Aerospace

Midlands Aerospace Alliance

Midlands Aerospace Alliance

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

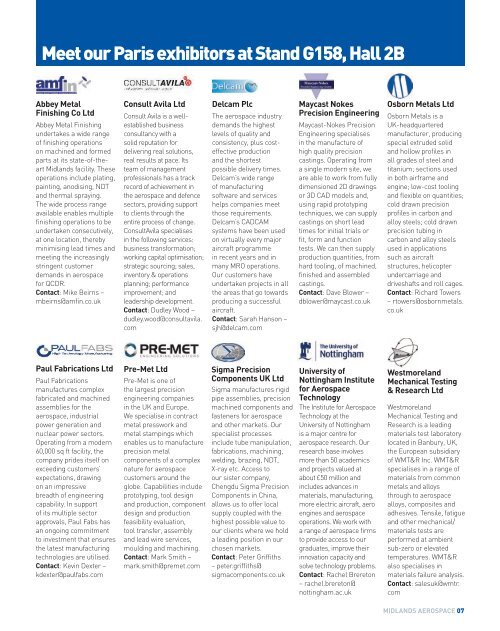

Meet our Paris exhibitors at Stand G158, Hall 2B<br />

Abbey Metal<br />

Finishing Co Ltd<br />

Abbey Metal Finishing<br />

undertakes a wide range<br />

of finishing operations<br />

on machined and formed<br />

parts at its state-of-theart<br />

Midlands facility. These<br />

operations include plating,<br />

painting, anodising, NDT<br />

and thermal spraying.<br />

The wide process range<br />

available enables multiple<br />

finishing operations to be<br />

undertaken consecutively,<br />

at one location, thereby<br />

minimising lead times and<br />

meeting the increasingly<br />

stringent customer<br />

demands in aerospace<br />

for QCDR.<br />

Contact: Mike Beirns –<br />

mbeirns@amfin.co.uk<br />

Consult Avila Ltd<br />

Consult Avila is a wellestablished<br />

business<br />

consultancy with a<br />

solid reputation for<br />

delivering real solutions,<br />

real results at pace. Its<br />

team of management<br />

professionals has a track<br />

record of achievement in<br />

the aerospace and defence<br />

sectors, providing support<br />

to clients through the<br />

entire process of change.<br />

ConsultAvila specialises<br />

in the following services:<br />

business transformation;<br />

working capital optimisation;<br />

strategic sourcing; sales,<br />

inventory & operations<br />

planning; performance<br />

improvement; and<br />

leadership development.<br />

Contact: Dudley Wood –<br />

dudley.wood@consultavila.<br />

com<br />

Delcam Plc<br />

The aerospace industry<br />

demands the highest<br />

levels of quality and<br />

consistency, plus costeffective<br />

production<br />

and the shortest<br />

possible delivery times.<br />

Delcam’s wide range<br />

of manufacturing<br />

software and services<br />

helps companies meet<br />

those requirements.<br />

Delcam’s CADCAM<br />

systems have been used<br />

on virtually every major<br />

aircraft programme<br />

in recent years and in<br />

many MRO operations.<br />

Our customers have<br />

undertaken projects in all<br />

the areas that go towards<br />

producing a successful<br />

aircraft.<br />

Contact: Sarah Hanson –<br />

sjh@delcam.com<br />

Maycast Nokes<br />

Precision Engineering<br />

Maycast-Nokes Precision<br />

Engineering specialises<br />

in the manufacture of<br />

high quality precision<br />

castings. Operating from<br />

a single modern site, we<br />

are able to work from fully<br />

dimensioned 2D drawings<br />

or 3D CAD models and,<br />

using rapid prototyping<br />

techniques, we can supply<br />

castings on short lead<br />

times for initial trials or<br />

fit, form and function<br />

tests. We can then supply<br />

production quantities, from<br />

hard tooling, of machined,<br />

finished and assembled<br />

castings.<br />

Contact: Dave Blower –<br />

dblower@maycast.co.uk<br />

Osborn Metals Ltd<br />

Osborn Metals is a<br />

UK-headquartered<br />

manufacturer, producing<br />

special extruded solid<br />

and hollow profiles in<br />

all grades of steel and<br />

titanium; sections used<br />

in both airframe and<br />

engine; low-cost tooling<br />

and flexible on quantities;<br />

cold drawn precision<br />

profiles in carbon and<br />

alloy steels; cold drawn<br />

precision tubing in<br />

carbon and alloy steels<br />

used in applications<br />

such as aircraft<br />

structures, helicopter<br />

undercarriage and<br />

driveshafts and roll cages.<br />

Contact: Richard Towers<br />

– rtowers@osbornmetals.<br />

co.uk<br />

Paul Fabrications Ltd<br />

Paul Fabrications<br />

manufactures complex<br />

fabricated and machined<br />

assemblies for the<br />

aerospace, industrial<br />

power generation and<br />

nuclear power sectors.<br />

Operating from a modern<br />

60,000 sq ft facility, the<br />

company prides itself on<br />

exceeding customers’<br />

expectations, drawing<br />

on an impressive<br />

breadth of engineering<br />

capability. In support<br />

of its multiple sector<br />

approvals, Paul Fabs has<br />

an ongoing commitment<br />

to investment that ensures<br />

the latest manufacturing<br />

technologies are utilised.<br />

Contact: Kevin Dexter –<br />

kdexter@paulfabs.com<br />

Pre-Met Ltd<br />

Pre-Met is one of<br />

the largest precision<br />

engineering companies<br />

in the UK and Europe.<br />

We specialise in contract<br />

metal presswork and<br />

metal stampings which<br />

enables us to manufacture<br />

precision metal<br />

components of a complex<br />

nature for aerospace<br />

customers around the<br />

globe. Capabilities include<br />

prototyping, tool design<br />

and production, component<br />

design and production<br />

feasibility evaluation,<br />

tool transfer, assembly<br />

and lead wire services,<br />

moulding and machining.<br />

Contact: Mark Smith –<br />

mark.smith@premet.com<br />

Sigma Precision<br />

Components UK Ltd<br />

Sigma manufactures rigid<br />

pipe assemblies, precision<br />

machined components and<br />

fasteners for aerospace<br />

and other markets. Our<br />

specialist processes<br />

include tube manipulation,<br />

fabrications, machining,<br />

welding, brazing, NDT,<br />

X-ray etc. Access to<br />

our sister company,<br />

Chengdu Sigma Precision<br />

Components in China,<br />

allows us to offer local<br />

supply coupled with the<br />

highest possible value to<br />

our clients where we hold<br />

a leading position in our<br />

chosen markets.<br />

Contact: Peter Griffiths<br />

– peter.griffiths@<br />

sigmacomponents.co.uk<br />

University of<br />

Nottingham Institute<br />

for <strong>Aerospace</strong><br />

Technology<br />

The Institute for <strong>Aerospace</strong><br />

Technology at the<br />

University of Nottingham<br />

is a major centre for<br />

aerospace research. Our<br />

research base involves<br />

more than 50 academics<br />

and projects valued at<br />

about £50 million and<br />

includes advances in<br />

materials, manufacturing,<br />

more electric aircraft, aero<br />

engines and aerospace<br />

operations. We work with<br />

a range of aerospace firms<br />

to provide access to our<br />

graduates, improve their<br />

innovation capacity and<br />

solve technology problems.<br />

Contact: Rachel Brereton<br />

– rachel.brereton@<br />

nottingham.ac.uk<br />

Westmoreland<br />

Mechanical Testing<br />

& Research Ltd<br />

Westmoreland<br />

Mechanical Testing and<br />

Research is a leading<br />

materials test laboratory<br />

located in Banbury, UK,<br />

the European subsidiary<br />

of WMT&R Inc. WMT&R<br />

specialises in a range of<br />

materials from common<br />

metals and alloys<br />

through to aerospace<br />

alloys, composites and<br />

adhesives. Tensile, fatigue<br />

and other mechanical/<br />

materials tests are<br />

performed at ambient<br />

sub-zero or elevated<br />

temperatures. WMT&R<br />

also specialises in<br />

materials failure analysis.<br />

Contact: salesuk@wmtr.<br />

com<br />

MIDLANDS AEROSPACE 07