HACCP

Hazard Analysis and Critical Control Point - Florida Sea Grant

Hazard Analysis and Critical Control Point - Florida Sea Grant

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 2<br />

• Traceability and product recalls: Procedures should be in place to ensure<br />

that raw material and finished products are coded and identified properly<br />

in order to trace the product backward (from receipt) and forward (into<br />

distribution). Traceability procedures are required by the Public Health<br />

Security and Bioterrorism Preparedness and Response Act of 2002<br />

(Bioterrorism Act). A product recall system should also be in place so that<br />

products can be removed from the marketplace quickly when necessary.<br />

Recall procedures can be found in Code of Federal Regulation (CFR) 21,<br />

Part 7, Enforcement.<br />

• Preventive maintenance: Facility and equipment often require routine<br />

maintenance before problems develop. Preventive maintenance schedules<br />

and procedures should be established and documented using manufacturer<br />

and other information as needed.<br />

Finally, there are a number of requirements that are also considered<br />

prerequisite programs that a processor should know (Slide 7). This course<br />

cannot discuss all prerequisite program in detail. Depending on the product or<br />

business, there will be additional compliance requirements that apply to the<br />

foods being processed.<br />

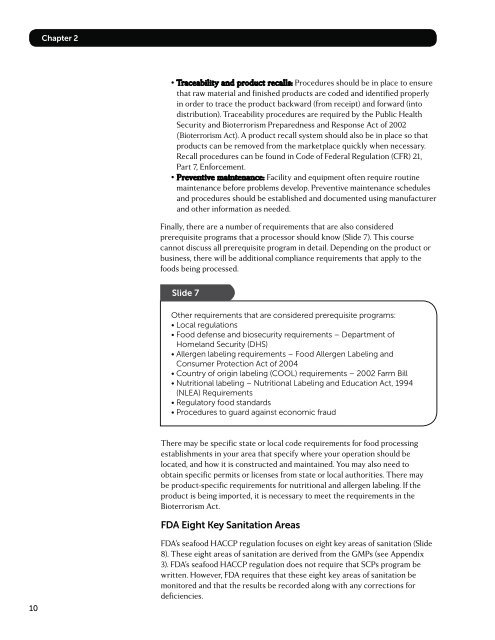

Slide 7<br />

Other requirements that are considered prerequisite programs:<br />

• Local regulations<br />

• Food defense and biosecurity requirements – Department of<br />

Homeland Security (DHS)<br />

• Allergen labeling requirements – Food Allergen Labeling and<br />

Consumer Protection Act of 2004<br />

• Country of origin labeling (COOL) requirements – 2002 Farm Bill<br />

• Nutritional labeling – Nutritional Labeling and Education Act, 1994<br />

(NLEA) Requirements<br />

• Regulatory food standards<br />

• Procedures to guard against economic fraud<br />

There may be specific state or local code requirements for food processing<br />

establishments in your area that specify where your operation should be<br />

located, and how it is constructed and maintained. You may also need to<br />

obtain specific permits or licenses from state or local authorities. There may<br />

be product-specific requirements for nutritional and allergen labeling. If the<br />

product is being imported, it is necessary to meet the requirements in the<br />

Bioterrorism Act.<br />

FDA Eight Key Sanitation Areas<br />

10<br />

FDA’s seafood <strong>HACCP</strong> regulation focuses on eight key areas of sanitation (Slide<br />

8). These eight areas of sanitation are derived from the GMPs (see Appendix<br />

3). FDA’s seafood <strong>HACCP</strong> regulation does not require that SCPs program be<br />

written. However, FDA requires that these eight key areas of sanitation be<br />

monitored and that the results be recorded along with any corrections for<br />

deficiencies.