Newsletter

1jO3RxD

1jO3RxD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

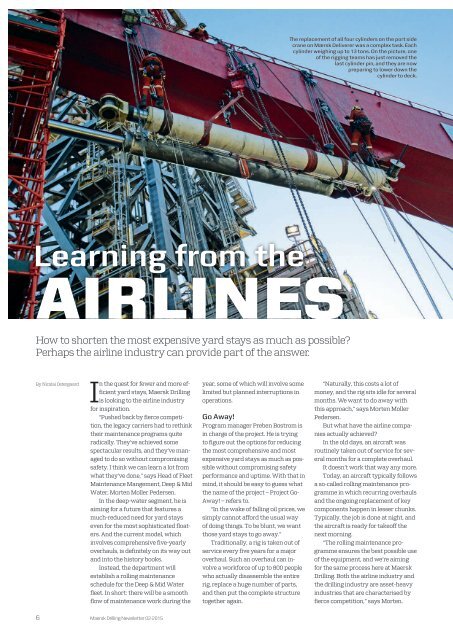

The replacement of all four cylinders on the port side<br />

crane on Mærsk Deliverer was a complex task. Each<br />

cylinder weighing up to 13 tons. On the picture, one<br />

of the rigging teams has just removed the<br />

last cylinder pin, and they are now<br />

preparing to lower down the<br />

cylinder to deck.<br />

Learning from the<br />

AIRLINES<br />

How to shorten the most expensive yard stays as much as possible?<br />

Perhaps the airline industry can provide part of the answer.<br />

By Nicolai Ostergaard<br />

In the quest for fewer and more efficient<br />

yard stays, Maersk Drilling<br />

is looking to the airline industry<br />

for inspiration.<br />

“Pushed back by fierce competition,<br />

the legacy carriers had to rethink<br />

their maintenance programs quite<br />

radically. They’ve achieved some<br />

spectacular results, and they’ve managed<br />

to do so without compromising<br />

safety. I think we can learn a lot from<br />

what they’ve done,” says Head of Fleet<br />

Maintenance Mangement, Deep & Mid<br />

Water, Morten Moller Pedersen.<br />

In the deep-water segment, he is<br />

aiming for a future that features a<br />

much-reduced need for yard stays<br />

even for the most sophisticated floaters.<br />

And the current model, which<br />

involves comprehensive five-yearly<br />

overhauls, is definitely on its way out<br />

and into the history books.<br />

Instead, the department will<br />

establish a rolling maintenance<br />

schedule for the Deep & Mid Water<br />

fleet. In short: there will be a smooth<br />

flow of maintenance work during the<br />

year, some of which will involve some<br />

limited but planned interruptions in<br />

operations.<br />

Go Away!<br />

Program manager Preben Bostrom is<br />

in charge of the project. He is trying<br />

to figure out the options for reducing<br />

the most comprehensive and most<br />

expensive yard stays as much as possible<br />

without compromising safety<br />

performance and uptime. With that in<br />

mind, it should be easy to guess what<br />

the name of the project – Project Go-<br />

Away! – refers to.<br />

“In the wake of falling oil prices, we<br />

simply cannot afford the usual way<br />

of doing things. To be blunt, we want<br />

those yard stays to go away.”<br />

Traditionally, a rig is taken out of<br />

service every five years for a major<br />

overhaul. Such an overhaul can involve<br />

a workforce of up to 800 people<br />

who actually disassemble the entire<br />

rig, replace a huge number of parts,<br />

and then put the complete structure<br />

together again.<br />

“Naturally, this costs a lot of<br />

money, and the rig sits idle for several<br />

months. We want to do away with<br />

this approach,” says Morten Moller<br />

Pedersen.<br />

But what have the airline companies<br />

actually achieved?<br />

In the old days, an aircraft was<br />

routinely taken out of service for several<br />

months for a complete overhaul.<br />

It doesn’t work that way any more.<br />

Today, an aircraft typically follows<br />

a so-called rolling maintenance programme<br />

in which recurring overhauls<br />

and the ongoing replacement of key<br />

components happen in lesser chunks.<br />

Typically, the job is done at night, and<br />

the aircraft is ready for takeoff the<br />

next morning.<br />

“The rolling maintenance programme<br />

ensures the best possible use<br />

of the equipment, and we’re aiming<br />

for the same process here at Maersk<br />

Drilling. Both the airline industry and<br />

the drilling industry are asset-heavy<br />

industries that are characterised by<br />

fierce competition,” says Morten.<br />

6 Maersk Drilling <strong>Newsletter</strong> 02·2015