Unimog

Download magazine - Mercedes-Benz

Download magazine - Mercedes-Benz

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.mercedes-benz.com | January 2004<br />

Mercedes-Benz<br />

<strong>Unimog</strong><br />

The magazine for multi-functional applications.<br />

2 | 2003<br />

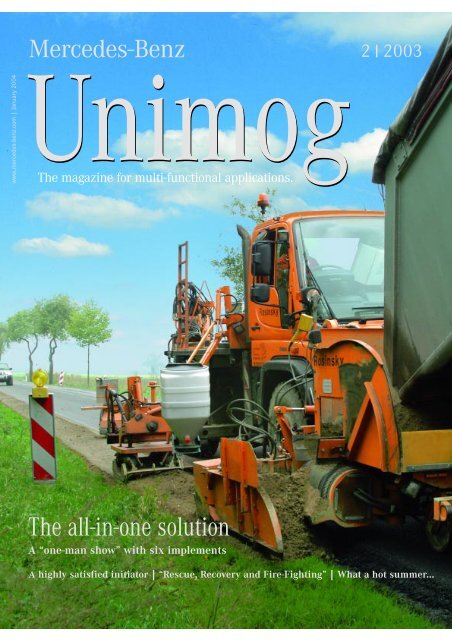

The all-in-one solution<br />

A “one-man show” with six implements<br />

A highly satisfied initiator | “Rescue, Recovery and Fire-Fighting” | What a hot summer...

Contents<br />

Road<br />

entertainment 12<br />

“One-man show”<br />

with six implements<br />

P u b l i s h e r ’ s d a t a<br />

Publisher:<br />

DaimlerChrysler AG, Product Unit <strong>Unimog</strong>/<br />

Speciality Vehicles<br />

Responsible publisher:<br />

Martin Adam, Product Unit <strong>Unimog</strong>/<br />

Speciality Vehicles<br />

Editorial committee:<br />

Martin Adam, Dieter Mutard, Dieter Sellnau,<br />

Karin Weidenbacher<br />

Contributors to this issue:<br />

Texts and photographs: Dieter Mutard,<br />

Stefan Loeffler, Petra Forberger,<br />

Product Unit <strong>Unimog</strong>/Speciality Vehicles<br />

Editorial office address:<br />

DaimlerChrysler AG,<br />

Product Unit <strong>Unimog</strong>/Speciality Vehicles<br />

Sales Marketing, 76742 Wörth, Germany<br />

Translations:<br />

Colin Brazier, Munich<br />

Production:<br />

Dieter Mutard DWM Pressebüro und Verlag,<br />

Ringstrasse 11, 89081 Ulm, Germany<br />

The next issue will be published in the spring of<br />

2004. The publishers accept no responsibility for<br />

unsolicited copy or photographs.<br />

Printed on paper bleached without chlorine<br />

Printed in the Federal Republic of Germany<br />

Practical test 4<br />

A highly satisfied initiator<br />

Anniversary 6<br />

A palace, Plenty of <strong>Unimog</strong>s and<br />

the rocks of Lançon-de-Provence<br />

Water authorities 10<br />

The “Eco-<strong>Unimog</strong>” in the biotope<br />

Road entertainment 12<br />

“One-man show” with six implements<br />

Two-way applications 13<br />

Moved as if by magic<br />

DaimlerChrysler Worldwide<br />

In everyday use 16<br />

A trip on the “New Silk Road” 17<br />

Western Star truck takes to the rails 18<br />

Living lakes 18<br />

Environmental care 14<br />

What a hot summer ...<br />

Report 15<br />

An example of best-practice methods<br />

DaimlerChrysler Worldwide 16<br />

Symposium 20<br />

“Rescue, Recovery and Fire-Fighting”<br />

UNISCOPE 22<br />

“Millionaire” in the bush<br />

Farewell to Hans-Jürgen Wischhof 23<br />

An off-road expert 23<br />

2 <strong>Unimog</strong> 2|2003

Contents<br />

Symposium 20<br />

“Rescue, Recovery<br />

and Fire-Fighting”<br />

Environmental care 14<br />

What a hot summer ...<br />

Anniversary 6<br />

A palace, plenty<br />

of <strong>Unimog</strong>s and<br />

the rocks of Lançonde-Provence<br />

<strong>Unimog</strong> 2|2003 3

Practical test<br />

This is what it<br />

looks like in the<br />

vehicle: The<br />

clutch pedal is<br />

folded upwards<br />

so that the<br />

driver’s left foot<br />

can do<br />

something else<br />

A highly satisfied initiator<br />

The <strong>Unimog</strong> equipped with the AutomaticShift® system is the most<br />

significant <strong>Unimog</strong> innovation this year and has passed the practical test<br />

carried out by one of the initiators to the complete satisfaction of all those<br />

involved. In addition to being one of the public authorities that asked for an<br />

alternative to the hydrostatic system, the Bayreuth roads department was<br />

also a cooperative test partner. After extensive testing, the authority’s<br />

administration issued a comprehensive report in January 2003, which<br />

reached positive conclusions in every respect and led to the purchase of<br />

the test vehicle, a U 400.<br />

The AutomaticShift® system proved to be the ideal<br />

solution for washing roadside posts and mowing in<br />

the Bayreuth test (far right)<br />

Siegfried Beck, Head of the Northern Bavarian<br />

Autobahn management’s equipment division (at the<br />

far right in the picture), workshop manager Wolfgang<br />

Rech (second from right) and driver Willi Hübner are<br />

highly satisfied with the AutomaticShift® system<br />

Siegfried Beck, who was then the head of<br />

this department at the Bayreuth public<br />

works authority, is satisfied with the results<br />

achieved with AutomaticShift® (Electronic<br />

automated Shifting or EAS) and proud of the<br />

fact that he is one of the initiators who, directly<br />

after the launch of the U 300 / U 400<br />

/ U 500 implement carrier generation, approached<br />

the Gaggenau-based company to<br />

propose the development of a alternative for<br />

the hydrostatic system. “A number of technologies<br />

were feasible, but nothing came<br />

close to the Actros’ EAS solution that was<br />

used as a basis for the <strong>Unimog</strong>’s AutomaticShift®<br />

system,” he says and confirms<br />

that he is very happy about the way that<br />

cooperation with <strong>Unimog</strong> worked out. This<br />

was the starting point for customising a<br />

U 400 according to what the Bayreuth road<br />

authorities needed and delivering it to the<br />

department concerned for a long-term test in<br />

January.<br />

In addition to the internal evaluation document,<br />

there are also statements from the experts<br />

who actually work with the unit. “The<br />

test extended over a long period of time as<br />

we wanted to test all our summer and winter<br />

service equipment with EAS. In this way we<br />

obtained an in-depth picture,” says Wolfgang<br />

Rech, workshop manager at the central<br />

Bayreuth municipal works department yard,<br />

who is responsible for three road maintenance<br />

authorities in the administrative district<br />

with depots in Bayreuth, Kulmbach and<br />

Wunsiedel. The range of practical applications<br />

in this region, with approx. 900 kilometres<br />

of regional, federal and state roads,<br />

provided a broad test basis covering the most<br />

diverse requirements. “Our summer work<br />

went without any problem and we haven’t<br />

had a single problem since AutomaticShift®<br />

reached series maturity. We worked closely<br />

4 <strong>Unimog</strong> 2|2003

The Bayreuth road<br />

maintenance authority’s<br />

municipal construction<br />

yard, with the <strong>Unimog</strong><br />

U 400 equipped with<br />

AutomaticShift®<br />

representing the future<br />

in the foreground and<br />

earlier models with<br />

cleaning equipment<br />

behind it<br />

Practical test<br />

together with DaimlerChrysler’s technicians<br />

during this test phase and I would like to<br />

take this opportunity to say that the cooperation<br />

was excellent and constructive<br />

throughout. We experienced no standstill<br />

times due to technical difficulties at any time<br />

after series maturity and I can emphasize<br />

that the AutomaticShift® system is an excellent<br />

alternative to the hydrostatic system,”<br />

says the workshop manager.<br />

Having received so much praise for this<br />

technical innovation, it was interesting to<br />

learn what the <strong>Unimog</strong> U 400 driver thinks<br />

of the AutomaticShift® system and what<br />

working with such innovative technology is<br />

like in real-world situations. To obtain a comparison<br />

based on many years of experience,<br />

the road maintenance authorities asked<br />

Willi Hübner to test the vehicle – a driver<br />

who has worked with different <strong>Unimog</strong><br />

model series for 22 years. “I started out on a<br />

<strong>Unimog</strong> U 900, but I wouldn’t want to trade<br />

the latest one in for any of the previous models.<br />

Anyone can see how dramatically the<br />

<strong>Unimog</strong> has been improved in all areas. To<br />

me, AutomaticShift® is a real advantage for<br />

safe driving. I can concentrate on just the<br />

traffic, and this is an important factor when<br />

operating implements in summer and winter<br />

on busy roads. The <strong>Unimog</strong> has also improved<br />

quite a lot for drivers of the U 300 –<br />

U 500, because we’ve never enjoyed such<br />

good visibility before!” says Willi Hübner in<br />

tones of great satisfaction.<br />

In order to prove this statement in a reallife<br />

situation, we took the U 400 for practical<br />

tests with a Mulag mowing implement and a<br />

roadside post washing device. Both these<br />

test runs were definite proof of the fact that<br />

road maintenance services need such means<br />

of simplifying their tasks; after all, if you<br />

work with a limited budget, the saying “time<br />

is money” is an all-too-obvious conclusion.■<br />

Advertisement<br />

<strong>Unimog</strong> 2|2003 5

Anniversary<br />

The U 5000 equipped<br />

to fight forest fires in the<br />

typical Estaque<br />

countryside of the<br />

Provence<br />

A chateau, plenty of <strong>Unimog</strong>s and<br />

the rocks of Lançon-de-Provence<br />

6 <strong>Unimog</strong> 2|2003

Anniversary<br />

Château Calisanne near Lancon-de-Provence (Bouche du Rhône), a place<br />

greatly respected among gourmets for its olive oil and sun-soaked<br />

Provençal wine, was chosen as the ideal venue for a very special event<br />

held on November 5 and 6, 2003: 55 years of the <strong>Unimog</strong> and – a welcome<br />

coincidence – the sale of the first <strong>Unimog</strong> in France took place 50 years ago.<br />

<strong>Unimog</strong> Sales, France, has felt it owed<br />

something to its customers, friends and<br />

the interested public ever since June 2001,<br />

the date when at our German production<br />

location in Gaggenau the “50 Years of Mercedes-Benz<br />

<strong>Unimog</strong>” anniversary was in full<br />

swing. In France itself, this event went unnoticed.<br />

It was high-time to make good on<br />

our negligence by organizing the “<strong>Unimog</strong><br />

55 ans” event. At Château Calisanne, two full<br />

days were dedicated to the <strong>Unimog</strong>, its customers<br />

and friends; and the press was of<br />

course also invited.<br />

On both days an interesting “anniversary<br />

show” was organized, presenting historic<br />

and contemporary <strong>Unimog</strong> vehicles, including<br />

the U 500 which will participate in the<br />

26th Paris – Dakar Rally in January 2004,<br />

and the latest off-road forest firefighting<br />

vehicles from the 437 series. In the information<br />

section Jean-Emile Martin, <strong>Unimog</strong><br />

Sales Manager at DaimlerChrysler France,<br />

and Didier Baille-Barelle, the Product Marketing<br />

Manager, presented the U 300/U 400/<br />

U 500 off-road implement carriers as well as<br />

the U 3000 / U 4000 / U 5000 models suitable<br />

for severe off-road travel in their relevant<br />

market segments and explained in<br />

some detail the latest technical innovations<br />

and details directly at the vehicles.<br />

Didier Baille-Barelle<br />

(above right) hosted the<br />

<strong>Unimog</strong> demonstration<br />

runs at Château<br />

Calissane<br />

Tree branch cutter and<br />

mower demonstrated on<br />

an all-terrain model<br />

All the guests were unanimous that the<br />

off-road driving demonstration was the<br />

event’s genuine highlight. The rocky landscape<br />

of Lançon-de-Provence not only provided<br />

magnificent scenery but also unique<br />

levels of challenge, giving passengers in var-<br />

<strong>Unimog</strong> 2|2003 7

Anniversary<br />

ious <strong>Unimog</strong> types impressive evidence of<br />

why the <strong>Unimog</strong> has been unsurpassed for<br />

55 years. The white chalk rocks and rolling,<br />

hilly landscape covered in Estaque tempted<br />

drivers to master different levels of topographic<br />

challenge with the <strong>Unimog</strong>. And so<br />

the U 400 and U 500 <strong>Unimog</strong>s with loaded<br />

platforms and the 4000 or U 5000 vehicles<br />

with their firefighting equipment climbed<br />

through the green Provençal landscape.<br />

Almost all the visitors participated in the<br />

<strong>Unimog</strong> test drives, though possibly relieved<br />

to feel the solid ground beneath their feet<br />

again when the unusual trip was over; nevertheless,<br />

most of them were extremely enthusiastic<br />

about the vehicles’ performance.<br />

Even during these early November days<br />

when the sun in the South of France still had<br />

enough strength to allow us to take our aperitif<br />

outside, in front of the Château. In addition<br />

to the excellent organization that coped<br />

well with several hundred guests on both<br />

days, Provençal cuisine and wines did their<br />

best to make the event unforgettable. Despite<br />

the five-year delay, this anniversary lacked<br />

nothing of what the official “50 Years of the<br />

<strong>Unimog</strong>” event had offered to its guests in<br />

Gaggenau.<br />

■<br />

A U 4000 fording water<br />

and crossing mudholes<br />

with supreme confidence<br />

A forest firefighting<br />

vehicle with Sides<br />

superstructure<br />

8 <strong>Unimog</strong> 2|2003

Sampling the <strong>Unimog</strong> U 5000: Commandant Lt.<br />

Colonel Jean-Louis Farcy from Marseille’s Pompiers<br />

Marin (top centre) tested his new vehicles thoroughly<br />

Jean-Emile Martin, <strong>Unimog</strong>’s French sales director, explained the technical features of the vehicles and implements<br />

The cavalcade of historic <strong>Unimog</strong>s<br />

Successful demonstrations were held among the rocks of Lançon-de-Provence on both days of the <strong>Unimog</strong><br />

anniversary event in France<br />

<strong>Unimog</strong> 2|2003 9

While trying to find the answers to these<br />

questions, we discovered some amazing<br />

and altogether innovative things. The<br />

Gelsenwasser AG water procurement company’s<br />

site in Essen-Burgaltendorf seems as<br />

well looked after as any golf course, except<br />

that the sand-filled pools are decidedly bigger<br />

than the usual bunkers and there are no<br />

flags to indicate where the holes are. This<br />

regional company supplies drinking water to<br />

three million people, businesses and industry<br />

in the Ruhr and Münsterland regions, on<br />

the Lower Rhine and in Eastern Westphalia.<br />

Annual water consumption in this region is<br />

approximately 290 million cubic metres,<br />

equivalent to 220,000 cubic metres of water<br />

per day. Supplying clean drinking water isn’t<br />

something that can be taken for granted:<br />

according to U.N. statistics, only 80 percent<br />

of the world’s population have daily access to<br />

clean water.<br />

The drinking water supply facilities in<br />

Essen, Dortmund, Haltern, Witten,<br />

Echthausen and Frondenberg (Sauerland<br />

region) operate some 20 <strong>Unimog</strong>s, of which<br />

the Essen-Burgaltendorf plant has five. All of<br />

the Gelsenwasser AG’s <strong>Unimog</strong>s used for<br />

water procurement run on ecological diesel<br />

oil (‘Bio-Diesel’) and biologically degradable<br />

oils for the engine, gearbox, axles, wheel<br />

hub gears and hydraulic system, in order to<br />

comply with stringent environmental protection<br />

requirements.<br />

The “Eco-<strong>Unimog</strong>” in the biotope<br />

Honestly – who gives much thought to where the clean drinking water<br />

comes from when they turn on the water tap? Or what methods are used<br />

to extract it, the preconditions for obtaining high-quality water, the role<br />

that biologically degradable oils for commercial vehicles have to play and<br />

what the Mercedes-Benz <strong>Unimog</strong> has to do with all of this?<br />

Using ecological oils at the Essen facilities<br />

was water procurement manager Otmar Jürgen’s<br />

idea. “When we decided to make this<br />

move in 1998, we needed a resolution from<br />

the Board of Management,” says Mr. Jürgen,<br />

“since a litre of ecological diesel fuel cost<br />

some DM 2.30 (approx. Euro 1.15) back then.<br />

Its ability to prevent soil and water pollution<br />

encouraged the Board of Management to approve<br />

our plan. The price for these fuels has<br />

in the meantime dropped substantially.”<br />

Otmar Jürgen searched hard for means of<br />

realising his project to operate the vehicles<br />

with biologically degradable oils. He adds,<br />

“We have had only positive results so far.<br />

Despite the often tough work conditions, use<br />

of these oils hasn’t caused any engine failures<br />

or major repairs.” This practicalminded<br />

individual’s work received the ap-<br />

10 <strong>Unimog</strong> 2|2003

Water authorities<br />

preciation it deserved in 1996, when he was<br />

awarded the Federal Republic of Germany’s<br />

Service Cross for his commitment to the use<br />

of ecological oils and fuels.<br />

Large portions of the Gelsenwasser AG’s<br />

water procurement area are similar to a natural<br />

biotope for water birds, rare plants and<br />

many small animals. This idyllic environment<br />

needs care, too. Otmar Jürgen and his<br />

colleague Helmut Pristovnik, who have both<br />

been on the Essen-Burgaltendorf company’s<br />

staff for almost 17 years, find their <strong>Unimog</strong><br />

indispensable for the work. The vehicles are<br />

used for mowing with implements at the<br />

front or rear, cleaning, transporting sand to<br />

the filter pools, grading the sand surfaces<br />

and for winter service. Two <strong>Unimog</strong> U 300s<br />

with wide tyres and a laser-controlled grading<br />

blade are used for the difficult work in<br />

the filter pools. This has to be carried out<br />

with particular care as the seepage pools,<br />

which contain the slow sand filter, must remain<br />

clean in order to ensure consistently<br />

high water quality.<br />

The <strong>Unimog</strong>s are used for important tasks<br />

during the entire water procurement<br />

process. Gelsenwasser AG is yet another example<br />

for <strong>Unimog</strong> implement carriers being<br />

used all the year round for landscape and<br />

environmental care.<br />

■<br />

Wide tyres, eco-diesel fuel in the tank and biologically<br />

degradable oils for the engine, gearbox, axles, wheel<br />

hub gears and hydraulic system are important<br />

preconditions for biologically clean water procurement<br />

(above and page on left)<br />

Among other tasks, Gelsenwasser AG’s <strong>Unimog</strong>s are<br />

used for mowing and gully cleaning in the water<br />

catchment area<br />

<strong>Unimog</strong> 2|2003 11

Road maintenance<br />

A “one-man show” with six implements<br />

This ‘jack-of-all-trades’ amazes even<br />

the most experienced road<br />

construction experts: a <strong>Unimog</strong><br />

U 500 with six attachments as a<br />

complete solution for road-shoulder<br />

construction, leaving not only a<br />

finished shoulder but also a clean<br />

road.<br />

The Söder shoulder building solution work stages are<br />

coordinated efficiently<br />

At one of the numerous beautiful spots in<br />

Germany’s Lüneburg Heath region, in<br />

the triangle between the towns of Celle,<br />

Gifhorn and Uelzen, a <strong>Unimog</strong> U 500 can be<br />

seen from some distance away on a country<br />

road. It is being driven behind a truck and is<br />

apparently swallowing large quantities of<br />

the material sliding out of the truck’s tipping<br />

body. This is the innovative shoulder building<br />

method developed by <strong>Unimog</strong> System<br />

Partner Alfred Söder in Burkardroth (Northern<br />

Bavaria) and the young company owner<br />

Achim Rosinsky based in Winsen an der<br />

Aller, who had the idea for building it.<br />

Rosinsky received help from <strong>Unimog</strong> consultant<br />

Christian Rabe, who works for <strong>Unimog</strong><br />

general agent Peter Meineke in Fallingbostel<br />

(Lower Saxony). “It’s quite obvious<br />

why I needed this combination of equipment,”<br />

says Achim Rosinsky, “I wanted to optimise<br />

the use of my U 500 all the year<br />

round, take full advantage of the four attachment<br />

points it possesses and become more<br />

competitive on the market.” Rosinsky’s goals<br />

have been achieved: his road shoulder construction<br />

services are hard to beat. The <strong>Unimog</strong><br />

U 500 with Söder shoulder building machine<br />

are far superior to the working<br />

methods used in the past. It can place up to<br />

1,500 tonnes of construction material such<br />

as asphalt, gravel, mineral mixtures or soil<br />

above or below street level with the <strong>Unimog</strong><br />

set up as a “multi-purpose solution” including<br />

VarioPilot® changeover steering and<br />

a combination of six attachments. In the past,<br />

a considerably higher workforce was needed<br />

and costly hourly rates for machines for the<br />

various work stages were incurred. The U 500<br />

is today driven along the road that needs the<br />

work, with push rollers for the truck and material<br />

bunker at the front, the shoulder building<br />

machine, Amman compacting plate and<br />

sowing machine (if plants are required) at<br />

the right and rear sweeper with brush, so<br />

that the construction site can be cleaned<br />

during the same work cycle. Once the work<br />

is done, nobody would guess that right next<br />

to the road, where the shoulder now finishes ➔<br />

12 <strong>Unimog</strong> 2|2003

Road-rail applications<br />

off the road neatly, the asphalt was previously<br />

broken up and the shoulder was a serious<br />

danger to passing vehicles.<br />

In addition to carrying the complete combination of<br />

equipment, the <strong>Unimog</strong> U 500 propels the truck with<br />

its tipping semi-trailer<br />

Achim Rosinsky is one of those young and<br />

flexible businessmen who manage the use of<br />

their vehicles from their “mobile office” – in<br />

his case, an off-roader – and travel to every<br />

construction site to discuss questions and<br />

problems with their customers on the spot.<br />

He owns 27 commercial vehicles, from narrow-track<br />

implement carriers to heavy goods<br />

trucks, including a semi-trailer tractor with a<br />

low-bed trailer for a maximum load of 62<br />

tonnes. He reserves special affection, however,<br />

for his various <strong>Unimog</strong>s, consisting of a<br />

U 1700 L, a U 406, a U 140 and a U 90 in<br />

addition to the U 500 mentioned above. They<br />

are used for winter service, sweeping, work<br />

with a grader blade installed between the<br />

axles, construction-site services and general<br />

transport tasks. This customer’s close relationship<br />

with his machinery is also due to<br />

<strong>Unimog</strong> general agent Meineke’s excellent<br />

customer support: Christian Rabe will<br />

provide assistance anywhere and attend<br />

promptly to any inquiry concerning the<br />

<strong>Unimog</strong> and its diverse applications. ■<br />

Moved as if by magic<br />

A road-rail <strong>Unimog</strong> is used for shunting in the port of Stralsund<br />

Anew kind of vehicle has now put in an<br />

appearance at the port of Stralsund. In<br />

the past, former Reichsbahn locomotives<br />

used to sound their horns, but since mid-<br />

2003, a road-rail <strong>Unimog</strong> has been used at<br />

the transhipment port operated by the Stralsunder<br />

Hafen- und Lagerhausgesellschaft<br />

(SHL). The <strong>Unimog</strong> for combined road and<br />

rail use is the economical solution for the<br />

implementation of an international business<br />

agreement. A five-year contract between<br />

SHL and a Norway-based company for the<br />

import of 100,000 tonnes of limestone per<br />

year via this port came into effect at the<br />

beginning of 2003.<br />

Various building materials including gypsum<br />

plaster board are produced in Drammen,<br />

on the Oslo fjord. The two 5,000-ton<br />

Norwegian bulk carriers “Marble Bay” and<br />

“Marble Sea” take turns to perform the<br />

weekly run to the North. Their destination is<br />

Jänschwalde power station in the State of<br />

Brandenburg. Once the gypsum has been<br />

discharged, the train is loaded again. Dieter<br />

Böse is delighted with this successful deal:<br />

“There are no empty movements – the transport<br />

cycle is complete.” Every working day, a<br />

1,800-ton train with 30 freight cars rolls into<br />

the harbour. A locomotive would normally be<br />

needed to shunt these, but since the big<br />

diesel locomotives turned out to be too<br />

expensive and too clumsy, SHL looked for an<br />

alternative and found it at Schoknecht in<br />

Demmin, the <strong>Unimog</strong> general agent for Western<br />

Pomerania. The <strong>Unimog</strong>, with rail guidance<br />

by <strong>Unimog</strong> System Partner Zwiehoff,<br />

can be driven on the road with its rubber<br />

tyres as well as on its steel rail wheels, and<br />

proved to be the ideal solution. It was tested<br />

for eight weeks at the dockside and gave<br />

such good results that SHL’s CEO Wolfgang<br />

Ostenberg decided to purchase it.<br />

Since then, many car drivers have been<br />

surprised to see this brand-new cross<br />

between a road vehicle and a locomotive suddenly<br />

appear in front of them on the transverse<br />

canal bridge, pulling a freight train.<br />

Its power output of 130 kW (177 hp) is fully<br />

adequate for the purpose. There is no driver<br />

anywhere in sight; instead, one of SHL’s<br />

eight shunting controllers trained by the<br />

Deutschen Bahn AG wears a remote control<br />

around his neck to move the 1,800-ton train<br />

and to control the separate air pressure system<br />

for opening and closing the freight car<br />

bodies at the touch of a button.<br />

According to Dieter Böse, the 200,000 Euro<br />

investment has definitely paid off, with<br />

prospects of a ten-year contract with this<br />

Norwegian client.<br />

■<br />

Top left: Shunting a 1,800-ton train; the historic<br />

“Alte Lotsenwache” (the former pilots’ building) can<br />

be seen in the background<br />

Top right: The SHL’s <strong>Unimog</strong> is remote-controlled<br />

Bottom: Mercedes-Benz encounter on transverse canal<br />

bridge in the port of Stralsund<br />

<strong>Unimog</strong> 2|2003 13

Environmental care<br />

The 4,000 trees and<br />

bushes in Straubing<br />

were very thirsty this<br />

summer<br />

What a hot summer...<br />

Two municipal works departments in the town of Straubing in Lower<br />

Bavaria (with approx. 45,000 inhabitants) decided to share one <strong>Unimog</strong> –<br />

and both benefit from it<br />

The vehicle sharing method ensures economical<br />

use of the <strong>Unimog</strong> all the year<br />

round and reduces the burden on the town’s<br />

budget. We watched the town’s gardening<br />

division at work. In the hot summer of 2003,<br />

the trees and flowers in the parks had to be<br />

watered with up to 28,000 litres of water per<br />

day.<br />

Whenever it gets really hot in Straubing,<br />

there is generally enough to drink, but it’s<br />

not quite as easy with the decorative flower<br />

beds, more than 120 plant troughs and approximately<br />

4,000 trees lining the streets<br />

that are spread out over the entire town and<br />

cover an area of 190 hectares. This area was<br />

less than 100 hectares twenty years ago, but<br />

its size was increased significantly for the<br />

1989 Bavarian Garden Show.<br />

The town’s gardening division staff starts<br />

out at five in the morning with the <strong>Unimog</strong><br />

and 4,000 litres of water. This journey is repeated<br />

up to seven times per day. Jörg Bär,<br />

head of the gardening division, sums up the<br />

requirements: “For this kind of work, it is<br />

important to have plenty of capacity available.<br />

The ‘little but often’ principle would<br />

have been completely useless in this summer’s<br />

temperatures. We previously used a<br />

truck with a capacity of 5,000 litres, but we<br />

needed two people for it as it wasn’t flexible<br />

enough for this kind of work.”<br />

Bär continues: “This is why we were looking<br />

for a more appropriate carrier vehicle,<br />

and the <strong>Unimog</strong> was one of the options.<br />

Ultimately, we purchased it because two<br />

divisions decided to buy one vehicle. The<br />

town’s gardeners use it with a watering<br />

system attached and in autumn, after the<br />

bird breeding period, with a Dücker hedge<br />

cutting machine, for which its off-road capabilities<br />

are also an advantage. Our yard<br />

workshop then installs a salt spreader and a<br />

snow plough on the <strong>Unimog</strong> for winter service.”<br />

The <strong>Unimog</strong>’s manoeuvrability is perfect<br />

for both applications, and its power hydraulics<br />

system offers lots of technical<br />

advantages. “It’s been the ideal investment<br />

for us,” says Jörg Bär, “and if the <strong>Unimog</strong><br />

hadn't been available, it would have had to<br />

be invented for our beautiful old town with<br />

its narrow lanes and sharp corners.”<br />

For Jörg Bär and his colleagues, the decisive<br />

advantage is that the <strong>Unimog</strong> and the<br />

watering device make their work easier.<br />

“Our driver Rupert Hopf doesn’t need to get<br />

out of the vehicle anymore; instead, he controls<br />

everything with the joystick and we<br />

don’t need a second person to work the hose<br />

outside the vehicle,” says the head of the<br />

town’s gardens division. The “Straubinger<br />

Rundschau” newspaper featured an enthusiastic<br />

report, too: “Rupert Hopf presses one of<br />

the many buttons on his instrument panel,<br />

which makes the hydraulically controlled<br />

watering arm move towards the flower bed.<br />

His right hand expertly manoeuvres the joystick.<br />

After pressing the red button briefly,<br />

the pump begins to run, and the water is<br />

sprayed out of the watering head.” After so<br />

much praise from the local press, we wouldn’t<br />

want to omit driver Hopf’s statement: “This<br />

is the best vehicle the town’s gardening department<br />

owns!” he confided to his local<br />

newspaper.<br />

■<br />

14 <strong>Unimog</strong> 2|2003

Report<br />

An example of best-practice methods<br />

In the English county of Wiltshire, two <strong>Unimog</strong> with implements<br />

combinations from <strong>Unimog</strong> System Partner Bucher-Schörling,<br />

Mulag and Schmidt are used for economical cleaning work<br />

Like communal administrations in Germany,<br />

those in England also have to<br />

work with limited budgets, and taxpayers<br />

expect them to demonstrate their efficiency.<br />

This is why the County of Wiltshire recently<br />

invested in devices and implements for the<br />

community that ensure efficient use of the<br />

<strong>Unimog</strong> system and encourage the citizens<br />

to be proud of the place they live in. The<br />

“Wiltshire Highways Partnership” is a network<br />

of companies and communities created<br />

for the purpose of sharing road maintenance<br />

duties in the county. The concept arose out<br />

of the necessity to use Wiltshire’s winter<br />

service fleet capacity to the fullest extent.<br />

Another decisive factor was the fact that the<br />

county has many main roads that are maintained<br />

by an external service provider rather<br />

than by the national authority.<br />

Since the autumn of 2002, a U 400 and,<br />

following its successful results, more<br />

recently a U 500 have been operated all the<br />

year round. Eighty percent of the winter<br />

service vehicles previously stood idle for<br />

eight or nine months of the year, as they<br />

were permanently equipped with spraying<br />

equipment, but this has changed with the<br />

advent of the <strong>Unimog</strong>. It is equipped with a<br />

snow plough, salt spreader and gritter devices,<br />

but can also carry mowers, weed<br />

brushes and replaceable sweepers for use in<br />

the summer. The combination of <strong>Unimog</strong><br />

and attachments from Schmidt, Mulag and<br />

Bucher-Schörling is giving full satisfaction<br />

in Wiltshire, especially since the increasing<br />

degree of automation applied to individual<br />

work processes, for which fewer staff are<br />

now needed, makes the investments twice as<br />

profitable.<br />

With the potential of its power hydraulic<br />

system, the <strong>Unimog</strong> can drive different kinds<br />

of machinery such as hedge cutting tools,<br />

mowers, weed brushes, cutting devices for<br />

gullies and road drains and the Bucher-<br />

Schörling road sweeper. People and material<br />

can be transported to the working location<br />

quickly – in short, these are compact, highly<br />

agile vehicles. Those responsible are particularly<br />

grateful for the implement carriers<br />

used in picturesque towns such as Marlborough<br />

and Devizes, in villages and in<br />

tourist centres such as Stonehenge and the<br />

Avebury Circle.<br />

On the continent of Europe, where<br />

<strong>Unimog</strong>s and Mulag machinery have been a<br />

common sight on the roads for decades, the<br />

communities definitely prefer this combination.<br />

Things are often done differently in<br />

Great Britain: kerb and gutter maintenance<br />

is very important here and only certain<br />

machines can be used for it.<br />

The “Wiltshire Highways Partnership” is a<br />

model scheme in which machinery and<br />

people both work with optimum efficiency.<br />

The option of being able to install the equipment<br />

combinations on both <strong>Unimog</strong>s plays<br />

an important role for this. Network support<br />

manager Paul Smith, who coordinates the<br />

cooperation process and the equipment<br />

schedules, is highly enthusiastic: “We are at<br />

the beginning of a learning process right<br />

now. Before long we shall see what can be<br />

accomplished!”<br />

■<br />

The U 500 with an impressive number of devices<br />

including a weed brush and a Bucher-Schörling sweeper<br />

<strong>Unimog</strong> 2|2003 15

DaimlerChrysler Worldwide<br />

A Sterling truck used by<br />

Crux Subsurface (left)<br />

“This is where it’ll be!”:<br />

Locating the best subsurface<br />

conditions for<br />

the bridge over the<br />

Colorado River (next<br />

page, far right)<br />

The geotechnical<br />

company’s U 500 with<br />

drilling equipment<br />

In everyday use<br />

The geotechnical company Crux Subsurface relies on DaimlerChrysler commercial vehicles for<br />

its work - and on financing solutions from Truck Finance<br />

The Hoover Dam is surrounded by desert<br />

interrupted by just a few rock formations<br />

and a deep scar in the earth’s surface. Imagine<br />

for a second that you’re attaching a rope<br />

to the canyon’s narrow peak at an altitude of<br />

800 metres. Slowly and with a firm step, you<br />

lower yourself down on the rope, with several<br />

hundreds of metres between you and<br />

the mighty Colorado River below. One wrong<br />

movement, and you’ll fall. The closer you are<br />

to your destination, the higher the temperatures<br />

get – up to 40 degrees Celsius. The<br />

beads of sweat that would normally appear<br />

on your skin are swallowed up instantly by<br />

the extreme dryness of the desert. And when<br />

you final reached your destination, the real<br />

work begins.<br />

Is this some kind of extreme sport for a<br />

new reality TV show? Far from it. This scenario<br />

is typical of a few hours in the “office”<br />

of Nick Salisbury and his team at Crux<br />

Subsurface. Some couple of years ago, the<br />

geotechnical company was commissioned to<br />

do preliminary work for a bridge construction<br />

project with an estimated value of 220<br />

million US-$. Crux Subsurface specialises in<br />

recording data in areas hard to access physically<br />

and logistically, and mainly works for<br />

the engineering industry.<br />

Known as the Hoover Dam Bypass Project,<br />

this bridge is to provide a link between<br />

Arizona and Nevada. Crux’s job was to<br />

gather information for scientific studies.<br />

Precision is essential<br />

Such tasks are very tricky and call for precision<br />

and special equipment. This is the<br />

reason why Nick Salisbury and his team<br />

were chosen for this challenge. “We can drill<br />

just about anywhere – even in places where<br />

other companies have given up. We specialise<br />

in these kinds of jobs, and this is why<br />

we get asked to do projects of this nature and<br />

scale,” explains Nick Salisbury.<br />

Mobile and ready for action immediately<br />

Just as their customers prefer Crux for<br />

specialised work, so Salisbury chooses<br />

DaimlerChrysler’s special vehicles and<br />

financing solutions from DC Services Truck<br />

Finance. Crux sets itself apart from competitors<br />

by offering mobility and being ready<br />

for action immediately. In order to fulfil this<br />

claim, the company uses Sterling and<br />

Freightliner trucks, among others.<br />

Competitive prices<br />

Not long ago, Nick Salisbury added a<br />

DaimlerChrysler vehicle that is new on the<br />

North American market to the fleet. This<br />

makes him the first U.S. customer to finance<br />

a <strong>Unimog</strong>. The <strong>Unimog</strong> has been available<br />

since the 1950s in Europe, but was only<br />

recently introduced to the USA and Canada.<br />

It is renowned for its versatility and can be<br />

combined with many kinds of machinery. Its<br />

functions can be changed quickly by replac-<br />

16 <strong>Unimog</strong> 2|2003

DaimlerChrysler Worldwide<br />

ing the equipment, and this is why it complements<br />

Crux’s fleet so perfectly. Nick<br />

Salisbury also took advantage of DC Services<br />

North America’s financing facilities.<br />

Various highly competitive financing<br />

schemes for the <strong>Unimog</strong> are available from<br />

Truck Finance. Thanks to its experience, the<br />

company can offer tailor-made solutions at<br />

competitive prices and under flexible<br />

conditions. A package including various<br />

implements is available for every <strong>Unimog</strong><br />

model.<br />

New offers for special-purpose vehicles<br />

“Until up to two years ago, our business<br />

was geared mainly towards fleets and oneperson<br />

companies. With the new financing<br />

and leasing solutions, we are taking full advantage<br />

of the potential this big market has<br />

to offer,” explains Klaus Entenmann, DC Services<br />

Truck Finance’s Vice President, who<br />

predicts dramatic growth for Truck Finance<br />

on the working vehicle market, which<br />

encompasses much more than heavy trucks<br />

for building contractors and vehicles for<br />

town administrations and authorities. It also<br />

includes the market for big and small service<br />

providers and passenger and goods<br />

transport operators such as drinks, parcel or<br />

pharmaceutical delivery companies.<br />

A market with huge potential<br />

Entenmann is positive that “in a couple of<br />

years’ time, we will be able to cover one fifth<br />

of our portfolio with working vehicles. In<br />

addition to specialising in medium-heavy<br />

and heavy trucks, Truck Finance is in an<br />

excellent position to become a major player<br />

on the working vehicle market. Truck<br />

Finance offers the right solution for any<br />

financing requirement.”<br />

■<br />

One of the vehicles used for the<br />

TRACECA project: the double-cabin U 4000<br />

with extreme off-road capability<br />

A trip on the “New Silk Road”<br />

Fascinating mountain roads with breathtaking<br />

scenery, 1,000 kilometres of sand<br />

and gravel in the Kara Kum desert and<br />

passes with steep uphill and downhill sections<br />

of road through mountain massifs that<br />

exceeded the tour participants’ fantasy by<br />

far. The “Help” convoy that DaimlerChrysler<br />

despatched on this 6,047-kilometre trip from<br />

Brussels to Kabul under the auspices of the<br />

European Union in early September consisted<br />

of thirteen Mercedes-Benz Actros<br />

trucks, five Mercedes-Benz Sprinter vans,<br />

one <strong>Unimog</strong> U 4000 with double cabin and<br />

five off-road vehicles. The convoy carried<br />

goods urgently needed for reconstruction<br />

work in Afghanistan and was also intended<br />

to establish about the economic viability of<br />

transporting goods on the so-called<br />

TRACECA route (Transport Corridor Europe<br />

Caucasus Asia), part of which is the same as<br />

the ancient “Silk Road” trade route. The<br />

service team’s conclusion on reaching its<br />

destination in Hayraton (Afghanistan) was<br />

clearly in favour of Mercedes-Benz products<br />

and could not have been more positive<br />

regarding the reliability of the Actros trucks,<br />

<strong>Unimog</strong>, vans and off-road vehicles: very few<br />

spare parts were needed, and only a few<br />

bulbs broke because of the rough roads. ■

Rubrik DaimlerChrysler Worldwide<br />

Western Star truck<br />

on rails<br />

A Western Star 4900 SA helps put 100-ton<br />

trains on the rails<br />

An unusual duo: Western Star pulling a suburban train onto the rails<br />

Bulky and heavy transports are nothing<br />

exceptional for Western Star Trucks,<br />

but the Western Star 4900 SA’s task for the<br />

MAX tram project in Portland, Oregon was<br />

unusual even for a professional heavy-duty<br />

vehicle.<br />

On the 5.8-mile (9.3-kilometre) extension<br />

to the Interstate Metropolitan Area Express<br />

(MAX), a 100-ton low-floor train had to be<br />

pulled on to the rails for the first time in<br />

order to check the track and the overhead<br />

wires. To perform this task efficiently the<br />

4900 SA modified by Canadian vehicle<br />

manufacturer Brandt Industries was guided<br />

by steel wheels on the rails while the normal<br />

twin tyres on the road surface drove it along.<br />

The Interstate MAX extension to be opened<br />

in the autumn of 2004 as the “Yellow Line”,<br />

is the fourth segment of the 38-mile modern<br />

streetcar network of the Portland region’s<br />

local public transport system. The new line<br />

connecting the city with the trade fair centre<br />

in the north cost 350 million US-$. The rail<br />

network is operated by the Tri-County Metropolitan<br />

Transportation District of Oregon<br />

(Tri-Met), which also owns the heavy truck<br />

used for checking the route.<br />

“The 4900 SA is an excellent all-round<br />

truck and one of our most versatile models,”<br />

says Cary Gatzke, Western Star’s Engineering<br />

Director.<br />

■<br />

www.westernstartrucks.com<br />

Living Lakes<br />

DaimlerChrysler is involved in<br />

conserving the lakes on our planet<br />

DaimlerChrysler has from the very outset<br />

supported the Living Lakes project, the<br />

Global Nature Fund’s worldwide lake<br />

network, with its international competence<br />

and modern technology. The company has<br />

now launched a new project as part of this<br />

cooperation: DaimlerChrysler Nature Workcamps.<br />

During the summer holidays this<br />

year, employees’ children and young<br />

Ambitious environmental protection:<br />

volunteers at Lake La Nava<br />

members of the DaimlerChrysler staff joined<br />

local people on six lakes and stretches of water<br />

particularly worthy of protection to contribute<br />

towards protecting these resources.<br />

For example, volunteers<br />

built socalled<br />

ecological<br />

paths, designed to<br />

promote sustained<br />

tourism in the area,<br />

on Siberia's Lake<br />

Baikal. At South<br />

Africa’s Lake St. Lucia,<br />

which is inhabited<br />

by endangered<br />

A hippopotamus in Lake<br />

St. Lucia, South Africa<br />

species such as hippopotamus, leather-back<br />

turtles and crocodiles, volunteers were<br />

involved in environmental education for children.<br />

On Lake La Nava in North-West Spain,<br />

which has been restored to its natural condition,<br />

the DaimlerChrysler team helped to ring<br />

rare birds.<br />

Living Lakes also supports worldwide<br />

environment-related cooperations. Last September<br />

scientists, activists, representatives<br />

of companies and governmental and non-governmental<br />

organisations met at the 8th Living<br />

Lakes Conference in Norwich, England,<br />

held at the University of East Anglia. The conference<br />

was an opportunity to exchange<br />

Resources worth protecting: Lake Baikal<br />

experience, present examples of best-practice<br />

solutions and prepare new joint projects.<br />

The key topics were the effects of climatic<br />

changes and new concepts for successful<br />

nature preserve management.<br />

■<br />

www.livinglakes.org<br />

www.globalnature.org<br />

18 <strong>Unimog</strong> 2|2003

Advertisements<br />

Technology that<br />

grabs you!<br />

Loader attachment<br />

Type M 213<br />

Tel. +49 (0) 83 31/94 87-0 Fax -40 Industriestrasse 6 87734 Benningen Germany www.ematec.de<br />

<strong>Unimog</strong> 2|2003 19

Symposium<br />

“Rescue, Recovery and Fire-Fighting”<br />

The Product Unit <strong>Unimog</strong>/Speciality<br />

Vehicles, several <strong>Unimog</strong> System<br />

Partners and special superstructure<br />

manufacturers presented<br />

equipment packages for specific,<br />

efficient firefighting and<br />

catastrophe services<br />

At the “International Symposium for<br />

Forest Fire-Fighting and Catastrophe<br />

Protection” held at the DC Rastatt customer<br />

centre and also at a gravel pit in Ötigheim,<br />

Europe’s most difficult off-road testing<br />

ground, the <strong>Unimog</strong>’s very diverse applications<br />

for saving lives, extinguishing the most<br />

difficult fires and salvaging goods were<br />

demonstrated. More than 600 experts from<br />

fire brigades, technical emergency services,<br />

the police and other help, firefighting and<br />

catastrophe prevention organisations from<br />

all over the world had been invited to attend<br />

this event. They witnessed presentations by<br />

17 <strong>Unimog</strong>s, from the U 300 to 500 off-road<br />

implement carrier models to the <strong>Unimog</strong> U 3000<br />

to U 5000 extreme off-road chassis series –<br />

all of them equipped with country-specific<br />

special attachments from international manufacturers<br />

and recovery and salvaging<br />

equipment from <strong>Unimog</strong>’s European System<br />

Partners. The presentations showed these<br />

decision-makers in an impressive manner<br />

just what can be accomplished with the<br />

<strong>Unimog</strong> in extreme working and off-road<br />

conditions, when fighting forest fires, carry-<br />

20 <strong>Unimog</strong> 2|2003

Martin Flammer of the<br />

<strong>Unimog</strong> sales<br />

department directed the<br />

“star parade” and<br />

presented the<br />

demonstrations in the<br />

Ötigheim gravel pit<br />

skilfully (left)<br />

Only the realistic work<br />

demonstrations were<br />

more spectacular than<br />

the “star parade” of<br />

working and rescue<br />

vehicles (strip at the<br />

bottom)<br />

combat fires quickly. In France alone, more<br />

than 1,000 <strong>Unimog</strong>s equipped for this purpose<br />

are in use; each of them can carry up to<br />

5,000 litres of water.<br />

ing out repairs after floods, storms and<br />

earthquakes or in post-accident rescuing<br />

operations.<br />

In addition to extensive information on<br />

the <strong>Unimog</strong>’s technology and application options,<br />

practice-oriented talks by Lt. Col. Didier<br />

Besson (head of the firefighting centre<br />

in Royan, South-West France) and Helmut<br />

Moser (four-wheel-drive training teacher and<br />

publisher/editor-in-chief of the “4 Wheel<br />

Drive” magazine, from Wels, Austria)<br />

aroused lots of interest. “We would have<br />

been helpless in many situations without<br />

our <strong>Unimog</strong>” – this statement by Mr. Besson<br />

made it clear to the experts in attendance<br />

how important the “appropriate equipment”<br />

is when fighting fires and other catastrophes.<br />

Besson, who in the summer months is<br />

often busy fighting severe forest fires, emphasized<br />

“his” <strong>Unimog</strong> working vehicles’<br />

technical concept, their reliability and the<br />

ability of the <strong>Unimog</strong> models U 3000 to<br />

U 5000 to be driven directly into the fires<br />

with their solid steel driver’s cab and special<br />

self-protection equipment, thus creating fire<br />

lanes. These <strong>Unimog</strong> units equipped with an<br />

extinguishing water tank are mainly used to<br />

The demonstrations in the Ötigheim<br />

gravel pit convinced firemen and catastrophy<br />

prevention staff of the merits of the new<br />

highly mobile <strong>Unimog</strong> chassis U 3000 -<br />

U 5000. The real-life working presentations<br />

of the U 300, U 400 and U 500 off-road implement<br />

carriers, too, were very impressive<br />

to watch – as a tank vehicle for emergency<br />

supplies of drinking water, as a hose tender,<br />

with a crane and/or winch, as a forest fire<br />

extinguishing vehicle, as a high-pressure<br />

cleaning unit or equipped with an excavatorloader<br />

or a special sand sack filling machine<br />

for flood disaster control.<br />

■<br />

<strong>Unimog</strong> 2|2003 21

The 1,000-litre liquid manure drum<br />

(which has of course been thoroughly<br />

cleaned) delivers water for the fields<br />

A “millionaire” in the bush<br />

Father Manfred Förg has run the Nyangana<br />

mission in Namibia’s north since<br />

1962, and for an equally long period has<br />

used a <strong>Unimog</strong> in the African bush on the<br />

Okavango river near the border with Angola.<br />

The priest and his helpers use the vehicle to<br />

negotiate rough terrain and reach the more<br />

than fifty mission communities with 22,000<br />

Christians located in a 100-kilometre radius.<br />

The <strong>Unimog</strong> is equipped for these journeys<br />

with a 200-litre water tank, a 50-litre spare<br />

can of diesel, a camping stove and a plank<br />

bed. Father Förg occasionally drives to the<br />

Namibian capital of Windhoek on the 1,000-<br />

kilometre road strewn with potholes. A large<br />

drum of water is often installed on the platform<br />

instead, to supply missions where the<br />

water supply has broken down. Sometimes,<br />

the carefully cleaned-out liquid manure<br />

trailer is filled with almost 1,000 litres of<br />

water so that the hand-planted gardens and<br />

fields can be watered. This <strong>Unimog</strong> has<br />

already covered more than a million kilometres,<br />

largely without any problems. Only<br />

the filters have had to be replaced from time<br />

to time. Luckily, minor repairs could be carried<br />

out at the mission. As veteran cars more<br />

than 40 years old aren’t subject to taxes in<br />

Namibia, Father Förg doesn’t have to pay tax<br />

on his <strong>Unimog</strong> any more. This saves 250<br />

Namibian dollars, which is a lot of money for<br />

a missionary. His second <strong>Unimog</strong> – a U 416<br />

with the U 406’s cab and engine – which the<br />

Father assembled with help from<br />

the locals, is still subject to tax. Fortunately,<br />

Father Förg can now rely on expert help for<br />

both of his “universal motor vehicles”:<br />

In Rundu, some 100 kilometres away, a<br />

mechanic of German origin has opened what<br />

is alleged to be the “best Mercedes truck<br />

workshop in the country”.<br />

■<br />

Advertisement<br />

22 <strong>Unimog</strong> 2|2003

UNISCOPE<br />

An off-road<br />

expert<br />

Farewell to<br />

Hans-Jürgen Wischhof<br />

Hans-Jürgen Wischhof was CEO of the<br />

<strong>Unimog</strong> Division for more than twelve<br />

years – longer than any of his predecessors<br />

– and on his retirement leaves a healthy<br />

company behind him. Dr. Klaus Maier, Head<br />

of the Mercedes-Benz Truck Division, held<br />

the official farewell speech on Thursday,<br />

October 9. In his words: “You could always<br />

rely on Hans-Jürgen Wischhof and he was<br />

and remains a true friend of the <strong>Unimog</strong>. He<br />

was always the company’s foremost engineer<br />

and salesman.”<br />

There were many speeches and therefore<br />

memories of Hans-Jürgen Wischhof’s activity,<br />

lasting almost 25 years, on behalf of the<br />

DaimlerChrysler Group. What was constantly<br />

evident was that he would accept<br />

every job and consider it “his task”. He came<br />

to Gaggenau in the spring of 1990 with this<br />

attitude, and set to work right away, making<br />

the necessary urgent decisions and leading<br />

the <strong>Unimog</strong> through one of its more difficult<br />

phases. With the help of his team and with<br />

the backing of the Group headquarters, the<br />

<strong>Unimog</strong> has entered the 21st century in<br />

great condition.<br />

During the Wischhof era, two product<br />

lines for different customer target groups<br />

were introduced – the off-road U 300 - U 500<br />

implement carriers and the extreme off-road<br />

U 3000 - U 5000 transport vehicles – and the<br />

U 500 USA was also the first model to be<br />

launched in North America. Wischhof set<br />

the signals in many important areas with a<br />

view to making the division more economical.<br />

Strategic re-orientation of the <strong>Unimog</strong> –<br />

which is in fact the world’s best-known<br />

Mercedes-Benz truck – culminated with relocation<br />

of the <strong>Unimog</strong> production facilities<br />

to the truck assembly plant in Wörth.<br />

“Now that I’m leaving, I’m absolutely<br />

positive that it has all been worthwhile,”<br />

said the former <strong>Unimog</strong> CEO. The festive<br />

environment in Gaggenau, with a vehicle<br />

parade through the factory and standing<br />

ovations for his emotional final speech, was<br />

a last and certainly pleasant highlight of an<br />

interesting and successful career. ■<br />

Gisbert Hindennach, author of several<br />

books about the <strong>Unimog</strong> that mainly deal<br />

with its driveline technology and extreme<br />

off-road situations, has now written<br />

another book entitled “<strong>Unimog</strong> Off Road<br />

Driving School”. It describes what can be<br />

done with the off-road <strong>Unimog</strong>. An off-road<br />

specialist from Freudenstadt in the Black<br />

Forest, Hindennach describes how to<br />

maintain preconditions for safe driving in<br />

extreme off-road terrain by appropriate<br />

driving techniques and by taking full<br />

advantage of the <strong>Unimog</strong>’s driveline technology.<br />

On 224 pages with 400 colour<br />

pictures, the author conveys many useful<br />

facts on how to look ahead and adopt the<br />

appropriate driving style, on basic physical<br />

principles and realistic assessment of<br />

risks. The book is obtainable in German and<br />

English, from:<br />

Ingenieurbüro Gisbert Hindennach<br />

Keplerstrasse 3,<br />

72250 Freudenstadt,<br />

Germany<br />

Phone +49 (0) 7441 - 91150<br />

Fax +49 (0) 7441 - 911519<br />

E-mail: gisbert.hindennach@t-online.de<br />

www.hindennach.com<br />

Flowers for Mrs. Wischhof and a heartfelt thank-you<br />

for Hans-Jürgen Wischhof (centre) from Dr. Klaus<br />

Maier (left)<br />

<strong>Unimog</strong> 2|2003 23