You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

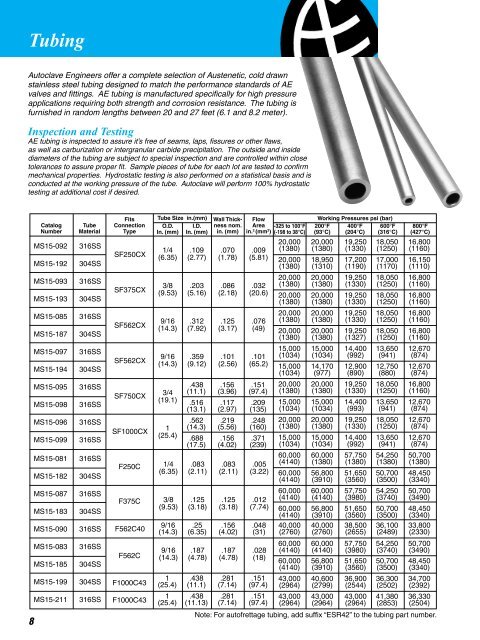

Tub<strong>in</strong>g<br />

<strong>Autoclave</strong> <strong>Eng<strong>in</strong>eers</strong> offer a complete selection of Austenetic, cold drawn<br />

sta<strong>in</strong>less steel tub<strong>in</strong>g designed to match the performance st<strong>and</strong>ards of AE<br />

<strong>valves</strong> <strong>and</strong> fitt<strong>in</strong>gs. AE tub<strong>in</strong>g is manufactured specifically for <strong>high</strong> <strong>pressure</strong><br />

applications requir<strong>in</strong>g both strength <strong>and</strong> corrosion resistance. <strong>The</strong> tub<strong>in</strong>g is<br />

furnished <strong>in</strong> r<strong>and</strong>om lengths between 20 <strong>and</strong> 27 feet (6.1 <strong>and</strong> 8.2 meter).<br />

Inspection <strong>and</strong> Test<strong>in</strong>g<br />

AE tub<strong>in</strong>g is <strong>in</strong>spected to assure it’s free of seams, laps, fissures or other flaws,<br />

as well as carburization or <strong>in</strong>tergranular carbide precipitation. <strong>The</strong> outside <strong>and</strong> <strong>in</strong>side<br />

diameters of the tub<strong>in</strong>g are subject to special <strong>in</strong>spection <strong>and</strong> are controlled with<strong>in</strong> close<br />

tolerances to assure proper fit. Sample pieces of tube for each lot are tested to confirm<br />

mechanical properties. Hydrostatic test<strong>in</strong>g is also performed on a statistical basis <strong>and</strong> is<br />

conducted at the work<strong>in</strong>g <strong>pressure</strong> of the tube. <strong>Autoclave</strong> will perform 100% hydrostatic<br />

test<strong>in</strong>g at additional cost if desired.<br />

8<br />

Fits Tube Size <strong>in</strong>.(mm) Wall Thick- Flow<br />

Catalog Tube Connection O.D. I.D. ness nom. Area -325 to 100°F<br />

Number Material Type In. (mm) In. (mm) <strong>in</strong>. (mm) <strong>in</strong>. 2 (mm 2 ) (-198 to 38°C)<br />

MS15-092<br />

MS15-192<br />

MS15-093<br />

MS15-193<br />

MS15-085<br />

MS15-187<br />

MS15-097<br />

MS15-194<br />

MS15-095<br />

MS15-098<br />

MS15-096<br />

MS15-099<br />

MS15-081<br />

MS15-182<br />

MS15-087<br />

MS15-183<br />

MS15-090<br />

MS15-083<br />

MS15-185<br />

MS15-199<br />

MS15-211<br />

316SS<br />

304SS<br />

316SS<br />

304SS<br />

316SS<br />

304SS<br />

316SS<br />

304SS<br />

316SS<br />

316SS<br />

316SS<br />

316SS<br />

316SS<br />

304SS<br />

316SS<br />

304SS<br />

316SS<br />

316SS<br />

304SS<br />

304SS<br />

316SS<br />

SF250CX<br />

SF375CX<br />

SF562CX<br />

SF562CX<br />

SF750CX<br />

SF1000CX<br />

F250C<br />

F375C<br />

F562C40<br />

F562C<br />

F1000C43<br />

F1000C43<br />

1/4 .109 .070 .009<br />

(6.35) (2.77) (1.78) (5.81)<br />

3/8 .203 .086 .032<br />

(9.53) (5.16) (2.18) (20.6)<br />

9/16 .312 .125 .076<br />

(14.3) (7.92) (3.17) (49)<br />

9/16 .359 .101 .101<br />

(14.3) (9.12) (2.56) (65.2)<br />

3/4<br />

(19.1)<br />

1<br />

(25.4)<br />

.438<br />

(11.1)<br />

.156<br />

(3.96)<br />

.151<br />

(97.4)<br />

.516<br />

(13.1)<br />

.117<br />

(2.97)<br />

.209<br />

(135)<br />

.562<br />

(14.3)<br />

.219<br />

(5.56)<br />

.248<br />

(160)<br />

.688<br />

(17.5)<br />

.156<br />

(4.02)<br />

.371<br />

(239)<br />

1/4 .083 .083 .005<br />

(6.35) (2.11) (2.11) (3.22)<br />

3/8 .125 .125 .012<br />

(9.53) (3.18) (3.18) (7.74)<br />

9/16 .25 .156 .048<br />

(14.3) (6.35) (4.02) (31)<br />

9/16 .187 .187 .028<br />

(14.3) (4.78) (4.78) (18)<br />

1<br />

(25.4)<br />

.438<br />

(11.1)<br />

.281<br />

(7.14)<br />

.151<br />

(97.4)<br />

1<br />

(25.4)<br />

.438<br />

(11.13)<br />

.281<br />

(7.14)<br />

.151<br />

(97.4)<br />

Work<strong>in</strong>g Pressures psi (bar)<br />

200°F 400°F 600°F<br />

(93°C) (204°C) (316°C)<br />

800°F<br />

(427°C)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1330)<br />

18,050<br />

(1250)<br />

16,800<br />

(1160)<br />

20,000<br />

(1380)<br />

18,950<br />

(1310)<br />

17,200<br />

(1190)<br />

17,000<br />

(1170)<br />

16,150<br />

(1110)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1330)<br />

18,050<br />

(1250)<br />

16,800<br />

(1160)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1330)<br />

18,050<br />

(1250)<br />

16,800<br />

(1160)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1330)<br />

18,050<br />

(1250)<br />

16,800<br />

(1160)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1327)<br />

18,050<br />

(1250)<br />

16,800<br />

(1160)<br />

15,000<br />

(1034)<br />

15,000<br />

(1034)<br />

14,400<br />

(992)<br />

13,650<br />

(941)<br />

12,670<br />

(874)<br />

15,000<br />

(1034)<br />

14,170<br />

(977)<br />

12,900<br />

(890)<br />

12,750<br />

(880)<br />

12,670<br />

(874)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1330)<br />

18,050<br />

(1250)<br />

16,800<br />

(1160)<br />

15,000<br />

(1034)<br />

15,000<br />

(1034)<br />

14,400<br />

(993)<br />

13,650<br />

(941)<br />

12,670<br />

(874)<br />

20,000<br />

(1380)<br />

20,000<br />

(1380)<br />

19,250<br />

(1330)<br />

18,050<br />

(1250)<br />

12,670<br />

(874)<br />

15,000<br />

(1034)<br />

15,000<br />

(1034)<br />

14,400<br />

(992)<br />

13,650<br />

(941)<br />

12,670<br />

(874)<br />

60,000<br />

(4140)<br />

60,000<br />

(1380)<br />

57,750<br />

(1380)<br />

54,250<br />

(1380)<br />

50,700<br />

(1380)<br />

60,000<br />

(4140)<br />

56,800<br />

(3910)<br />

51,650<br />

(3560)<br />

50,700<br />

(3500)<br />

48,450<br />

(3340)<br />

60,000<br />

(4140)<br />

60,000<br />

(4140)<br />

57,750<br />

(3980)<br />

54,250<br />

(3740)<br />

50,700<br />

(3490)<br />

60,000<br />

(4140)<br />

56,800<br />

(3910)<br />

51,650<br />

(3560)<br />

50,700<br />

(3500)<br />

48,450<br />

(3340)<br />

40,000<br />

(2760)<br />

40,000<br />

(2760)<br />

38,500<br />

(2655)<br />

36,100<br />

(2489)<br />

33,800<br />

(2330)<br />

60,000<br />

(4140)<br />

60,000<br />

(4140)<br />

57,750<br />

(3980)<br />

54,250<br />

(3740)<br />

50,700<br />

(3490)<br />

60,000<br />

(4140)<br />

56,800<br />

(3910)<br />

51,650<br />

(3560)<br />

50,700<br />

(3500)<br />

48,450<br />

(3340)<br />

43,000<br />

(2964)<br />

40,600<br />

(2799)<br />

36,900<br />

(2544)<br />

36,300<br />

(2502)<br />

34,700<br />

(2392)<br />

43,000<br />

(2964)<br />

43,000<br />

(2964)<br />

43,000<br />

(2964)<br />

41,380<br />

(2853)<br />

36,330<br />

(2504)<br />

Note: For autofrettage tub<strong>in</strong>g, add suffix “ESR42” to the tub<strong>in</strong>g part number.