HACCP

Hazard Analysis and Critical Control Point - Florida Sea Grant

Hazard Analysis and Critical Control Point - Florida Sea Grant

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

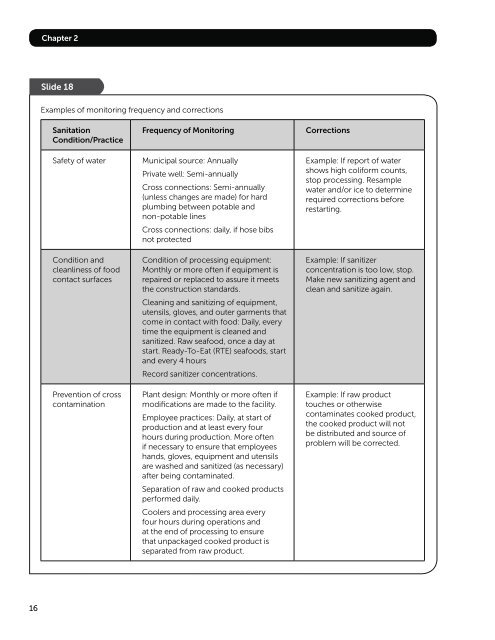

Chapter 2<br />

Slide 18<br />

Examples of monitoring frequency and corrections<br />

Sanitation<br />

Condition/Practice<br />

Safety of water<br />

Condition and<br />

cleanliness of food<br />

contact surfaces<br />

Prevention of cross<br />

contamination<br />

Frequency of Monitoring<br />

Municipal source: Annually<br />

Private well: Semi-annually<br />

Cross connections: Semi-annually<br />

(unless changes are made) for hard<br />

plumbing between potable and<br />

non-potable lines<br />

Cross connections: daily, if hose bibs<br />

not protected<br />

Condition of processing equipment:<br />

Monthly or more often if equipment is<br />

repaired or replaced to assure it meets<br />

the construction standards.<br />

Cleaning and sanitizing of equipment,<br />

utensils, gloves, and outer garments that<br />

come in contact with food: Daily, every<br />

time the equipment is cleaned and<br />

sanitized. Raw seafood, once a day at<br />

start. Ready-To-Eat (RTE) seafoods, start<br />

and every 4 hours<br />

Record sanitizer concentrations.<br />

Plant design: Monthly or more often if<br />

modifications are made to the facility.<br />

Employee practices: Daily, at start of<br />

production and at least every four<br />

hours during production. More often<br />

if necessary to ensure that employees<br />

hands, gloves, equipment and utensils<br />

are washed and sanitized (as necessary)<br />

after being contaminated.<br />

Separation of raw and cooked products<br />

performed daily.<br />

Coolers and processing area every<br />

four hours during operations and<br />

at the end of processing to ensure<br />

that unpackaged cooked product is<br />

separated from raw product.<br />

Corrections<br />

Example: If report of water<br />

shows high coliform counts,<br />

stop processing. Resample<br />

water and/or ice to determine<br />

required corrections before<br />

restarting.<br />

Example: If sanitizer<br />

concentration is too low, stop.<br />

Make new sanitizing agent and<br />

clean and sanitize again.<br />

Example: If raw product<br />

touches or otherwise<br />

contaminates cooked product,<br />

the cooked product will not<br />

be distributed and source of<br />

problem will be corrected.<br />

16