ACL REPORTER

ACL Newsletter Issue 19.pdf

ACL Newsletter Issue 19.pdf

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

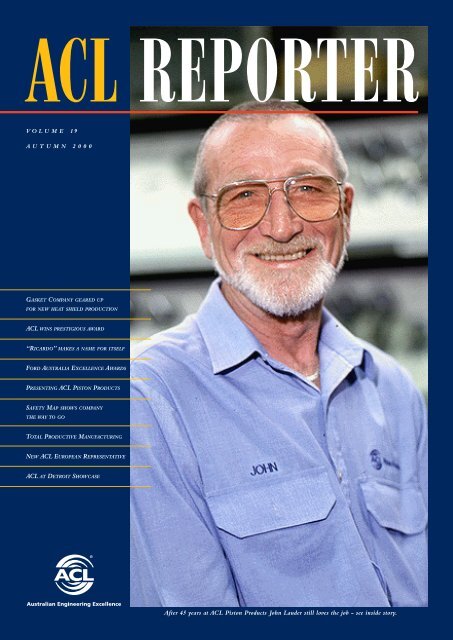

<strong>ACL</strong> <strong>REPORTER</strong><br />

VOLUME 19<br />

AUTUMN 2000<br />

GASKET COMPANY GEARED UP<br />

FOR NEW HEAT SHIELD PRODUCTION<br />

<strong>ACL</strong> WINS PRESTIGIOUS AWARD<br />

“RICARDO” MAKES A NAME FOR ITSELF<br />

FORD AUSTRALIA EXCELLENCE AWARDS<br />

PRESENTING <strong>ACL</strong> PISTON PRODUCTS<br />

SAFETY MAP SHOWS COMPANY<br />

THE WAY TO GO<br />

TOTAL PRODUCTIVE MANUFACTURING<br />

NEW <strong>ACL</strong> EUROPEAN REPRESENTATIVE<br />

<strong>ACL</strong> AT DETROIT SHOWCASE<br />

®<br />

Australian Engineering Excellence<br />

After 45 years at <strong>ACL</strong> Piston Products John Lauder still loves the job - see inside story.

NEW R&D ENGINEER<br />

JOINS GASKET COMPANY<br />

<strong>ACL</strong> Gasket Company has signalled<br />

the importance of research and<br />

development with the recent appointment<br />

of Matt Dargush to the Brisbane plant.<br />

Matt, a post Doctoral Research Fellow<br />

at the University of Queensland, who<br />

then worked with CRC in alloys and<br />

solidification technology, will co-ordinate<br />

most of the research and development<br />

activity at Eagle Farm.<br />

“I will be looking at building linkages<br />

with external R&D and technology providers,”<br />

explained Matt.“You can split this kind of<br />

work into two basic areas. One is looking<br />

at achieving incremental improvement to a<br />

process.This involves developing processes<br />

and implementing technology and finding<br />

technology providers to improve our process.<br />

“The other area is a strategic development of<br />

product development.This includes knowledge<br />

of competitors’products,patent information,<br />

all obtainable through research activity.”<br />

He said that to research new technology<br />

and new products he would explore open<br />

literature, the Internet, and patent literature.<br />

“When a patent is published, it enters the<br />

body of knowledge.There are a number of<br />

licensors that <strong>ACL</strong> deals with and in addition,<br />

we are building partnerships with such bodies<br />

as the University of Queensland and the<br />

CSIRO, to see how we can work with these<br />

kinds of people.”<br />

An example of incremental improvement<br />

quoted by Matt, was a company that might<br />

cure products. This type of liaison could<br />

provide <strong>ACL</strong> Gasket Company with the<br />

technical know-how on a particular task.<br />

Matt said that one of the reasons he was<br />

keen to join <strong>ACL</strong> was the opportunity of<br />

“getting into a real manufacturing environment<br />

which has a range of different projects.”<br />

Married, with a little girl, Matt enjoys<br />

fishing and watching rugby. And how does<br />

the new job compare to the cloistered life<br />

of the university? “It’s a more hectic life than<br />

being at university,” was his reply.<br />

GASKET COMPANY<br />

GEARED UP FOR<br />

NEW HEAT SHIELD<br />

PRODUCTION<br />

<strong>ACL</strong> is involved in the production of a<br />

new series of heat shields for Holden’s<br />

Generation 3 Series V-8 engines,as Bill Fraser,<br />

Gasket’s Engineering Manager explains to<br />

the “<strong>ACL</strong> <strong>REPORTER</strong>”.<br />

“This product was specially developed<br />

for the 3 Series and offers specific properties.<br />

That is why it’s interesting. It’s a heat shield<br />

that’s non-metallic. Holden’s requirement was<br />

that it had to be almost zero transfer of heat,<br />

as the heat shield was to protect the ECU<br />

(Electronic Control Unit) in the vehicle.<br />

“To do this we bond two phenolic<br />

components. The phenolic material that<br />

is made up of impregnated glass. The rear<br />

part is held in a slide and the ECU is behind<br />

it.You have a situation where the ECU is<br />

located near the exhaust manifold, which<br />

reaches 700 degrees Celsius, while the ECU<br />

is temperature sensitive to about 110 degrees.<br />

So it does a pretty good job of creating a heat<br />

barrier for the ECU. If the ECU reaches<br />

125 degrees Celsius it just stops.<br />

“Before we came up with this material,<br />

they had trialled a number of different<br />

materials, one being steel multi-layer. The<br />

idea was that the steel would reflect the heat<br />

but there was still too much heat transferred<br />

through the shield and the plastic carrier<br />

holding the ECU melted.”<br />

Bill said that the company was in full<br />

production for both domestic and export<br />

markets.<br />

..AND THAT’S NOT ALL!!<br />

Bill Fraser with the two new<br />

products manufactured at Gasket<br />

Company’s Eagle Farm plant.<br />

<strong>ACL</strong> Gasket Company is also involved<br />

in another heat shield exercise, this one for<br />

Ford’s new engine. It is a corrugated exhaust<br />

manifold heat shield for the upgrade Falcon<br />

and the material used was a twin layer of<br />

aluminium steel with ceramic paper. Bill<br />

said the steel goes through a rolling process<br />

and a film of aluminium is pressed over the<br />

top and bonded with the paper.While the<br />

materials are obtained overseas, all the design<br />

and production work was done at Eagle Farm.

FCAI President Mr. Peter Hanenberger (left)<br />

presents Bob Panitzki with the “Supplier of the Year” award.<br />

<strong>ACL</strong> BEARING COMPANY WINS<br />

PRESTIGIOUS FCAI SUPPLIEROF<br />

THE YEAR AWARD<br />

In a gathering of 140 of the “who’s who”<br />

of Australian motor industry component<br />

manufacturers, Mr Peter Hanenberger,<br />

President of the Federal Chamber of Automotive<br />

Industries, presented <strong>ACL</strong> Bearing<br />

Company with the 14th FCA1 1999 Supplier<br />

of the Year Award in Adelaide recently.<br />

The award is judged by the Purchasing<br />

Directors of the vehicle manufacturers, on<br />

behalf of the peak industry body. Criteria<br />

includes not just product quality and competitiveness<br />

of price and delivery but also product<br />

development and process management.<br />

<strong>ACL</strong> Bearing Company is the sole<br />

manufacturer of precision engine bearings in<br />

Australia and the largest powder metallurgy<br />

manufacturer.<br />

It was the first time that the company<br />

had won the title, though they were finalists<br />

in 1998.The competition this year included<br />

such well-known names as Australian Automotive<br />

Air, Bridgestone Tyres, Finemore’s<br />

Logistics and Transport and Air International.<br />

Mr Hanenberger, who is also Chairman<br />

and Managing Director of Holden Limited<br />

in Australia, said the award bears testimony<br />

to the great strength of partnership between<br />

the various members of the Australian<br />

automotive industry.<br />

“Efficient supply of goods and services,<br />

both internationally and domestically, to a<br />

portfolio of local manufacturers and importers<br />

is the key strength we have, and is one we<br />

must continue to nurture and grow,” he said.<br />

“Tonight is a celebration and recognition<br />

of the excellent standards of our supplier<br />

industry. Excellence in product and business<br />

strategies, excellence in their execution,<br />

delivery, and value, and excellence in creating<br />

a vision for the next decade.”<br />

General Manager, Bearing Company,<br />

Bob Panitzki, said to be acknowledged as the<br />

FCAI Supplier of the Year was a tremendous<br />

recognition from the four Australian<br />

companies. Three of these car companies<br />

recognised <strong>ACL</strong> Bearing Company with<br />

Supplier Excellence Awards in 1999 so it was<br />

a good all-round performance he said.<br />

“We have a good working relationship<br />

with our employees, many of whom are<br />

long-serving, and who are committed to<br />

continuously improving all operations within<br />

the company. This award is a wonderful<br />

recognition of their efforts.”<br />

Mr Hanenberger also stressed the importance<br />

of continuous improvement when he<br />

told the gathering:“Our immediate challenge<br />

is to be innovative and creative both in<br />

engineering and marketing terms and to<br />

increase our local share.”<br />

He said the automotive export market<br />

grew 23% in 1999 to a record $3.2 billion,<br />

which topped both the wool and beef sectors.<br />

Attending the presentation on behalf<br />

of <strong>ACL</strong> were Bob Panitzki, Ivan James,<br />

Chris Brooks, and Ewen Kilpatrick.

PRESENTING <strong>ACL</strong> PISTON PRODUCTS<br />

NEW<br />

FINANCIAL<br />

CONTROLLER<br />

IS A BIT OF<br />

A SWINGER<br />

Adrian working with RICARDO<br />

New Financial Controller at<br />

<strong>ACL</strong> Piston Products is<br />

Peter Lane. Peter is a very, very,<br />

keen baseball player and it occupies<br />

a lot of his time during summer.<br />

“I play and coach,” explained<br />

Peter, who only took up the sport<br />

a couple of years ago.<br />

“When my son was playing in<br />

the juniors, they said ‘we’re short<br />

on the 4th would you play?’ So I<br />

played on the 4th on the Sunday<br />

and then they said that I was old<br />

enough to play in the Masters on<br />

a Monday night, so on Tuesday I<br />

didn’t walk too well.”<br />

Peter said that it’s a great sport,<br />

and while he’s occupied with his<br />

son on Saturdays, his wife who runs<br />

a ballet school, is involved with their<br />

three daughters at netball.<br />

Prior to joining <strong>ACL</strong> Piston<br />

Products, Peter was with Flexibox<br />

- John Crane for twelve years.<br />

He was state accountant for<br />

Beaurepaire’s and has also worked<br />

for Dunlop Tyres.<br />

RICARDO MAKES A<br />

NAME FOR ITSELF AT<br />

PISTON PRODUCTS<br />

Anew high tech computer software program<br />

is making the job of designing pistons<br />

and rings a lot quicker and cheaper said<br />

Technical Group Leader, Adrian Martin,<br />

when he showed the “<strong>ACL</strong> <strong>REPORTER</strong>”<br />

RICARDO, the latest way to see how pistons<br />

and rings move in an engine.“We can use it as<br />

a design tool to optimise the skirt shape and<br />

the rings, in order to minimise wear, reduce<br />

noise and provide better fuel consumption,”<br />

explained Adrian.<br />

“We’ve been using it for just over a year<br />

now and we are really starting to get the<br />

hang of it. We are finding it to be a good<br />

predictive tool. It gives us the capability to<br />

be design independent.”<br />

He said that if they created a design to<br />

optimise the skirt shape, Piston Products can<br />

undertake a run overnight and obtain the<br />

results in the morning.“Whereas, if we have<br />

to do an engine test, we have to make the<br />

sample, which takes several days; measure<br />

them all up; build them, which takes another<br />

few days; run the engine test; then rip the<br />

engine down and look at the pistons. So<br />

basically, what you can do overnight using<br />

the program, would take two or three weeks<br />

previously, saving about $20,000.”<br />

A number of other piston manufacturers<br />

have RICARDO or have developed their<br />

own system.Adrian said it was used initially<br />

to predict what the team actually had.“From<br />

an engine test we modelled it and tuned the<br />

model to match what we were actually<br />

getting at the end of the day,” said Adrian.<br />

“We knew then that we had the right parameters.<br />

So now, it is being used as a predictive<br />

source to develop the design of our pistons.”

<strong>ACL</strong> PISTON PRODUCTS A<br />

FINALIST IN FORD AUSTRALIA’S<br />

EXCELLENCE AWARDS<br />

A<br />

CL Piston Products made the final cut<br />

for the 1999 Ford Australia Excellence<br />

Awards held in Melbourne recently.<br />

Robert Edwards, Piston Products’<br />

Quality & Human Resources Group Leader<br />

said the screening process, which was based<br />

on the 1999 performance, involved a number<br />

of key factors.<br />

“We had to complete a survey covering<br />

a whole range of issues including occupational<br />

health & safety; site issues; environmental<br />

factors and if we were a good corporate<br />

citizen,” said Robert.<br />

“Ford measured us on all those aspects,<br />

combined with our quality and delivery<br />

performance, plus other factors. From all the<br />

suppliers who provide Ford with goods and<br />

services, they reduced the number to about<br />

twenty.<br />

Representatives from those finalists were<br />

invited to attend a dinner and <strong>ACL</strong> Piston<br />

Products was represented by Trevor Day<br />

our Senior Shop Steward, Nigel Tate, Chief<br />

Engineer, Ian Veale, Group Leader of the<br />

Technical Centre and myself.”<br />

Robert said that they were seated with<br />

Mr Tony Simpson the Senior Vice President<br />

of Purchasing for Ford Australia. Unfortunately,<br />

while the company didn’t take any of the<br />

major awards, congratulations go to Bearing<br />

Company which won the Silver Award, and<br />

it was a great thrill being amongst a select<br />

few to make the finals.<br />

ONE YEAR FINISHED, THREE TO GO, FOR BEN<br />

Ben Male, <strong>ACL</strong> Piston Product’s electrical apprentice, has just finished the first year<br />

of his four-year apprenticeship. We caught up with Ben as he looked out on<br />

another year of trade school and learning on the job and asked him how it was going?<br />

“It’s going pretty well and I’m learning a lot.When I finish my time, I’d like to stay<br />

here for a few more years to get greater experience. I’m doing my advanced schooling<br />

now and I’d like to go from a C8 to a C7 and that’s what the advanced schooling is for.<br />

“It’s been a good company to work for and compared to just wiring houses, there’s<br />

a lot more to learn with the machines we have here. I’m involved in the maintenance<br />

of the machines, and I’ve built a couple of machines myself, which were used for the<br />

piston machine shop. One was an air knife machine that cleans all the coolants off the<br />

piston, and the other was a washing machine. I work under Jason Sapulla and in my<br />

first year of schooling, I was doing block release, which was a week every month. Now<br />

I’m at Sunshine, it’s one day a week. The Advanced Schooling is at night.”<br />

Spare time activities include playing football for the Altona Vikings Seniors and<br />

“working out at the gym a lot”.

PRESENTING <strong>ACL</strong> PISTON PRODUCTS<br />

45 YEARS ON,<br />

JOHN STILL ENJOYS<br />

THE CHALLENGE<br />

One could be forgiven for believing that<br />

after 45 years’involvement in the manufacture<br />

of automotive pistons, John Lauder<br />

has seen and done it all. But when the “<strong>ACL</strong><br />

<strong>REPORTER</strong>” spoke to him recently, after<br />

achieving his 45th year with the company,<br />

John was still seeing his job as a challenge.<br />

“We’re introducing families of products to<br />

make the manufacture of product quicker,”<br />

explained John. “I’m still involved, and am<br />

organising the new tooling as far as the dies<br />

are concerned, for the new pistons we’re<br />

making. Since we started the North American<br />

project, we’ve put through sixty new part<br />

numbers, so I’m terribly involved in all this.”<br />

What memories and thoughts had he<br />

as he looked back on 45 years of work? “The<br />

hardest part is looking forward to the next<br />

45 years,” laughed John.The years have gone<br />

so fast. I can vividly remember the very first<br />

day when I started. I walked into the place<br />

as a junior draftsman and spent most of the<br />

day sharpening pencils, and as I mentioned<br />

to somebody the other day, nothing has<br />

changed!<br />

“I joined the Rolloy Piston Company in<br />

Port Melbourne, which was a company that<br />

made pistons as well as general castings for<br />

motor mowers, outboard motors, manifolds,<br />

etc. It was very diversified.”<br />

John said that things like the introduction<br />

of Kanban, had made a huge change in<br />

the way things were done.“It’s very different,<br />

especially with the smaller batches, so we<br />

have to take the next step, which is achieving<br />

quicker tool changes and that’s on the board<br />

now.Without the support of the people on<br />

the shop floor, we can’t achieve anything.<br />

So we have to ensure that they’re on our side<br />

and are kept informed as we go along.”<br />

He said that there had been a number<br />

of changes with the grouping of products<br />

with duplicated tooling.“With all the lines<br />

independent of each other, there is no<br />

switching or swapping and products are<br />

Adrian Martin (left) Ewen Kilpatrick (centre)<br />

make a presentation to John on his 45th year.<br />

PRASAD BRINGS<br />

OVERSEAS<br />

EXPERIENCE TO<br />

PISTON PRODUCTS<br />

Arecent addition to the ranks<br />

of toolmakers at <strong>ACL</strong> Piston<br />

Products, is Prasad Mandava, who<br />

originally came from Hyderabad<br />

in the south of India.<br />

He studied and worked for<br />

five years in India with ITW, an<br />

American manufacturer of packaging<br />

products. He then migrated<br />

to Malaysia where he worked for<br />

another five years for a company<br />

making semi-conductor chips in<br />

Kuala Lumpur.<br />

Having parents in Australia<br />

has helped Prasad acclimatise to<br />

his new country. While married,<br />

there aren’t any little “Prasads” at<br />

this moment in time. Spare-time<br />

activities? Cricket naturally, and the<br />

odd game of tennis.<br />

manufactured in family groups. We try to<br />

lay them out as a minimal change in each<br />

product, and it’s working quite well, as it has<br />

to with Kanban.”<br />

John said that the company had a big<br />

push on export and was relying on <strong>ACL</strong><br />

America to support where they could.“They’re<br />

trying to sell engine parts as a package. Pistons,<br />

bearings, gaskets as a whole kit and this was<br />

launched in January.”<br />

John moved to Melton, then a new<br />

suburb and closer to <strong>ACL</strong>, after many years<br />

living at Port Melbourne.<br />

He said the move was “a real shock” to<br />

his system.“I came from a terrace house with<br />

bluestone paving out the back and a few pots,<br />

to a house that actually had a backyard with<br />

grass. So, one of the first things I had to do,<br />

was go out and buy a lawn mower and learn<br />

how to drive it.”

TOTAL PRODUCTIVE MANUFACTURING<br />

(TPM) EMBRACED BY PISTON PRODUCTS<br />

Total Productive Manufacturing is one of<br />

the key strategic projects being commenced<br />

this year at <strong>ACL</strong> Piston Products.<br />

TPM is a proven improvement strategy that<br />

focuses on equipment management. Like<br />

TQM, which is company-wide Quality<br />

Management through team activities,TPM<br />

is equipment management performed on a<br />

company-wide basis, again using the power<br />

of teamwork.<br />

Ewen Kilpatrick, Piston Products General<br />

Manager stated:“The starting principle behind<br />

TPM is that ‘there is nothing inevitable about<br />

failure’. Every time a machine fails or breaks<br />

down something could have been done to<br />

prevent it.”<br />

He said that from this starting point,<br />

TPM is the systematic identification and<br />

correction of equipment ‘defects’ by the<br />

people who know the equipment best - that<br />

is the production and maintenance personnel.<br />

The TPM program is being managed<br />

and steered by the Consultative Committee<br />

who have endorsed it as a strategic activity<br />

for commencement in 2000, and continuing<br />

into the future.<br />

Piston Products commenced the TPM<br />

programme by conducting a 2-day training<br />

course early in March. Kon Archon has been<br />

appointed as TPM Co-ordinator and now a<br />

number of pilot teams will be set up.“Over<br />

the last few years, most of our production<br />

improvements have been through simplification<br />

of processes and capital expenditure,”<br />

Ewen added. “Now that our basic process<br />

arrangements and capital programmes are<br />

mostly completed, improvements will come<br />

from operational initiatives such as TPM.”<br />

(Back row from left) Don Jarvis,Andrew Corech, Brendan Cross, (front) Karen Massese, Jane Reid and Lillian Ognenovski.<br />

SAFETY MAP SHOWS<br />

COMPANY THE WAY TO GO<br />

After twenty months of hard work and<br />

dedication from a number of team<br />

members, <strong>ACL</strong> Piston Products has successfully<br />

completed the initial Work Cover Safety<br />

MAP program. Safety MAP is an audit tool<br />

that helps organisations improve the management<br />

of health and safety within a company.<br />

It promotes safer working procedures by<br />

systematically measuring how well the safety<br />

procedures operate within an organisation.<br />

There are three levels of performance -<br />

Initial Level,Transition Level and Advanced<br />

Level. Piston Products had considered instigating<br />

a Safety MAP program as far back<br />

as 1998, and has undertaken a total review<br />

of procedures and policies over that time.<br />

Karen Massese, Piston Products’ Occupational<br />

Health & Safety Nurse, said the major<br />

issue was identifying every piece of plant<br />

and equipment that existed on the factory<br />

floor.“This is done by a risk assessment team<br />

from within each individual department,”<br />

explained Karen.<br />

“Each group of machines had to be<br />

assessed and the assessors will be back in<br />

May to do the immediate level. I don’t<br />

think we’ll have the hazard identification<br />

completed by then but we’ll have done a<br />

lot of work in that area.”<br />

Karen took each department through a<br />

training session and she said that the reaction<br />

from each section had been very positive.The<br />

team heading up the Safety MAP program<br />

was awarded their certificate of approval<br />

back in January by Lloyd’s Register Quality<br />

Assurance, after meeting 58 criteria needed<br />

to qualify for the Initial Level.<br />

Team member Brendan Cross?, Plant<br />

Safety Manager in charge of dangerous and<br />

hazardous goods said, “I think it’s brilliant<br />

- I really do. It will help enforce the rules<br />

and improve the site as far as safety goes.”<br />

Another team member Andrew Corech<br />

added, “It helps with managing safety and<br />

so far it’s been pretty good. I’m the diecast<br />

rep. and it can be a dangerous area.”<br />

Lillian Ognenovski Human Resources<br />

Manager said,“It’s definitely been a long and<br />

tiring road but everyone has been great. I<br />

want to thank people for their support and<br />

encouragement. It took a lot of hard work<br />

but it was all worth it in the end.”

PRESENTING <strong>ACL</strong> PISTON PRODUCTS<br />

CARMEL HAS<br />

IMPROVEMENT<br />

IN HER SIGHTS<br />

PISTON PRODUCTS<br />

WAREHOUSE MOVES INTO<br />

THE RADIO AGE<br />

<strong>ACL</strong> Piston products is moving into the<br />

RF (radio frequency) method of<br />

barcode reading, which will make picking<br />

and product selection easier for warehouse<br />

staff. The new system, which has been<br />

installed to reduce the error rate in picking,<br />

will also eventually assist the company with<br />

stock-taking. The RF units will scan the<br />

barcodes on the packages of rings and tell<br />

the pickers if they have the right product<br />

and the number required.<br />

The system has been under consideration<br />

for the past year and is still going through<br />

an evaluation phase. The scanners will be<br />

totally hands-free, being mounted on a<br />

mobile trolley.<br />

Process improvement is a way of<br />

business life, that newly-appointed<br />

Components Purchasing Manager,<br />

Carmel Pendreigh knows a lot about.<br />

“Prior to joining <strong>ACL</strong> Gasket<br />

Company, I was with CSR Construction<br />

Materials,” said Carmel. “I<br />

started in Townsville as a Process<br />

Improvement Engineer and have<br />

worked as a process engineer, process<br />

improvement engineer, sales representative,<br />

computer implementation<br />

team member, maintenance engineer<br />

and finally, production manager.”<br />

Carmel said that she was getting<br />

a “crash course” in understanding how<br />

the factory worked and the biggest<br />

change she faced was the products.<br />

“Previously with CSR, we were manufacturing<br />

components which weighed<br />

1-20 tons and made 30 of these a day.<br />

Here, the product only weighs a few<br />

grams but we make thousands of these<br />

each day.We focus on processing and<br />

achieving a large throughput of high<br />

volume low mass products.<br />

“There are a lot of innovative<br />

ideas implemented at <strong>ACL</strong>, and a lot<br />

of different ways of doing things.”<br />

In her spare time, Carmel is<br />

something of a “sports fiend” and<br />

enjoys cricket, squash and golf.<br />

NEW VOICE OF GASKET COMPANY<br />

RICARDO<br />

JOINS <strong>ACL</strong><br />

PISTON<br />

PRODUCTS<br />

New Project Engineer at <strong>ACL</strong> Piston<br />

Products, is Ricardo Alonso, who can<br />

be found working on a project involving<br />

diesel steel rings. Ricardo said the project<br />

involved manufacturing steel rings for the<br />

export market.<br />

“I’ve just finished my Degree, graduating<br />

as a Mechanical Engineer from Swinburne<br />

University of Technology. Prior to that I<br />

worked as a draftsman-come-everything at<br />

a small company in Melbourne.<br />

“The course at Swinburne is an excellent<br />

The pleasant “voice” that a customer<br />

now hears when he or she telephones<br />

<strong>ACL</strong> Gasket Company in Brisbane,is that<br />

of Carly Clayton. Carly has been with<br />

the company for four and a half years.<br />

Starting in the assembly area, she was<br />

involved in packing gasket sets, then<br />

labelling them.“I did this for four years,”<br />

said Carly.“Then I moved up to accounts.<br />

I thought it would be a good step.<br />

I report to Terry and Graham, handle<br />

inwards and outwards mail and pay all<br />

the <strong>ACL</strong> Gasket Co accounts, as well as<br />

being the company telephonist. I just<br />

love it. It’s a challenge this job.”<br />

In her spare time Carly loves to run.<br />

She also works out in the gym she has at<br />

her home.<br />

course where they focus on the practical side<br />

of engineering. Naturally, there is still a lot<br />

of theory - most university courses have a<br />

lot of theory - but it was still a great course.<br />

I’m really enjoying my work here.”<br />

In his spare time,Ricardo enjoys squash,<br />

cricket, and likes to run.

LONG SERVICE<br />

AWARDS RECOGNISE<br />

TWO VALUED<br />

EMPLOYEES<br />

AFTER 36 YEARS<br />

CON CALLS IT A DAY<br />

One of the best known people at <strong>ACL</strong><br />

Gasket Company - Mr Con O’Brien<br />

- retired recently after 36 years with the<br />

company. Con said looking back over that<br />

time, there would be little that he would<br />

change given the time over again.“I’m happy<br />

with the career I chose and there are people<br />

in all organisations who don’t want to come<br />

to work each day,” said Con. “I think that<br />

having this kind of attitude is very sad.<br />

“Sure there have been stressful times<br />

and you’d wish it was tomorrow, but I always<br />

wanted to do something with an engineering<br />

background and that’s what I did.You have<br />

a sense of achievement at the end of the day<br />

- I made this,or made that.That’s something<br />

I consciously did.That particularly applied<br />

when we were involved in new product<br />

development.<br />

“I’d ask ‘how much better are we today<br />

than we were yesterday?’<br />

Con said that back in the 60s and 70s,<br />

“everyone made a bucket of money”. That<br />

time of abundance flowed not only through<br />

the company but also through Australia<br />

generally. Those kinds of conditions put<br />

everyone in a good frame of mind.You can’t<br />

blame the company, but money is tight,<br />

things are tough and everything’s more<br />

competitive, with imports that we didn’t<br />

have in those days.”<br />

Con said one aspect of the company<br />

that’s long gone was the large numbers of<br />

family members who all worked for the<br />

company.“We’d have 5, 6, 7, people from the<br />

same family and this caused some complications<br />

on occasions when one of the family<br />

would jump in to defend a relative.But overall<br />

it made for good working relationships.”<br />

Numbers of employees was another facet<br />

of a changed working life,said Con.“We had<br />

320-odd people in those days and when you<br />

had the presses and the whole place ticking<br />

over that created an environment as well.”<br />

Con started out as a toolmaker and then<br />

became toolroom supervisor,then production<br />

supervisor for 13 years.“After that I went to<br />

Flexatalic which is now the Specialised Gasket<br />

Company and was Production Manager<br />

there twice.”<br />

When APS moved its operation from<br />

Melbourne,Con said it was one of the stressful<br />

times, as they were faced with having to<br />

make gaskets that they’d never made before.<br />

He said that with retirement he would<br />

be devoting more time to his workshop and<br />

lathe he has at home. “One of the things<br />

on my ‘to do’ list this year, is making a<br />

grandfather clock,” said Con. “Naturally,<br />

I’ve become very good at making toys for<br />

the grandchildren as well.”<br />

Best of luck Con, for the years ahead.<br />

PUBLICO SOLUTA<br />

Originally from the Philippines,<br />

Publico has had ten and a half years<br />

continuous service with <strong>ACL</strong> Piston<br />

Products. He is currently employed<br />

in the Ring Shop at Piston Products.<br />

SELIM (SAMMY) KIROGLU<br />

A Team Leader on the afternoon shift<br />

at Piston Products, Sammy has notched<br />

up ten and a half years of continuous<br />

service also. He works on the afternoon<br />

shift in the Die Cast Shop and he is<br />

originally from Turkey.

NEW <strong>ACL</strong> EUROPEAN<br />

REPRESENTATIVE BELIEVES<br />

BUSINESS COULD BE GOOD<br />

Newly appointed <strong>ACL</strong> European Representative Mr Andreas Weller, believes that <strong>ACL</strong> has the right product mix<br />

to attract good business from European customers. On a visit to inspect <strong>ACL</strong>’s manufacturing plants, Andreas had<br />

a chat with the “<strong>ACL</strong> <strong>REPORTER</strong>” and outlined some of the developments taking place in the new Europe.<br />

’ve spent all my working life in the<br />

‘‘I automotive industry,” explained<br />

Andreas, “and for the past seven years<br />

have been Manager of AE Auto Parts<br />

Germany. After the business was sold to<br />

Federal-Mogul, I spent another year with<br />

the company before meeting Antony Pearse<br />

and accepting his offer to join <strong>ACL</strong>.<br />

“We were responsible for engine<br />

part sales in Germany, Switzerland, and<br />

Austria and Eastern Europe.”<br />

Andreas said that his division was<br />

charged with selling to the after market,<br />

and like elsewhere in a highly developed<br />

country, many of the common item parts<br />

like brake pads, are sold in Germany<br />

through supermarkets and discount auto<br />

parts stores.<br />

“In the engine parts market, the<br />

marketing of parts is much more<br />

straightforward, because this involves<br />

specialists. There are about 400 engine<br />

reconditioners in Germany and I would<br />

say that about 250 of these were doing<br />

well, with about 100 of them being mid<br />

size to large.”<br />

He said a lot of engine reconditioners<br />

haven’t wanted to touch Japanese engines<br />

because they had great difficulty getting<br />

correct parts.<br />

With <strong>ACL</strong>’s range of parts for this<br />

sector of the market, German rebuilders<br />

can now purchase with confidence.<br />

“With the range we have, we will<br />

be able to develop a growing business.”<br />

In Germany, Japanese makers had<br />

captured around 25% of the market with<br />

many of these smaller vehicles bought by<br />

families as the second car. Andreas said<br />

that the average age of a vehicle in<br />

Germany was around seven years with<br />

cars in Eastern Europe being older.<br />

“The Eastern European market is one<br />

with great potential.They have difficulty<br />

getting parts for many of these Japanese<br />

vehicles and that’s the opportunity for us,”<br />

said Andreas.<br />

“It’s an important market. In some<br />

Eastern European countries where they<br />

are now better off financially, the people<br />

want to buy newer cars. The market<br />

therefore has moved further to the east<br />

into Russia and the Ukraine and we have<br />

a very good distributor in Hungary,<br />

who supplies these markets in the east.”<br />

<strong>ACL</strong>’s office will be situated in a suburb<br />

of Stuttgart, the home of the German<br />

automobile industry. Mercedes-Benz,<br />

Porsche and many of the OE supplier<br />

companies like Bosch, are all there.<br />

Married with two girls,Andreas loves<br />

to accompany his wife when she goes<br />

horse-back riding, and his favourite pasttime<br />

when he has the time, is mountain<br />

bike riding.<br />

Andreas is looking forward to<br />

developing <strong>ACL</strong>’s product range into<br />

Europe.<br />

PRABA CONCENTRATES ON<br />

RESEARCH AT PISTON PRODUCTS<br />

P<br />

rabakaran Naganathan - “Praba” for<br />

short - is another new arrival at <strong>ACL</strong><br />

Piston Products. Joining the Technical<br />

Department only recently, Praba is working<br />

on the design and testing for wear and<br />

noise. A graduate in Engineering from<br />

the University of Sydney, Praba joined<br />

<strong>ACL</strong> from a stint at Amcor Research &<br />

Technology at Fairfield in Victoria.<br />

At Amcor, Praba researched the use<br />

of corrugated board as a shipping material<br />

and was involved in a lot of testing. Praba<br />

came to Victoria because “he likes to move<br />

around”.He said the work he’s been doing<br />

with Ian Veale in the Research Unit “has<br />

been very interesting”.<br />

Listening to music and soccer are two<br />

of Praba’s main after-work activities.

<strong>ACL</strong> JOINS AUSTRALIAN<br />

MANUFACTURERS<br />

AT DETROIT SHOWCASE<br />

The <strong>ACL</strong> Detroit team from left Antony Pearse, Adrian Martin, Ivan James, Chris Worthington and <strong>ACL</strong> America’s Tim Vehlewald.<br />

<strong>ACL</strong> was one of 25 Australian automotive Antony said that the Federal Government<br />

component manufacturers who were played a big part in assembling and assisting<br />

invited to showcase their product range and the various exhibitors and was very pleased<br />

expertise at the Ford Technology Review with the outcome.“Michael Thawley - the<br />

Centre in Detroit.This was the first time that new Ambassador - spoke at a press conference<br />

the manufacturing muscle of the country’s and outlined the 25% growth achieved in<br />

automotive component industry has been automotive products exports over the last<br />

put on display.<br />

12 months.We are now part of a $3 billion<br />

Not only was this a fabulous opportunity industry and the industry is now challenging<br />

for <strong>ACL</strong> to show the influential purchasing traditional dollar earners like wheat, in its<br />

arms of Ford what the company could growth.”<br />

supply, but Ford President, Mr Jac Nasser<br />

- the President from Down Under - also<br />

invited Damiler Chrysler and General<br />

Motors to view the show.<br />

Antony Pearse, President <strong>ACL</strong> International<br />

said that other major manufacturers<br />

who attended included PBR who released<br />

a new braking system; Bosch with a voiceactivated<br />

system for vehicles, Air International<br />

and BTR.<br />

“<strong>ACL</strong> Bearing Company getting the<br />

Supplier of the Year from FCAI was an<br />

ideal focal point for <strong>ACL</strong>,” said Antony.“It<br />

gave us some real standing. People said ‘OK<br />

you’ve been through the quality levels, so<br />

that goes a long way to becoming an<br />

accredited supplier to the US’. We obtained<br />

names and made contacts and it gave us something<br />

to focus on as potential suppliers from Visitors showed a great deal of interest on the <strong>ACL</strong> stand.<br />

Australia.”<br />

The Ford facility used by the Australians<br />

was visited by OE purchasing managers,<br />

many of whom have global responsibility.<br />

“We had for instance, visiting the stand Jean<br />

Mayer, Executive Director, Global Purchasing<br />

for Ford Motor Company”explained Antony.<br />

“She is responsible for global purchasing of<br />

powertrain and material products with an<br />

annual buy of $18 billion a year!<br />

“The other really good thing was that<br />

we were able to spend productive time with<br />

other Australian manufacturers and from that<br />

we will be looking at increasing sales of<br />

components to them. There will be some<br />

interesting opportunities to come out of these<br />

meetings.<br />

“The people we spoke to were impressed<br />

with our ‘can-do’ attitude and that we are<br />

prepared to get in there and move quickly<br />

on projects. We are not looking at huge<br />

slabs of one-off business because we might<br />

not have the capacity to handle it. But there<br />

is lower volume OE business which the bigger<br />

guys may not be interested in, which would<br />

be a perfect fit for <strong>ACL</strong>.”<br />

Ivan James, Antony Pearse, Adrian<br />

Martin (<strong>ACL</strong> Piston Products) and Chris<br />

Worthington (<strong>ACL</strong> Bearing Company)<br />

headed <strong>ACL</strong>’s delegation.

50 GOOD REASONS<br />

FOR FUN ON THE RIVER<br />

Imagine the quiet North-East<br />

Tasmanian town of Derby -<br />

once a bustling mining town<br />

but now with just a population<br />

of 200 - a sleepy, picturesque<br />

place on the banks of the<br />

Ringarooma River.<br />

That’s what you would find for 364 days<br />

of the year, but on Saturday 24th October,<br />

the scene was very different. On that day<br />

Derby hosted the “Derby River Derby”, an<br />

entertaining event intended to give up to<br />

1,000 competitors in around 200 craft, a<br />

chance to enjoy water based activities.<br />

That was “something different”. To<br />

maximise publicity <strong>ACL</strong> would enter the<br />

main event of the 17 river races - the “Super<br />

Multi” section, which required a minimum<br />

of 12 crew. This was a great opportunity for<br />

social bonding and teamwork in an informal<br />

environment. In a company of nearly 500<br />

employees, it was tempting to stack the team<br />

with weight lifters & exercise freaks to ensure<br />

success.But as the DRD is a fun experience,<br />

people with a love of life chosen from a<br />

mix of departments was the selection criteria.<br />

So it was that a group from Engineering,<br />

Toolroom, Projects, Production, Office &<br />

Maintenance became the “<strong>ACL</strong>-erator”team.<br />

The name was, it was unanimously agreed,<br />

more suitable than a competitor’s suggestion<br />

- “The Titanic”.<br />

Steve Parkinson (Maintenance), a veteran<br />

of one previous race, and the company contract<br />

plumber Rod Fulton organised the<br />

main vessel design and construction. Peter<br />

Longman handled the publicity and acquisition<br />

of equipment, as did John Martin<br />

from Supply.<br />

<strong>ACL</strong> Head Office gave permission to use<br />

the <strong>ACL</strong> name and supplied an “identity”<br />

in the form of T-shirts, caps & stickers.<br />

Bearing Co. supplied transport for the vessel<br />

and a number of auxiliary items. Rodney<br />

supplied PVC pipe & fittings for the frame<br />

and local tyre companies donated old<br />

“skidder” inner tubes.<br />

Good rain fell early in the week of the<br />

race and on the eve of the race, the local<br />

newspaper featured an article with a picture<br />

of the <strong>ACL</strong> team.<br />

A perfect day greeted early risers.<br />

Team identities began to appear.Teams<br />

in helmets & lifejackets (including <strong>ACL</strong>’s<br />

Duncan Wood), men in dresses (including<br />

<strong>ACL</strong>’s Simon Okerby), all created an atmosphere<br />

along with the first white, smoky<br />

puffs of flour bombs.<br />

<strong>ACL</strong> had kept a low profile BUT as<br />

soon as the T-shirts were donned, the flags<br />

unfurled, the balloons & banners attached,<br />

then the floodgates were opened! Flour<br />

bombs, eggs, buckets of baked beans, sprays<br />

of dyed water and things too disgusting to<br />

report, deluged the boat and crew. The<br />

“<strong>ACL</strong>-erator” was well equipped to fight<br />

back.The TV crews braved the barrage to<br />

capture all the action.We had succeeded...<br />

<strong>ACL</strong> was the ... Centre of Attention !!<br />

The team pushed past everyone to secure<br />

prime start position. 29 jealous teams called<br />

for our disqualification - “they were out to<br />

get us!” <strong>ACL</strong> were in the spotlight.<br />

Relegation to the back position on the<br />

bank was the final penalty for notoriety.<br />

The young <strong>ACL</strong> crew now had something to<br />

prove.“<strong>ACL</strong>-erator”started to battle through<br />

the debris, the shipwrecks and the dejected<br />

back markers. Broken paddles, torn tubes,<br />

splintered wood and plastic floated everywhere.<br />

The leisurely, the sunbathers, the<br />

broken down, all were now weaponless and<br />

all drenched with the “<strong>ACL</strong>-erators” formidable<br />

armoury. Only the cold, wet and<br />

shivering crews were shown any mercy.Yes<br />

- it was all going to plan.<br />

All too soon the finishing line was ahead<br />

and with it the final indignity, buckets of<br />

red dye being poured over the rim of the<br />

bridge onto crews below.<br />

<strong>ACL</strong> finished 9th from 30, and none<br />

had more fun or were known by more<br />

people than the “<strong>ACL</strong>-erator” team. <strong>ACL</strong><br />

had prime place on “Nine” news around<br />

Tasmania & Australia-wide.<br />

Traditional celebrations followed at<br />

various “watering holes” and it hadn’t exactly<br />

been a “dry” boat on the river!! A reunion<br />

BBQ the following week completed the team<br />

bonding and the resolve from the “<strong>ACL</strong>erator”<br />

crew - “We’ll be Back!!”<br />

YOUR CONTACTS ARE:<br />

Paul Greentree.............Gasket Company<br />

Donna Stevens .................Piston Products<br />

Yvette Saunders.........Bearing Company<br />

Warren Dick.....................National Parts<br />

Phil Anderson ...........................ACNZL<br />

Tim Vehlewald .......................<strong>ACL</strong> USA<br />

Daniel Dedomenico .......<strong>ACL</strong> Comcork