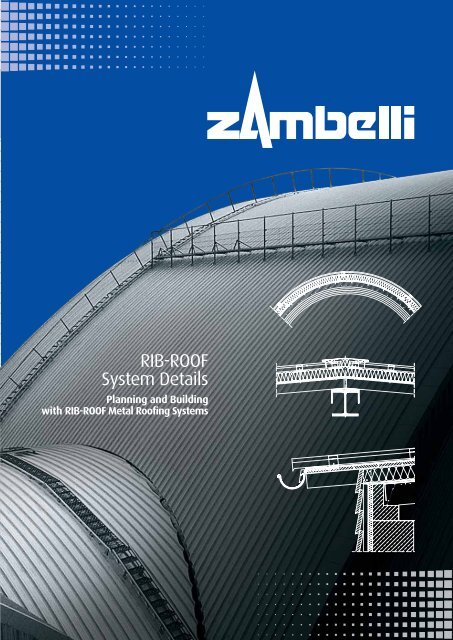

RIB-ROOF System Details

RIB-ROOF System Details

RIB-ROOF System Details

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>RIB</strong>-<strong>ROOF</strong><br />

<strong>System</strong> <strong>Details</strong><br />

Planning and Building<br />

with <strong>RIB</strong>-<strong>ROOF</strong> Metal Roofing <strong>System</strong>s

<strong>RIB</strong>-<strong>ROOF</strong> Metal Roofing <strong>System</strong>s<br />

Zambelli – A Tradition of Innovation<br />

The success of Zambelli had its origins in quality,<br />

competence and the spirit of innovation. Since our<br />

beginning we have been continually putting product<br />

novelties in the metal processing sector onto the<br />

market. We accomplish this by constantly investing<br />

in the advancement of production processes, in the<br />

research of new technologies and in the optimization<br />

of our products.<br />

<strong>RIB</strong>-<strong>ROOF</strong> – <strong>Details</strong> for Planning<br />

Our metal roofing system <strong>RIB</strong>-<strong>ROOF</strong> is installed with<br />

system-specific sliding clips without penetration of<br />

the roofing material. This metal roofing system offers<br />

manifold areas of application, ranging from backventilated<br />

cold roofs to thermal insulated nonventilated<br />

roofs.<br />

<strong>RIB</strong>-<strong>ROOF</strong> profile sheets are available in the construction<br />

widths 465 and 500 mm (special widths: 400<br />

and 333 mm) in different material thicknesses. They<br />

are produced in the materials steel, aluminium,<br />

titanium zinc and copper and can also be delivered<br />

in curved or conical design.<br />

Apart from our range of standard products we are<br />

also offering supplementary system accessories like<br />

snow fence devices, solar module transports, roofstep<br />

holders and harness security systems.<br />

You can fully trust in Zambelli products, since their high<br />

manufacturing quality and precision are able to meet<br />

even the highest demands, a fact which is also documented<br />

in the ISO-certification.<br />

In 1999, Zambelli was awarded the East Bavarian Technology<br />

Transfer Prize for its innovative force and environmental<br />

consciousness – we have eliminated pollution<br />

intensive work processes in the interest of the environment,<br />

use non-polluting materials and have voluntarily<br />

joined the “Umweltpakt Bayern”.<br />

Being fully-developed, the <strong>RIB</strong>-<strong>ROOF</strong> systems from Zambelli<br />

offer numerous advantages in the planning and<br />

installing phases, and also enables you to realize extraordinary<br />

designs. This brochure gives you ideas by providing<br />

a great number of detailed colour illustrations and explicit<br />

technical drawings. You will be able to integrate the <strong>RIB</strong>-<br />

<strong>ROOF</strong> system into your project professionally and creatively<br />

as well as safely and quickly. All technical drawings are<br />

license-free for your use. On request we will be glad to<br />

send you the data by e-mail. For further details, please<br />

see our Practical Guide.<br />

Should you have any questions about our products, services<br />

and prices, please do not hesitate to contact us.<br />

Please phone +49-8555 409-54 (export <strong>RIB</strong>-<strong>ROOF</strong>),<br />

+49-85 55 4 09-0 (phone central), send your fax enquiries<br />

to +49-8555 409-49 and e-mails to rib-roof@zambelli.de.<br />

Contents<br />

Introduction, contents<br />

1<br />

Wall joints<br />

17<br />

Rib-Roof – the system<br />

Range of products and accessories<br />

Rib-Roof speed 500<br />

Rib-Roof 465<br />

2<br />

3<br />

4<br />

Eaves<br />

Attached gutters/projecting eaves<br />

Terraced gradients/<br />

Eaves security against wind suction<br />

19<br />

21<br />

1<br />

Roof construction<br />

Curved, conical, and conical curved<br />

Roof construction /<br />

Installation on full surface support with clip guide<br />

Roof renovation<br />

Flat roof renovation with new wood roof structure<br />

Roof renovation on fibre cement boards<br />

Ridge<br />

Arris<br />

Verge<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

5<br />

7<br />

9<br />

9<br />

11<br />

13<br />

15<br />

Inside gutters/parapet gutters<br />

Valleys<br />

Roof penetrations<br />

Round roof penetrations<br />

Domelight curbs<br />

Continuous roof lighting<br />

Rectangular roof penetrations<br />

<strong>System</strong> accessories<br />

Snow fence devices, solar module transports,<br />

tread holders and harness security systems<br />

23<br />

25<br />

27<br />

29<br />

31<br />

33<br />

35<br />

37

<strong>RIB</strong>-<strong>ROOF</strong> – the <strong>System</strong><br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500 – Range of Products and Accessories<br />

Profile sheet<br />

standard construction width 500mm<br />

Profile sheet<br />

special construction width 400mm<br />

Profile sheet<br />

special construction width 333mm<br />

Standard sliding clip<br />

Clip border Clip bar Curved profile sheet Turned clip Conical profile sheet<br />

Closure<br />

Profile filler upper side<br />

Ridge cap<br />

Ventilation ridge ccap<br />

Verge insert profile<br />

Verge cover<br />

Lock plate<br />

Gutter inlet sheet<br />

Eaves blind<br />

Ventilation Closure<br />

Profile filler underside<br />

Eaves angle<br />

Snow fence pipe,<br />

pipe connector<br />

Clamping plate Ice stopper Mounted bracket for<br />

solar module /<br />

lightning conductor<br />

Fastening angle Tread holder Coil Special edge parts Curb Tools Harness security system<br />

<strong>RIB</strong>-<strong>ROOF</strong> 465 – Range of Products and Accessories<br />

Profile sheet<br />

Curved profile sheet Standard sliding Clip Start clip End clip Anchor point clip<br />

Diagonal clip Closure Profile filler upper side Ridge cap Ventilation ridge cap Verge insert profile Verge cover<br />

Lock plate<br />

Gutter inlet sheet<br />

Eaves blind Ventilation closure Profile filler for underside Eaves angle Snow fence pipe<br />

Clamping plate<br />

Ice stopper<br />

Pipe connector<br />

Mounted bracket for<br />

solar module /<br />

lightning conductor<br />

Fastening angle<br />

Tread holder<br />

Coil<br />

Special edge parts Curb Tools Harness security system<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

2

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

65<br />

500<br />

63<br />

Standard Clip Speed 500<br />

Quality:<br />

aluzinc t=1,30mm<br />

stainless steel t=1,20mm<br />

copper t=1,30mm<br />

75 50<br />

Clip border Speed 500<br />

profiled or flat<br />

(overall length 3m)<br />

Standard-Clip and <strong>RIB</strong>-<strong>ROOF</strong><br />

profile sheet Speed 500 on wooden lathing<br />

standard construction width 500mm, special widths e.g. 333 mm, 400 mm.<br />

1. Place the first row of clips<br />

Building inspection licence<br />

Nr. Z-14.1–473 (steel), Nr. Z-14.1–474 (aluminium)<br />

Non-penetrative installation on sliding clips or clip<br />

border – no perforation of the water-carrying plane,<br />

optimal dilatation ability for large roof surfaces<br />

2. Insert the first profile sheet<br />

Accessible and self-supporting – thus suitable for all<br />

standard fields of application on purlins or full suface<br />

support from the single-shelled rear ventilated roof to<br />

the thermally insulated unventilated roof structure<br />

Ultimate in easy, quick installation even at low<br />

temperatures – no pre-assembly of the sliding clips<br />

and no mechanical beading of the profile sheets required<br />

3. Place the next row of clips<br />

No transverse joints due to virtually unlimited<br />

length – profile sheets up to 32m length are<br />

transported by lorry (europe), longer sheets are profiled<br />

on-site with mobile roll-forming equipment. Projects in<br />

overseas with on-site profiling available on request.<br />

May be used from 1.5° pitch upwards<br />

Standard construction width 500 mm<br />

other overall widths on request<br />

2. Insert the next profile sheet<br />

Conical and conical curved profile sheets<br />

Curved profile sheets from a radius of 2m on –<br />

smaller radii on request<br />

3<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Full range of accessories, wide range of materials<br />

and colours<br />

Profile sheets available with prefabricated eaves side<br />

beading or ridge side bending of the bottom chord

<strong>RIB</strong>-<strong>ROOF</strong> 465<br />

<strong>RIB</strong>-<strong>ROOF</strong> – the <strong>System</strong><br />

48<br />

465<br />

50<br />

Start clip system 465<br />

Quality:<br />

aluzinc t=1.30mm<br />

stainless steell t=1.20mm<br />

copper t=1.30mm<br />

232<br />

50<br />

50<br />

Standard sliding clip 465<br />

Standard Clip and <strong>RIB</strong>-<strong>ROOF</strong><br />

profile sheet 465 on wooden lathing<br />

232<br />

50<br />

Building inspection licence<br />

Nr. Z-14.1–345 (steel), Nr. Z-14.1–346 (aluminium)<br />

Installation on sliding clips or clip border without<br />

penetration – no perforation of the water-carrying<br />

plane, optimal dilatation ability for large roof surfaces<br />

Accessible and self-supporting – thus suitable for all<br />

standard fields of application on purlins or full surface<br />

support, from single-leaf, rear ventilated roofs to<br />

thermally insulated, non-ventilated roof structures<br />

Ultimate in easy, quick installation even at low<br />

temperatures – no pre-insatllation of sliding clips and<br />

no mechanical beading of the profile sheets required<br />

No transverse joints due to virtually unlimited<br />

length – profile sheets up to 32m length are<br />

transported by lorry (Europe), longer sheets are profiled<br />

on-site with mobile roll-forming equipment. Projects in<br />

overseas with on-site profiling available on request.<br />

May be used from 1.5° pitch upwards<br />

Conical profile sheets (on request)<br />

Curved profile sheets from a radius of 6m upwards<br />

(smaller radii on request), alternative rounding by<br />

bending<br />

Full range of accessories, wide range of materials<br />

and colours<br />

Profile sheets available with prefabricated eaves side<br />

beading or ridge side bending of the bottom chord<br />

1. Place the first row of clips<br />

2. Insert the first profile sheet<br />

3. Place the next row of clips<br />

2. Insert the next profile sheet<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

4

Minimum bending radii<br />

The following minimum bending radii must be taken into consideration for<br />

mechanical cambering; they depend on the type of material and thickness [t]:<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500 – Convexe<br />

profile sheets<br />

Material Material thickness t [mm] Radius [m]<br />

Steel 0.63 4.00<br />

Aluminium 1.00 2.00<br />

Aluminium 0,90 0.80 oder 0.90 3.00<br />

Aluminium 0,80 0.70 4.00<br />

Titanium zinc 1.00 on demand<br />

Copper 0.60 on demand<br />

<strong>RIB</strong>-<strong>ROOF</strong> 465 – Convexe<br />

profile sheets<br />

Material Material thickness t [mm] Radius [m]<br />

Steel 0.63 6.00<br />

Aluminium 1.00 6.00<br />

Aluminium 0.80 or 0.90 10.00<br />

Aluminium 0.70 15.00<br />

Titanium zinc 1.00 on demand<br />

Copper 0.60 on demand<br />

5 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Curved roof

Roof Construction<br />

The Variety of Shapes<br />

Curved, conical and conical curved Conical profile sheet <strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

We also deliver <strong>RIB</strong>-<strong>ROOF</strong> profile sheets in curved (convex<br />

or concave), conical, and conical-curved design.<br />

Arches with large radii can be executed with straight<br />

profile sheets, profile sheets for smaller radii are<br />

pre-fabricated or roll formed with mobile plants on site.<br />

<strong>RIB</strong>-<strong>ROOF</strong> 465 in extremely small radii requires a<br />

round bent execution of the profile sheets.<br />

Curved <strong>RIB</strong>-<strong>ROOF</strong> Speed 500 profile sheets with small<br />

radii are fixed with turned clips. For conical designs,<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500 profile sheets can be used in<br />

different construction widths.<br />

Curved profile sheet <strong>RIB</strong>-<strong>ROOF</strong> Speed 500, turned clip<br />

See also our Practical Guide for Planning and Installing<br />

chapter „Conical/curved/conical curved profile sheets“.<br />

Curved roof – roof construction with wooden lateral and counter lathing<br />

Possible for r>8,0m when wooden lateral<br />

and counter lathing is used<br />

<strong>RIB</strong>-<strong>ROOF</strong> curved<br />

Thermal insulation with intervening<br />

lateral and counter lathing<br />

Vapour barrier<br />

Trapezoidal sheet metal<br />

Truss<br />

Radii from r>4m on are possible when wooden<br />

lateral lathing or a metallic Z-profile or a<br />

domed profile is used. Smaller radii on request.<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

6

Roof construction<br />

with roof boarding<br />

Roof construction<br />

with porous concrete<br />

Roof construction with<br />

reinforced concrete ceiling<br />

Energy saving with wooden lathing<br />

According to an examination report of FIW of 11 April 2005<br />

you save about 1300,– € per year per 1000 m 2 roof surface<br />

if you use a distance construction of wooden lathing instead<br />

of a construction with metallic Z-profile. Compared to metallic<br />

holders penetrating the thermal insulation, the energy saving<br />

is about 540,– € for the same surface.<br />

7<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Installation on wooden lathing<br />

Installation on metallic Z-profile

Roof construction<br />

For every roof structure the right solution!<br />

Roof construction<br />

For the metal roofing system <strong>RIB</strong>-<strong>ROOF</strong> all common<br />

substructures are possible as roof structure: trapezoidal<br />

profiles, wood binding rafters, wood boarding (t=24<br />

mm), steel rafters, lightweight concrete or reinforced<br />

concrete. A variant to the full-surface lathing is high<br />

compressive mineral wool. An alternative to this method<br />

is offered by the high compressive mineral wool. The<br />

installation of profile sheets is executed on spacers which<br />

correspond to the thickness of the insulation, or on<br />

pressure distribution profiles or clip borders directly in<br />

the load-bearing structure.<br />

Installation on full-surface support<br />

with clip border<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500 may alternatively be installed on<br />

full-surface supports. A variation in addition to the roof<br />

boarding is the high compressive strength mineral wool<br />

with high density top layer which improves the resistance<br />

to site work (application type DAA-dm according to DIN<br />

V 4108-10: thermal insulation).<br />

Gutter entry<br />

flashing<br />

Gutter<br />

Eaves cover sheet<br />

Edge reinforcement<br />

Trapezoidal profile<br />

Single layer<br />

thermal insulation<br />

Eaves plank<br />

Clip<br />

Clip<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Roof construction with trapezoidal profile<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Diagonal clip<br />

Wood boarding<br />

laid diagonally<br />

Thermal insulation<br />

Wood truss<br />

End angle flashing<br />

Masonry<br />

Roof construction with roof boarding, porous concrete,<br />

and reinforced concrete ceiling<br />

Separation layer<br />

Wood boarding<br />

Rafters<br />

Installation of the profile sheets may either be done on<br />

distance profiles which correspond to the thickness of<br />

the thermal insulation or on the clip border – structure<br />

profiled or flat which is fastened directly onto the support<br />

structure.<br />

It is important to avoid gaps when laying the insulation<br />

boards. This finish is also transferable to <strong>RIB</strong>-<strong>ROOF</strong> 465<br />

if so-called pressure distribution profiles are used.<br />

Clip<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Lightweight<br />

concrete<br />

Pressure distribution strip<br />

High compressive<br />

thermal insulation<br />

Vapour barrier<br />

Installation on high-compressive<br />

mineral wool<br />

Clip<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Concrete<br />

contraction<br />

roof<br />

Transverse lathing<br />

Single layer high compressive<br />

thermal insulation<br />

Vapour barrier<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

8

9 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Flat roof renovation with new wooden roof structure

Roof renovation<br />

Flat roof renovation with new wooden roof structure<br />

Even for renovating flat roofs, the <strong>RIB</strong>-<strong>ROOF</strong> metal roofing<br />

system offers outstanding possibilities. No limits are set<br />

to the architectural freedom: by installing <strong>RIB</strong>-<strong>ROOF</strong><br />

profile sheets with the corresponding minimum roof<br />

slope on a new wood roof structure or on a steel roof<br />

structure, defect and unattractive flatroofs can be renovated,<br />

appearances improved and greater longevity<br />

achieved.<br />

The ventilation of the roof area can be done either with<br />

cross-ventilation on the gables or with ventilation openings<br />

at the eaves and at the ridge (e.g. ventilation ridge).<br />

Flat roof renovation with new wooden roof structure<br />

Clip<br />

Bonding strip<br />

Gutter inlet sheet<br />

Gutter<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Separation layer<br />

Wooden lathing<br />

Wooden roof structure<br />

Closure<br />

Anchor points<br />

Fastening brackets<br />

Ridge cap<br />

Perforated panel<br />

Existing conditions:<br />

· existing sealant<br />

· thermal insulation<br />

Roof renovation on fibre cement<br />

boards<br />

For roof renovation on existing fibre cement boards you<br />

receive project-related solutions. In this example, L-<br />

angles (short pieces) with elongated holes are used<br />

which are installed onto the fixing screws of the existing<br />

fibre cement boards. Z-shaped profiles are fixed on the<br />

L-angles as substructure for the sliding clips.<br />

In Germany, the planned renovation type have to be<br />

approved by the local trade supervisory office; outside<br />

Germany the specific needs have to be checked.<br />

Ice stopper<br />

Snow fence pipe Ø 32mm<br />

Clamping plate<br />

Existing fibre cement boards<br />

L-corner (short pieces)<br />

Existing fixing screw<br />

Z-profile<br />

Roof renovation on fibre cement boards<br />

Existing fibre<br />

cement boards<br />

Vapour barrier<br />

Wood boarding<br />

Thermal insulation<br />

Clip aluzinc<br />

<strong>RIB</strong>-<strong>ROOF</strong> 465<br />

Eaves blind<br />

Gutter inlet sheet<br />

Gutter and gutter hooks<br />

L-corner (short pieces)<br />

Rafters<br />

Facade<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

10

11 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Penthouse roof ridge cap

Ridge<br />

Ridge covering<br />

Single pitch roof ridge<br />

The penthouse ridge forms a design and installationtechnical<br />

unit with the corresponding verge. The penthouse<br />

ridge can also be installed to a vertical wall (see also wall<br />

joints ridge side with, and without, ventilation opening).<br />

Transverse and counter lathing<br />

Vapour barrier<br />

The close couple roof cap without ventilation opening is<br />

first inserted into the closure with its double sided back<br />

edge folds, and subsequently, the fold is pressed together.<br />

The close couple roof cap with ventilation opening is<br />

supplied as standard equipment in flat, aerodynamic<br />

optimal design (structure height 80 mm) with opening<br />

ventilation cross section of 450cm2/m. It is usually installed<br />

with profile fillers to prevent the penetration of driving<br />

snow or the suction of undesirable air. On request we are<br />

also able to deliver a higher one (structure height 170mm).<br />

See also the chapter „Ridge“ in our „Practical Guide<br />

for Planning and Installing“.<br />

Acoustic trapezoidal<br />

profile<br />

Edge reinforcement<br />

Noise insulation layer<br />

with dizzle protection<br />

Steel truss<br />

Close couple roof without ventilation<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Double layer compressed<br />

thermal insulation<br />

Transverse and counter lathing<br />

Vapour barrier<br />

Anchor point<br />

Ridge cap<br />

<strong>RIB</strong>-<strong>ROOF</strong>-bottom chord<br />

at the height of the ribs<br />

Closure<br />

Clip<br />

Ridge flashing<br />

Trapezoidal profile sheet<br />

Steel truss<br />

Ventilation ridge structure height 80 mm<br />

Close couple roof with ventilation opening Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> 12

13 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Arris cap

Arris<br />

Arris cap<br />

Arris areas are executed similar to close couple roof<br />

ridges. By marking the cutouts for the profile sheet<br />

ribs (high increase) to the closure and cutting them<br />

by using a sheet metal cutter on site, an optimal fit<br />

is attained. In principle, the construction details for<br />

the ridge cap can be applied in this case.<br />

See also the chapter „Arris“ in our „Practical Guide<br />

for Planning and Installing“.<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Pressure distribution<br />

profile strip<br />

Clip<br />

High compressive<br />

thermal insulation<br />

Vapour barrier<br />

Arris cap<br />

Anchor point<br />

Ridge insertion profile<br />

Arris cap<br />

Ridge flashing<br />

Trapezoidal profile sheet<br />

Arris binding rafter with angle iron support<br />

Ventilated arris cap – analogous to the ventilation ridge<br />

The ventilated arris cap can<br />

also be executed with a<br />

ventilation closure<br />

Arris cap,<br />

ventilated<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Ventilation closure<br />

Profile filler for arris<br />

Carrying construction<br />

(e.g. wood rafter)<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

14

15 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> Verge projection on steel sword

Verge<br />

Verge projection on steel sword<br />

Verge projection on trapezoidal profile<br />

Trapezoidal profile<br />

Vapour barrier<br />

Transverse and counter lathing<br />

Double layer<br />

thermal insulation<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Verge cover<br />

Verge insertion profile<br />

Verge covering<br />

Verge insertion profile<br />

Verge plank<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Double layer<br />

thermal insulation<br />

Transverse and counter lathing<br />

Vapour barrier<br />

Edge angle<br />

Insertion profile<br />

Joint flashing<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Double clip<br />

Verge covering<br />

Verge insertion profile<br />

Projection flashing<br />

Steel pan wall with<br />

thermal insulation<br />

Facade profile<br />

Profile filler<br />

Thermal insulation<br />

Steel sword<br />

Steel beam<br />

Insertion flashing<br />

Edge angle<br />

Profile filler<br />

Cover profile sheet<br />

Facade profile<br />

Steel pan wall<br />

Trapezoidal profile<br />

Profile filler<br />

Crease filler<br />

Reinforced concrete truss<br />

Support<br />

Verge projection<br />

The system-specific verge insertion profile sheet, supplied<br />

as a standard product in the <strong>RIB</strong>-<strong>ROOF</strong> metal roofing<br />

range, enables you to architecturally optimize all verge<br />

building elements optically and technically. The individual<br />

adaptation is executed manually using the verge cover.<br />

For verge projections with trapezoidal sheets as substructure,<br />

trapezoidal profile filler is used for appearance<br />

and thermal-technical purposes.<br />

See also the chapter „Verge“ in our „Practical Guide<br />

for Planning and Installing”.<br />

Verge projection on trapezoidal profile sheet<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

16

17 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Side and ridge wall joint

Wall joint<br />

Side wall joint<br />

Roof parapet joint<br />

Sealant strip<br />

Flat pan<br />

Join vapour<br />

barrier closely<br />

Wood plank<br />

Wall joint flashing<br />

Insertion profile sheet<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Single layer<br />

thermal insulation<br />

Z-profile (diagonal)<br />

Thermal separation<br />

Vapour barrier<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Thermal insulation<br />

Clip<br />

Transverse lathing<br />

Vapour barrier<br />

Insertion profile sheet<br />

Projection flashing<br />

Wood plank<br />

Separation layer<br />

Parapet flashing<br />

Closure<br />

Edge reinforcement<br />

Trapezoidal flashing sheet<br />

Steel binding rafter<br />

Existing corrugated sheet<br />

Truss<br />

Steel binding rafter<br />

Side and ridge wall joint/<br />

Roof parapet joint<br />

For joints to masonry walls and stucco surfaces, an<br />

overlap strip must be cut into the wall, which is backed<br />

with a sealant strip or non-hardening sealing compound,<br />

and pressed into the joint using clamps. The overlap<br />

strip must be worked into the masonry before stucco<br />

operations.<br />

When forming joints between a penthouse roof and a<br />

vertical wall, a closure is used. The side wall joint to the<br />

masonry wall is executed using the verge (insertion)<br />

profile strip. In principle, the details applicable to the<br />

verge also have validity for this work.<br />

The wall joint can be completed under certain structural<br />

conditions with a ridge-side roof parapet cover. In this<br />

case the overlap strip will not be required.<br />

See also the chapter „Wall joints“ in our „Practical<br />

Guide for Planning and Installing”.<br />

Roof parapet joint Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> 18

19 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Self-supporting projecting eaves structure

Eaves<br />

Thermal insulation<br />

Wood boarding<br />

Gutter inlet sheet<br />

Self-supporting projecting eaves structure<br />

Double layer of<br />

compressed thermal insulation<br />

Vapour barrier<br />

Separation layer<br />

Transverse lathing/<br />

Counter lathing<br />

Clip<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Fascia<br />

Gutter inlet sheet<br />

Halfround gutter<br />

Eaves structure with attached gutter<br />

(the solution for TiZi is ventilated)<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Transverse lathing<br />

Extended rafters<br />

Luft<br />

Perforated sheet<br />

Insertion flashing<br />

Eaves rafters<br />

Eaves cross member<br />

Facade<br />

Trapezoidal profile<br />

Edge reinforcement<br />

Reinforced concrete truss<br />

Trapezoidal profile<br />

Vapour barrier<br />

Counter lathing with<br />

thermal insulation<br />

Steel beam<br />

Edge angle<br />

Attached gutter<br />

Self-supporting projecting eaves<br />

Outside attached half-round or box-shaped gutters which<br />

are attached using hangers to the fascia are the most<br />

simple eaves-type design. <strong>System</strong> integrated profile<br />

fillers can be installed in the eaves area: this is, however,<br />

only required in exceptional cases. The joint of the roof<br />

to the gutter is executed using eaves flashing (gutter<br />

entry flashing). The vapour diffusion open protective<br />

layer or other separation layers cover the eaves flashing<br />

to drain off secondary condensation into the gutter which<br />

may be formed. For the profile sheet <strong>RIB</strong>-<strong>ROOF</strong> Speed<br />

500, a system-related eaves angle is installed which is<br />

not required for the profile <strong>RIB</strong>-<strong>ROOF</strong> 465.<br />

For eaves structures with self-supporting projections, a<br />

roof overhang using the necessary substructures (e.g.<br />

eaves rafters) is produced. For ventilated roof designs<br />

with attached gutters, ventilation openings below the<br />

eaves are necessary.<br />

See also the chapter „Eaves area“ in our „Practical<br />

Guide for Planning and Installing”.<br />

Eaves structure with attached gutter – solution with ventilation if titanium zinc is used<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

20

21 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Eaves structure with sloped steps

Eaves<br />

Eaves structure with sloped steps<br />

Eaves safety against wind uplift force<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Wood plank<br />

Flashing<br />

Gutter<br />

Gutter inlet sheet<br />

Double standing seam covering<br />

Double layer compressed<br />

thermal insulation<br />

Transverse and counter lathing<br />

Vapour barrier<br />

Clip<br />

Eaves plank<br />

Gutter inlet sheet<br />

Wind uplift security<br />

with overlapping fold<br />

Z<br />

Gutter<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Transverse<br />

lathing<br />

Rafter<br />

Separation layer<br />

Wood boarding<br />

Steel sword<br />

T-shaped steel element<br />

Steel pan wall with<br />

thermal insulation<br />

Facade profile<br />

Trapezoidal profile<br />

Steel beam<br />

Profile filler<br />

Detail Z:<br />

Wind uplift security<br />

Through overlapping fold<br />

Riveted<br />

Sloped steps<br />

Eaves safety against wind uplift force<br />

Eaves structures with sloped steps are used as design<br />

elements in architecture, or for extremely long profile<br />

sheets. In principle, the details of execution are the same<br />

as for the penthouse roof joints to vertical walls.<br />

The eaves safety against wind uplift force at the eaves<br />

is executed by overlapping folds corresponding to detail<br />

Z with rivet.<br />

See also the chapter „Sloped Steps“ in our „Practical<br />

Guide for Planning and Installing“.<br />

Eaves stucture with box-shaped gutter Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> 22

23 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Inside gutter with safety gutter and two-piece gutter leader head with conical entry

Gutter<br />

Innenliegende Rinne<br />

Parapet gutter<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Transverse and<br />

counter lathing<br />

Double layer compressed<br />

thermal insulation<br />

Vapour barrier<br />

Water conducting gutter<br />

High compressive mineral wool<br />

Safety gutter<br />

Gutter inlet sheet<br />

Holder for sliding<br />

attachment<br />

Wood plank<br />

Projection flashing<br />

Roof parapet wood plank<br />

Separation layer<br />

Parapet flashing<br />

Wall coping<br />

Water conducting gutter<br />

High-compressive<br />

mineral wool<br />

Load-bearing safety gutter<br />

Gutter heating<br />

Gutter inlet sheet<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Double layer<br />

Thermal insulation<br />

Vapour barrier<br />

Transverse and counter<br />

lathing<br />

Trapezoidal profile sheet<br />

Clip<br />

Edge reinforcement<br />

Trapezoidal sheet<br />

Reinforced concrete truss<br />

Gutter outlet<br />

soldered with conical inlet<br />

Wood plank<br />

Holders for sliding<br />

attachment<br />

Inside gutters<br />

Parapet gutters<br />

Inside gutters offer the possibility of forming special architectural<br />

structures. To guarantee their optimal functionality, we recommend<br />

the safety measures described in detail in our „Practical Guide<br />

for Planning and Installing“: sufficient size, expansion joints for<br />

longitudinal expansion, funnel-shaped leader heads, minimum<br />

distance between water conducting gutters and safety gutters,<br />

as well as sufficient slope.<br />

A snow guard system or gutter heating guarantees that the<br />

gutter remains free of snow. If contractors are not able to carry<br />

out the necessary maintenance work on their own, a maintenance<br />

agreement should be concluded between the contractor and<br />

the execution company.<br />

See also the chapter “Inside Gutter“ in our „Practical Guide<br />

for Planning and Installing”.<br />

For parapet gutters, the eaves side is executed as wall joint with parapet structure Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> 24

25 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Valley gutter

Valley gutter<br />

Depressed valley structure<br />

For roof designs with slopes below 7°, it is recommendable<br />

to install deeper valleys. In principle, the fundamental<br />

rules for the execution of inside gutters also<br />

apply to the valleys.<br />

If the valley gutter is made by welding, it is important<br />

to make anchor points with the welding.<br />

See also the chapter “Valleys “ in our „Practical Guide<br />

for Planning and Installing”.<br />

Depressed valley gutter<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Clip<br />

Transverse lathing<br />

Single layer compressed<br />

thermal insulation<br />

Vapour barrier<br />

Valley gutter<br />

Inlet sheet<br />

Holders for sliding<br />

attachment<br />

Wood framing<br />

Valley rafter<br />

Binding rafter<br />

Welded valley gutter<br />

Valley gutter alu stucco<br />

Rafter<br />

<strong>RIB</strong>-<strong>ROOF</strong> and<br />

welded valley gutter<br />

Rafter<br />

Clip<br />

<strong>RIB</strong>-<strong>ROOF</strong> alu stucco<br />

Underlay sheet with<br />

high open diffusion<br />

Wood lathing<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

26

27 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Sanitary ventilation pipe

Roof penetration<br />

Room ventilation pipe, welded<br />

Roof dome with<br />

plug-in connection<br />

Pipe cover<br />

Insulation<br />

Welding seam<br />

continuous<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Thermal insulation<br />

(double-layered)<br />

Clip<br />

Lateral and<br />

counter lathing<br />

Reinforcing sheet<br />

Trapezoidal profile<br />

Ventilation pipe<br />

Vapour<br />

barrier<br />

Round roof penetration<br />

Round roof penetrations such as room ventilation pipes<br />

are sealed using prefabricated, conical supports on the<br />

roof surface. The rain cap which is not customarily used<br />

for room ventilation pipes is provided for room ventilation.<br />

See also the chapter “Round roof penetrations “ in<br />

our „Practical Guide for Planning and Installing”.<br />

Pipe cover<br />

Insulation<br />

Sanitary ventilation pipe<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Thermal insulation,<br />

double layered<br />

Lateral and<br />

counter lathing<br />

Clip<br />

Reinforcing sheet<br />

Trapezoidal profile<br />

Pipe<br />

Vapour barrier<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

28

Aluminium domed roof light hood, welded<br />

29 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Execution with rear-side lean-to sheet panel

Roof penetration<br />

Curb for rooflight with backup security<br />

Double layered<br />

thermal insulation with<br />

lateral and counter lathing<br />

Insert profile<br />

Wood support<br />

Domed roof light hoods<br />

Curb<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Vapour barrier<br />

Trapezoidal profile<br />

Clip<br />

Curb<br />

Domed roof light hood<br />

Closure<br />

Clip<br />

1<br />

Curb<br />

Domed light drainage sheet<br />

Insertion sheet<br />

Separation layer<br />

Framing > 1.5°<br />

Lathing<br />

1<br />

Surfacing sheet<br />

Wood plank frame<br />

Steel beam<br />

Surfacing sheet<br />

Wood plank frame<br />

Static framing<br />

Steel beam<br />

Domed roof light hood<br />

Domed roof lights fulfill an important function in the<br />

architectural integration of light in rooms directly below<br />

roofs. If the execution of domed roof lights is planned,<br />

please take into consideration the load distribution on<br />

the weight-bearing structure in the planning stage and<br />

install the necessary static framing if necessary.<br />

Water drainage and longitudinal expansion of the profile<br />

sheets in the area of the roof penetration have to be<br />

guaranteed using suitable measures. The heights of the<br />

hoods depend on the roof incline and should not be less<br />

than 15 cm if possible.<br />

For larger sizes and the elimination of watertight welding<br />

or soldering operations, the domed roof light hood should<br />

be executed with a backup security. Additional information<br />

on this topic can be found in our “Practical Guide for<br />

Planning and Installing”.<br />

For the domed roof light hood, we recommend the<br />

welded model in aluminium.<br />

See also the chapter “Curb for domelight” in our<br />

„Practical Guide for Planning and Installing”.<br />

Domed roof light hood with backup security Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> 30

31 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Continuous row lighting flashing

Roof penetration<br />

Continuous row lighting flashing<br />

Thermal insulation<br />

Continuous row lighting flashing<br />

Clip<br />

Closure<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Edge angle<br />

Vapour barrier<br />

Trapezoidal profile<br />

Continuous row lighting frame<br />

Double layer compressed<br />

thermal insulation with<br />

transverse and counter lathing<br />

Continuous row lighting flashing<br />

Depending on the materials used, roof penetrations<br />

and their flashings are executed manually, or a<br />

waterproof joint is formed by welding or soldering.<br />

During the planning phase, please take the expected<br />

material expansion into consideration.<br />

If continuous row lighting is installed, the rules for<br />

domed roof light hoods generally apply.<br />

See also the chapter “Continuous row lighting<br />

flashing” in our „Practical Guide for Planning and<br />

Installing”.<br />

Continuous row lighting flashing<br />

Thermal insulation<br />

Continuous row lighting flashing<br />

Clip<br />

Closure<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Edge angle<br />

Vapour barrier<br />

Trapezoidal profile<br />

Clip<br />

Double layer compressed<br />

thermal insulation with<br />

transverse and counter lathing<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

32

33 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

Roof window

Roof penetration<br />

Roof window<br />

Chimney flashing<br />

Roof window<br />

Wood plank framing<br />

Roof window hood<br />

Vapour barrier<br />

Double layer compressed thermal<br />

insulation with transverse<br />

and counter lathing<br />

Clip<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Sealant strip<br />

Flat pan<br />

Flashing eaves side<br />

Closure<br />

Wood plank framing<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Base flashing<br />

Thermal insulation<br />

Rear base flashing<br />

Clip<br />

Interior panelling<br />

Trapezoidal profile<br />

Rafter<br />

Profile filler<br />

Vapour barrier<br />

Z-shaped profile (transverse)<br />

with thermal separation<br />

Base flashing<br />

Trapezoidal profile<br />

Steel binding rafter<br />

Rectangular roof penetrations<br />

Chimney flashing requires the installation of an additional<br />

flat pan strip. In principle, the rules valid for<br />

wall joints are to be followed.<br />

For roof windows with pitches of 15° and more, the<br />

execution with sealing frames is sufficient. Additional<br />

information can be found in our “Practical Guide for<br />

Planning and Installing”.<br />

See also the chapter “Chimney flashings” in our<br />

„Practical Guide for Planning and Installing”.<br />

Chimney flashing Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> 34

35 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong> Snow fence device with ice stopper – <strong>System</strong>s <strong>RIB</strong>-<strong>ROOF</strong> Speed 500 (left) and <strong>RIB</strong>-<strong>ROOF</strong> 465 (right)

<strong>System</strong> accessories<br />

Snow fence device/ice stopper/mounted brackets for solar module,<br />

lightning conductor and terraced gradients<br />

Terraced gradients<br />

Roof and facade work with <strong>RIB</strong>-<strong>ROOF</strong> offers numerous<br />

possibilities, taking into consideration special structural<br />

requirements. Our wide range of accessories includes<br />

snow fence device, ice stoppers, mounted brackets for<br />

solar module, lightning conductor and terraced gradients,<br />

harness security system etc.<br />

All accessories have been optimized in design and<br />

functionality for <strong>RIB</strong>-<strong>ROOF</strong> and can be installed using the<br />

system-typical clamping principle without needing to<br />

perforate the profile sheets.<br />

See also the chapter “Snow fence, ice stopper,<br />

mounted bracket for solar module and harness security<br />

system” in our „Practical Guide for Planning and<br />

Installing”.<br />

Ice stopper<br />

Snow fence pipe Ø 32mm<br />

Clamping plate<br />

Gutter<br />

Underlay sheet with<br />

Gutter inlet sheet high open diffusion<br />

Eaves blind <strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

Snow fence device<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Wood lathing<br />

Rafter<br />

Clip<br />

Snow fence device with ice stopper – <strong>System</strong> <strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Ice stopper<br />

Clamping plate<br />

Snow fence pipe Ø 32mm<br />

Snow fence device with ice stopper – <strong>System</strong> <strong>RIB</strong>-<strong>ROOF</strong> Speed 465<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

Ice stopper<br />

Clamping plate<br />

Snow fence pipe Ø 32mm<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

36

37 Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong>

<strong>System</strong> accessories<br />

Harness security system on curved <strong>RIB</strong>-<strong>ROOF</strong> 465<br />

Harness security system<br />

The gliding element can be opened and attached or<br />

removed at any place in the system. In this way, the<br />

inconvenient reattachment at intermediate brackets<br />

and prescribed entry points is avoided.<br />

Harness security systems are stationary installations.<br />

They are conceived for all horizontal, sloped and vertical<br />

areas of application. The bearing elements are made<br />

of stainless steel or aluminium alloy. Methods for<br />

movement around corners in various designs enable<br />

unimpaired changes in the direction.<br />

The harness security system can be installed on any place at all<br />

The harness security system products fulfill the EC<br />

Guideline 89/686 EEC, have been tested for construction<br />

applications, and are made according to current DIN<br />

standards and carry a CE certification.<br />

Fastening of the harness security system<br />

without penetration<br />

Intermediate support may be crossed<br />

Corner by-pass<br />

Zambelli <strong>RIB</strong>-<strong>ROOF</strong> – <strong>System</strong> <strong>Details</strong><br />

38

<strong>RIB</strong>-<strong>ROOF</strong><br />

Metal Roofing <strong>System</strong>s<br />

<br />

Shelving <strong>System</strong>s<br />

Roof And Wall<br />

Industrial Metal Works<br />

Supply for Caravan Industry<br />

<br />

Zambelli<br />

<br />

<strong>RIB</strong>-<strong>ROOF</strong> GmbH & Co. KG<br />

<br />

Passauer Straße 3 + 5<br />

<br />

D - 94481 Grafenau<br />

<br />

Export <strong>RIB</strong>-<strong>ROOF</strong> +49(0)85 55 409-54 <br />

Telephone Fax +49(0)85 55 409-54 409-49 <br />

E-mail Fax +49(0)85 rib-roof@zambelli.de<br />

55 409-49 <br />

E-mail www <br />

rib-roof@zambelli.de<br />

www zambelli.de