B~W Pantex

Pantex TYSP - National Nuclear Security Administration - U.S. ...

Pantex TYSP - National Nuclear Security Administration - U.S. ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FINAL <strong>Pantex</strong> Index No.: PLAN-TYSP-FY13<br />

18 of 55<br />

• HE Inert Machining<br />

• HE Formulation<br />

• Zone 11 HPFL Replacement<br />

• HE Component Fabrication and<br />

Qualification Facility<br />

These same projects support the HE R&D<br />

efforts. The HEPF is under construction.<br />

The HE ST&E CD-1 documentation is being<br />

finalized and should result in design efforts<br />

being started within the next year.<br />

Future Vision<br />

The RoD for the Complex Transformation<br />

SPEIS selected <strong>Pantex</strong> Plant as the CoE for<br />

HE production. The <strong>Pantex</strong> HE production<br />

mission is required to support nuclear<br />

weapons stockpile stewardship while<br />

continuously improving levels of safety and<br />

productivity. Major activities include:<br />

• Manufacturing special stockpile<br />

explosives<br />

• Fabricating explosive components<br />

• Performing comprehensive<br />

destructive/non-destructive testing of<br />

explosive products<br />

• Providing explosives asset stewardship<br />

When the HE CoE is fully implemented,<br />

<strong>Pantex</strong> will have the sustainable<br />

infrastructure in place to support the HE<br />

need for the foreseeable future. Production<br />

will be performed in modern sustainable<br />

buildings with efficient and effective<br />

processes to minimize costs and maximize<br />

operability. Explosive formulation could be<br />

performed in large lots to minimize<br />

variations and testing. Pressing could be<br />

done with near net-shape precision and<br />

machining will be minimal.<br />

The Physics Laboratories will have<br />

validated aging models developed through<br />

the accumulation of surveillance and testing<br />

data that will allow historical materials to be<br />

minimized reducing the footprint currently<br />

required for long-term storage. <strong>Pantex</strong> will<br />

continuously manage its explosive inventory<br />

to ensure sufficient storage space to meet<br />

future stockpile stewardship requirements.<br />

Tactical Horizon (FY13-FY22)<br />

Capability/Needs to Achieve NNSA Strategic<br />

Goals and Objectives<br />

• Commence and sustain two-shift<br />

operations for main charge fabrication<br />

(pressing and machining) to satisfy<br />

W76-1 LEP schedule demands<br />

• Planning is also underway with regard to<br />

the B61 LEP scheduled for FPU at<br />

<strong>Pantex</strong> in FY19. In preparation for this<br />

LEP, the site must establish appropriate<br />

Insensitive High Explosives (IHE) main<br />

charge fabrication processes. This<br />

effort will require some degree of<br />

process development and formalized<br />

implementation at the site<br />

• Establish and implement appropriate<br />

IHE charge fabrication process for B61<br />

LEP scheduled for FPU at <strong>Pantex</strong> in<br />

FY19<br />

• Modernize extrudable HE loading and<br />

testing capability to meet B61 LEP<br />

requirements<br />

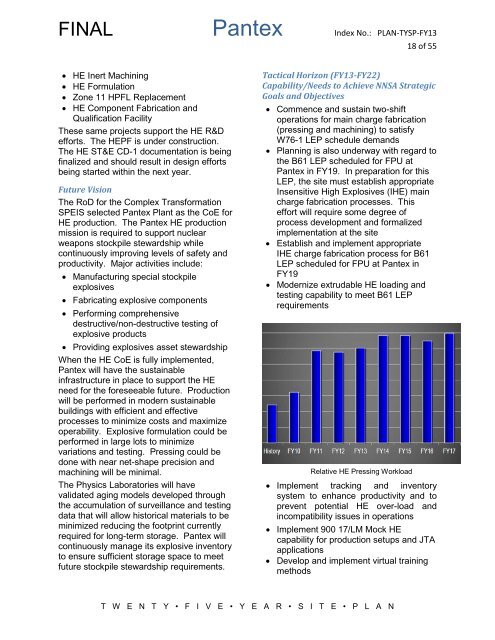

Relative HE Pressing Workload<br />

• Implement tracking and inventory<br />

system to enhance productivity and to<br />

prevent potential HE over-load and<br />

incompatibility issues in operations<br />

• Implement 900 17/LM Mock HE<br />

capability for production setups and JTA<br />

applications<br />

• Develop and implement virtual training<br />

methods<br />

T W E N T Y • F I V E • Y E A R • S I T E • P L A N