Please click for content. - Orhan Holding

Please click for content. - Orhan Holding

Please click for content. - Orhan Holding

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Euro 5 changement and hot pin applications<br />

The effects of environmental pollution and global warming<br />

are seen through the eyes in recent years and<br />

environmental consciousness is getting more and more<br />

importance day by day.With the acceptance of Kyoto<br />

protocol which focuses on global warming and climate<br />

cahnges , each country and each sector had to have<br />

responsibilities on environment.<br />

Considering that more than one billion vehicles on road<br />

every day; exhaust gases has very large impact on<br />

environmental pollution .When fuel is conbusted <strong>for</strong> an<br />

engine; nitrogen oxides (NOx), Carbon oxides (COx),<br />

Hydrocarbons (HC) and particle materials are released<br />

with in the exhaust gas<br />

• Nitrogen Oxide (NOx): is the result of high temperature<br />

combustion, mixed with water and turns into acid rain.<br />

• Carbon Monoxide (CO): is released as a result of<br />

inefficient conbustion. It is colorless, odorless and not toxic<br />

irritant gas.But it has much more powerfull greenhouse<br />

effect.<br />

• Hidro Karbon: It is released with unburned fuel.<br />

• Particle materials (PM): are smaller than 2,5 μm, and<br />

filled bronchus.<br />

Because of that automotive sector is started to work<br />

towards raducing emisyon gases with Euro 1 (1993) and<br />

continue job by stages.<br />

As Nobel Automotive , our products are fuel lines and<br />

surely we have to develope our products com<strong>for</strong>ming to<br />

Euro normes.<br />

For the Euro5 changement, our serial raw materials PA11,<br />

PA12 replaced by harder, lower permeability and high<br />

per<strong>for</strong>mance material MLT 4300, MLT4540, EVX which<br />

includies EVOH .<br />

Banu YILMAZ<br />

Project Engineer<br />

21<br />

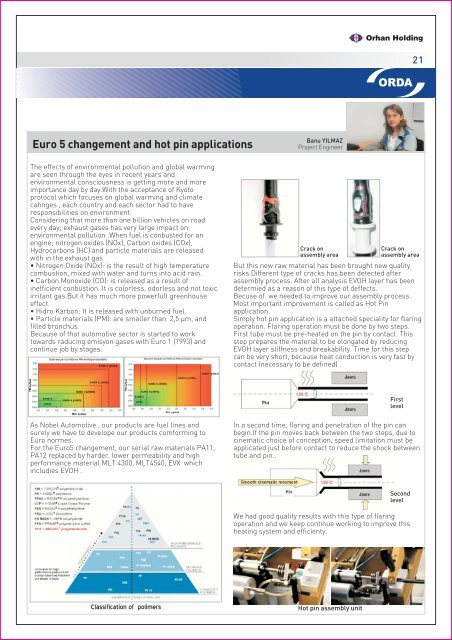

But this new raw material has been brought new quality<br />

risks.Different type of cracks has been detected after<br />

assembly process. After all analysis EVOH layer has been<br />

determied as a reason of this type of deffects.<br />

Becuse of we needed to improve our assembly process.<br />

Most important improvement is called as Hot Pin<br />

application.<br />

Simply hot pin application is a attached speciality <strong>for</strong> flaring<br />

operation. Flaring operation must be done by two steps.<br />

First tube must be pre-heated on the pin by contact. This<br />

step prepares the material to be elongated by reducing<br />

EVOH layer stiffness and breakability. Time <strong>for</strong> this step<br />

can be very short, because heat conduction is very fast by<br />

contact (necessary to be defined) .<br />

In a second time, flaring and penetration of the pin can<br />

begin.If the pin moves back between the two steps, due to<br />

cinematic choice of conception, speed limitation must be<br />

applicated just be<strong>for</strong>e contact to reduce the shock between<br />

tube and pin..<br />

We had good quality results with this type of flaring<br />

operation and we keep continue working to improve this<br />

heating system and efficienty.<br />

Hot pin assembly unit<br />

First<br />

level<br />

Second<br />

level