Dale Doughty

Dale Doughty

Dale Doughty

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

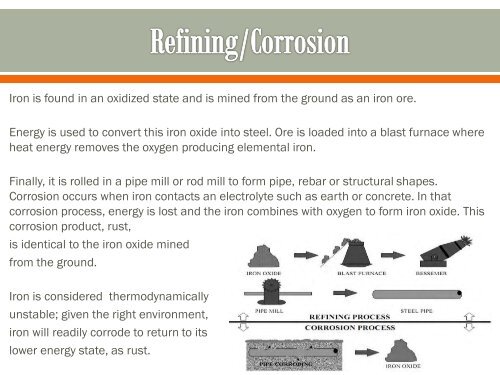

Iron is found in an oxidized state and is mined from the ground as an iron ore.<br />

Energy is used to convert this iron oxide into steel. Ore is loaded into a blast furnace where<br />

heat energy removes the oxygen producing elemental iron.<br />

Finally, it is rolled in a pipe mill or rod mill to form pipe, rebar or structural shapes.<br />

Corrosion occurs when iron contacts an electrolyte such as earth or concrete. In that<br />

corrosion process, energy is lost and the iron combines with oxygen to form iron oxide. This<br />

corrosion product, rust,<br />

is identical to the iron oxide mined<br />

from the ground.<br />

Iron is considered thermodynamically<br />

unstable; given the right environment,<br />

iron will readily corrode to return to its<br />

lower energy state, as rust.

Corrosion can be defined as the deterioration of metal due to<br />

interaction with the environment.<br />

Corrosion is a natural phenomenon that is expected to occur.<br />

Metals as high energy materials exist because heat energy<br />

was added to natural iron ores during the smelting process.<br />

Environmental contact constantly attacks these high energy<br />

materials and breaks them back down to the natural elements<br />

from which they were derived.

The anode and the cathode can be on different metals or on<br />

the same metal as shown:

For many metals, the rate of corrosion increases appreciably<br />

below a pH of about 4.<br />

Between 4 and 8 corrosion rate is fairly independent of pH.<br />

Above 8, the environment becomes passive and corrosion<br />

rates tend to decrease.

Corrosion cells may form because of differences in the<br />

electrolyte. For example, when a single metal structure spans<br />

an electrolyte made up of different types of soils, different<br />

chemical substances, different concentrations of the same<br />

substance, or temperature variations, the structure may<br />

experience voltage differences.

Potential Difference Between Anode and Cathode (Galvanic<br />

Series)<br />

Circuit resistance – Resistivity of the Electrolyte<br />

Chemical Activity

Example connecting zinc with carbon will produce a corrosion cell with a potential of<br />

about 1.4 volts.<br />

METAL<br />

VOLTS (CSE)<br />

Commercially Pure Magnesium -1.75<br />

Magnesium Alloy -1.60<br />

Zinc -1.10<br />

Aluminum Alloy -1.05<br />

Commercially Pure Aluminum -0.80<br />

Mild Steel (clean & shiny) -0.50 to -0.80<br />

Mild Steel (rusted) -0.20 to -0.50<br />

Cast Iron (not graphitized) -0.50<br />

Lead -0.50<br />

Mild Steel in Concrete -0.20<br />

Copper, Brass, Bronze -0.20<br />

High Silicon Cast Iron -0.20<br />

Carbon, Graphite, Coke +0.30

Circuit resistance includes the following:<br />

Resistance of the anode<br />

Resistance of the cathode<br />

Resistance of the electrolyte<br />

Resistance of the metallic path<br />

Increasing the resistance will reduce the corrosion rate.

Soils – High resistivity soils reduce the corrosion rate,<br />

while low resistivity soils increase the corrosion rate.<br />

CLASSIFICATION<br />

ELECTROLYTE<br />

RESISTIVITY<br />

(ohm-cm)<br />

ANTICIPATED<br />

CORROSIVITY<br />

Low Resistance 50 to 2,000 Severe<br />

Medium 2,000 to 10,000 Moderate<br />

High 10,000 to 30,000 Mild<br />

Very High Above 30,000 Increasingly Less

Passive (less corrosive) Environment<br />

High pH (neutral or basic)<br />

Low Moisture Content<br />

Lack of Salts<br />

High Resistivity<br />

Low Temperature<br />

Homogenous Environment

Uniform or near uniform (slow)<br />

Localized (moderate)<br />

Pitting (can be very rapid)

Uniform or near uniform - Corrosion attacks all areas of the<br />

metal at the same or similar rate typically by atmospheric<br />

contact. Weathering steel alloy.

Localized - Some areas of metal corrode at different rates due<br />

to heterogeneities in the metal or environment. This type of<br />

attack can approach pitting.

Pitting - Very highly localized attack resulting in small pits that<br />

may quickly penetrate to perforation.

Reference electrodes, or half-cells, are important devices that<br />

permit measuring the potential of a metal exposed to an<br />

electrolyte. An example is a structure-to-soil potential<br />

measurement.<br />

Structure-to-soil potentials are measured in reference to an<br />

electrode.

Saturated CSE Reference

Over the center line of the buried structure.

Piping<br />

Underground or submerged steel, cast iron, aluminum, and<br />

pre-stressed concrete cylinder pipelines.

Buried Tanks<br />

Underground Storage Tanks (UST) and piping

Aboveground Storage Tanks<br />

Exterior tank bottoms (both primary and secondary) of<br />

Aboveground Storage Tanks (AST).

Foundation piles<br />

Piling

Concrete<br />

Concrete bridge deck reinforcement and substructures

Corrosion can occur at the steel/concrete interface, resulting<br />

in spalling.<br />

Reinforced concrete is susceptible to chlorides when used in<br />

marine environments.<br />

Sulfate exposure physically damages concrete.

Galvanic (or sacrificial) cathodic protection makes practical use of dissimilar<br />

metal corrosion. It requires a substantial potential difference, or driving voltage,<br />

between a galvanic anode and the structure to be protected.<br />

The galvanic anode is connected to the structure it is protecting, either directly or<br />

through a test station so it can be monitored.

There are several metals commonly used as galvanic anodes:<br />

• Aluminum<br />

• Magnesium<br />

• Zinc.

Typically most effective with electrically isolated and wellcoated<br />

structures.<br />

No external power source required but limited driving potential<br />

(driving potential based upon the galvanic series).<br />

Limited output makes it ineffective when trying to protect large<br />

surfaces.<br />

Requires a low resistivity electrolyte to function well.

IM PRESSED CURRENT SY STEM<br />

Anode Groundbed<br />

Rectifier<br />

AC Power Supply<br />

Pos itiv e Cable<br />

Negativ e Cable<br />

Pipeline

Graphite Anodes<br />

Conductive Polymer<br />

High-Silicon Chromium-Bearing Cast Iron<br />

Lead-silver<br />

Mixed-metal oxide (MMO)<br />

Platinum<br />

Scrap iron or steel<br />

Metallized titanium<br />

Thermal sprayed zinc and aluminum<br />

Magnetite<br />

Aluminum

Deep anode installations are those where anodes are installed<br />

at the bottom of a drilled hole.<br />

Deep anodes are at least 15.24 m (50 ft) deep

A horizontal groundbed is installed similar to a vertical installation.<br />

The anode installation details depend upon the spacing of the<br />

anodes. If the spacing is more than 10 feet, it is usually best to<br />

excavate a separate hole for each anode. With closer spacing, it is<br />

usually more economical to excavate one long trench for both the<br />

header cable and the anodes.

Potential measurement test stations are used to monitor the<br />

effectiveness of cathodic protection, check for stray current<br />

effects, and, on unprotected or partially protected pipelines, to<br />

locate areas of active corrosion.

Test station

CIS/DCVG

CIS

CIS

-