ACL Newsletter Issue 28

ACL Newsletter Issue 28

ACL Newsletter Issue 28

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A FOCUS ON <strong>ACL</strong> BEARING COMPANY<br />

NEW BEARING COMPANY GM SEES<br />

ENORMOUS POTENTIAL THROUGH<br />

CONTINUOUS IMPROVEMENT<br />

Following the retirement of Bob<br />

Panitzki in September, Jim Degnian<br />

has been appointed General<br />

Manager of <strong>ACL</strong> Bearing<br />

Company; having been General<br />

Manager of <strong>ACL</strong> Gasket Company<br />

from 1997 to 2003. Jim is not<br />

completely new to the Launceston<br />

operation as he undertook a project<br />

earlier in the year to help implement<br />

a continuous improvement program.<br />

outcome from our processes - and I’m talking<br />

about all of our processes not just those in<br />

production areas. Process Control is a risk<br />

management methodology for continuous<br />

improvement of the quality control tools used<br />

at each and every operation.”<br />

“I find that the term Continuous<br />

Improvement is often quite misunderstood,”<br />

said Jim.“To me it is a process of chipping<br />

away at the problem - do something today<br />

at relatively low cost and effort that will<br />

help you see the problem in a different light<br />

tomorrow - then make another small change<br />

tomorrow.In the last edition of <strong>ACL</strong> Reporter,<br />

Alan Smith told us about his activities to<br />

reduce the set-up time within one of our<br />

Bearing machine lines. Alan has become a<br />

great supporter of the small step improvement<br />

philosophy. Alan and his team have made<br />

many hundreds of small, and not so small,<br />

improvements to the same machines - and<br />

there are still many more hundreds to go.”<br />

‘<strong>ACL</strong> Reporter’ asked Jim: Now<br />

that you have a permanent role at Bearing<br />

Company, has anything changed in your<br />

approach? “No, my understanding is that in<br />

the past when Bearing Company has tried to<br />

implement systems like this,it was introduced<br />

into one small area at a time and wasn’t<br />

integrated well with other business systems.<br />

It then tended to lose momentum and stop.<br />

The important thing is to make sure that<br />

continuous improvement activities are<br />

integrated into our everyday activities so that<br />

the improvement does not stop. The twin<br />

approach of Process Flow and Process Control<br />

is part of what we call Management Review<br />

- it’s about the way the business is being<br />

managed and continuously improved - striving<br />

to reduce waste in every part of the business.”<br />

“Complementing this is a process called<br />

Leadership Review - planning and creating<br />

the future that we collectively want for the<br />

company.”<br />

“The difficulty,” says Jim,“is that everyone<br />

within the company will see the future<br />

differently; from a different perspective. So<br />

what do we do? Well I see my role being to<br />

provide the clear direction in which we need<br />

to move - the road we are going to travel on.<br />

The next important step is to then try and<br />

develop some ‘shared vision’of what we want<br />

to create. It’s pointless my saying:‘this is my<br />

vision and therefore this is now our shared<br />

vision’. It won’t work. The management<br />

team has started and will continue to meet<br />

regularly to talk about these issues. In the<br />

near future we will start holding employee<br />

forums to try and understand what other<br />

people see for our future.”<br />

“Clearly people in this business see<br />

a need for change, and clearly there are<br />

opportunities for improvements.With everyone’s<br />

help we’ll get there.”<br />

<strong>ACL</strong> Bearing Company<br />

General Manager, Jim Degnian<br />

he continuous improvement program<br />

‘‘T focused on the two management<br />

principles of Process Flow and Process<br />

Control,” said Jim.<br />

“Process Flow is just another way of<br />

looking at Lean Production. Making processes<br />

flow faster is all about doing things in smaller<br />

and smaller batches.The faster the flow, the<br />

more problems are uncovered - remove the<br />

problems - faster flow - reduce the waste.”<br />

According to Jim:“The word ‘quality’ is<br />

all about getting a predictable and repeatable<br />

Bearing’s Leadership Team (L-R Rear) Chris Brooks, David Midgley, Peter Smith, Phil Dowl, Nathan Lawson, Mal Matthews and Jim<br />

Degnian. (L-R Front), Lee Chadwick,Yvette Saunders, Ian Coulson, Darren von Stieglitz. Absent on annual leave was Mike Lambert.

TONY KEEPS AFIRM GRIP<br />

ON MAINTENANCE<br />

T<br />

ony Hannan is <strong>ACL</strong> Bearing Company’s<br />

Maintenance Team Leader, who has the<br />

responsibility of looking after Plants 1 and 3<br />

and planning for all plants.There has been an<br />

overhaul of the maintenance administration,<br />

which has seen an increase in safety hazards<br />

being exposed.<br />

“We now have five different coloured<br />

forms when maintenance is required,”<br />

explained Tony.“Blue for mechanical. Pink<br />

for electrical. Yellow for safety. Green for<br />

environmental, and white covers suggestions<br />

for improvements.<br />

“Anybody can raise a form, and they<br />

fill out the plant number, machine number,<br />

the machine name and the area.They include<br />

their name, the date it’s raised and the<br />

problem.This then goes to the supervisor.<br />

He assesses it and it’s allocated a priority<br />

depending on production needs.”<br />

Tony said that can be either low,medium<br />

or high and the date it needs to be fixed.<br />

“From there it comes to me and I allocate it<br />

to a fitter,electrician or contractor.I also check<br />

to see if any safety plan is required and this<br />

is printed on the reverse side of the form.<br />

“If a safety plan is required, we indicate<br />

that and put it into my maintenance database<br />

and assign a database number. If it goes to a<br />

contractor, I review the job with them and<br />

go through any company requirements.We<br />

detail what’s required and when, and list<br />

any appropriate Workplace Safety or other<br />

safety standards that the contractor must<br />

comply with.”<br />

At this point Tony said the contractor<br />

indicates what he will do to protect <strong>ACL</strong><br />

personnel.“This covers his employees,and our<br />

equipment and if I deem it necessary,I involve<br />

the Safety Officer. If the work involves some<br />

danger, they have to fill out what protective<br />

measures they’re going to take.”<br />

MSD’s have to be submitted prior to<br />

any work being carried out, and the safety<br />

rules take the place of a lot of the safety<br />

permits previously used.“I think it’s a good<br />

thing that they are displayed on the job-sheet.<br />

They let everyone know what action is<br />

required prior to the job being started,”added<br />

Tony.“On an average day, I get up to 30 of<br />

these forms and that’s only for Plant 2. In the<br />

short-term, the flow will be high until we<br />

get on top of them.Some of the problems we<br />

knew about; others have surfaced through<br />

risk management, and because machines are<br />

being looked at more closely than previously.”<br />

RACE SERIES<br />

NOW AVAILABLE FOR<br />

AUSSIE MARKET<br />

The Australian domestic engine rebuilding<br />

market will be able to enjoy what their<br />

American cousins have had for a while.<br />

“While we have had Race Series on the<br />

Australian market for some time, we’ve<br />

actually improved the performance with new<br />

design and improved metallurgy,” revealed<br />

Product Engineer, Bruce Williams.<br />

“The new bearings have higher specs.than<br />

we’ve had before,and have been designed for<br />

Ford and Holden and gives us an extra string<br />

to our bow here in Australia.We haven’t been<br />

terribly strong in this area before, so now we<br />

have a range that can compete with imports.”<br />

Bruce said the bearings had been released<br />

in New Zealand in September, and there<br />

had been small releases in Queensland.“This<br />

new series will eventually replace the series<br />

in the re-build kits.<br />

“In the metallurgy, the main improvement<br />

was the conrod bearings where we<br />

created a harder steel backing,to improve their<br />

strength.We also improved the chemistry in<br />

the overlay.We’ve been able to put a higher<br />

fatigue strength overlay on the bearings, by<br />

changing our processes.”<br />

He said the improved range gave <strong>ACL</strong><br />

Bearings what was called three-quarter<br />

grooving across the range, where previously<br />

it was featured on just Australian domestic<br />

engines.“As well as extending the range,we’ve<br />

added some additional undersize bearings,<br />

to expand the range for high performance<br />

rebuilders,so they have a choice of clearance.”

A FOCUS ON <strong>ACL</strong> BEARING COMPANY<br />

The team responsible for the introduction of the Kanban system into the Powder Metallurgy plant (L-R) - Paul Johnstone, Graham Milbourne, Maureen Cadman and Phil Dowl (absent Peter Longman).<br />

KANBAN SYSTEM INTRODUCED<br />

AT BEARING COMPANY<br />

To explain what the recently adopted<br />

Kanban system means to production,<br />

we asked somebody who has been involved<br />

in introducing the manufacturing system<br />

to a number of Australian companies.<br />

<strong>ACL</strong> Bearing Company’s Planning &<br />

Procurement Manager, Darren von Stieglitz,<br />

said:“Kanban is a visual planning system<br />

built around a ‘pull system’ of manufacturing<br />

rather than a ‘push system’.<br />

“Customer demands pull the system<br />

and that in turn necessitates production of<br />

parts. It’s a replenishment system based<br />

around issues such as delivery lead-time,<br />

batch quantities, production capacity, set-up<br />

times and production cycle times. It all<br />

starts in the warehouse, and is based upon<br />

a pre-determined order point calculated<br />

on demand for the product/ parts. Once<br />

a part is called up, it triggers a message<br />

(“Kanban”) for the up-stream work centre<br />

to replenish the product/parts taken.”<br />

Darren said Bearing Company’s Kanban<br />

system was a hybrid of the pure Kanban<br />

method due to implications relating to<br />

available technology, machine capacity and<br />

set-up times.<br />

“OEM’s for a long time, have worked<br />

with Kanban and it’s notable that car<br />

companies were among the first to adopt<br />

the system in Australia. It works and is a<br />

proven planning/replenishment technique.<br />

Gasket Company has had the system for<br />

some time, although you can’t exactly<br />

replicate what they do up there, as every<br />

operation is different.<br />

“Jim Degnian came down from<br />

Brisbane in February with the vision to<br />

introduce Kanban at Launceston.We had<br />

been working an MRP system (Materials<br />

Requirement Planning), which is a push<br />

system based on forecast. And we know<br />

how forecasts can be wrong.With Kanban<br />

you don’t even have to be involved in the<br />

production to see what’s going on as the<br />

status and visual nature of the Kanban<br />

cards tell you.”<br />

Plant 3 was chosen as the initial<br />

operation for the introduction of Kanban<br />

into Bearing Company due to the compact<br />

size and stand alone nature of the powder<br />

metallurgy production process.The majority<br />

of Plant 3’s customer base are also OEM<br />

customers. “One of the complexities we<br />

face is that we have a number of product<br />

lines which are make to stock items which<br />

Kanban controls very well, but equally we<br />

have other products which are made to<br />

order,” he said.“We’re targeting 72 make<br />

to stock items to get them up on Kanban,<br />

while the made to order items will remain<br />

MRP driven at this stage to ensure visibility<br />

of long lead time raw material<br />

requirements.”<br />

Darren said the advantages of the<br />

system are that it’s visual; it eliminates waste<br />

and associated costs; it’s pull rather than<br />

push which reduces lead times and reduces<br />

overall inventory levels. This also helps<br />

reduce the risk of product obsolescence.<br />

“Kanban was physically introduced into<br />

Plant 3 during June of this year and I believe<br />

it will be operating to expectations by<br />

Christmas. Some preliminary work in the<br />

Bush-Line section in Plant 2 has commenced<br />

in readiness for the introduction of Kanban<br />

into this plant in the near future. At the<br />

end of the day, Kanban will create a higher<br />

level of customer satisfaction due to us<br />

having finished product available when<br />

they need it.”<br />

Production Scheduler, Graham<br />

Milbourne, added that it’s a system that<br />

reveals the problems rather than covering<br />

them up.“With this system, you only make<br />

what your customer buys, as opposed to<br />

making a lot of products in expectation of<br />

selling them. In the old system the more<br />

you made the cheaper the unit cost but<br />

you then had to hold the stock.”

NEW ALCOHOL AND OTHER<br />

DRUGS POLICY OUT TO HELP<br />

et’s be clear,” explained Andrew Flood<br />

‘‘L when discussing Bearing Company’s<br />

new Alcohol and Other Drugs policy with<br />

the <strong>ACL</strong> REPORTER,“we are not out to<br />

police our employees.While we have had a<br />

policy for some time that alcohol can’t be<br />

consumed on the site, we realised that this isn’t<br />

sufficient to ensure those attending work do so<br />

in a safe environment.It’s not only a safety issue<br />

for themselves but for their fellow employees.”<br />

An agreement was reached with the<br />

unions in a previous Enterprise Agreement,<br />

that <strong>ACL</strong> would explore a policy of promoting<br />

the importance of having a drug and alcohol<br />

free work environment.The Bearing Company<br />

Safety Committee established a sub-committee<br />

composed of representatives across all plants.<br />

“Rob Hodgetts from the Tool Room<br />

chaired the group, and besides myself, we<br />

also had Shirley Schroeter our occupational<br />

health nurse on the committee. We also<br />

had input from Dr Alex Thompson the site<br />

consulting doctor, who raised a few issues<br />

and contributed,” said Andrew. “What we<br />

didn’t want to move to, was random alcohol<br />

and drug testing.<br />

“The time we would generally test for<br />

this type of thing would be pre-employment,<br />

and if there was an accident or near miss on<br />

site, where drugs or alcohol might have been<br />

a contributor. But if it was clear that nothing<br />

Members of the Drug and Alcohol Committee (left to right) Robin Cocker,Andrew Flood, Robyn Harrison,<br />

David Dornauf and Rob Hodgetts (absent Shirley Schroeter and Ross Stevens).<br />

of the sort had caused the problem, we<br />

wouldn’t test.The only other occasion would<br />

be if there was a report.”<br />

Andrew said through education and<br />

promotion,it was hoped that should someone<br />

attend work under the influence of alcohol<br />

or other drugs,other employees would realise<br />

the potential risk, and report the matter<br />

to their supervisor.“We are introducing the<br />

programme by Team Communications at<br />

each Team meeting, and through this we<br />

hope to explain that it’s other employees<br />

health that can be at stake.<br />

“We currently have no procedures in<br />

place if somebody does attend work and<br />

looks intoxicated. We need something so<br />

everybody understands the serious consequences<br />

that an affected worker can cause.”<br />

TAEKWONDO CHAMP SETS HIS<br />

SIGHTS ON AUSTRALIAN TEAM<br />

W<br />

hen you’ve been part of the<br />

Launceston martial arts community<br />

as long as Jason Cassidy, you quickly know<br />

who’s good and who’s not.<br />

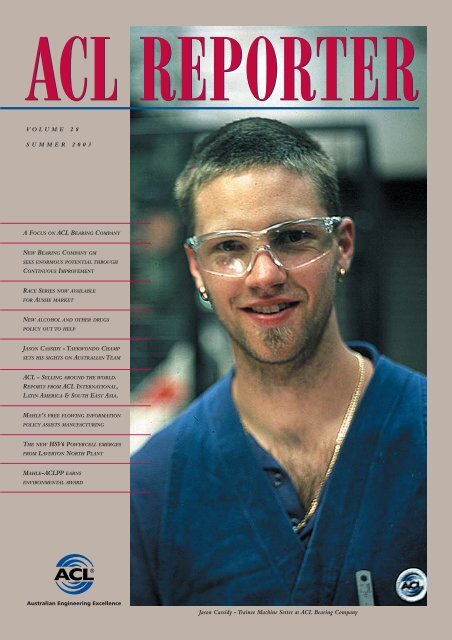

A trainee machine setter at <strong>ACL</strong><br />

Bearing Company, Jason’s ambition is to<br />

be part of the Australian team competing<br />

at the World Taekwondo Championships<br />

in Seoul next year.<br />

“At the moment, I’m training 5-6<br />

times a week but hopefully by next year<br />

I’ll be doing 10 sessions a week,” declared<br />

Jason. No newcomer to the sport, Jason<br />

has been competing for the past 16 years.<br />

He was a national champion from 13 to 18,<br />

and attended the World Juniors in Barcelona<br />

where he won through to the top 16.“I was<br />

picked to be in the Australian team for the<br />

Athens Olympic trials held in Korea; a group<br />

made up of 4 men and 4 women. Unfortunately,<br />

I hurt my back and also had to<br />

give it away for a year to help my feet heal.<br />

Competition consists of two 3-minute<br />

bouts and from the semi onwards, there<br />

are three 3-minute bouts.“You score points<br />

by landing punches on the body, and<br />

comparing Taekwondo to other martial<br />

arts sports, Taekwondo is like amateur<br />

boxing.You don’t try to kill each other.”<br />

Jason also represented Tasmania in a<br />

Taekwondo tournament in New Zealand,<br />

where he won the New Zealand Open,<br />

against teams from New Zealand and the<br />

Pacific Islands.“I’ve been doing it for so<br />

long now that training and competing are<br />

part of my life,” he said.<br />

Best of luck Jason for the competition<br />

ahead.

GASKET COMPANY<br />

ACHIEVES FIRST WITH<br />

REPORTING CHANGES<br />

FORMER<br />

FORKLIFT REP.<br />

HAS HIS FEET<br />

FIRMLY<br />

ON COMCORK<br />

FLOORING<br />

New Sales Manager at Comcork,<br />

Secondo Gastaldello, has sold<br />

forklift trucks for some of Australia’s<br />

leading companies. These days, his feet<br />

are firmly on the floor selling Australia’s<br />

best-kept secret - Comcork flooring.<br />

“What appealed to me about this<br />

position was the challenge of trying to<br />

push the product forward,” revealed ‘Sec’.<br />

“It’s a niche product that nobody else in<br />

Australia makes, and it really is one of<br />

the best-kept secrets I’ve come across.<br />

“Being made from rubber and cork<br />

offers users real benefits. In the short<br />

period I’ve been with the company and<br />

visiting architects, I can see the benefits<br />

of offering an economically sustainable<br />

product. It’s really creating a lot of interest.<br />

Architects are driven by the market, and<br />

the market is saying we want products<br />

that are good for the environment.”<br />

He said he’s confident that in the<br />

future, more and more people specifying<br />

flooring, will be using Comcork Walk<br />

Easy and other Comcork products.In the<br />

period ‘Sec’s’ been with the company,<br />

substantial new sales have been made<br />

across a number of areas, with more in<br />

the pipeline.<br />

In his spare time, it’s soccer and golf<br />

for the married Sales Manager, who plays<br />

centre mid-field for the Pascoe Vale soccer<br />

club,which has won its divisional competition<br />

three times in a row.<br />

The Financial Team (L-R):Terry Witham, Lorraine Foran, Graeme Fraser, Bob Jackson and Margaret Blake.<br />

The end of month reporting process has<br />

been turned on its ear as <strong>ACL</strong> Gasket<br />

Company streamlined the way it undertakes<br />

the function. Gasket Company’s new General<br />

Manager, Steve Smee explains.<br />

“Traditionally it has taken us 3-5 days to<br />

do the end of month accounts. So steps were<br />

put in place, and through some very good<br />

work by our financial team with Smartlink<br />

journal processing assistance from Lyette at<br />

MAHLE-<strong>ACL</strong>, we have reduced that time<br />

to around a day.<br />

“We now have our reconciliations being<br />

done on a daily basis in many areas, and this<br />

has given us tighter control over our financial<br />

performance. It has also paved the way for<br />

us to move towards a one-day processing of<br />

end-of-month journals, and profit results.<br />

Which in turn has enabled us to complete our<br />

end of month reports faster & with greater<br />

confidence. So the process improvements<br />

we’ve made have been fairly significant.”<br />

Steve said the team consisted of Graeme<br />

Fraser as Team Leader and Terry Witham,Bob<br />

Jackson, Margaret Blake and Lorraine Foran.<br />

Lorraine, said Steve had been instrumental<br />

in bringing forth the changes and<br />

reviewing the way things were done.“It has<br />

been a good implementation to our visual<br />

management programme,” he said.<br />

Lorraine said reporting for <strong>ACL</strong> 2 (the<br />

company accounting package), formed the<br />

basis of the balance sheet, and everything<br />

was pivotal to this.“This has to balance and<br />

reconcile.What we are getting away from is<br />

doing the journals, balance sheet, and <strong>ACL</strong><br />

Reports, and at the end of that the general<br />

ledger reconciliations. We decided to pull<br />

the reconciliation forward so that when we<br />

did the journals, and reconciliations we’d<br />

know the balance sheet is all reconciled.<br />

“This means you have a high level of<br />

confidence in your monthly performance<br />

results and balance sheet. Processing the<br />

information daily means you can see a<br />

problem earlier, and any out of balance areas<br />

are corrected as you go.We’re not waiting<br />

until the end of the month to find problems.<br />

Another benefit is we don’t have to wade<br />

through pages of print-outs - we have converted<br />

them to downloads which go on to a<br />

spread sheet, so it’s a lot more automated.”<br />

The team then split the <strong>ACL</strong>2 into sections<br />

showing cash, receivables, stock, debtors,<br />

creditors etc. Prompts have been installed in<br />

the system, which call for Yes answers and<br />

verifies that everything is correct.<br />

“Any daily problems are highlighted and<br />

resolved then and there,” added Lorraine.<br />

“They’re signed off by the accounts person<br />

and checked by our Financial Controller.<br />

The new system has saved a lot of time and<br />

doesn’t cause a backlog for the next month.<br />

Not only do you get the end of month<br />

accounts completed quicker, but you have<br />

greater confidence that they are correct.”

<strong>ACL</strong> - SELLING AROUND THE WORLD<br />

A BUSY YEAR IDENTIFYING<br />

MARKETS BRINGS RESULTS<br />

The International Team (L-R):<br />

Gregory Tait, Antony Pearse and<br />

Shemek Wisniewski<br />

<strong>ACL</strong>, like many Australian manufacturers has to look beyond<br />

Australia’s shores if it is to maintain jobs here and grow the<br />

company. Antony Pearse, President of <strong>ACL</strong> International, and<br />

his team scan the world for business opportunities.<br />

CL REPORTER” caught up with<br />

‘‘A Antony and Shemek Wisniewski<br />

<strong>ACL</strong>’s Regional Manager for Europe and<br />

the Middle East, prior to Antony’s quick<br />

visit to Malaysia, Singapore, the UK, France<br />

and the USA. We asked him for his<br />

assessment of 2003 in terms of selling<br />

<strong>ACL</strong> products internationally.<br />

“The best way to summarise our<br />

international trade position in 2003 is to<br />

say it’s been a year with a lot of change -<br />

created by the world economic situation.<br />

While the international terrorism problem<br />

hasn’t had a direct impact on automotive<br />

part sales, it does have a ‘knock-on’ effect<br />

as far as people’s confidence goes.This has<br />

been particularly true of the US economy.<br />

“We export and sell to, in excess of<br />

fifty countries around the world.And while<br />

bearings are certainly the door opener for<br />

us, when we’re speaking to potential customers<br />

we can also discuss other parts of<br />

the business like pistons, rings and gaskets.”<br />

Antony said in a number of markets<br />

<strong>ACL</strong> has had good success selling gaskets,<br />

pistons and rings which hadn’t been<br />

possible in the past.<br />

The Middle East - an emerging market for <strong>ACL</strong><br />

He said over the last twelve months the<br />

company had concentrated on improving<br />

and emphasising its quality, particularly in<br />

North American markets.“We have some<br />

unique products that other manufacturers<br />

don’t offer. Examples are bearings for<br />

particular applications, and short runs on<br />

products that other companies haven’t been<br />

interested in manufacturing.”<br />

He explained that <strong>ACL</strong> had obtained<br />

some significant business in the US, purely<br />

by following through and finding out the<br />

customers’ requirements and developing<br />

a bearing to meet that need. “However,<br />

it is a very competitive market. In one<br />

instance, after all the testing was done on<br />

the bearings we supplied and which proved<br />

successful for the application, our competitors<br />

are now bending over backwards in<br />

an attempt to obtain that business.”<br />

<strong>ACL</strong> faced stiff competition worldwide<br />

and this depended on the market<br />

location.“Our greatest competitors in the<br />

US come from local manufacturers, and<br />

that’s the same for Europe.<br />

“This year we’ve done an incredible<br />

amount of travelling visiting customers,<br />

and there are a number of markets where<br />

we have very strong distribution.There are<br />

other markets which present a challenge<br />

to ensure stronger representation.”<br />

Antony said promoting <strong>ACL</strong>’s product<br />

range often comes back to the efforts of<br />

the distributor. Often he said, it doesn’t<br />

need millions of dollars in support.“We<br />

recently saw it in South Africa where the<br />

difference between our bearings - which<br />

are bored and competitor’s bearings, which<br />

are broached - was strongly identified.<br />

The market there has a strong preference<br />

for an aero bored bearing because of the<br />

quality and that wasn’t achieved with a<br />

million-dollar promotion but unique selling<br />

proposition.”<br />

He believes Europe offers some very<br />

good prospects for 2004 and some old<br />

prospects have been revitalised.“The US<br />

has some very interesting opportunities<br />

which we are working on. Furthermore,<br />

the Middle East has been outstanding for<br />

us over the past year.We’ve really built on<br />

that because of what Shemek has done<br />

through identifying customers.”<br />

Las Vegas - Location of the recent US Trade Fair

<strong>ACL</strong> - SELLING AROUND THE WORLD<br />

GREAT PRESENCE EVERYWHERE<br />

IS SHEMEK’S AMBITION FOR 2004<br />

Agoal of having <strong>ACL</strong> product recognised<br />

in 80-90% of the countries of Europe<br />

is what Shemek has set his sights on for 2004.<br />

“I think we shall see stronger sales across<br />

Europe and I’d like to see sales in markets<br />

we haven’t sold to in the past.<br />

“I handle Europe and the Middle East,”<br />

he said,“and in the Middle East, our brand<br />

wasn’t as well known as in Europe. However,<br />

sales are occurring faster there than in Europe,<br />

once the product is on the shelf and the<br />

customer can see it.Over the last six months,<br />

we have seen a very large number of inquiries<br />

coming from the Middle East areas we are<br />

selling in.<br />

“Australia’s vehicle export drive has<br />

helped,” he said,“Because the market knows<br />

vehicles are coming from Australia, Australianmade<br />

products are being sought after and<br />

these are sold through distributors. We are<br />

currently selling to countries like U.A.E.,<br />

Iran, Saudi Arabia, Syria, Jordan, Lebanon,<br />

and we’re looking at surrounding markets,”<br />

he said.“These have similar requirements for<br />

the range of cars and engines available there.<br />

“The presence of our competitors in<br />

the region for over thirty years means that<br />

introducing a new brand is difficult. Japanese<br />

manufacturers have particularly well established<br />

brands and are determined to hold their<br />

market share by offering very low prices.”<br />

Shemek believes good opportunities still<br />

exist in Central and Eastern Europe.“I have<br />

just come back from Russia, and there is a<br />

large and expanding market with potential<br />

for us. However, there are a lot of competitors<br />

evident and over the next few months we’ll<br />

have a better understanding of the market.<br />

“Some of these European markets are<br />

fairly small and are serviced by the customers<br />

we already have. For instance, customers in<br />

Poland look after export to some of the<br />

surrounding markets. Hungary, whom we<br />

also sell to, looks after smaller customers in<br />

other countries.”<br />

APPRECIATING DOLLAR AFFECTS SALES<br />

<strong>ACL</strong> Regional Sales Director Tan Kit Long (right)<br />

with Mr Chiam Eng Huat (left) and Mr Ng Seng Keen (centre) both from SK Auto Parts Sdn Bhd, Kuala Lumpur<br />

The currency fluctuations during the<br />

past twelve months have had a serious<br />

affect on sales in South East Asia. The<br />

Australian Dollar appreciated 30% against<br />

Malaysian Ringgit while other currencies<br />

increased by 10-15%.<strong>ACL</strong>’s Regional Sales<br />

Director Tan Kit Long - an employee with<br />

more than ten years experience selling<br />

<strong>ACL</strong> products - said the strong Australian<br />

currency and the slow down of sales in<br />

Asia had all taken their toll.<br />

“There’s a difference between the<br />

countries I cover, in the way I sell our<br />

products, the way we have to declare the<br />

goods, and the forwarding requirement<br />

of each country,” Kit Long said, when<br />

reviewing the challenge of selling to<br />

Malaysia, China, Indonesia, Viet Nam,<br />

Singapore, the Philippines, and Bangladesh.<br />

“I try to visit all of them every two<br />

or three months, and the most popular<br />

product range we sell are <strong>ACL</strong> Bearings.<br />

It’s very tough selling pistons and gaskets,<br />

although we sell gaskets into Indonesia.<br />

Kit Long said brand awareness has<br />

continued to increase amongst the distributors,<br />

and these distributors supply engine<br />

parts to engine rebuilders and retail outlets.<br />

The ASEAN Free Trade agreement<br />

is fourteen months away and this will<br />

reduce the tariffs on imported vehicles<br />

and parts. Because of the uncertainty of<br />

what this will do to vehicle prices, many<br />

Malaysians are choosing to keep their old<br />

cars until the picture becomes clearer.<br />

“This is good for <strong>ACL</strong>,” said Kit Long<br />

“as these cars will need extra servicing<br />

and parts. We face stiff competition in<br />

China where competition is very tough<br />

and where we now have to find suitable<br />

distributors.<br />

“There are a lot of joint ventures there<br />

with European companies supplying the<br />

technical know-how. The most popular<br />

car in China, the VW Santana, has about<br />

2 million units on the road”.

DIVERSITY IS KINGIN<br />

LATIN AMERICAN MARKETS<br />

If you ever thought that the<br />

countries within South America<br />

were similar, then you haven’t<br />

spent time talking to <strong>ACL</strong>’s<br />

Regional Manager for Latin<br />

America, Raymond Rondon.<br />

Raymond, who’s been with the company<br />

for almost six years, said that while<br />

many of the nations that make up the South<br />

American continent have historical roots from<br />

Spain or Portugal, their automotive parts<br />

markets are totally diverse.<br />

“All the nations that make up Latin<br />

America and the Caribbean are highly dependent<br />

on how the government performs<br />

economically, and these governments<br />

influence sales,” explained Raymond.“The<br />

economy has a flow-on effect for sales. In<br />

the past,Venezuela had a strong economy<br />

but since the change of government the<br />

economy has experienced a downturn.<br />

“The countries where things are moving<br />

The sales team at Rehispana/<strong>ACL</strong><br />

well include Colombia, Chile, Guatemala and<br />

El Salvador which have all had good growth.<br />

Brazil continues to be a powerhouse, and<br />

it’s an important market for us. It’s a highly<br />

competitive market,with local engine bearing<br />

manufacturers holding strong positions in<br />

the market.”<br />

Raymond said he spends between 30 to<br />

40% of his time travelling to visit customers.<br />

Within the region,<strong>ACL</strong> distributes through<br />

wholesalers as well as retail outlets and chains.<br />

“These chains are very specific for engine<br />

parts and today the biggest competitors are<br />

the Japanese manufacturers.When you add<br />

the Mahle group’s Brazilian production you<br />

can see it’s a very competitive environment.”<br />

(L-R): Mr Hugo Duarte, Rehispana Salesman, Bogota Colombia, Mr Jorge Mora,<strong>ACL</strong> Rehispana ( Colombia) Agent,<br />

Mr Luis Discamargo, Colombian <strong>ACL</strong> Customer, Bogota Colombia, Raymond C. Rondon,<strong>ACL</strong> Regional Manager.<br />

“The markets are different for each<br />

country you sell to,”said Raymond.“Venezuela<br />

is a US vehicle market. 50% of its car population<br />

comprises American vehicles. Another<br />

50% is represented by Japanese and Korean<br />

cars with a high preponderance of Hyundai<br />

and Daewoo. Some of the Daewoos in Latin<br />

America are fitted with the Holden Family<br />

2 engine.”<br />

“Colombia’ market consists of Japanese<br />

makes with larger type vehicles.In Argentina,<br />

Chile, and Brazil there are mainly European<br />

vehicles, with Japanese and Korean makes<br />

supplementing the market.<br />

“Bearings,” Raymond explains,“are the<br />

most important product he sells, with gaskets<br />

being a much slower mover because of the<br />

strong competition from the US and Europe<br />

as well as local manufacturers.<br />

“We do sell some pistons and have<br />

undertaken customer education nights, given<br />

away T-shirts and supplied catalogues, but<br />

we need to do more. Brand image is a very<br />

important factor in Latin America, and we<br />

need to address promoting the brand more<br />

aggressively, in order to counter Chinese and<br />

Japanese manufacturers.<br />

“<strong>ACL</strong>’s quality stands up exceptionally<br />

well against other brands and has an excellent<br />

reputation. Our problem is that the counter<br />

salesmen don’t know the brand, and that’s why<br />

we need a program which involves gradual<br />

reinforcement of our brand and products.<br />

We’re always looking for new business and<br />

are constantly receiving enquiries from new<br />

customers.We ARE penetrating the market<br />

but it’s not a one-day deal.”<br />

Left to right: Dr. Miriam Moreno de Mora - Assistant Manager<br />

Rehispana, Sonia Perez - Rehispana/<strong>ACL</strong> Sales Coordinator,<br />

Hugo Duarte - Rehispana/<strong>ACL</strong> Salesman,<br />

Astrid Manrique - Rehispana/<strong>ACL</strong> Sales Coordinator and<br />

Edwin Jimenez - Rehispana/<strong>ACL</strong> Salesman.<br />

<strong>ACL</strong> agent Rehispana recently celebrated their 30th Anniversary.<br />

Enjoying the occasion was <strong>ACL</strong> Regional Manager Raymond<br />

C. Rondon (second from left) with the Rehispana team.

MAHLE’S FREE FLOWING<br />

INFORMATION POLICY ASSISTS<br />

AUSTRALIAN MANUFACTURING<br />

years,Nigel unashamedly admits that starting<br />

with the Repco Company and being part<br />

of the Repco Brabham racing car project,<br />

were two of his career highlights.<br />

“I was lucky to work for the Repco<br />

Brabham team in a junior capacity, and I<br />

have looked after both the Repco Brabham<br />

BT19 and Matich SR4 cars for many years<br />

with continuous involvement with them<br />

longer than anybody else. I started out as a<br />

cadet and had the least contribution of<br />

anybody, but made my intentions clear once<br />

I knew they were building racing engines,<br />

that I wanted to be part of it. Luckily Repco<br />

‘broke the rules’and let me start in the engine<br />

laboratory rather than in a factory as was<br />

the custom with cadets.”<br />

<strong>ACL</strong>’s Chief Engineer - Nigel Tait<br />

he association between <strong>ACL</strong> and<br />

‘‘T MAHLE has been fantastic,” declared<br />

<strong>ACL</strong>’s Chief Engineer, Nigel Tait, when<br />

asked how the new factory and relationship<br />

was working out.“It’s brought a new level<br />

of technology to us. Previously, we’d only<br />

been involved in licensing agreements for<br />

one product, now we’ve strengthened that<br />

relationship to a joint venture.<br />

“We have complete access with no<br />

limitations for both pistons and rings, to a<br />

degree we could never have contemplated<br />

before. We’ve never had such a complete<br />

open-door policy, and MAHLE’s technology<br />

is by far the best in the world. Ian Veale and<br />

I and many others here have visited various<br />

MAHLE facilities and know what they’re<br />

developing,and we know they’re ahead of the<br />

rest.The new venture here with MAHLE has<br />

allowed us to get the new Holden HFV6<br />

business, and getting that business necessitated<br />

our moving to a greenfield site in order to<br />

better house the new MAHLE casting and<br />

machining plant. Anybody who worked at<br />

Maidstone has witnessed the huge improvement<br />

we’ve had in working conditions.<br />

“Mahle has a huge R&D capability in<br />

Germany as well as a considerable resource<br />

in America. MAHLE Technology Inc. (MTI)<br />

in Detroit has in excess of 100 working on<br />

pistons, bearings, and ring development.<br />

That’s just their research lab.At their plants in<br />

Mexico, Brazil and Tennessee, they undertake<br />

research as well. So it’s an enormous R&D<br />

Ian Veale<br />

capability and it will provide MAHLE-<strong>ACL</strong><br />

with a wonderful opportunity for taking on<br />

more ambitious projects in the future.”<br />

The new <strong>ACL</strong> Technical Centre currently<br />

being built at the MAHLE-<strong>ACL</strong> Laverton<br />

site, is still owned by <strong>ACL</strong>.“The reason for<br />

this,” explained Nigel,“is the continuing need<br />

to provide ongoing engine and components<br />

testing capability for <strong>ACL</strong> Bearing and<br />

<strong>ACL</strong> Gasket Company projects as well as<br />

for MAHLE-<strong>ACL</strong> Piston Products. With<br />

Maidstone closing, the company felt the best<br />

place to build a new technical centre would<br />

be in Melbourne, as it’s the centre of the<br />

Australian automotive industry. There was<br />

sufficient room at the new MAHLE-<strong>ACL</strong><br />

site, so we’re building a facility that offers us<br />

the same capacity and which will be up and<br />

running before the commencement of 2004.”<br />

Having been with the company for 38<br />

The Repco Brabham BT19<br />

Another milestone for the highly<br />

experienced engineer, was when he was<br />

sent to the UK to work a short time with<br />

Brico, and Glacier Bearing Company, both<br />

licensors of Repco manufacturing companies.<br />

He was involved with development of a<br />

petrol injection system at Brico, and bearing<br />

design and testing at Glacier. “The experience<br />

of working in an overseas environment and<br />

with engineers at companies licensing us<br />

was invaluable and paved the way for some<br />

long-lasting and special relationships.”<br />

When the Repco management buy-out<br />

occurred in 1986, Nigel was invited to join<br />

the fledgling <strong>ACL</strong> as one of the nine in the<br />

buyout group and has held the position of<br />

Chief Engineer for the past seventeen years.<br />

“We’ve always agreed on everything, so it’s<br />

been a terrific and good relationship,” he<br />

said. “As far as management buy-outs go,there<br />

aren’t too many that survive more than 3-4<br />

years let alone 17 years. I have the greatest<br />

respect for everyone I’ve worked with over<br />

those years.”

MAHLE-<strong>ACL</strong>PP EARNS<br />

ENVIRONMENTAL AWARD<br />

With the guidance of Russell Flanders,<br />

MAHLE-<strong>ACL</strong>PP Environmental<br />

Co-Ordinator and his team, MAPP has<br />

been accredited with the much sought-after<br />

ISO14001 accreditation.<br />

Nata Certification Services International,<br />

the accreditation auditors, conducted the<br />

assessment audit in late September. MAPP<br />

passed the audit with flying colours and<br />

now has the certificate proudly displayed in<br />

the foyer.<br />

Russell said he would like to thank,<br />

Phil Warren from Bearing Company and all<br />

MAPP personnel for their assistance during<br />

the development and implementation of the<br />

system.<br />

He indicated that MAPP is fortunate in<br />

that it is now in a new factory and many of<br />

the environmental issues have been addressed<br />

in the Laverton site’s design. “The most identify our environmental risks by reporting agement system now in place, we are well<br />

significant environmental aspects, are the and controlling any issues that may arise. positioned to abide by all government<br />

possibility of spills and contaminated storm Cleanaway have built and now operate our legislation and minimise our impact on the<br />

water, leaving the site and the treatment of effluent treatment plant which allows us to environment.This will ensure that we contribute<br />

to the well-being of our environment<br />

chrome plating discharges.<br />

concentrate on other areas of the plant.”<br />

“MAPP has set in place procedures to With the ISO1401 environmental man-<br />

for now and future generations.<br />

THE HSV6 POWERCELL EMERGES<br />

FROM LAVERTON NORTH PLANT<br />

It was something of a “red-letter day” when the first HSV6 Powercell was<br />

finally assembled and ready at MAHLE-<strong>ACL</strong> North Laverton plant.<br />

The engines, according to Group<br />

Leader, Simon Parker, will go into<br />

part production this year with a 3.6L<br />

version for export to Mexico for a Buick<br />

cross-over vehicle. Mid next year, volumes<br />

will increase to 600 units per day when<br />

the engine is also introduced into the local<br />

Holden Commodore.<br />

“MAHLE in America and Germany<br />

undertook the design work for what has<br />

been a lengthy program,” explained Simon.<br />

“Here at Laverton we are involved in the<br />

casting, machining and assembly of the<br />

Powercells utilising new equipment that<br />

was supplied from MAHLE in Germany.<br />

“The pistons are made locally while<br />

the actual assembly is a bit of a United<br />

Nations effort, where we made the pistons;<br />

the rings for the export versions came<br />

from MAHLE COFAP in Brazil and the<br />

rods were supplied from MAHLE Mexico.<br />

Next year for the local program, we will<br />

also be manufacturing the rings.”<br />

Simon said the awarding of this order<br />

a couple of years ago resulted in the move<br />

to the new site.“We believe the contract<br />

will go for a minimum of five years and<br />

over that time, there will be other models<br />

coming to fruition. At the moment there<br />

are three engine types, a 2.8L, 3.2L and<br />

3.6L and with possibilities of other variants<br />

for the future.<br />

He said the order will fill the capacity<br />

of the new plant which will be working<br />

a single shift until March next year and<br />

from then progressively add a second and<br />

third shift to fulfil the requirements.<br />

“At that point, we’ll certainly need<br />

more employees and we’ve already started<br />

to recruit new people with two engineers<br />

joining us, and we’ve plans to expand the<br />

production areas as volume increases.”<br />

Simon Parker (right) with Terry Spiteri

COMCORK SAILS INTO SYDNEY<br />

Comcork WalkEasy White has made a grand appearance at the Sydney Opera House when it was selected<br />

to be the flooring for a gallery within the giant complex.While called the Opera House the building of sails<br />

is a lot more and acts as the venue for opera, ballet, drama, plays, musicals, and exhibitions.<br />

General Manager Daniel DeDomenico<br />

said that the Opera House installation<br />

was one of a number of installations the<br />

company had successfully tendered for<br />

over the past six months.“The prestigious<br />

nature of the job makes everyone pleased,<br />

but we are also laying flooring in a number<br />

of large installation, at Port Melbourne<br />

Library; Melbourne Grammar School;<br />

Woolworth’s trolley bays, and the QV<br />

Building complex in Lonsdale Street<br />

Melbourne, which is on the site of the<br />

old Queen Victoria hospital, and which<br />

will be a city within a city.<br />

“Our first shipment for the USA has<br />

left Australia, and with increased marketing<br />

being done over there by our distributor<br />

and <strong>ACL</strong> Marketing, we’re hoping a lot<br />

more orders will be following.”<br />

PHIL MAKES IT A DATE IN ROTORUA<br />

The picturesque central North Island<br />

tourist destination of Rotorua is also<br />

the location of a Repco branch which is<br />

particularly successful in selling <strong>ACL</strong> product.<br />

Branch manager, Des Wenmoth, promotes<br />

an annual trade sale/special day, featuring<br />

the attendance of selected key suppliers, such<br />

as <strong>ACL</strong>.<br />

<strong>ACL</strong> General Manager Phil Anderson<br />

was seen representing the <strong>ACL</strong> range, with<br />

performance and heat shield a major focus.<br />

Visiting apprentices were particularly interested<br />

in development of the RACE range with<br />

the new ‘H’ type bearings, and the increasing<br />

possibility of a range of forged pistons.<br />

The promotional part of the day began<br />

at 3.00pm, finishing at 8.00pm, which ensured<br />

that a trip to the geothermal splendours of<br />

Rotorua were not purely ‘thermal relaxation’<br />

for Phil.<br />

Repco trade counter specialist Bella, on extreme right,<br />

discussing RACE product with customers.<br />

An automotive apprentice(left) discussing the finer<br />

points of performance bearings with Repco’s Ellen & Katie.<br />

These ladies know there stuff!<br />

<strong>ACL</strong> General Manger, Phil Anderson (right) talking with a trade customer.<br />

YOUR CONTACTS ARE:<br />

Paul Greentree ......................Gasket Company<br />

Briony Gardner......................................... MAPP<br />

Yvette Saunders.................. Bearing Company<br />

Warren Dick...............................National Parts<br />

Phil Anderson........................................ ACNZL<br />

Daniel De Domenico............. <strong>ACL</strong> Comcork