludes fullduplex<br />

crossband operation required for<br />

satellite work. Finally. at those frequencies.<br />

the cost ofremote mounted antenna switching<br />

relays would far exceed the cost of separate<br />

feedlines!<br />

Construction<br />

The following co nstruction plan s appear [0<br />

be the easiest 500 to 750 impedance matching<br />

arrangemen t to du plicate. using the most<br />

common materials I've run across. Although<br />

this project was originally intended for Mode<br />

L uplink use only. Table I includes dimensions<br />

for all popular VHFfUHF bands.<br />

Parts<br />

Build two identical units for each cable.<br />

«Outer Conductor: Standa rd .lA-inch copper<br />

pipe. available at any plumhing supply house<br />

or hardware<br />

*<br />

store. Insu re that it actually measures<br />

~ (0 .875 ~) outside di<strong>am</strong>cter and has a<br />

0.032 ~ wall thickness.<br />

«Inner Conductor: Hobby brass tubing measuring<br />

9f32 - (0.281 ") outside di<strong>am</strong>eter. Miscellaneous<br />

sizes of brass tubing and assorted<br />

shapes are available in many hardware stores<br />

and model shops. These are typically stocked<br />

in t z-inch lengths. Where longer pieces are<br />

req uired . buy two 12-inch lengths for each<br />

co nverter and slip a 4-inch length of the next<br />

smaller size inside. then so lder them together.<br />

Be sure the asse mbly is straight.<br />

«Coa xial Connector: You ca n get away with<br />

using the UHF type (50-239) connector at 2<br />

meters. although it is not ideal. At any higher<br />

frequency. always use high quality Te fl on"<br />

and silver N connectors. normally designated<br />

UG-58fU. These co nnectors cost S3-5 each<br />

new. but if you are going to go to the trouble<br />

of buildi ng equipment for these bands. it is<br />

fal se economy to use cheap co nnectors . Also.<br />

stay away from the inexpensive bright nickel<br />

plated ones. as they will corrode. and usually<br />

do not have insulators capable of tolerating<br />

the so ldering heal required for asse mbling<br />

these impedance conveners. lr's depressing<br />

to watch the center melt and drop OUI of a<br />

connector as you attempt to solder the fla nge .<br />

18 73AmateurRadio . Juty, 1989<br />

Good used UG-58s are widely available at<br />

harnfests and surplus outlets . A good cleaning<br />

in the d ishwasher and the use o f a used<br />

(soft) Scotch-Brite" cleaning pad does wonde<br />

rs. Stay away from clea ning with steel<br />

wool . as you'llleave brass where silver used<br />

to be! Also. stee l wool has the bad habit of<br />

leaving little electrically-conductive strands<br />

in the least noticeable place!'>.<br />

«Center Contact: Since the ce nter cond uctor<br />

of the CATV hardlinc is copper-coated aluminum.<br />

you will need some fonn of finger<br />

connector for posi tive contact. The most elegant<br />

solution I have seen was published by<br />

Bill Olson W3HQT in his .. > 50" column<br />

for QEXmagazine in March. 1988. Bill used<br />

the double female center pin removed from a<br />

UHF " T" co nnector. cut in half 10 provide<br />

twoscrsoffingers for two impedance converters<br />

that just fit the hardline ce nte r conducto r.<br />

- Miscellaneous:<br />

Silver hobby solder. Th is is a highstrength<br />

. low-temperature solder available at<br />

most hardware and hobby stores. Silver solder<br />

resists corrosion in ou tdoor service. and<br />

is reputed to provide better conductivity to<br />

RF than it!'> ordinary lead-tin relative. It has<br />

separate solder and flux.<br />

Hose ch<strong>am</strong> ps. Use stainless steel. screw<br />

types. One for each impedance converter.<br />

Hand tools. Include a tubing cutter. hacksaw.<br />

small triangular file , and small steel<br />

square for alignment. Also. a small pencil<br />

torch is much easier to usc than a regular<br />

propane torch.<br />

So AI Ox"'. or similar compound for preventing<br />

corrosion between the aluminum outer<br />

jacket o f the hardline and the copper<br />

impedance convener . Available at electrical<br />

supply houses.<br />

A solderi ng a nd assembly fixture. made<br />

by drilling an Il fl6-inch hole . * inch deep in<br />

a wood board. Not absolutely necessary. but<br />

sure beat!'> trying to hold a hOI connecto r in<br />

you r fingers .<br />

Parts Preparation<br />

SOLDER<br />

.../ l".,<br />

eCcnrer Contacts:<br />

Disassembl e the UHF T connecto r by<br />

grasping the male connector ce nter pin with<br />

vise grips and unscrewing it counterclockwise.<br />

Drive the double female center conductor<br />

out of the end of the co nnector. Note that<br />

so me T co nnectors have a slight crimp on one<br />

end. so gently d rive the pin out the opposite<br />

end . Discard all pieces except the double<br />

female pin . Saw me dou ble female in half to<br />

make two center contacts. one for each end of<br />

you r hardline system.<br />

Fit the end of the contact opposite the fingers<br />

to the 9f3 2 center conductor tube. It may<br />

well be a perfect. tight fit . If not. tum the<br />

outside di<strong>am</strong>eter of the solid end to lit the<br />

9/32 tube tightly. It is best to use a lathe. but<br />

you ca n do a satisfacto ry job by chucking the<br />

pin in the chuck of a drill cl<strong>am</strong>ped in a vise<br />

and " turning" it with a fil e . When cl<strong>am</strong>ping<br />

the co ntact in the drill chuck . slide it in far<br />

enough for the jaws to co ntact the solid part,<br />

not the finge rs. Be ca refu l. Turning down a<br />

1/16 to I,t -inch length is adequate since the<br />

contact and the center tube conducto r will be<br />

soldered together. Set the prepared pins aside<br />

for later assembly.<br />

- Cemcr Conductor:<br />

One end of me 9f32-inch tube ce nter conductor<br />

must be necked down to the I,i inch<br />

di<strong>am</strong>eter of the solder pin on the UG-58. Do<br />

this before you cut the tube to length. so that if<br />

you goo f. you can cut the end off and try again.<br />

First. clea n the tube and insure that one end<br />

is square. Scribe a mark around the tube 3/32<br />

inch from the end. Then. cut eight equally<br />

spaced stors in the end of the tube to the 3/32<br />

line. with the small triangular file. file each<br />

slot slightly to create eight equal fingers that<br />

each taper to abou t 111 6 inch at the outer<br />

ends. Remove all burrs. Gently bend each<br />

finger inward a little at a time until you have a<br />

Ill-inch hole in the center. Be patient. Check<br />

the fit on the center pin of the UG-58. When<br />

you are satisfied. clean and tin the end lightly<br />

with the silver solder and n ux.<br />

Now assemble Ihe VG-58 and the ce nter<br />

conductor. Place the connector, threaded end<br />

do.....n. intothe hole in the " assembly fixture ."<br />

Tin the connector pin. Heat the necked-down<br />

end ofthe center conductor and slip it over the<br />

connector pin. then solder the two together .<br />

Whi le the joint is still hot. usc the steel square<br />

to insure that the ce nter conductor is perpendicu<br />

lar to the flange of the co nnector in all<br />

planes . Hold the piece until it cools.<br />

Next. lay the previously-prepared ce nter<br />

contact pin next to the soldered center co n<br />

ductor and connector assembly. Measuring<br />

from the insu lator-on the UG-58 outtothe end<br />

ofthe ce nter contact pin fingers. set the overall<br />

length to that required by the frequency of<br />

interest . Mark me ce nter conductor tube so<br />

that . whe n cut and pressed together with the<br />

center co ntact pin. it will be the right length .<br />

Cut the 9/32 lube. Clea n and deburr the end.<br />

Put some flux on it and press the center pin<br />

into the end of the tube. Rechec k the overall<br />

length. then solder. Remove all traces of nux<br />

with alcohol.<br />

«Outer Conductor:<br />

Standard a-Inch copper pipe with its<br />

O.03r wall is almost exactly 0 .065- larger<br />

than Ihe outside di<strong>am</strong>eter of the jacket on the<br />

~- inch hardline . So. we need to prepare a<br />

spacer sleeve to match the two di<strong>am</strong>eters.<br />

First. square one end o f a piece of copper<br />

pipe, then clean and deburr it. Now . with a<br />

tubing cu tter, cut off a l -inch long section.<br />

This length will be the space r sleeve. Now<br />

mark and saw a lA-inch wide section lengthwise<br />

from the side of this sleeve. Deburr Ihe<br />

cut. then compress the sleeve evenly until it will<br />

just start imo the end ofthe uncut copper pipe.