JCB | METALS RECYCLING

JCB | METALS RECYCLING

JCB | METALS RECYCLING

- TAGS

- metals

- recycling

- terra.co.hu

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

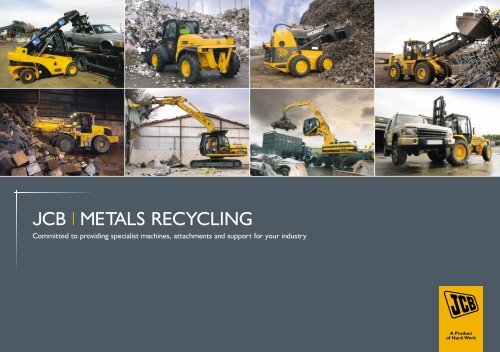

<strong>JCB</strong> | <strong>METALS</strong> <strong>RECYCLING</strong><br />

Committed to providing specialist machines, attachments and support for your industry

CONTENTS<br />

A <strong>JCB</strong> FOR EVERY TASK<br />

PAGES 1 – 2<br />

END-OF-LIFE VEHICLES<br />

PAGES 3 – 4<br />

AUTOMOTIVE <strong>RECYCLING</strong><br />

PAGES 5 – 6<br />

DEFRAGMENTATION<br />

MILLS & SHREDDERS<br />

PAGES 7 – 8<br />

FERROUS & NON-FERROUS<br />

<strong>METALS</strong> <strong>RECYCLING</strong><br />

PAGES 9 – 10<br />

FRIDGE <strong>RECYCLING</strong><br />

PAGES 11 – 12<br />

BATTERY <strong>RECYCLING</strong><br />

PAGES 13 – 14<br />

CONSTRUCTION <strong>METALS</strong> RECOVERY<br />

PAGES 15 – 16<br />

MILLS & FOUNDRIES<br />

PAGES 17 – 18<br />

A <strong>JCB</strong> for Every Task<br />

With the manufacturing sector using more recycled<br />

metals than ever before, the business potential in<br />

metals recycling has never been greater.<br />

Whatever you specialise in – from cars, batteries and<br />

fridges to recovered steel from demolition and melting<br />

down frag into ingots, <strong>JCB</strong> supply the right machines to<br />

help your business run efficiently.<br />

Wheeled loading shovels to tip into high-sided<br />

containers, <strong>JCB</strong> Robot skid steer loaders to transport<br />

scrap iron, telescopic Teletruk forklifts to keep<br />

hazardous loads safely away from the operator,<br />

compact Loadalls to handle loose ingots, and big<br />

wheeled re-handlers to load shredders and balers;<br />

these are just a few of our specific solutions built for<br />

metals recovery operations.<br />

At <strong>JCB</strong> we also tailor our machines to suit your specific<br />

applications. This includes underbelly protection,<br />

heavy-duty filtration, turbo-2 pre-cleaners, extra guard<br />

protection for the operator, solid or filled tyres for<br />

puncture protection, and much more. Our specialists<br />

will advise and help you achieve the ideal specification<br />

for your metals operation.

3<br />

End-of-Life Vehicles<br />

The challenge of End-of-Life Vehicle (ELV) legislation<br />

has transformed the industry. Now that ELV directives<br />

require safe de-pollution before car bodies can be<br />

recycled, a more specialist machine is needed: the<br />

<strong>JCB</strong> Teletruk 35D.<br />

Developed in consultation with the metals recycling<br />

industry, the 3.5-tonne capacity Teletruk is perfect for<br />

handling End-of-Life cars.<br />

With a telescopic boom instead of a conventional<br />

vertical mast, visibility from the Teletruk cab is superb.<br />

The forks carriage rotates up-down through 111°,<br />

far more than any ordinary forklift, so difficult loads<br />

can be tilted right back and held securely. A 360° left-<br />

right rotator attachment – together with the Teletruk’s<br />

forward reach – ensures safe and accurate placing of<br />

the car on the de-pollution rig. Plus there’s a choice<br />

of 2- or 4-wheeled-drive models to suit your site<br />

conditions precisely.<br />

However, the Teletruk is not the only <strong>JCB</strong> machine<br />

for the ELV industry. The <strong>JCB</strong> 416 is a compact,<br />

high-torque wheeled loader for heavy-duty work in<br />

confined spaces and for work on uneven ground.<br />

And the 930 RTFL is a conventional forklift ideally<br />

suited to rough terrain conditions, providing a higher<br />

operating position for improved visibility across vehicle<br />

storage yards.

FAST FACTS<br />

● 3.5-tonne lift and 2430mm<br />

forwards reach allow the<br />

Teletruk to accurately place<br />

cars on ELV rigs<br />

● 111° carriage tilt forwardsback<br />

safely transports<br />

unstable loads<br />

● Excellent all-round vision<br />

enhances health and safety<br />

● High capacity and compact<br />

size are perfect for hightraffic<br />

environments<br />

● <strong>JCB</strong> 416 and 930 RTFL gives<br />

strong performance in<br />

confined, rough-terrain sites<br />

4

5<br />

Automotive Recycling<br />

15 million cars are scrapped in Europe each year<br />

(2.3 million in the UK alone). But many of these are<br />

relatively new cars, making the recycling of parts a<br />

strongly growing business potential.<br />

Automotive recyclers need a machine that can stack<br />

safely onto a rack and then lift the car chassis down<br />

when needed. Just as in the ELV sector, this is where<br />

the <strong>JCB</strong> Teletruk 35D comes into its own. The tele-<br />

scopic boom offers 2430mm forwards reach and<br />

superb visibility, so the operator stays safe while handling<br />

awkward loads in busy environments. The 111 ° carriage<br />

rotation allows back-tilt of the load for safe site travel.<br />

Plus, this compact and manoeuvrable machine is<br />

designed to keep you fully operational when busy<br />

areas get congested and incoming deliveries start<br />

queuing to be offloaded.<br />

It’s the confined space in most yards that presents the<br />

biggest challenge. That’s why automotive recyclers are<br />

also turning to <strong>JCB</strong> compact Loadalls, Robot skid-steer<br />

loaders and masted RTFLs.<br />

Compact Loadalls – the <strong>JCB</strong> 520-40, 524-50 and<br />

527-55 – offer capacities of 2 to 2.7-tonnes and lift<br />

heights from 4 to 5.6 metres, all in a package less<br />

than 2 metres high and 2 metres wide. The machines<br />

feature hydrostatic drive, providing excellent pushing<br />

power particularly at low speeds, as well as the ability<br />

to operate using only the accelerator. This ensures<br />

smooth acceleration and deceleration and precise<br />

control in tight spaces.<br />

Meanwhile, both the <strong>JCB</strong> RTFL fitted with extended<br />

forks, and the skid-steer Robot fitted with an industrial<br />

grapple are ideal for shifting cars around the roughest<br />

terrain. Together with the Teletruk 35D, you won’t<br />

find a better choice of equipment (with a choice of<br />

thousands of attachments) to give the efficient and<br />

reliable performance you need and expect.

FAST FACTS<br />

● 3.5-tonne lift and 2430mm<br />

reach allow the Teletruk<br />

to safely stack and grab<br />

car bodies<br />

● 111° carriage up-down<br />

rotation keeps unstable<br />

loads secure during<br />

site travel<br />

● Telescopic boom provides<br />

superb forward vision for<br />

accuracy and safe handling<br />

● Compact Loadalls provide<br />

excellent pushing power<br />

and control in confined<br />

spaces<br />

● Skid-steer Robots and the<br />

RTFL perform even on the<br />

roughest terrain<br />

6

7<br />

Defragmentation Mills & Shredders<br />

About a third of all recycled metals comes from car<br />

bodies, and 80% of a new car’s body is from recycled<br />

metal. These surprising statistics show how important<br />

the industry has become. And with new legislation<br />

continually setting ever-more challenging targets,<br />

serious players in the industry simply can’t afford to<br />

get left behind.<br />

Defragmentation mills and shredder operations are<br />

all about bulk throughput; getting the maximum<br />

amount of recyclables away to the customer each<br />

day. So the quicker you can get raw product in and<br />

frag out, the better.<br />

With proven reliability, specialist features and extra<br />

guards, the new <strong>JCB</strong> JS200W is our biggest materials<br />

handler yet. A choice of fixed raised cab or hydraulically<br />

raised cab ensures an unimpaired view into containers<br />

and hoppers. There’s a wide range of boom and<br />

dipper options, including mono, tab or materials<br />

handling rig, and for scrap metals a 5-tine cactus grab.<br />

Add all this to a state-of-the-art cab with filtered<br />

heating and ventilation, and you’ve found the perfect<br />

partner for shredder or baler operations.<br />

For loading frag onto trucks or freight trains, you can’t<br />

get better or quicker than the robust and reliable <strong>JCB</strong><br />

wheeled loading shovel. Featuring extra protection<br />

guarding, the <strong>JCB</strong> 456 has optional best-in-class super-<br />

high-lift arms for plenty of clearance when loading.<br />

The arms also have 4-ram geometry for excellent<br />

visibility. Superb traction and power, along with heavy-<br />

duty, puncture-resistant tyres, keep this machine<br />

performing on challenging terrain, while features like<br />

servo controls, low noise levels and the sophisticated<br />

Electronic Monitoring System make for easy operation<br />

throughout every shift.

FAST FACTS<br />

● JS200W features a raised<br />

cab for an unimpaired view<br />

into shredders or balers<br />

● 5-tine cactus grab effectively<br />

handles whole or flattened<br />

car bodies<br />

● 456 wheeled loading shovel<br />

features optional superhigh-lift<br />

arms for loading<br />

● 4-ram geometry loader<br />

end gives excellent visibility<br />

● Machine guards ensure<br />

operator safety and stateof-the-art<br />

cab enhances<br />

comfort<br />

8

9<br />

Ferrous & Non-Ferrous Metals Recycling<br />

Whether you’re a ferrous or non-ferrous specialist, or<br />

you refine non-ferrous metals, the sheer variety of<br />

product for recovery, cleaning, processing and upgrading<br />

(from structured steelwork and white goods casings,<br />

to brass, copper and zinc) means you require versatile<br />

and reliable handling machines.<br />

<strong>JCB</strong> offer the biggest machine you’re likely to need on<br />

site: the JS200W. With a huge choice of grabs, buckets<br />

and specialist equipment (such as a selector grab with<br />

full rotation or a 5-tine cactus grab) it can load virtually<br />

anything into anything. And it boasts a superb cab<br />

environment with excellent visibility for the most<br />

productive performance all shift.<br />

You’ll also need a couple of compact machines to deal<br />

with shifting metals safely and speedily around the site,<br />

such as the <strong>JCB</strong> 160 Robot and the Teletruk 35D.<br />

The <strong>JCB</strong> Robot’s unique single-arm design offers<br />

excellent visibility even in the tightest areas. Fitted with<br />

a grab and solid tyres, the Robot is reliable, fast and<br />

efficient for metals handling in tough conditions.<br />

Developed specifically for metals recycling, the Teletruk<br />

35D is without doubt the most versatile small forklift<br />

you can choose. Compatible with all standard forklift<br />

attachments, what really sets this machine apart in the<br />

metals recycling environment is the Health and Safety<br />

considerations: the cab structure features Roll Over<br />

Protection (ROPS) and Falling Objects Protection<br />

(FOPS) as standard; a front load guard protects the<br />

driver at all times; the telescopic boom keeps dangerous<br />

loads away from the operator; and back-tilt of the 111 °<br />

carriage carries unstable loads securely around the<br />

yard and factory.

FAST FACTS<br />

● JS200W offers a wide<br />

choice of grabs, buckets<br />

and attachments<br />

● Fixed or hydraulically raised<br />

cab allows a clear view into<br />

containers, hoppers or<br />

shredders<br />

● 160 Robot features a unique<br />

single arm for superb<br />

visibility of dangerous loads<br />

● Teletruk 35D is compatible<br />

with standard forklift<br />

attachments for maximum<br />

versatility<br />

● Teletruk offers unique<br />

manual or hydraulic quickchange<br />

of attachments<br />

10

11<br />

Fridge Recycling<br />

Gone are the days, thankfully, when old fridges were<br />

exported to developing countries or buried in landfill –<br />

about 2.5million every year for the UK alone. An<br />

increasing number of European operators have identified<br />

a business niche through obtaining necessary EU<br />

authorisation for fridge recycling. And, due to legislation,<br />

it’s all happened extremely quickly, with the first<br />

licensed fridge recycling plant opening in the UK as<br />

recently as 2002.<br />

A number of highly specialised processes are required<br />

for compliance with the WEEE Directive, such as<br />

degassing and the removal of foam insulation containing<br />

CFCs, before the metal shell of the fridge can be<br />

recycled. If you’re in the business, you’ll know this<br />

means it’s essential that fridges are handled carefully<br />

throughout these processes to prevent gases leaking<br />

before they can be extracted and properly contained<br />

or neutralised.<br />

The Teletruk 35D and compact Loadall are ideal<br />

solutions providing manoeuvrable and productive<br />

performance combined with precision control<br />

and accuracy.<br />

The Teletruk 35D is <strong>JCB</strong>’s new flagship counterbalanced<br />

forklift, designed specifically for metals recycling.<br />

The telescopic arm is unique on a counterbalanced<br />

industrial truck and gives the big advantage of loading<br />

lorries and rail wagons from one side only. It also<br />

provides reach of up to 2-tonne loads to 2 metres<br />

forwards, so you can accurately place loads.<br />

Another unique feature for a counterbalanced forklift is<br />

a 4-wheel drive option, which brings the benefits of<br />

industrial forklift compactness to rough-site surfaces.<br />

The standard forklift attachment for handling fridges is<br />

of course the flat-face recycling grab, but on the Teletruk<br />

there’s the additional benefit of the forwards-back<br />

111° carriage tilt.

FAST FACTS<br />

● Teletruk 35D lifts 3.5-tonnes<br />

maximum plus there are<br />

4x4 models.<br />

● 111° carriage rotation keeps<br />

loads secure during site<br />

travel with no risk of damage<br />

● Telescopic boom offers<br />

superb visibility and<br />

accurate placing<br />

● Compact Loadalls can be<br />

operated using only the<br />

accelerator for smooth<br />

control<br />

● All compact Loadalls and<br />

Teletruks feature fullyenclosed<br />

hydrostatic drive<br />

for damage-free operation<br />

12

13<br />

Battery Recycling<br />

Battery recycling and lead cell recovery is now a well<br />

established industry in its own right. Whichever type<br />

of battery your business handles, you’re going to need<br />

reliable and versatile machines that keep your operation<br />

running day after day.<br />

The <strong>JCB</strong> 436 and 456 wheeled loading shovels are<br />

solid workhorses that give dependable performance.<br />

The 456 features best-in-class super-high-lift arms as<br />

an option, ideal for tipping battery loads into containers.<br />

You can also choose heavy-duty, puncture-resistant<br />

tyres to help minimise downtime on challenging<br />

ground conditions. On both machines, servo controls,<br />

low noise levels and an advanced Electronic Monitoring<br />

System make operation easy and comfortable over<br />

long periods of time. Plus, reversing fans and wide-<br />

core radiators help maintain trouble-free working.<br />

The Teletruk 35D is unique in that unlike any other<br />

counterbalanced forklift it offers forwards reach from<br />

a telescopic boom. The ability to lift 2-tonne loads to<br />

2-metre forwards reach gives you increased options,<br />

like loading stillages of battery casings into road trailers<br />

or containers. The forwards reach can reduce the need<br />

for loading space by up to 50% as well as eliminating<br />

the need for heavy goods vehicles to turn trailers for<br />

loading from both sides.<br />

But the Teletruk range is also built with safety in mind.<br />

A fully-enclosed cab can be specified for eliminating any<br />

risk of acid-splash to the forklift operator. The telescopic<br />

boom keeps hazardous loads as far away from the<br />

operator as possible, optional full air conditioning<br />

protects against noxious fumes and 111° carriage tilt<br />

forwards-back adds benefit to the versatility of a<br />

standard 360 degree load rotator. The <strong>JCB</strong> Teletruk<br />

is the perfect choice for working with hazardous acids<br />

and materials.

FAST FACTS<br />

● Wheeled loading shovels<br />

feature servo controls,<br />

low noise levels and an<br />

Electronic Monitoring<br />

System<br />

● <strong>JCB</strong> 456 offers optional<br />

super-high-lift arms for<br />

tipping into containers<br />

● Teletruk 35D allows loading<br />

of lorries from one side only,<br />

saving space in the yard<br />

● Enhanced safety features<br />

keep the operator safe<br />

and secure<br />

● Telescopic boom keeps<br />

hazardous loads away from<br />

the operator environment<br />

14

15<br />

Construction Metals Recovery<br />

Steel used in construction is usually of a very high grade<br />

so during demolition work it makes good business sense<br />

to recover it from the concrete frame, particularly when<br />

you consider that a typical 4-storey office development<br />

can contain as much as 166-tonnes of steel.<br />

Few work environments are as demanding as demolition,<br />

but there’s a <strong>JCB</strong> machine designed to more than<br />

stand the pace . . . the JS260XD tracked excavator.<br />

The dipper on the JS260XD is specially reinforced so<br />

it can handle the most arduous of loads and the rear<br />

plate is also strengthened, protecting it when material is<br />

gripped between a grab attachment and the underside<br />

of the dipper. A 10mm plate protects the whole<br />

underside of the mainframe and the reinforced turret<br />

belly guard is flush fitted to prevent reinforced steel<br />

bars penetrating the machine belly.<br />

Protective measures continue with flush fitted covers<br />

that safeguard the track from re-bar and all other debris,<br />

an engine air pre-cleaner that removes the heavier<br />

dust particles before they get to the air filter, and a fine<br />

mesh grille to keep the radiator clear. All hoses and<br />

pipe work are run inside the undercarriage framework<br />

to avoid damage.<br />

When it comes to maximum performance on site,<br />

you’ll find this machine gives optimum productivity<br />

from whatever attachment you choose to fit. An<br />

optional merged pump facility in the hydraulic system<br />

allows high flows to be delivered to the dipper-end via<br />

the optional combined pipe work for fast operation of<br />

larger hydraulic attachments. Plus, the combined pipe<br />

work provides two-way flow for <strong>JCB</strong> attachments<br />

such as cutters and crushers.<br />

Specifically designed and built for the industry’s needs,<br />

the JS260XD fitted with <strong>JCB</strong> industrial shears really is<br />

the perfect machine for cutting away that valuable<br />

metal from concrete constructions.<br />

Speed valve reduces<br />

opening and closing times<br />

Piston rod guards fully protect<br />

cylinders from damage<br />

Two different interchangeable<br />

jaws. Universal and steel<br />

Interchangeable cutting and<br />

crushing teeth<br />

Simple fastening system allows<br />

for easy on-site replacement<br />

Heavy duty swing gear offers<br />

unlimited 360° hydraulic rotation<br />

Interchangeable jaws to provide<br />

maximum versatility<br />

Interchangeable teeth are<br />

made from wear resistant<br />

material for maximum life<br />

and low running costs

FAST FACTS<br />

● Heavy-duty reinforcements<br />

protect the JS260XD for<br />

increased performance and<br />

a longer life<br />

● Engine air pre-cleaner and<br />

mesh radiator grille help<br />

minimise maintenance<br />

● Optional merged pump<br />

delivers high flows to the<br />

dipper end for faster<br />

operation of large<br />

attachments<br />

● Combined pipe work<br />

provides two-way flow<br />

for industrial shears<br />

● Superior cab keeps the<br />

operator safe and<br />

comfortable and improves<br />

productivity<br />

16

17<br />

Mills & Foundries<br />

Health and Safety; it’s got to be the top priority issue<br />

for a mill or a foundry where you’re dealing with<br />

hazardous and unstable molten metal. But the first<br />

job in the process is to get raw product delivered<br />

through the door. And for that you must consider the<br />

very compact <strong>JCB</strong> Teletruk 35D.<br />

Unlike any other counterbalanced forklift, the TLT35D<br />

offers a tremendous benefit; forwards reach to load and<br />

unload lorries all from one side. It’s perfect alongside<br />

freight containers, trucks or hoppers as loading space<br />

can be reduced by up to 50%.<br />

Another major difference between Teletruks and<br />

conventional masted forklifts is the degree to which the<br />

forks can be rotated forwards-back. Masted industrial<br />

forklifts only offer 6-8° of forwards-tilt for work with<br />

pallets in storage racking. But the Teletruk 35D carriage<br />

rotates 111° allowing excellent back-tilt so there can be<br />

no danger of difficult loads becoming dislodged from<br />

the forks during yard travel.<br />

The most important benefits come from the Teletruk’s<br />

telescopic boom. With excellent visibility and a reach<br />

of 2430mm, this ensures that hazardous loads are<br />

kept well away from the operator. Plus, full cab air-<br />

conditioning is an option no operator should be<br />

without if by-product fumes are present.<br />

Another very versatile machine for mills and foundries<br />

is the <strong>JCB</strong> Robot skid steer loader. This unique machine<br />

is the only skid steer to offer a maximum-safety, cab<br />

door side-entry design. With a single loader tower for<br />

optimum visibility, the Robot is a compact and highly<br />

manoeuvrable machine which allows direction changes<br />

to be made within the machine length. There is also a<br />

choice of extra-safety kits; heavy-duty bars, front-<br />

screen guards, level II FOPS guards and shatter-proof<br />

screens. It’s a versatile, productive and safe partner<br />

machine for the Teletruk 35D.

FAST FACTS<br />

● Teletruk 35D can load and<br />

unload from one side<br />

● Teletruk 111° carriage tilt<br />

keeps loads stable during<br />

travel<br />

● Telescopic boom keeps<br />

hazardous materials away<br />

from the operator<br />

● <strong>JCB</strong> Robot features maximum<br />

safety, side-entry design<br />

● Special kits enhance Robot<br />

safety even further

THE BEST BACK-UP IN THE BUSINESS<br />

Always on hand to help<br />

You demand more from your machines than ever before:<br />

more efficiency, more reliability, more performance. That’s why<br />

superb product support has never been so vital.<br />

Together with our extensive dealer<br />

network, at <strong>JCB</strong> we’re as innovative<br />

and forward-thinking when it comes<br />

to customer care as we are in<br />

machine development. Our product<br />

support and after-sales service have<br />

one aim: to give you peace of mind.<br />

The care and quality we offer is exceptional. All servicing<br />

is carried out by the best, factory-trained <strong>JCB</strong> engineers.<br />

Using the internet to pass vital information between on-site<br />

service personnel and our product support engineers,<br />

these professionals always have specialist information at their<br />

fingertips, so they can get you up and running again, faster.<br />

Protect your machine and your cashflow<br />

Everyone has individual needs and preferences. So we offer<br />

a range of service options all designed to help you cope with<br />

the unexpected and minimise costly downtime. Whether it’s<br />

additional breakdown cover, an all-inclusive scheduled service<br />

programme, or servicing, we’ve got the best service option<br />

for you.<br />

Finance packages, tailored to your needs<br />

With ever-growing pressures on cashflows, the finance options<br />

available through <strong>JCB</strong> can provide a vital lifeline. Backed by <strong>JCB</strong><br />

Finance, who can provide tax-efficient and cost-effective finance<br />

solutions, designed and tailored specifically to your needs.<br />

Trust the genuine article<br />

<strong>JCB</strong> parts are renowned worldwide for performance, reliability<br />

and safety. With replacement parts, we supply only the genuine<br />

article, helping to safeguard the impressive residual values that<br />

you can expect in years to come.<br />

As well as large stocks of parts engineered specifically for your<br />

machine, your <strong>JCB</strong> dealer also holds an extensive range of<br />

<strong>JCB</strong> premium lubricants, <strong>JCB</strong> filters and <strong>JCB</strong> Powermaster<br />

batteries, all manufactured to the same exacting standards.<br />

Your requirements can usually be supplied immediately by our<br />

dealers, but where this is not possible they can be ordered<br />

through the direct computer link between your dealer and<br />

<strong>JCB</strong> Service and processed through our impressive automated<br />

World Parts Centre warehouse. Despatch is normally the<br />

same day either to you or the dealer.<br />

Whether we’re providing you with support, parts or<br />

finance, we aim for 100% satisfaction. It’s all part of<br />

our promise to put you, the customer, first.<br />

<strong>JCB</strong> Sales Limited, Rocester, Staffordshire ST14 5JP. Tel: 01889 590312. Fax: 01889 590588. Web: http://www.jcb.com<br />

©2006 <strong>JCB</strong> Sales. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or<br />

otherwise, without prior permission from <strong>JCB</strong> Service. <strong>JCB</strong> reserves the right to change specifications without notice. Illustrations & specifications shown may include optional equipment and accessories.<br />

The <strong>JCB</strong> logo is a registered trademark of J C Bamford Excavators Ltd. Printed in England. 9999/5225 1/06 Issue 1