energize oil & gas 01/2011 - GL Group

energize oil & gas 01/2011 - GL Group

energize oil & gas 01/2011 - GL Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

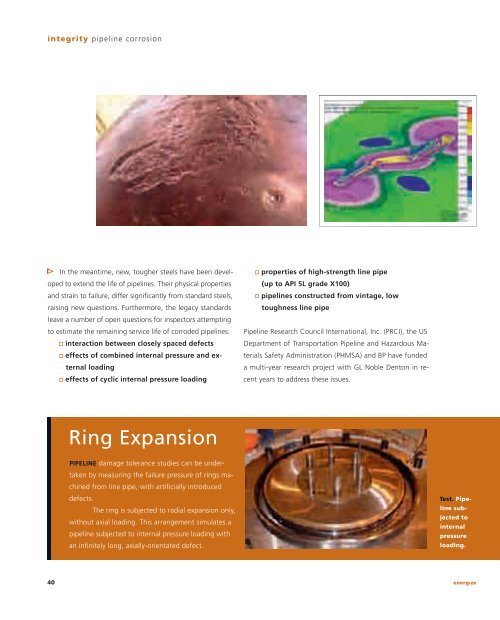

integrity pipeline corrosion<br />

In the meantime, new, tougher steels have been devel-<br />

oped to extend the life of pipelines. Their physical properties<br />

and strain to failure, differ signifi cantly from standard steels,<br />

raising new questions. Furthermore, the legacy standards<br />

leave a number of open questions for inspectors attempting<br />

to estimate the remaining service life of corroded pipelines:<br />

interaction between closely spaced defects<br />

effects of combined internal pressure and ex-<br />

ternal loading<br />

effects of cyclic internal pressure loading<br />

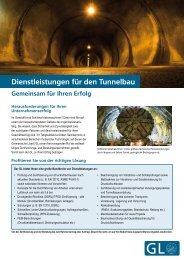

Ring Expansion<br />

PIPELINE damage tolerance studies can be under-<br />

taken by measuring the failure pressure of rings ma-<br />

chined from line pipe, with artifi cially introduced<br />

defects.<br />

The ring is subjected to radial expansion only,<br />

without axial loading. This arrangement simulates a<br />

pipeline subjected to internal pressure loading with<br />

an infi nitely long, axially-orientated defect.<br />

properties of high-strength line pipe<br />

(up to API 5L grade X100)<br />

pipelines constructed from vintage, low<br />

toughness line pipe<br />

Pipeline Research Council International, Inc. (PRCI), the US<br />

Department of Transportation Pipeline and Hazardous Materials<br />

Safety Administration (PHMSA) and BP have funded<br />

a multi-year research project with <strong>GL</strong> Noble Denton in recent<br />

years to address these issues.<br />

Test. Pipe-<br />

linesub- jected to<br />

internal<br />

pressure<br />

loading.<br />

40 energıze