DK Suction Gas Heat Exchanger

DK Suction Gas Heat Exchanger

DK Suction Gas Heat Exchanger

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The best choice<br />

in heat recovery and cold water systems.<br />

<strong>DK</strong> <strong>Suction</strong> <strong>Gas</strong> <strong>Heat</strong> <strong>Exchanger</strong><br />

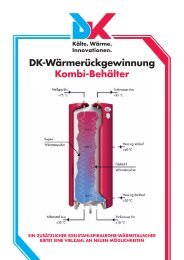

tc +40°C<br />

Condenser<br />

-25°C<br />

Header<br />

Example:<br />

to -30°C<br />

tc +40°C<br />

R 404A<br />

+40°C<br />

+30°C<br />

Dryer<br />

-5°C<br />

-5°C<br />

Inspection glass<br />

TEV<br />

to -30°C<br />

Evaporator

The best choice<br />

in heat recovery and cold water systems.<br />

<strong>DK</strong> <strong>Suction</strong> <strong>Gas</strong> <strong>Heat</strong> <strong>Exchanger</strong><br />

-Details at a glance-<br />

Application: all R404A/R507 refrigeration units with evaporation temperatures < = +5°C<br />

Operation: Installation in suction and fluid line. The fluid is super-cooled by the cold<br />

suction gas, in return for which the suction gas is overheated by the warm<br />

fluid.<br />

Background: Refrigeration units with semi-hermetic piston compressors offer greater<br />

refrigeration capacities with increasing suction temperature of the suction gas<br />

by up to +25°C and strongly super-cooled fluid<br />

Advantages: The refrigeration unit, depending on application, achieves up to 15% greater<br />

performance with the suction gas heat exchanger compared to a refrigeration<br />

unit without exchanger.<br />

In spite of a greater refrigeration performance the input power remains<br />

almost even.<br />

This results in an enhanced performance figure Qo/Pe<br />

If a suction gas heat exchanger is taken into account during planning then<br />

smaller compressors can be chosen. This results in a reduction of the<br />

applied electric energy, which throughout the entire year results in<br />

significant savings.<br />

Smaller tube dimensions can be chosen<br />

➔lower investment costs<br />

Enhances use of heat recovery since hot gas temperatures rise.<br />

Special note: The use of a suction gas heat exchanger requires the careful layout of the<br />

solenoid valves and e-valves.

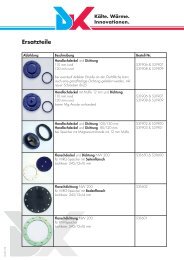

Fluid IN<br />

_____mm<br />

green/red<br />

Fluid IN<br />

_____mm<br />

green/red<br />

<strong>Suction</strong> line OUT<br />

..............mm<br />

blue/red<br />

<strong>Suction</strong> line OUT<br />

..............mm<br />

blue/red<br />

Fluid IN<br />

_____mm<br />

green/red<br />

<strong>Suction</strong> line OUT<br />

..............mm<br />

blue/red<br />

The best choice<br />

in heat recovery and cold water systems.<br />

<strong>DK</strong> <strong>Suction</strong> <strong>Gas</strong> <strong>Heat</strong> <strong>Exchanger</strong><br />

-<strong>Suction</strong> Line Connection Options-<br />

Side View<br />

- Top connections -<br />

Distance mounting<br />

- Bottom connections -<br />

Distance mounting<br />

- Top/bottom connections -<br />

Distance mounting<br />

<strong>Suction</strong> line IN<br />

.............mm<br />

blue<br />

<strong>Suction</strong> line IN<br />

.............mm<br />

blue<br />

<strong>Suction</strong> line IN<br />

.............mm<br />

blue<br />

Fluid OUT<br />

____mm<br />

green<br />

Fluid OUT<br />

____mm<br />

green<br />

Fluid OUT<br />

____mm<br />

green

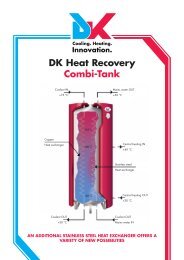

<strong>DK</strong> <strong>Suction</strong> <strong>Gas</strong> <strong>Heat</strong> <strong>Exchanger</strong> (1.0 m)<br />

Made of Cu tube with inserted single-walled<br />

finned tube including mounting and insulation.<br />

Model 42/3x13 54/5x13 64/7x13 76/9x13 89/12x13 108/20x13 133/30x13 159/40x13 219/64x13<br />

Tubular<br />

shell<br />

No. of<br />

inner tubes<br />

Length of<br />

inner tubes/ mm<br />

Distance mounting<br />

Length / total<br />

construction<br />

Height / total<br />

construction<br />

<strong>Suction</strong><br />

line mm<br />

Fluid line/mm<br />

Surface LP-carrying<br />

side/m 2<br />

Capacity of<br />

exchanger in Watt 1)<br />

Shell volume (LP-<br />

carrying side) in dm 3<br />

Tube volume (HP-<br />

carrying side) in dm 3<br />

42 mm 54 mm 64 mm 76 mm 89 mm 108 mm 133 mm 159 mm 219<br />

3x13 5x13 7x13 9x13 12x13 20x13 30x13 40x13 64x13<br />

1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000<br />

500 500 500 500 500 500 500 500 500<br />

1.250 1.250 1.300 1.300 1.300 1.350 1.350 1.400 1.450<br />

360 370 380 400 420 450 480 500 560<br />

28 35 42 54 64 76 89 108 133<br />

12 16 22 22 28 35 42 54 64<br />

0,48 0,8 1,12 1,44 1,92 3,2 4,8 6,4 10,24<br />

1.550 2.590 3.620 4.665 6.220 10.360 15.550 20.700 33.100<br />

0,8 1,3 1,9 2,8 4,0 5,5 8,3 12,4 26,1<br />

0,26 0,35 0,5 0,6 0,8 1,3 2,0 2,8 4,8<br />

Maximum operating pressure: Shell 16 bar Tube 28 bar<br />

The best choice<br />

in heat recovery and cold water systems.<br />

1) Performance quoted for R404A design:<br />

Refrigeration units:<br />

Super-cooling of fluid from +40°C to +35°C – overheating of suction gas from +-0°C to +10°C<br />

Deep-freezing units:<br />

Super-cooling of fluid from +40°C to +30°C – overheating of suction gas from –25°C to –5°C