MANmagazine Truck edition 2/2015

The Schmitz family has been driving trucks made by MAN for 57 years and three generations – with no end in sight for this long-term relationship. The fleet operators talk about their experiences with these vehicles and reflect why they have remained loyal to MAN for such a long time. In addition, read this issue’s comprehensive coverage on the 100-year anniversary of MAN Truck & Bus, encounter the MAN HydroDrive during its deployment in a quarry and accompany a cooling transport from Croatia to Poland.

The Schmitz family has been driving trucks made by MAN for 57 years and three generations – with no end in sight for this long-term relationship. The fleet operators talk about their experiences with these vehicles and reflect why they have remained loyal to MAN for such a long time. In addition, read this issue’s comprehensive coverage on the 100-year anniversary of MAN Truck & Bus, encounter the MAN HydroDrive during its deployment in a quarry and accompany a cooling transport from Croatia to Poland.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2/<strong>2015</strong><br />

International<br />

Story<br />

Special<br />

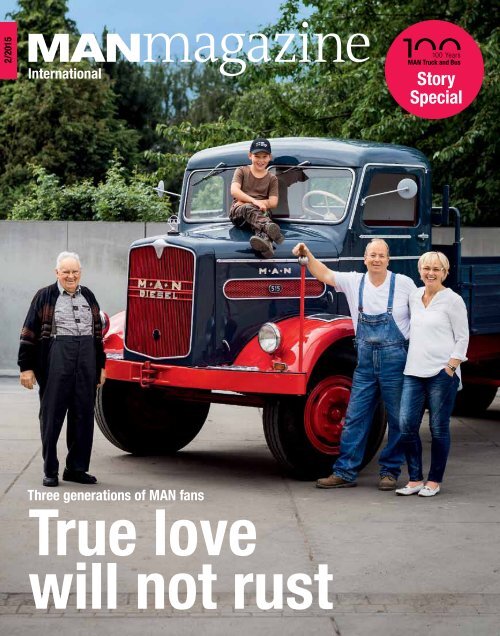

Three generations of MAN fans<br />

True love<br />

will not rust

2/<strong>2015</strong><br />

Explore much<br />

more of<br />

on your tablet.<br />

digitally<br />

06<br />

Content<br />

International<br />

04 Heart and soul<br />

Simone Wenzel and her MAN LE 220 C<br />

have been close partners for seven years.<br />

for Android<br />

Simply<br />

download the<br />

app for free:<br />

for ios<br />

2/<strong>2015</strong><br />

International<br />

Three generations of MAN fans<br />

True love<br />

will not rust<br />

Story<br />

Special<br />

14_MAN_Magazin_<strong>Truck</strong>_0215_01_Cover.indd-EN_en.indd 3 19.08.15 16:20<br />

Masthead<br />

<strong>MANmagazine</strong> is published twice a year<br />

in 16 languages.<br />

Published by MAN <strong>Truck</strong> & Bus<br />

Stefan Klatt (V.i.S.d.P.),<br />

Dachauer Straße 667, 80995 Munich, Germany<br />

Responsible Editor &<br />

Project Manager<br />

Joachim Kelz, Tel.: +49. 89. 1580-1175,<br />

magazin@man.eu, www.man.eu<br />

Publisher C3 Creative Code and Content GmbH,<br />

Heiligegeistkirchplatz 1, 10178 Berlin, Germany<br />

www.c3.co<br />

Head of CONTENT UNIT Klaus-Peter Hilger<br />

Editors & Authors Yasmine Sailer (resp.)<br />

Freelance Authors: Danja Antonovic, Tobias Birzer,<br />

Sophie Knoll, David Mayer, Leonie March,<br />

Marcus Schick, Vanessa Schmidt<br />

International Editors Nadia Lawrence, Patricia<br />

Preston (resp., freelance editor), Asa C. Tomash,<br />

Priscilla Totiyapungprasert<br />

Managing Editor Sara Austen<br />

Graphics Micheline Pollach, Christian Kühn<br />

Graphics Editor Elke Latinovic<br />

Cover Image Tillmann Franzen<br />

Production C3 Creative Code and Content GmbH<br />

Printing Gotteswinter und Aumaier GmbH,<br />

Joseph-Dollinger-Bogen 22, 80807 Munich, Germany<br />

Reproduction permitted with reference.<br />

Any changes must be coordinated with the editors.<br />

Subscription Service Thomas Mahler GmbH,<br />

Postfach 50 04 65, 80974 Munich, Germany<br />

Tel.: +49. 89. 1580-3724,<br />

Thomas.Mahler-ext@man.eu<br />

Advertising Service Zeitzeichen Vertriebs GmbH,<br />

Radka Neumann, Tel.: +49. 8323. 9984630,<br />

radkaneumann@zeitzeichen.de<br />

Copyright ©<strong>2015</strong> MAN and C3 Creative Code and<br />

Content GmbH<br />

04<br />

14<br />

STORY SPECIAL<br />

MAN fans: The Schmitz clan consider<br />

their trucks as part of the family.<br />

06 Harvest hand<br />

MAN offers a broad vehicle portfolio for<br />

agricultural operations.<br />

08 Players of tomorrow<br />

Two NEOPLAN buses transport young<br />

footballers to the summer camp of FC<br />

Barcelona in Sochi, Russia.<br />

10 News<br />

Current reports from MAN's world<br />

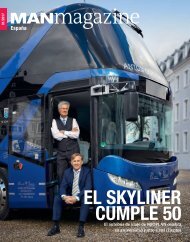

14 True love<br />

The Schmitz family's tradition of driving<br />

trucks made by MAN dates back 57 years<br />

and four generations.<br />

19 Under Bavarian colours<br />

Munich's brewery Augustiner Bräu has<br />

trusted MAN vehicles since 1915.<br />

20 Well roared, lion!<br />

For its anniversary, MAN markets the<br />

TGX D38 in a “100-Years Edition”.<br />

24 Top shape<br />

Customers around the world appreciate<br />

the pre-owned vehicles of MAN TopUsed.<br />

28 With an extra bit of traction<br />

The MAN HydroDrive delivers reliable<br />

performance in a quarry.<br />

The best of MAN’s world<br />

Which customers purchased the first<br />

MAN trucks? And what about the effective<br />

appearance of buses back in 1915? This issue of<br />

<strong>MANmagazine</strong> is dedicated to a landmark<br />

occasion, namely the 100th anniversary of<br />

trucks and buses made by MAN. While our<br />

story special highlights the long history of<br />

commercial vehicle manufacturing at MAN,<br />

additional coverage on technology, products<br />

and mobility – including a feature on the<br />

MAN HydroDrive or a bus tour of Israel’s Haifa<br />

– makes for interesting reading and discovery.<br />

Enjoy and experience the printed <strong>edition</strong> of<br />

<strong>MANmagazine</strong> or download a digital tablet<br />

version for free, which is available as an app<br />

for iOS and Android.<br />

Photos: APPLE INC. Pr<br />

28<br />

46<br />

32 All in sight<br />

Vehicle fleet managers save real money<br />

with MAN TeleMatics.<br />

36 The sun of South Africa<br />

The first climate-neutral MAN plant is<br />

located in South Africa's Pinetown.<br />

42 Green light for the Metronit<br />

In Israel's city of Haifa, the Bus Rapid<br />

Transit satisfies passengers and<br />

operators alike.<br />

46 Fresh seafood by MAN<br />

On tour with refrigerated transport from<br />

Croatia to Poland.<br />

02<br />

03

2/<strong>2015</strong><br />

Her heart beats for MAN: Simone<br />

Wenzel relies 100% on her truck.<br />

Passionate feelings about her<br />

job: Simone Wenzel has been<br />

driving trucks for 16 years.<br />

Discover additional images<br />

of Simone Wenzel and her<br />

kilometre millionaire in the app.<br />

Simone Wenzel is a self-employed truck<br />

driver from Lünen in North Rhine-Westphalia,<br />

Germany. She has been operating trucks since<br />

1999 and discovered her passion for MAN after<br />

only six months behind the wheel. Simone has<br />

been on the road with a red MAN LE 220 C<br />

since 2008.<br />

Simone, what kind of vehicle are you<br />

driving? This one is an MAN truck, built in<br />

June 2002. The odometer has already hit<br />

1,018,444 kilometres. I think that’s quite a<br />

performance for such a small truck!<br />

Can you tell us about your daily work<br />

routine with the truck? I deliver newspapers<br />

and general cargo throughout the region five<br />

days per week. That adds up to about 85,000<br />

kilometres behind the wheel each year.<br />

What do you especially like about your<br />

vehicle? Its reliability. My MAN has never<br />

my man<br />

failed me. As a self-employed person, I must<br />

Heart<br />

and soul<br />

Photos: Dominik Asbach<br />

Kilometre millionaire: The MAN LE<br />

220 C from 2002 has run up an<br />

impressive 1,018 ,444 kilometres<br />

on its clock.<br />

depend on the functionality of my work tool<br />

and I can rely on this truck 100%. Naturally,<br />

regular maintenance every three months is a<br />

necessity, just like for any other truck. Yet<br />

except for replacing the injection nozzles last<br />

year, there have never been any major repairs.<br />

It’s even still running with its first engine and<br />

the original transmission.<br />

In your opinion, what features must a<br />

good truck have? Definitely a powerful drive.<br />

My 6-cylinder engine has fantastic traction<br />

and I’d never swap it for a 4-cylinder again.<br />

When your current truck finally needs<br />

to be retired, which vehicle would you buy<br />

next? It would definitely be an MAN! I would<br />

not consider anything else. The truck of my<br />

dreams would be the new MAN TGL.<br />

04<br />

05

2/<strong>2015</strong><br />

Series vehicle with special<br />

agricultural tyres: The TGS 8x8 is<br />

ideally suited for any surface.<br />

Greenfield deployment: The current MAN<br />

vehicle from the <strong>Truck</strong>nology Roadshow<br />

demonstration fleet is reaping grass.<br />

From the farm to the field and then on<br />

to storage facilities, the biogas plant or the<br />

sugar factory: Highly efficient yet extremely<br />

versatile trucks are needed for the varied<br />

deployment and ever-increasing distances<br />

found throughout the entire agricultural<br />

transportation chain. In this industry,<br />

utilised trucks must be economical on the<br />

roads, as well as being capable of safely<br />

navigating unpaved terrain. In addition,<br />

farmers and contractors have diverging<br />

needs: Some want to take their harvest<br />

directly from the field and therefore require<br />

off-road vehicles that especially protect the<br />

soil. Others deliver fertiliser to the edge of<br />

the field, or load cargo such as grain to carry<br />

it to more distant destinations.<br />

With its vast product portfolio, MAN is well<br />

positioned to handle these needs. Farmers and<br />

contractors can choose from series trucks that<br />

efficiently handle long routes and are optionally<br />

equipped with traction aids such as the<br />

MAN HydroDrive. Or they might pick from<br />

among all-wheel drive vehicles that are<br />

assembled at the plant in a fashion that allows<br />

for easy customisation for agricultural use<br />

afterwards – including adaptations in terms of<br />

tyres, hydraulic systems or lighting. MAN<br />

also offers manufacturers of combine and<br />

forage harvesters or large tractors especially<br />

developed six- and 12-cylinder engines of the<br />

latest emission classes. The next harvest may<br />

commence!<br />

Interested visitors can experience MAN<br />

vehicles for agricultural purposes and the new<br />

engines D2862 and D3876 at the Agritechnica<br />

show in Hall 17, Booth A0411. This trade fair<br />

for agricultural technology takes place on<br />

8–14 November <strong>2015</strong>, in Hanover, Germany.<br />

> www.agritechnica.com<br />

06Harvest hand<br />

Photos: MAN<br />

07

2/<strong>2015</strong><br />

Total engagement: The young<br />

football fans could really throw<br />

themselves into the game at the<br />

FCBEscola Summer Camp.<br />

Safe travels to training: Two<br />

NEOPLAN buses transport the<br />

children to camp.<br />

Players of<br />

tomorrow<br />

Photos: Evgeniy Reutov<br />

When children from around the world<br />

meet up with the pros from FC Barcelona on<br />

the football pitch in Sochi, Russia, the time has<br />

clearly come for another round of FCBEscola<br />

summer camp. For two full months, nearly<br />

400 kids between the ages of six and 13 from<br />

different regions of Russia and the entire<br />

world trained their ball-handling skills with<br />

the Barça pros. The young boys and girls at the<br />

training camp also learned more about the<br />

core values of the Spanish football club,<br />

including respect, drive and teamwork.<br />

As a partner of the FCBEscola Camp in<br />

Sochi, MAN provided two NEOPLAN Tourliner<br />

travel coaches to transport the young football<br />

players safely and comfortably to training.<br />

The vehicles are equipped with an electronic<br />

stability program (ESP), two-point safety belts<br />

for each of the 46 seats and a reversing<br />

camera. The young passengers’ safety was<br />

therefore always a top priority – and the<br />

future football hopefuls showed up for their<br />

training sessions relaxed and well rested.<br />

Scan here for the video – and<br />

experience the Barcelona<br />

summer camp.<br />

Tips from a professional: FCBEscola coach Sergi Pi shares not<br />

only football knowledge but also core values such as respect<br />

and teamwork.<br />

08<br />

09

2/<strong>2015</strong><br />

Model range<br />

and new<br />

technology<br />

Interschutz, the leading international<br />

trade fair for fire prevention, disaster relief,<br />

rescue, safety and security that took place in<br />

Hanover in June <strong>2015</strong>, served as the platform<br />

for MAN to present its wide model range of<br />

fire department vehicles. Since MAN’s early<br />

beginnings 100 years ago, the company has<br />

been a partner for fire departments and is<br />

known for its experience, broad product<br />

portfolio and technological innovation.<br />

For the varied operations undertaken by<br />

fire departments and rescue teams, MAN is<br />

offering vehicles from the TGL, TGM, TGX and<br />

TGS series in the Euro 5 and Euro 6 emission<br />

standard categories – for in countries such as<br />

Germany, Austria and the United Kingdom,<br />

vehicles with Euro 5-compliant engines may<br />

still be deployed for a longer transition<br />

period. To show the flexible product range,<br />

MAN also exhibited the medium-sized<br />

fire engine MLF in a Euro 5 version from the<br />

MAN TGL range. At 7.49 tonnes, it may also<br />

be operated by drivers with the earlier<br />

German Class 3 licence.<br />

The large variety of driver’s cabs also<br />

highlights the strong affinity of MAN for this<br />

Broad portfolio: MAN offers different chassis for emergency<br />

vehicles such as the TGL (top) and the TGX (bottom)<br />

in Euro 5 and Euro 6 emission standard categories.<br />

Partnership for 100 years:<br />

Fire departments trust<br />

MAN emergency vehicles.<br />

industry. No matter the vehicle type, MAN<br />

offers fitting cabs for any size team of three or<br />

more that meet the European occupant<br />

protection regulations (ECE-R29). The team<br />

cabin with nine seats is the largest version<br />

from the MAN Modification Center.<br />

Seen for the first time at Interschutz<br />

were versions of the TGM and TGS range with<br />

integrated Allison converter-automatic<br />

transmissions, adding another alternative to<br />

MAN’s manual transmission and its proven<br />

MAN TipMatic automatic transmission.<br />

Another novelty is the ESP electronic stability<br />

programme for four-wheel drive vehicles<br />

with switch-activated front-wheel drive,<br />

which is available for optional order as of<br />

early 2016. This significantly increases safety<br />

and security, especially for emergency<br />

vehicles responding to alarms.<br />

MAN is very successful in this industry.<br />

“In terms of building chassis for fire trucks,<br />

this is our third year as the market leader,”<br />

states Martin Zaindl, Municipal Sales<br />

Germany. “And we will keep advancing and<br />

developing our products.”<br />

Photos: MAN, Nir Shaanani (1)<br />

50 Years of MAN<br />

in Israel<br />

50 years of market presence of the<br />

MAN brand in Israel and the 100th anniversary<br />

of MAN <strong>Truck</strong> & Bus coincided and were<br />

the occasion for great festivities in Tel Aviv<br />

this year. Israel’s MAN importer Automotive<br />

Equipment & <strong>Truck</strong>s (AET) marked the occasion<br />

by inviting customers and partners to<br />

the Tel Aviv Exhibition Center in late May.<br />

The customer event started off with an<br />

exhibition of MAN trucks, engine displays<br />

and much more. The evening event was<br />

attended by more than 800 truck and bus<br />

customers, supplier representatives, journalists<br />

and delegates from various European<br />

diplomatic missions. Several MAN customers<br />

from Israel used the opportunity to order a<br />

total of 65 trucks.<br />

Here’s to the next 50 years: (left to right) Zvi Neta,<br />

Chairman Automotive Equipment Group, Heinz-Jürgen<br />

Löw, MAN Director Sales & Marketing, and Danny Vardi,<br />

CEO Automotive Equipment and <strong>Truck</strong>s<br />

2014 CR Report<br />

MAN reports its sustainability activities<br />

at MAN 2014 under the title Corporate<br />

Responsibility. On the website, there is a<br />

wide range of facts, location background<br />

and international impressions, prepared<br />

in a multi-media, interactive fashion.<br />

Accompanying the online presentation,<br />

MAN introduces its CR accomplishments<br />

in a printed booklet and in PDF format.<br />

> cr-report2014.man.eu<br />

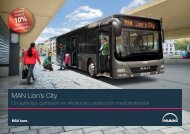

Optimal passenger flow: The 18-metre-long<br />

Lion’s City GL has five double-width doors.<br />

Buses of the future<br />

smile – was the motto of the 61st global<br />

congress of UITP, the international organization<br />

for public transport authorities and<br />

operators, which took place in Milan in June<br />

<strong>2015</strong>. SMILE stood here for the topics of<br />

sustainability, mobility, innovation, lifestyle<br />

and economy. These issues demonstrate the<br />

broad range of challenges faced by urban<br />

mobility that require sustainable solutions<br />

for the future.<br />

MAN’s efficient urban bus family was<br />

represented by the Lion’s City GL at the UITP<br />

exhibit stand. With the bus, MAN displayed<br />

a vehicle concept designed for inner city<br />

traffic with especially high passenger<br />

Triplicate: The Corporate Responsibility at MAN<br />

2014 report is available on a website, as a printed<br />

journal and in PDF format.<br />

volumes. The articulated bus is 18.75 metres<br />

long and features five double-width doors.<br />

Unique in the market, this door concept<br />

ensures the rapid and optimised flow of<br />

passengers and short stopping times, even<br />

during peak periods.<br />

MAN has been investing in the future for<br />

100 years and signifies the highest quality<br />

and efficiency of its own products and<br />

services. With its highly diverse urban bus<br />

line MAN Lion’s City, the company offers<br />

fuel saving and environmentally friendly<br />

mobility solutions for urban transport that<br />

are tailored perfectly to the individual needs<br />

of its customers and markets.<br />

100<br />

TGX for Vortex<br />

The Dutch general cargo expert Vortex<br />

Logistics is updating its fleet with<br />

100 MAN TGX EfficientLine trucks.<br />

The company aims to operate the<br />

eco-friendliest fleet in Europe.<br />

10<br />

11

Happy birthday,<br />

MAN <strong>Truck</strong> & Bus!<br />

2/<strong>2015</strong><br />

#MAN100years<br />

83<br />

New: The MAN WebKiosk<br />

<strong>Truck</strong>s and chassis<br />

MAN delivers 83 trucks and chassis to<br />

Belarus. The lumber transport company<br />

Silva Sp zoo ordered 55 TGS chassis and<br />

10 TGX tractor-trailers, while CJSC<br />

MZBN, Minsk, the second largest<br />

beverage producer in Belarus, ordered<br />

18 MAN TGL.<br />

Find more information on<br />

the MAN chronicles under<br />

www.augustdreesbachverlag.de/<br />

buecher/geschichte/man.html<br />

For 100 years, MAN has been building<br />

trucks and buses and the publishing company<br />

August Dreesbach Verlag is presenting a 320-<br />

page book to mark the occasion. MAN – Ein<br />

Jahrhundert (MAN – A Century) imparts the<br />

history of MAN’s commercial vehicle manufacturing,<br />

with short texts and hundreds of<br />

images taken from the historical archives of<br />

MAN <strong>Truck</strong> & Bus, most of which are being<br />

published here for the first time.<br />

Four MAN TGX D38<br />

for racing teams<br />

Secure transport: The race cars of<br />

Matthias Ekström are delivered to the<br />

motor sports events by MAN trucks.<br />

On a special anniversary website, MAN<br />

also tells fascinating stories about how the<br />

company has played a decisive role in shaping<br />

the development of future mobility in the<br />

commercial vehicle segment, and highlights<br />

values such as efficiency, customer relations<br />

and enthusiasm for the product. The digital<br />

journey through 100 years of commercial<br />

vehicle manufacturing at MAN can be<br />

experienced at > www.100years.man.eu<br />

Touring car racer Mattias Ekström and<br />

his team at EKS Performance AB and ABT<br />

Sportsline can now enjoy the new MAN<br />

trucks for transporting their racing cars:<br />

both teams have received two MAN TGX D28<br />

tractor-trailers each.<br />

EKS Performance AB is the private<br />

Rallycross team of Mattias Ekström. The<br />

Swede has been driving in the Deutsche<br />

Tourenwagen Masters (DTM) for ABT<br />

Sportsline since 2001.<br />

With his two DTM titles won in 2004 and<br />

2007, Ekström is considered one of the best<br />

touring car racers in the world. He’s also the<br />

most senior and successful Audi driver in the<br />

DTM. In <strong>2015</strong>, Mattias Ekström wants to seize<br />

the opportunity to win both the DTM with<br />

Audi and the World RX with EKS. MAN has<br />

been supplying EKS Performance AB with<br />

tractor-trailers for transporting racing cars<br />

since 2014, while the partnership between<br />

MAN and the team at ABT Sportsline has<br />

lasted for more than 20 years.<br />

Photo: MAN, Corbis (1)<br />

Safety<br />

ahead<br />

Publications by MAN are now available free of charge in the new web kiosk.<br />

Here readers can read the publications from the business units <strong>Truck</strong> & Bus<br />

(including <strong>MANmagazine</strong>), Diesel & Turbo and other corporate publications<br />

such as the annual reports online. The English MAN web kiosk can be found at<br />

> www.webkiosk.man.eu<br />

The new generation of emergency brake<br />

assists (EBA) and emergency stopping signals<br />

(ESS) have been available from MAN since<br />

July <strong>2015</strong>. The latest generation of EBA combines<br />

the information from radar sensors in<br />

the vehicle’s front and the camera in the<br />

windscreen. Due to this sensor fusion, the<br />

system can more reliably interpret complex<br />

traffic scenarios. It can identify vehicles in<br />

front and stationary obstacles more quickly<br />

and with greater security. This creates a<br />

larger time window for the system to<br />

activate the EBA earlier, if necessary.<br />

In the event of an emergency stop, the ESS<br />

activates the hazard lights with a higher<br />

blinking frequency (emergency stopping<br />

signal) in addition to the brake lights. This<br />

signals an emergency situation to the traffic<br />

behind and helps avoid rear-end collisions.<br />

Since July <strong>2015</strong>, EBA and the new lane<br />

guidance system (LGS) have been installed in<br />

all series production vehicles requiring the<br />

mandatory equipment for new registrations<br />

as of November <strong>2015</strong>. > www.man.eu/eba<br />

Twice as much attention:<br />

Radar and camera can<br />

permanently monitor the<br />

conditions ahead.<br />

12<br />

13

2/<strong>2015</strong><br />

Story<br />

Special<br />

For 57 years and four generations, the Schmitz<br />

family has been driving trucks made by the<br />

MAN company – with no end in sight for this<br />

special relationship.<br />

<strong>2015</strong>: Four decades later, Johannes<br />

Schmitz is running the company with his<br />

father Reiner (left) and his wife Heike, while<br />

son Niklas is already waiting in the wings.<br />

1975: Johann and Elisabeth Schmitz with<br />

grandchildren Agnes Schmitz, Johannes<br />

Baum and Johannes Schmitz (right to left)<br />

and one of their first MAN vehicles<br />

True love<br />

Photos: Tillmann Franzen<br />

14<br />

15

2/<strong>2015</strong><br />

24<br />

MAN trucks<br />

In <strong>2015</strong>, the Schmitz vehicle fleet<br />

comprises 24 vehicles, with 17 of them<br />

deployed in operations – more than ever<br />

before in the company’s 76-year history.<br />

Y<br />

ou don’t mean to tell me you<br />

actually paid money for that<br />

scrap heap?” Resi Schmitz just<br />

shook her head when son Johannes navigated<br />

his trailer into the Zaunstrasse depot a few<br />

years ago. It certainly took some imagination<br />

to recognise a valuable historic truck in the<br />

rusted vehicle skeleton on board. Yet Johannes<br />

was able to convince his mother that he had<br />

indeed discovered an automotive treasure –<br />

which he, as a passionate truck fan and compulsive<br />

DIY tinkerer, would be able to restore<br />

to its former glory by investing many hours of<br />

his free time. Today, people turn their heads<br />

when he drives past in his type 515 MAN flatbed<br />

truck dating from the year 1955, now highly<br />

polished and a bright shiny blue.<br />

trucks are a love affair for the Schmitz<br />

family, who come from Bedburg-Kirchherten<br />

in Germany’s Rhineland area. They have<br />

vehicles from seven decades parked on the<br />

company yard. Other than the type 515 flatbed,<br />

these include other MAN classics as well:<br />

tractors from the 1950s, dumper trucks and<br />

semi-trailers from the 1960s and 1970s. The<br />

KAT roll-off tipper, built in 1980, is actually<br />

still used today and is the longest-serving<br />

member of the current vehicle fleet. The<br />

17 trucks belonging to the Schmitz family<br />

are used as road sweepers, container transporters,<br />

dumpers and semi-trailers.<br />

The Reiner Schmitz Transport Company is<br />

a textbook example of a family business. The<br />

company is represented by five heads – senior<br />

bosses Reiner, aged 74, and Resi Schmitz, 67;<br />

their children Johannes, 45, and Agnes, 46;<br />

and daughter-in-law Heike, 48. With Sandra,<br />

12, and Niklas, 9, the fourth generation of the<br />

family is slowly but surely getting to know<br />

the company. “In our family, everyone has to<br />

lend a hand. When we reliably deliver and enjoy<br />

our work, that is the key to success,” says<br />

Resi Schmitz. It is important to her that a<br />

good dash of optimism always contributes to<br />

the business strategy – backed up by the<br />

Rhinelanders’ characteristic cheerfulness.<br />

The 515 vintage flatbed serves as a<br />

tangible illustration of this. It has been<br />

splendidly restored to its pristine condition<br />

and is completely roadworthy, which is<br />

definitely not a given. “Because it had been<br />

stationary for so long, the engine had seized<br />

up and we couldn’t find a way to free up the<br />

caught pistons,” recalls Johannes Schmitz.<br />

Until, that is, an MAN tractor dealer from the<br />

Bavarian Forest came up with a bright idea:<br />

“You must feed it some cola,” he suggested.<br />

No sooner said than done. ‘There was an<br />

alarming fizzing and hissing in the cylinder.<br />

In the end the dirt, rust, grease and cola<br />

liquid combined to make such a disgusting<br />

brew that it was pretty scary. The upshot is<br />

that we got the engine running again,” recalls<br />

Johannes Schmitz.<br />

The courage to try different things and<br />

explore new paths has been a constant<br />

leitmotif in the history of the Schmitz family<br />

business. Its beginnings date back to the year<br />

1939, when Johann and Elisabeth set up a<br />

“one-horsepower” haulage company in order<br />

to supplement their income as farmers – with<br />

just one forage wagon and a horse and cart.<br />

Yet before the business could get off the<br />

ground, Johann was called up for army<br />

service – just six weeks after the company<br />

had been founded. When he returned<br />

from the war unharmed in 1945, he found<br />

that tanks had driven over the business<br />

equipment, reducing it to splinters. The<br />

young couple had reason to rejoice, however:<br />

In 1940, their son Reiner had been born.<br />

In 1948, Johann and Elisabeth restarted<br />

the business, again with a horse and cart.<br />

Soon the first truck came along, one that still<br />

had a wood gasifier. Little Reiner followed his<br />

father around like a shadow. “My grandad<br />

once said I’d do better to become a pastor –<br />

then I could have a glass of wine every day<br />

and no stress,” says Reiner Schmitz with a<br />

twinkle. “But I wanted to be a car mechanic<br />

and transport operator like my father – in<br />

spite of the seven-day week, and having to be<br />

Photos: Tillmann Franzen<br />

MAN vehicle fleet:<br />

<strong>Truck</strong>s from seven<br />

decades are parked on<br />

the Schmitz yard.<br />

Modern flagship: The Schmitz<br />

family doesn’t just own historic<br />

vehicles – they also have new trucks,<br />

such as this MAN TGS, which has<br />

been modified for roadsweeping duty.<br />

Tomorrow belongs to him:<br />

Nine-year-old Niklas can’t wait to<br />

get his hands on the wheel.<br />

Glimpse of the family album: For<br />

many years, the Schmitz trucks<br />

were used for waste collection.<br />

Business in their bones: Resi and Reiner Schmitz have followed<br />

the fortunes of their haulage company through all its ups and<br />

downs – and they are still passionately involved.<br />

16<br />

17

2/<strong>2015</strong><br />

Family photo: MAN trucks,<br />

whether old or new, are a big love<br />

affair for the Schmitz family.<br />

Under Bavarian colours<br />

the mayor called for tenders from all over<br />

“For us,<br />

everything has<br />

always revolved<br />

around MAN.”<br />

Johannes Schmitz, transport entrepreneur<br />

Learn more about the<br />

likeable Schmitz family and<br />

their MAN trucks on the app.<br />

available right around the clock. When you’ve<br />

grown up with it from the cradle, the haulage<br />

business is just a natural part of your life,”<br />

the senior manager recalls today.<br />

In the early years, the Schmitz company<br />

mostly carried coal briquettes from the vast<br />

open-cast brown coal mines of the Lower<br />

Rhine Embayment, which supplied fuel to<br />

domestic industry and private households.<br />

One experience in 1958 left an abiding<br />

impression on Reiner Schmitz. Together with<br />

his father, he had travelled on the train to<br />

Munich (“a world tour in those days”) to pick<br />

up the first MAN for the company and drive it<br />

home. “It was incredibly exciting,” Reiner says.<br />

From then on, the company’s fortunes have<br />

continually improved – although the core<br />

business for 63 years was rubbish collection.<br />

“In the early days of refuse collection, you still<br />

had to heave the bins onto the trailers and<br />

empty them by hand. The worst thing was<br />

having hot ashes flutter in your shoes,” he<br />

recollects.<br />

Then in 2002, their focus on waste almost<br />

took a precarious turn for the company, when<br />

Europe and the local service provider fell<br />

to wayside due to the resulting price wars.<br />

“It was a big shock for us at the time, as we<br />

literally lost more than 60% of our turnover<br />

overnight,” remembers Resi Schmitz. “Yet we<br />

didn’t let this experience get us down and<br />

instead reorganised the family business.” The<br />

company bid farewell to rubbish collection<br />

and now uses its MAN vehicle fleet to<br />

specialise in road sweeping and the transport<br />

of green waste, bark mulch and building<br />

rubble. “And that was a wise move,” concludes<br />

junior manager Johannes Schmitz. “Due to<br />

the volume of incoming orders, we have more<br />

trucks in action than ever before in company<br />

history.” Johannes and his sister Agnes had<br />

learned the tools of the trade at MAN in<br />

Cologne- Mülheim, before joining the family<br />

business. Agnes took the position of commercial<br />

administrative assistant, while<br />

Johannes trained as a vehicle mechanic. “For<br />

us, everything has always revolved around<br />

MAN,” states Johannes Schmitz. “Right up<br />

to the present day, the MAN connection in<br />

our eyes is associated with living up to the<br />

highest standards in our own endeavours.”<br />

and this tradition is bound to continue.<br />

Johannes’s son Niklas is just moving on from<br />

primary to secondary school. He wears a<br />

baseball cap , work gloves and a stick-on<br />

tattoo decorating his lower left arm. Yet<br />

rather than choosing an image of pop star<br />

Rihanna or the 1. FC Köln football team, like<br />

other boys his age might do, it reads “MAN<br />

Traction on Tour”. The depot still houses the<br />

blue Kettcar truck that Niklas zoomed<br />

around the yard in as a little guy, pulling a<br />

homemade trailer holding miniature orange<br />

metal container. Now, whenever possible,<br />

Niklas rides on the passenger seat of whatever<br />

vehicle his father or grandfather is<br />

steering. He already enthusiastically looks<br />

forward to taking his place at the wheel.<br />

“That’s just the way it was with me,” says his<br />

father Johannes. “As you grow bigger, so do<br />

your responsibilities.”<br />

Photos: Tillmann Franzen, Max Kratzer<br />

While MAN <strong>Truck</strong> & Bus celebrates its 100th product anniversary in <strong>2015</strong>, Munich’s<br />

Augustiner brewery has delivered its beer barrels via MAN trucks for almost as long.<br />

Fire departments and breweries –<br />

these two sectors provided the first<br />

customers for Lastwagenwerke<br />

M.A.N.-Saurer, first established 100<br />

years ago. In 1915, Munich-based<br />

breweries such as Augustiner<br />

planned to transport their beer barrels further<br />

out, but the distances to regional towns like<br />

Traunstein and Rosenheim outstripped the<br />

endurance of horses. This called for faster<br />

means of transport with greater reach, marking<br />

the beginning of a partnership between<br />

Augustiner and MAN – one that is still going<br />

strong today.<br />

“It’s really quite amazing,” comments<br />

Wolfgang Ketterl, director of the vehicle fleet<br />

for Augustiner-Bräu Wagner KG. “Here we are<br />

100 years later and still transporting our<br />

wooden kegs with MAN trucks – although<br />

with 440 hp now instead of the earlier 36 hp.”<br />

It isn’t just any beer that is loaded onto the<br />

trucks at the logistics center in Munich’s<br />

Freiham district. Augustiner still produces its<br />

barley malt at its own malting facility. Such<br />

consistent quality commitment has its<br />

rewards: Augustiner Beer has long since enjoyed<br />

a special status. And since the brewery<br />

places great value on regionality, it specifically<br />

chose service providers from Munich –<br />

such as MAN. “It’s important to us that our<br />

partners speak the same language as we do,”<br />

Century-old partnership: As early as 1915, a truck<br />

by M.A.N.-Saurer drove for Augustiner-Bräu.<br />

explains Ketterl. “Over the years, we have<br />

developed a great bond of trust.” Under<br />

standably so, as the relationship is rooted in a<br />

long and shared history. From trucks with a<br />

maximum speed of 23 kph to the F90 after<br />

the Second World War to the brand new TGX,<br />

Augustiner has always relied on MAN.<br />

“Excellent vehicle efficiency was always a<br />

crucial factor – especially in terms of fuel<br />

consumption and low maintenance,” emphasises<br />

Ketterl.<br />

As Augustiner-Bräu tends to avoid paid<br />

advertising, the white trucks with the blue<br />

Augustiner lettering reflect the Bavarian colours<br />

and serve as billboards throughout the<br />

city. The fleet pauses only on the weekends –<br />

when the brewery delivers its beer with<br />

historic horse-drawn wagons. The reins are<br />

often in the hands of Augustiner truck drivers<br />

who operate ultramodern MAN trucks during<br />

the week. They carry on the spirit that has<br />

shaped the partnership between Augustiner<br />

and MAN for 100 years: Keeping up with the<br />

times without losing sight of tradition.<br />

Interesting and emotional details about<br />

100 years of MAN are at > www.100years.man.eu<br />

Proud of tradition: The popular beer<br />

is still being brewed in the historical<br />

buildings of Augustiner in the inner<br />

city of Munich.<br />

“We’ve enjoyed<br />

a true bond of<br />

trust with MAN<br />

for 100 years.”<br />

Wolfgang Ketterl, director of the vehicle fleet at<br />

Augustiner-Bräu Wagner KG<br />

18<br />

19

2/<strong>2015</strong><br />

Well roared,<br />

LION!<br />

For its 100th anniversary,<br />

MAN offers its TGX D38<br />

in a “100 Years Edition”.<br />

Customers purchasing this<br />

special vehicle can enjoy<br />

certain embellishments –<br />

ranging from stainless<br />

steel details to the flaming<br />

lions design.<br />

Precision work:<br />

The customised<br />

emblems are<br />

carefully applied.<br />

The TGX D38 bares its teeth:<br />

The flaming lions design on the<br />

door is the most striking detail<br />

of the TGX special <strong>edition</strong>.<br />

Photos: Florian Generotzky<br />

Tanja Hässler’s eyes are sparkling:<br />

“Wow, isn’t that one just so<br />

dreamy!” The junior owner of<br />

Sp<strong>edition</strong> Hässler, a Bavarian<br />

forwarding company located<br />

in Mintraching near the city of<br />

Regens burg, already has 18 MAN vehicles in<br />

her fleet, but the 100 Years Edition of the TGX<br />

D38 is indeed very special, even for the die <br />

hard MAN fan. This special model for the<br />

100th anniversary of the truck division at<br />

MAN was created for especially enthusiastic<br />

customers – and could be considered a thank<br />

you for their many years of loyalty.<br />

The special <strong>edition</strong> is outfitted to grab<br />

major attention: Highly polished front and<br />

side bars made of stainless steel with<br />

integrated LED lighting accents make for a<br />

splashy appearance. The massive rooftop<br />

bridge with four halogen headlights and the<br />

step leading up to the door are also made of<br />

stainless steel. Highlights of the design<br />

include two flaming lions parading in redorange<br />

on both sides of the vehicle. They are<br />

blazingly applied on a choice of the new paint<br />

colours MAN Stone Grey Metallic, MAN D38<br />

Finale: The stainless<br />

steel rooftop bridge is<br />

attached at the end.<br />

20<br />

21

2/<strong>2015</strong><br />

“This one will make<br />

quite a splash at<br />

trucker meetings.”<br />

Tanja Hässler, junior owner of Sp<strong>edition</strong> Hässler<br />

30<br />

LED Lights<br />

Even at night, up to 30 LED lights<br />

illuminate the full beauty of<br />

the TGX D38 “100 Years Edition”.<br />

Red, MAN Steel Blue Metallic or MAN Crystal<br />

White Metallic, which are now available for<br />

this model. Another embellishment are the<br />

aluminium fenders that maintain a permanent<br />

shininess due to special finishing.<br />

“We wanted to produce a special model<br />

for our anniversary that reflects emotion and<br />

enthusiasm for the product,” explains Stefan<br />

Kaserer at MAN Product Marketing. The ideas<br />

for this anniversary <strong>edition</strong> were honed since<br />

November 2014 and the first model was<br />

finished just in time for the <strong>Truck</strong>nology Days<br />

event in late March <strong>2015</strong>. Customers spotting<br />

the flagship at this event for the first time<br />

were just thrilled – so thrilled in fact that<br />

some ordered the truck right there on the<br />

spot, just like the Hässlers. “We saw the<br />

flaming lion for the first time on a banner<br />

at a MAN tipper truck presentation in<br />

Regensburg and knew right away that we<br />

would love to have a truck with that motif,”<br />

explains Tanja Hässler. When she later read on<br />

MAN’s Facebook page that the truck was<br />

actually being produced, the entire family<br />

spontaneously decided to experience the<br />

vehicle live at the <strong>Truck</strong>nology Days. Once in<br />

Munich, it was an easy decision to make:<br />

S p<strong>edition</strong> Hässler was the first customer to<br />

purchase the special <strong>edition</strong>.<br />

In addition to the elegant details on the<br />

outside, Anton and Tanja Hässler are pleased<br />

with the focus on the driver’s interior. “Our<br />

drivers appreciate the feeling of generous<br />

space inside the cab,” she reports. MAN put<br />

extra emphasis on creating premium driving<br />

comfort in the interior. The driver’s comfort<br />

package for one or two drivers features<br />

comfortable air-suspension seats with back<br />

support, adjustable shoulder support and<br />

heating, which especially support drivers and<br />

co-drivers during long trips with their<br />

optimised ergonomics. The Infotainment<br />

Package “Plus” comes with a sound system,<br />

the MAN Media <strong>Truck</strong> Advanced navigation<br />

radio, a USB port, an infrared remote control<br />

and a hands-freeBluetooth kit for relaxed<br />

periods of driving and rest. On top of that are<br />

retractable sun visors, reading lights,<br />

footrests and armrests, a multifunctional<br />

leather-wrapped steering wheel, an auxiliary<br />

heating system and a cabin refrigerator with<br />

stow-away table.<br />

The “100 Years Edition” has been<br />

available in all of Europe since July <strong>2015</strong> in a<br />

520-hp and 560-hp version. Customers can<br />

still order the special vehicle until the end of<br />

<strong>2015</strong>. And the special <strong>edition</strong> is not just<br />

available for the tractor-trailer, but also for all<br />

TGX D38 models with a plastic bumper and<br />

high roof. Vehicles with a chassis add-on or<br />

heavy-duty transporter can also be equipped<br />

with the package. “So a broad customer range<br />

has the option of equipping their vehicle with<br />

these premium add-ons,” says Stefan Kaserer.<br />

The “100 Years Edition” vehicles are<br />

assembled in the Munich plant, including all<br />

the available special accessories, such as<br />

aluminium rims, the drivers’ comfort package<br />

or the sun visor. During the modification<br />

process, the stainless steel package is installed<br />

and the flaming lions applied, with delivery<br />

then commencing straight from the <strong>Truck</strong><br />

Modification Center to the customer. Of<br />

course, the first one went to Tanja Hässler,<br />

who takes turns with her uncle in driving the<br />

anniversary truck. At their firm, the truck will<br />

be mostly deployed for national refrigerated<br />

transport. “And this one will make quite a<br />

splash at trucker meetings, since the details<br />

were not implemented later, but delivered<br />

straight from the plant. Now this is our crown<br />

jewel,” beams a very proud Tanja Hässler.<br />

Find out more about the exclusive<br />

features of the TGX D38 “100 Years Edition” at<br />

> www.man.eu/tgx100years<br />

Photos: Florian Generotzky<br />

The first off the line: Sp<strong>edition</strong> Hässler<br />

received the very first special model<br />

of the TGX D38. From left are Angelika,<br />

Tanja, Anton and Hannelore Hässler.<br />

22<br />

23

2/<strong>2015</strong><br />

top<br />

shape<br />

MAN TopUsed offers high-quality pre-owned<br />

commercial vehicles in more than 30 countries.<br />

Individual financing solutions, trans-European<br />

warranties and tailored repair and maintenance<br />

contracts round out the service range.<br />

Trust in pre-owned MAN trucks:<br />

Jörg Eichhorn, Head of Dispatch<br />

Logistics at Dauphin<br />

On the road across Europe:<br />

MAN trucks run an annual<br />

110,000 kilometres for Dauphin.<br />

Focus on drivers:<br />

Jörg Eichhorn purchases<br />

comfortable vehicles for<br />

his employees.<br />

W<br />

hen the telephone rings at<br />

the MAN TopUsed Center<br />

in Nuremberg and the<br />

display shows the number of the company<br />

Dauphin, Marcus Feniuk knows immediately<br />

what needs to be done. His long-standing<br />

customer Jörg Eichhorn, Head of Dispatch<br />

Logistics for the office furniture manufacturer<br />

Dauphin, requires another used vehicle. And a<br />

special one this time around. “Fully equipped,<br />

440 hp, large cab, white, top condition!,” says<br />

Eichhorn, who relies entirely on the MAN<br />

sales representative to pick the right one.<br />

The customer has already acquired four<br />

tractor-trailers through MAN TopUsed and<br />

is very satisfied with the pre-owned trucks.<br />

“These vehicles are truly in mint condition,<br />

with impeccably refurbished interiors. That’s<br />

pretty important to me personally,” says<br />

Eichhorn. “My drivers get to return home just<br />

once a week, so they should feel comfortable in<br />

their trucks.”<br />

In order to guarantee the premium<br />

condition of the vehicles, MAN introduced a<br />

500 000<br />

Kilometres<br />

MAN vehicles receiving the MAN<br />

TopUsed seal of quality with three stars<br />

are no older than 48 months and have<br />

clocked 500,000 kilometres or less.<br />

Foto:<br />

As good as new: The<br />

cab interiors of MAN<br />

TopUsed vehicles are<br />

perfectly refurbished.<br />

Photos: Max Kratzer<br />

24<br />

25

1<br />

“I get everything<br />

from a single<br />

source – and all<br />

of it custom<br />

tailored.”<br />

Norbert Sommerbauer, owner of Sommerbauer<br />

Transport GmH<br />

seal of quality. The seal of the highest category<br />

is applied exclusively to vehicles no older than<br />

48 months and with an absolute maximum of<br />

500,000 kilometres on the clock. A thorough<br />

check examines everything from the engine to<br />

the chassis, from the axles to the driver’s cab.<br />

A seal of quality with three stars includes a<br />

12-month guarantee on the powertrain.<br />

Norbert Sommerbauer, the owner of<br />

Sommerbauer Transport in Oeynhausen,<br />

Austria, found especially appealing the<br />

360-degree package offered by MAN TopUsed.<br />

“I get everything I need from a single source:<br />

customer care, financing, service, warranty –<br />

and all of it custom tailored.” The contractor<br />

has entertained a close business relationship<br />

with MAN since 2008, and has purchased<br />

more than 20 MAN TopUsed vehicles during<br />

that time. “There is an enormous selection, so<br />

there is always matching right vehicle,” states<br />

Sommerbauer. He uses an offer from MAN<br />

Finance to realise his purchases. “We were<br />

attracted by the flexible contract conditions.”<br />

The Austrian is also pleased by the customer<br />

support provided by his MAN TopUsed salesman.<br />

“He helps us with any matter concerning<br />

my fleet and is always available. And he’s proactive.<br />

When a pre-owned vehicle that fits my<br />

needs arrives in the used vehicle inventory of<br />

MAN <strong>Truck</strong> & Bus, he contacts me right away.”<br />

a similar experience is that of Javier<br />

Fuentes, manager of the bus company Arriva<br />

Esfera, which operates the TeatroBus project in<br />

Madrid. Converted into mobile theatres, the<br />

buses now feature original theatre seats and a<br />

professional lighting and sound system. “We<br />

need very particular vehicles for our purposes,<br />

and we finally found four of them in the MAN<br />

TopUsed newsletter that we receive regularly,”<br />

states Fuentes. “We gained a solid impression<br />

even in advance, as the newsletter is thoroughly<br />

detailed, offers clear insights and<br />

includes plenty of photos – both of the<br />

exteriors and interiors of the vehicles,”<br />

explains the manager. “Our sales contact, who<br />

instantly understood our needs, took care of<br />

everything else.”<br />

Better Braking with Water.<br />

The Aquatarder PWR<br />

3<br />

2<br />

Satisfied customers all over the world:<br />

1 Norbert Sommerbauer, owner of Sommerbauer<br />

Transport GmbH in Austria 2 Javier Fuentes,<br />

manager of the bus company Arriva Esfera in Spain<br />

3 Ulrich Kluxen, owner of the forwarder Hanse<br />

Freight in South Africa and Malawi<br />

For Ulrich Kluxen, owner of the<br />

forwarding company Hanse Freight based in<br />

South Africa and Malawi, the priceperformance<br />

ratio is a decisive factor. There<br />

are 18 pre-owned MAN TGA in his fleet. Kluxen<br />

prefers vehicles that come off a full<br />

maintenance leasing contract. “This way,<br />

I receive a truck in premium quality with little<br />

mileage and a seamless service history for<br />

merely 50% of the original price. It represents<br />

a combination of modern technology and<br />

affordable price, perfect for the challenging<br />

conditions in the African transport sector,”<br />

says Kluxen. The South African also believes<br />

that the successful partnership with the MAN<br />

service team plays a key role. “Timing is<br />

everything in our business and due to the<br />

support of MAN, my trucks never spend more<br />

than 24 hours in the workshop.”<br />

Economically and eco-friendly on the road: with the Voith Aquatarder PWR. The primary<br />

continuous braking system uses the cooling water as operating medium and is therefore<br />

maintenance-free. It performs up to 90% of all braking operations wear-free – which<br />

reduces stays in the workshop.<br />

As part of the MAN PriTarder braking system the Aquatarder PWR achieves high braking<br />

outputs already at low speeds – with a weight of just 33 kg. All this makes it an ideal<br />

continuous braking system for distribution and construction site vehicles, as well as for<br />

combined use with the MAN HydroDrive.<br />

www.voith.com<br />

Learn and read more about the extensive<br />

range of pre-owned vehicles from MAN at<br />

> www.man-topused.com<br />

Photos: MAN<br />

26

2/<strong>2015</strong><br />

MAN HydroDrive is a safe and comfortable<br />

system that has offered truck drivers more<br />

traction and power for the last decade –<br />

ranging in applications from stone quarries<br />

to forest paths.<br />

With an extra bit of<br />

28Tract ion<br />

Photo: Max Kratzer<br />

R<br />

emaining here is not an<br />

option,” says Christian<br />

Schlögel after receiving a<br />

call and presses on to leave. All vehicles – cars,<br />

tippers and wheel loaders – head towards the<br />

entrance of the quarry. There is a moment of<br />

quiet, followed by a thunderous roar that<br />

shakes the earth as a chunk of the 30-metrehigh<br />

rock face collapses. The blast envelops the<br />

area in a looming cloud of dust. Once it has<br />

settled, the wheel loaders and tippers get right<br />

to work. “Our people will have this rubble<br />

cleared away in two days at the most,” states<br />

Schlögel.<br />

The 56-year-old with a business degree is<br />

employed as Head of Transport for the<br />

Bärnreuther+Deuerlein Schotterwerke, a<br />

medium-sized company based in Bavaria’s<br />

Upper Palatinate. He runs a fleet of 85 vehicles<br />

for transporting bulk goods in Weickenhof<br />

and five other quarries owned by the<br />

company. They deliver the extracted stone for<br />

various construction needs, be it underlying<br />

material for streets and roadways, stone,<br />

cement and asphalt chips, drainage gravel or<br />

fertilizer lime. “These are heavy loads in the<br />

truest sense of the world and must be moved<br />

along roads as well as difficult, often steep<br />

and slippery surfaces,” explains Schlögel.<br />

Working under these conditions safely<br />

and profitably requires “intelligent drive<br />

systems”. Schlögel found what he was looking<br />

29

2/<strong>2015</strong><br />

Traction at the turn of a button:<br />

MAN HydroDrive makes it<br />

easy to activate all-wheel drive.<br />

30<br />

Working at the quarry:<br />

The HydroDrive trucks<br />

have a safe and reliable<br />

grip on gravel surfaces.<br />

Safe distance: Driver Albert<br />

Seitz (right) and manager<br />

Christian Schlögel wait for<br />

the blast to blow over.<br />

“MAN HydroDrive<br />

is a clever<br />

compromise.”<br />

Christian Schlögel, Head of Transport for<br />

Bärnreuther+Deuerlein Schotterwerke<br />

Photos: Max Kratzer, MAN<br />

for in the MAN HydroDrive. Florian Reiter<br />

from MAN Sales Management in Munich<br />

explains the benefits of this technology<br />

that has been successful for a decade: “The<br />

typical transfer gearbox needed for classic allwheel<br />

drive is rendered expendable by the<br />

hydrostatic front-wheel engine. That saves<br />

space and weight. Only rear-wheel drive is<br />

used for on-road operation, hydraulic pumps<br />

and wheel hub motors do not generate any<br />

friction. When operating in all-wheel drive,<br />

however, the transfer elements in the front<br />

axle drive turn along, even though switched<br />

off.” The powered front axle offers additional<br />

directional control. According to Schlögel, this<br />

is an important aspect in the quarry, where<br />

the non-all-wheelers are often referred to as<br />

“footsores” by the drivers.<br />

Christian Schlögel thinks the HydroDrive<br />

is a clever compromise for all situations. “The<br />

all-wheel drive can be activated at the flick of<br />

a switch and is used only where it is needed<br />

and beneficial,” says the quarry boss. This<br />

makes the HydroDrive more efficient than<br />

a full-time all-wheel drive vehicle. The<br />

truck with HydroDrive weighs about 400<br />

kilogrammes less than an all-wheel drive –<br />

and this clearly results in higher transport<br />

load and lower fuel costs. He already has<br />

seven TGX trucks with 440 hp operating in<br />

his fleet and added this summer another<br />

four TGX with 480 hp each. “Even though<br />

providers now offer similar concepts in the<br />

market, we are sticking with MAN. Here we no<br />

longer have to worry about ‘growing pains’,”<br />

adds Schlögel.<br />

In the quarry, the gigantic wheel loader is<br />

now tackling the blasted limestone. The supersized<br />

truck stands a whopping 5.4 metres tall,<br />

with each tyre measuring more than two and a<br />

half metres. The bucket has a capacity of about<br />

30 tonnes. The TGX tipper sways like a ship<br />

on the open sea, as the wheel loader fills it<br />

with gravel. Loading time takes merely a few<br />

seconds. To master the steep ramp leading<br />

across the gravel track towards the exit, Albert<br />

“Atschi” Seitz activates the HydroDrive with<br />

the turn of a knob. The scree grinds beneath<br />

the lugged tires and the machine vigorously<br />

makes its way up the incline. “You can tell that<br />

this is a totally different kind of load,” says the<br />

appreciative 49-year-old driver. The TGX leaves<br />

the Weickhof quarry heading for the next site<br />

in Laaber, with the truck quickly shifting into<br />

cruising mode on the road. Once the truck<br />

reaches 28 kilometres per hour, the HydroDrive<br />

switches off automatically and the vehicle with<br />

its heavy cargo rolls over the smooth asphalt as<br />

efficiently as any other on-road vehicle.<br />

Schlögel uses MAN TeleMatics to find the<br />

optimum balance for all the different<br />

demands on his vehicles. “That’s the key to<br />

successful fleet management. We coordinate<br />

the utilisation and efficiency of the vehicles,<br />

exactly identify wear and tear and thereby<br />

directly influence the durability of the fleet,”<br />

emphasises Schlögel. And last but not least,<br />

the gathered information also assists the<br />

drivers, he says. “Utilising the technology<br />

properly results in reduced stress, a more<br />

relaxed attitude and ultimately a healthier<br />

condition,” states a convinced Schlöger. He<br />

proudly relates how he had used MAN<br />

HydroDrive, Telematics and the related data<br />

analysis to continuously optimise the<br />

efficiency and transport security of the fleet.<br />

In matters of safety, Schlögel invites the<br />

MAN experts to conduct training sessions.<br />

“We conduct courses for drivers with MAN<br />

ProfiDrive and our own trainers at regular<br />

intervals and will occasionally even flood<br />

inclines with water to render the surface<br />

soapy and oily. Then our drivers can<br />

experience what it means to drive the fully<br />

loaded vehicle with HydroDrive under the<br />

most difficult conditions,” relates Schlögel.<br />

“There’s always a little adventure touch to<br />

those days, but ultimately, however, everyone<br />

drives even more safely, with less wear and<br />

tear and also reduced fuel consumption,<br />

which also means lower emissions. Everyone<br />

benefits from that.”<br />

A spectacular film about MAN HydroDrive<br />

trucks operating in the quarry is available at<br />

> www.man.eu/discoverman-10yearshydrodrive<br />

Find more impressive<br />

images from the<br />

quarry in the app.<br />

Numerous applications<br />

MAN HydroDrive serves all industries and<br />

market segments, ranging from long-distance<br />

travel to special-purpose vehicles. The vehicle<br />

programme of the TGS and TGX series includes<br />

two-axle and four-axle vehicles. More than<br />

11,000 customers have purchased MAN<br />

HydroDrive since its market launch in 2005.<br />

One of them is the volunteer fire department in<br />

the Lower Austrian city of Bruck an der Leitha.<br />

They’ve been using a TGS 440 HydroDrive as<br />

their rescue and tank firetruck since 2012.<br />

While the construction laws of Lower Austria<br />

actually stipulate that fire trucks require a<br />

permanent all-wheel drive, Commander Claus<br />

Wimmer was able to persuade the regional fire<br />

department to use MAN HydroDrive. “The<br />

all-wheel drive is used when we need traction,<br />

for example while recovering stranded vehicles<br />

on the side of the road, in off-road conditions or<br />

in the snow. We’ve only had the best experience<br />

with this vehicle.”<br />

Florian Tränkl, a timber transporter in the<br />

Swabian district of Aichach-Friedberg, is also on<br />

the road with a TGS 540 HydroDrive. He<br />

particularly requires a lot of agility and traction<br />

when he loads logs in the forest. The 6x6-4<br />

drive concept with an articulated trailing axle<br />

had impressed from the beginning. “The truck is<br />

extremely agile and produces traction exactly<br />

where I need it, due to the HydroDrive. This<br />

spares me the hassle of complicated chain<br />

work.” Its efficiency persuaded him as well.<br />

“Compared to my old 6x4 drive, I need six litres<br />

less diesel fuel for 100 kilometres. After<br />

200,000 kilometres, the extra cost of the<br />

HydroDrive system has already been amortised.”<br />

31

2/<strong>2015</strong><br />

Friendly rivalry: with the<br />

TeleMatics app, drivers can<br />

monitor the fuel consumption<br />

of their own vehicle as well<br />

as that of their colleagues.<br />

All<br />

in<br />

sight<br />

W<br />

hen Peter Flensted, CEO<br />

of the Denmark-based<br />

forwarding company<br />

“Viggo Petersens Eftf. A/S”, decided to expand<br />

three and a half years ago, he had to entirely<br />

rethink the fleet management system. As a<br />

locally operating forwarder with just under<br />

50 trucks, Flensted had previously tried to get<br />

a handle on the consumption and maintenance<br />

data for every vehicle truck through<br />

Excel tables. “But then we chose to double the<br />

size of our fleet and extend our radius to all of<br />

Denmark,” explains Flensted. “That’s when we<br />

started looking for an instrument that would<br />

offer a better overview of all this data.”<br />

Since efficiency was truly at the top of<br />

Flensted’s list, he chose to add 46 MAN<br />

EfficientLine trucks to his fleet. “A sales expert<br />

at MAN analysed the needs of our new<br />

fleet structure at the time and drew our<br />

attention to MAN TeleMatics,” says Flensted.<br />

Optimisation: Every few months,<br />

TeleMatics specialist Jack Kelberg<br />

(right) works with truck operator Lars<br />

Markland to analyse his driving style.<br />

less fuel<br />

By introducing MAN TeleMatics,<br />

hauliers can save 10% of fuel<br />

volume and decrease downtime.<br />

Happy boss: CEO Peter<br />

Flensted appreciates the<br />

benefits of MAN TeleMatics.<br />

10 %<br />

From tyre pressure to fuel consumption:<br />

MAN TeleMatics facilitates the analysis of all relevant<br />

operational and maintenance data, thereby<br />

increasing the profitability of haulage businesses.<br />

Photos: Rasmus Degnbol<br />

32<br />

33

2/<strong>2015</strong><br />

Connected CoDriver<br />

the effect. “Since the introduction of MAN<br />

TeleMatics, we’ve recorded fuel savings of<br />

10%, which is incredibly efficient!” Notz<br />

combined the telematics system with<br />

ProfiDrive training, whereby MAN trainers<br />

analyse driving styles and offer suggestions<br />

for improvement. “The positive aspect of<br />

MAN TeleMatics is the ability to immediately<br />

check whether the training was effective,”<br />

says Notz. Setting up the telematics system<br />

on the shipping company’s computers went<br />

quickly and smoothly. “We had it installed in<br />

just ten minutes,” says Peter Notz. “And the<br />

next day we could already track the fuel<br />

consumption patterns of our drivers.”<br />

He is very pleased with the quality of MAN’s<br />

support. “Whenever there was a question,<br />

even later in the day, my MAN contact was<br />

available by phone at any time. It was indeed<br />

a great collaboration!”<br />

“We’ve reduced<br />

our downtime<br />

to a minimum.”<br />

Peter Notz, authorised signatory for Rohlog GmbH<br />

In addition to the driver training sessions<br />

conducted by MAN ProfiDrive, MAN offers<br />

Connected CoDriver, a kind of virtual driving<br />

instructor. During the hands-on live remote<br />

training programme, an MAN coach can<br />

access the data via MAN TeleMatics and<br />

then work with the driver at regular intervals<br />

to develop a more economical driving style.<br />

Guido Rölver, owner of Timeflextrans GmbH<br />

in Schermbeck, Germany, had his drivers<br />

trained through the Connected CoDriver.<br />

Mr Rölver, what made you decide to use<br />

MAN Connected CoDriver?<br />

At first, we were attracted by the very<br />

reasonable price and so we thought we’d<br />

give it a try.<br />

Are you satisfied with the results?<br />

It’s been incredibly successful. Especially<br />

with regard to our regular service vehicles,<br />

we’ve seen a reduction of nearly 10% in<br />

fuel consumption. And in a sustainable<br />

way, not just for a couple of weeks.<br />

What’s different about the training?<br />

The programme is individually customised<br />

for each driver. And the instructors are<br />

extremely well qualified. They know how to<br />

strike the right note with the drivers and<br />

that’s very important.<br />

One of the best drivers in the team: Lars Markland loading his truck<br />

How often should each vehicle receive maintenance,<br />

which wear and tear data has entered ServiceCare, in order to transfer maintenance<br />

maintenance management with MAN<br />

a critical stage and, naturally, how fuel- scheduling and implementation to the MAN<br />

intensive is each operator’s driving style? service point. This process maximises<br />

Flensted receives assistance from his operating time while reducing repair and<br />

colleague Jack Kelberg, who was trained in administration costs.<br />

TeleMatics by MAN and coordinates everything<br />

from the carrier’s central office. “It was Peter Notz, authorised signatory for the<br />

the best decision to use MAN TeleMatics,” haulage firm Rohlog GmbH in Memmingen,<br />

says Jack Kelberg. “With so many vehicles, it’s Germany, chose MAN TeleMatics primarily to<br />

impossible to stay on top of all the important receive access to maintenance data for his<br />

information,” adds Peter Flensted. The MAN vehicles. “It’s important for us that an<br />

system consists of the telematics unit in the employee at any relevant MAN location<br />

vehicle, which constantly monitors all of the should retain an overview at all times and<br />

important operating data such as the vehicle’s contact us, for example, when the oil level<br />

position, speed and technical condition. Once becomes critical. That’s how we’ve managed<br />

collected, the data is then transferred by GSM to reduce our vehicles’ downtime to a minimum.”<br />

Fuel savings had initially not been the<br />

module to Peter Flensted and Jack Kelberg.<br />

Another important aspect here is proactive first priority for Notz and he was surprised by<br />

Data collector: With<br />

MAN TeleMatics, Jack<br />

Kelberg keeps track<br />

of the vehicle data.<br />

Photo:<br />

Peter Flensted relies on his drivers’<br />

competitive spirit to achieve fuel savings.<br />

“Nearly all my drivers have the telematics app<br />

installed on their smart phones. They can<br />

Photos: Rasmus Degnbol, privat, Eric Chmil<br />

view their own data as well as the consumption<br />

figures of the other drivers.” When one<br />

driver steps ahead in terms of efficiency, the<br />

others try to keep pace, explains Flensted. Lars<br />

Markland, for example, is one of the best<br />

drivers, and proud of his achievement. In this<br />

way, operators learn from one another<br />

through MAN TeleMatics and accept the<br />

system as a useful tool for their daily work<br />

routine. In addition to fuel savings, the fleet<br />

manager considers the time savings a special<br />

bonus. “I don’t have to deal with the analysis<br />

myself and can focus on our core business<br />

instead. There are so many contributing<br />

factors to profitability that we used to ignore<br />

because we didn’t have the time. Now we<br />

do know better.” The expectations of the<br />

company in terms of savings, work simplification<br />

and user friendliness have been fulfilled.<br />

“I would wholeheartedly recommend MAN<br />

TeleMatics,” says Flensted.<br />

Find out how your own<br />

efficiency gets into gear in<br />

the video and infographic<br />

featured in the app.<br />

Would you recommend this programme<br />

to other people?<br />

Absolutely! If everyone knew how well the<br />

MAN Connected CoDriver training works,<br />

they would all have adopted it by now.<br />

Guido Rölver (right) discusses the results of the<br />

training with driver Josef Vierhaus.<br />

Experience driver training in action with<br />

MAN ProfiDrive trainer Hugo Siewert<br />

and Josef Vierhaus at Timeflextrans: > www.<br />

man.eu/discoverman-connectedcodriver<br />

34<br />

35

2/<strong>2015</strong><br />

Lots of light, little energy: The infrared<br />

chamber where the chassis paint is<br />

dried used to run on a diesel generator. Today<br />

it operates with clean electricity.<br />

the sun of<br />

The MAN factory in Pinetown runs on solar energy.<br />

This makes it both the first climate-neutral<br />

commercial vehicle plant in South Africa and the<br />

first in the global production network of MAN.<br />

Photo: Roger Jardine<br />

south africa<br />

36<br />

37

2/<strong>2015</strong><br />

Heiko Kayser has seen his wish<br />

come true. Quite proudly, the<br />

plant manager looks out over<br />

the rooftops of his production<br />

halls: The enormous photovoltaic<br />

panels shine blue in the South African<br />

winter sun. “Our vision of the first CO 2 -neutral<br />

factory has now become reality,” says Kayser.<br />

This not only renders the Pinetown site a<br />

pioneer in South Africa, but also a trendsetter<br />

in MAN’s global production network. On the<br />

way to his office, Kayser passes a monitor<br />

that reflects the current solar system’s output.<br />

By the end of <strong>2015</strong>, it should produce about<br />

810 megawatt hours, nearly 100 more than the<br />

plant uses. The surplus energy is then fed into<br />

the public grid for a profit. This step alone<br />

should lower CO 2 emissions by up to 860<br />

tonnes per year.<br />

The 160 employees at the MAN <strong>Truck</strong> &<br />

Bus assembly plant are also very proud of this<br />

quantum leap in environmental protection.<br />

While fastening cable harnesses to a truck<br />

chassis in the bright and tidy production hall,<br />

staff member Nqobile Mkhungo explains that<br />

she could hardly imagine at first that their<br />

plant could run entirely on solar energy.<br />

While the port city of Durban is blessed with<br />

more than 300 days of sun annually, the utilisation<br />

of renewable energy in South Africa is<br />

still at a fledgling stage. “It was very exciting<br />

for me to experience this process at first<br />

hand,” remembers Mkhungo.<br />

Plant Manager Kayser had set himself and<br />

his employees an “ambitious goal”. When the<br />

Munich resident began working in Pinetown<br />

in late 2012, he promptly initiated the “Green<br />

“Our vision of<br />

the first climateneutral<br />

factory is<br />

now a reality.”<br />

Heiko Kayser, Plant Manager for the<br />

MAN plant in Pinetown<br />

Production” initiative and had various<br />

concepts for renewable power generation<br />

tested. “In South Africa, wind and sun are the<br />

obvious candidates and photovoltaic energy<br />

was the most economic choice.” MAN has<br />

invested 10 million rand (about €730,000) in<br />

the system. Kayser estimates that the costs<br />

will be amortised in six to seven years and<br />