AN EXPERIMENTAL ON USE OF FLY ASH PELLETS IN CONCRETE IN PLACE OF

A construction industry plays vital role in India which leads into the economic developments. The materials like fine aggregate, coarse aggregate are used to prepare cement concrete which are easily available natural resources in our country, but now there is high demand in materials which have gone to a high scenario. The quantity of fly ash produced from thermal power plants in India is approximately 80 million tons each year, and its percentage utilization is less than 10%. Majority of fly ash produced is of Class F type. During the last few years, some cement companies have started using fly ash in manufacturing cement, known as ‘Pozzalanic Portland cement. It mainly concentrated on replacement of cement with fly ash but production of artificial aggregate with fly ash helps in utilizing large volume of fly ash in concrete. The world is much interested in this part recently due to this large scale utilization which also reduces environmental pollution and dwindling of natural resources.

A construction industry plays vital role in India which leads into the economic developments. The materials like fine

aggregate, coarse aggregate are used to prepare cement concrete which are easily available natural resources in our

country, but now there is high demand in materials which have gone to a high scenario.

The quantity of fly ash produced from thermal power plants in India is approximately 80 million tons each year, and its

percentage utilization is less than 10%. Majority of fly ash produced is of Class F type. During the last few years, some

cement companies have started using fly ash in manufacturing cement, known as ‘Pozzalanic Portland cement. It mainly

concentrated on replacement of cement with fly ash but production of artificial aggregate with fly ash helps in utilizing

large volume of fly ash in concrete. The world is much interested in this part recently due to this large scale utilization

which also reduces environmental pollution and dwindling of natural resources.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

International Journal of Research and Innovation (IJRI)<br />

any other method of fly ash disposal. It is however necessary<br />

to have the following three conditions fulfilled for<br />

satisfactory operation by this system:<br />

• Availability of large areas of waste land for ponding;<br />

• Regular emptying of filled up ponds and<br />

• Unrestricted water supply.<br />

PROBLEM STATEMENT<br />

Many studies done on fly ash aggregates fully replacement<br />

of coarse aggregate in concrete. By the replacement<br />

of fly ash aggregate saving our natural resources and less<br />

labour is used by not shipping raw material from distant<br />

places to where glass is available saving time and money.<br />

First we can prepare fly ash aggregate 15:85 ratio of cement<br />

fly ash at 0.3 water cement ratio. By the replacement<br />

of this fly ash aggregate, and a basic experimental<br />

study on the physical and mechanical properties of concrete<br />

containing fly ash aggregate was carried out.<br />

THESIS LAYOUT<br />

Chapter 2 includes general literature over view for studying<br />

the use of fly ash aggregate in engineering properties.<br />

This research highlighted the different properties of fly<br />

ash aggregate and behavior of concrete at different percentages<br />

of fly ash aggregate replacement in to that.<br />

Chapter 3 discusses scope and objective of the present<br />

project<br />

Chapter 4 displays the descriptive variables in the experimental<br />

testing considering the properties of aggregates<br />

and raw materials. This chapter states with different raw<br />

components of concrete, sieve analysis, concrete mix, the<br />

test results of concrete and compressive strength of hardened<br />

concrete. This chapter ends with a detailed list of the<br />

different proportions of fly ash aggregate used in concrete.<br />

SCOPE <strong>AN</strong>D OBJECTIVES<br />

This research is mainly focusing on studying the effect of<br />

fly ash aggregate on the properties of concrete mixtures<br />

as a partially replacement of coarse aggregate.<br />

Within the scope of this study, the main goal is to improve<br />

compressive strength of concrete at what percentage of<br />

replacement of fly ash aggregate. Fly ash is the cheapest<br />

material of all concrete constituents and is much less<br />

expensive than natural aggregate and sand as possible to<br />

save money.<br />

The main aim of the research is to study the effect of concrete<br />

when partially replacing the fly ash aggregate in to<br />

the concrete. This objective can be achieved through the<br />

following conditions:<br />

• To determine normal consistency, initial and final setting<br />

times, soundness and fineness of cement.<br />

• To study specific gravity, water absorption of coarse aggregate<br />

of normal and fly ash aggregate.<br />

• To find out specific gravity, water absorption of fine aggregate<br />

of river sand and fly aggregate.<br />

• To examine the effects of these substances with different<br />

dosages like 10%, 20%, 30% and 40% replacement of<br />

coarse aggregate by weight in the concrete cubes on short<br />

term and long term strength development by finding the<br />

compressive strength values at different ages i.e. 3 days,<br />

7 days, 28 days, 60 days and 90 days.<br />

• To assess split tensile strength of conventional concrete<br />

and partially replacement of fly ash aggregate.<br />

• To find the strength of cement concrete cubes after conducting<br />

various durability test like Acid Test<br />

• To identify the chemical compounds formed in different<br />

combinations of cement concrete by assessing the spatial<br />

variations in the chemical compositions which was done<br />

by using X-Ray diffraction studies.<br />

RESEARCH METHODOLOGY<br />

The following are to be carried out in order to achieve the<br />

research objectives.<br />

•To collect the fly ash from thermal power plant RTPP.<br />

•Prepare the fly ash aggregate at 15:85 proportions.<br />

•To study about the fly ash aggregate.<br />

•Experimental study on strength replacement of fly ash<br />

aggregate in concrete.<br />

•Analyse the experimental results to draw conclusions.<br />

MATERIALS <strong>AN</strong>D METHODS<br />

GENERAL<br />

The physic-chemical properties of cement, sand , granite<br />

aggregate and water used in the investigation were analyzed<br />

based on and the standard experimental procedure<br />

laid down in the standard codes, like IS, ASTM and BS<br />

codes. These standard experimental procedures were<br />

adopted for the determination of normal consistency,<br />

initial and final setting times, soundness of cement and<br />

compressive strength and split tensile strength.<br />

MATERIALS<br />

The materials used in the present experimental investigation<br />

include;<br />

1. Cement : Ordinary Portland cement (OPC)<br />

2. Mineral admixtures : Fly ash<br />

3. Fine aggregate : Sand<br />

4. Coarse aggregate<br />

a) Granite<br />

b) Fly ash aggregate<br />

5. Water<br />

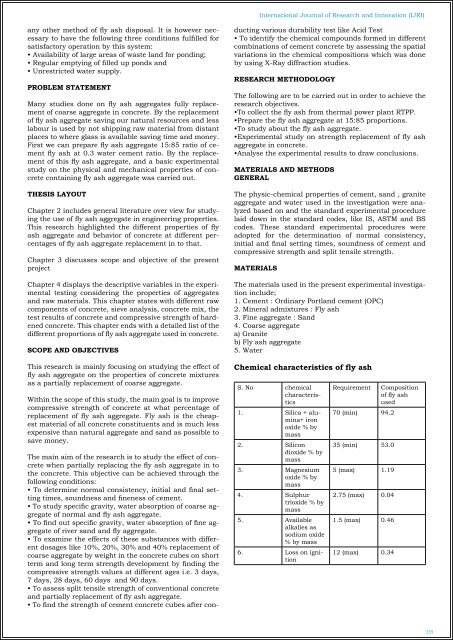

Chemical characteristics of fly ash<br />

S. No chemical<br />

characteristics<br />

1. Silica + alumina+<br />

iron<br />

oxide % by<br />

mass<br />

2. Silicon<br />

dioxide % by<br />

mass<br />

3. Magnesium<br />

oxide % by<br />

mass<br />

4. Sulphur<br />

trioxide % by<br />

mass<br />

5. Available<br />

alkalies as<br />

sodium oxide<br />

% by mass<br />

6. Loss on ignition<br />

Requirement Composition<br />

of fly ash<br />

used<br />

70 (min) 94.2<br />

35 (min) 53.0<br />

5 (max) 1.19<br />

2.75 (max) 0.04<br />

1.5 (max) 0.46<br />

12 (max) 0.34<br />

235