Portable Compressors MOBILAIR M 270

Portable Compressors MOBILAIR M 270

Portable Compressors MOBILAIR M 270

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Made in Germany<br />

KAESER’s renowned <strong>MOBILAIR</strong> range<br />

of portable compressors is manufactured<br />

in a state-of-the-art production facility<br />

located directly next to the KAESER<br />

main plant in Coburg, Northern Bavaria.<br />

Equipped with the very latest technology,<br />

the recently modernised portable<br />

compressor plant boasts TÜV (German<br />

Technical Inspection Agency) certified<br />

sound testing facilities for free-field<br />

sound level measurement, an advanced<br />

powder coating installation and highly efficient production logistics.<br />

With minimal turn-around time, KAESER’s highly qualified<br />

personnel are able to assemble portable compressors<br />

of all sizes and equipment levels to suit our<br />

customers' specific needs.<br />

A powerful team<br />

Via the innovative SIGMA CONTROL mobile compressor controller<br />

with optional start-stop features, M <strong>270</strong> compressors can be started<br />

and controlled by compressed air management systems such as<br />

the SIGMA AIR MANAGER. This capability enables full integration<br />

into stationary compressed air supply systems (e.g. for back-up in<br />

the event of power failure) or the creation of fully power-independent<br />

compressor stations (e.g. for large construction sites where there<br />

maybe no access to infrastructure, or reserve power).<br />

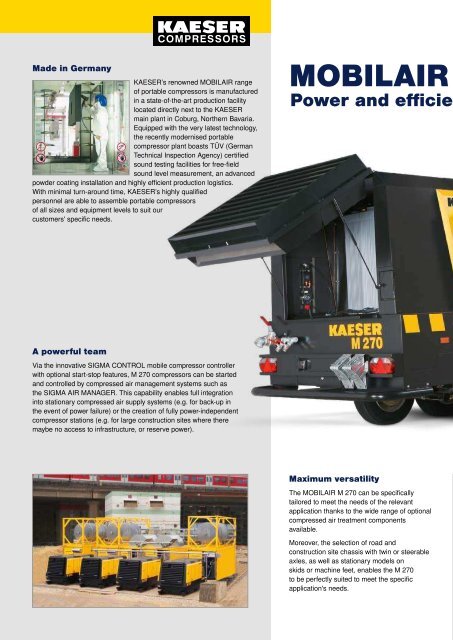

<strong>MOBILAIR</strong> M <strong>270</strong> –<br />

Power and efficiency<br />

Maximum versatility<br />

The <strong>MOBILAIR</strong> M <strong>270</strong> can be specifically<br />

tailored to meet the needs of the relevant<br />

application thanks to the wide range of optional<br />

compressed air treatment components<br />

available.<br />

Moreover, the selection of road and<br />

construction site chassis with twin or steerable<br />

axles, as well as stationary models on<br />

skids or machine feet, enables the M <strong>270</strong><br />

to be perfectly suited to meet the specific<br />

application's needs.<br />

Simple and convenient<br />

pressure adjustment<br />

Using the arrow keys, system pressure<br />

can be precisely adjusted in 0.1 bar<br />

increments on the SIGMA CONTROL<br />

mobile's display. This simplifies operation<br />

and, in combination with the electronic<br />

inlet valve control, leads to significant<br />

fuel savings – especially when operating<br />

in partial load.<br />

Precision oil temperature<br />

control<br />

Maximum road safety<br />

The perfect energy-saving combination:<br />

Mercedes-Benz engines and KAESER airends<br />

The M <strong>270</strong>’s automatically controlled<br />

thermostatic valve ensures that optimal<br />

operating temperature is reached<br />

quickly and reliably. It therefore protects<br />

the compressor's fluid circulation<br />

loop from excessive condensate<br />

accumulation. This in turn significantly<br />

extends cooling fluid and separator<br />

cartridge service life and also enhances<br />

the unit's long-term durability.<br />

As an alternative to the two available<br />

construction site chassis models<br />

featuring a parking brake, a twin axle<br />

chassis version with solid carrying<br />

wheel (also optionally with compressed<br />

air brakes and ABS) is available for<br />

road use. This model is equipped with<br />

ECE compliant lighting and a 24 V<br />

connection from the towing vehicle. The<br />

height-adjustable tow bar can be set to<br />

a coupling height of up to 890 mm to<br />

ensure safe road use.<br />

The powerful combination of an energy-saving Mercedes-Benz engine and a highly<br />

efficient KAESER SIGMA PROFILE airend provides outstanding performance with<br />

considerably reduced fuel consumption. The <strong>MOBILAIR</strong> M <strong>270</strong> can operate at full<br />

power for a whole shift without refuelling. The water-cooled Mercedes-Benz diesel<br />

engine complies with applicable exhaust emission regulations and is certified to<br />

EU directive 97/68 (Class 3a). Furthermore, users not only benefit from the quality<br />

of two world-class products, but can also rely on the comprehensive KAESER and<br />

Mercedes-Benz global service networks to ensure maximum machine availability.