Building Design Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.BDCuniversity.com<br />

www.BDCnetwork.com<br />

May 2016<br />

19 TH ANNUAL<br />

BUILDING TEAM<br />

AWARDS<br />

2014 + 2015 +2016<br />

JESSE H. NEAL<br />

AWARD WINNER<br />

2014 + 2015<br />

JESSE H. NEAL<br />

AWARD WINNER<br />

Fulton Center<br />

New York, N.Y.

Contemporary Curve<br />

Jefferson County Western Health Center, Midfield, AL<br />

Owner: Jefferson County Department of Health<br />

Architect: Birchfield Penuel & Associates, Birmingham, AL<br />

General contractor: M.J. Harris <strong>Construction</strong> Services, Birmingham, AL<br />

Installing contractor: CSC Roofing, Birmingham, AL<br />

Profiles: Tite-Loc curved, Reveal Wall Panels<br />

Colors: Cardinal Red, Sierra Tan<br />

“The curved roof in Cardinal Red and the Sierra Tan<br />

metal wall panels complement the other materials<br />

and really create a contemporary appearance...”<br />

Tom Kidwell, senior associate and project architect, Birchfield Penuel & Associates<br />

REVEAL<br />

Sierra Tan - Energy Star - Cool Color<br />

TITE-LOC<br />

Cardinal Red - Energy Star - Cool Color<br />

CASE STUDY<br />

See us at the AIA Expo - booth 2225<br />

<br />

PAC-CLAD.COM | IL: 1 800 PAC CLAD | MD: 1 800 344 1400 | TX: 1 800 441 8661 | GA: 1 800 272 4482 | MN: 1 877 571 2025<br />

Circle 751

DAVID REVETTE/REVETTE STUDIO INC.<br />

25<br />

MAY<br />

COVER STORY<br />

VOLUME 57, NO. 05<br />

19th Annual<br />

<strong>Building</strong> Team Awards<br />

BD+C’s <strong>Building</strong> Team Awards is the industry’s only recognition program to<br />

honor projects both for their design/construction excellence and the successful<br />

collaboration of the AEC team. This year, we honor 12 world-class projects.<br />

ABOVE<br />

The Onondaga Lakeview Amphitheater,<br />

near Syracuse, N.Y., seats 17,500. It is the<br />

first phase of a more extensive revitalization<br />

initiative that will benefit two nearby<br />

communities. The project won a Platinum<br />

Award in BD+C’s 19th annual <strong>Building</strong><br />

Team Awards. More on page 26.<br />

PLATINUM AWARDS 26 / 30<br />

GOLD AWARDS 34 / 38<br />

SILVER AWARDS 40 / 42<br />

BRONZE AWARDS 44 / 48 / 50 / 52<br />

HONORABLE MENTIONS 54 / 56<br />

MEET THE JUDGES 58<br />

FEATURES<br />

60 5 FACTORS GUIDING<br />

RESTAURANT DESIGN<br />

Restaurants are for more than just eating,<br />

with tech-driven dining experiences, art<br />

installations, and bolder designs.<br />

2014 JESSE H. NEAL<br />

AWARD WINNER<br />

Best Single Issue<br />

Best Instructional Content<br />

2015 JESSE H. NEAL<br />

AWARD WINNER<br />

Best Newsletter<br />

Best Subject-Related Package<br />

2016 JESSE H. NEAL<br />

AWARD WINNER<br />

Best Website<br />

Body of Work by a Single Author<br />

AIA CONTINUING<br />

EDUCATION<br />

71 PREVENTING AND TREATING<br />

DISTRESS IN BRICK VENEER<br />

CAVITY WALLS<br />

Earn 1.0 AIA CES HSW learning units<br />

by studying this article and successfully<br />

completing the online exam.<br />

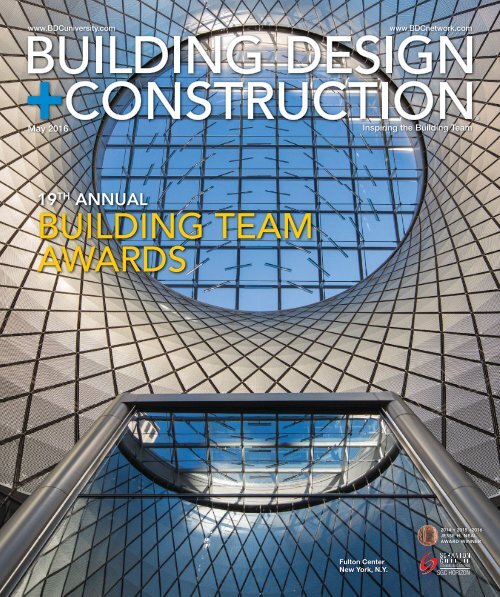

ON THE COVER<br />

A 53-foot-diameter oculus looms over the<br />

grand atrium of the new Fulton Center transit<br />

station in Lower Manhattan. Suspended<br />

under tension within the conical atrium is<br />

the “Sky Reflector-Net,” by James Carpenter<br />

<strong>Design</strong> Associates, Grimshaw Architects,<br />

and Arup. The Fulton Center is a Platinum<br />

Award winner in BD+C’s 19th annual <strong>Building</strong><br />

Team Awards. More on page 30.<br />

PHOTO: © JAMES EWING / OTTO<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 3

© 2016 Technical Glass Products. UL and the UL logo are trademarks of UL LLC. Pilkington Pyrostop is a registered trademark of Pilkington plc. Technical Glass Products, One Source. Many Solutions,<br />

Fireglass and Fireframes ClearFloor are registered trademarks of Technical Glass Products.

The Fireframes ClearFloor® System from Technical Glass Products is<br />

a clear departure from the expected. Bring daylight deep into building<br />

interiors, creating dramatic visual effects between levels. This innovative,<br />

UL-classified system, combines steel framing and Pilkington Pyrostop®<br />

glass for impact resistance and a 2-hour fire-rating.<br />

Find out more about this groundbreaking floor at<br />

fireglass.com/clearfloor<br />

fireglass.com | 800.426.0279<br />

Circle 752

DEPARTMENTS<br />

09 EDITORIAL<br />

Is the nation’s tech boom<br />

really an innovation funk?<br />

U.S. hotel built with 100%<br />

cross-laminated timber<br />

construction<br />

Out of Sight...<br />

Peace of Mind<br />

Automatic Smoke and Fire Curtains<br />

Open Up <strong>Design</strong> Possibilities<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

10 NEWS<br />

Nation’s school buildings face<br />

$46 billion funding shortfall<br />

20 ON THE DRAWING<br />

BOARD<br />

Aquarium of the Pacifi c<br />

unveils a whale of a project<br />

80 NEW PROJECTS<br />

PORTFOLIO<br />

Candlewood Suites fi rst<br />

BD+Cnetwork.com<br />

82 PRODUCTS AT WORK<br />

Starbucks specifi es highperformance<br />

fl oor to keep<br />

up with foot traffi c<br />

86 ADVERTISER INDEX<br />

90 PRODUCT SOLUTIONS<br />

Outdoor charging stations<br />

blur the line between inside<br />

and outside<br />

e-Contents<br />

TOP STORIES ON BDCNETWORK.COM<br />

Why drawing remains relevant in the design process. Handdrawn<br />

concepts allow ideas to emerge and build stronger connections<br />

between the design and the audience, writes Gensler <strong>Design</strong><br />

Director Alex Fernández. www.BDCnetwork.com/Sketching<br />

Santiago Calatrava tower in Dubai could be taller than the<br />

Burj Khalifa. The slender structure will have 10 observation platforms,<br />

two Hanging Garden decks, and a illuminating fl ower bud at<br />

the top. www.BDCnetwork.com/DubaiCalatrava<br />

Carbon fiber strings make Japanese office building earthquake<br />

resistant. Kengo Kuma developed the rods, which are<br />

stronger and lighter than iron. www.BDCnetwork.com/QuakeStrings<br />

Skanska will use Microsoft HoloLens to lease planned Seattle<br />

high rise. The mixed reality headset will allow people to take a<br />

holographic tour of the building while keeping visual contact with the<br />

leasing representative. www.BDCnetwork.com/HoloLens<br />

Should architects learn to code? Even if learning to code does<br />

not personally interest you, the growing demand for having these<br />

capabilities in an architectural business cannot be overlooked, writes<br />

computational design expert Nathan Miller. www.BDCnetwork.com/<br />

Coding<br />

<br />

Circle 753<br />

FOLLOW BD+C ON TWITTER & LINKEDIN<br />

‘LIKE’ BD+C ON FACEBOOK<br />

6 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

BRING<br />

YOUR<br />

VISION.<br />

SunGuard ® SNX 51/23<br />

Visit us at AIA: Booth #4025<br />

“Our choice in glass opens up a historical<br />

structure to highlight its character, while creating<br />

a bright, comfortable, modern workplace.<br />

SNX 51/23 delivers exceptional clarity and energy<br />

performance, without unwanted tint or reflections.”<br />

JOSH BOLTINHOUSE, AIA, LEED AP | LAMBERT ARCHITECTURE + CONSTRUCTION SERVICES<br />

522 LADY STREET, COLUMBIA, SC<br />

©2016 Guardian Industries | Guardian.com/commercial | 1.866.GuardSG (866.482.7374)<br />

Circle 754

9 OUT OF 10 CONTRACTORS AGREE —<br />

ULTRA SPEC ® 500 SAVES TIME<br />

AND EFFORT ON THE JOB *<br />

Formulated to meet the needs of<br />

professional contractors: Smooth application,<br />

quick dry-time & fast job turnaround<br />

To find your local Benjamin Moore® retailer visit benjaminmoore.com<br />

*Based on an independently conducted 2014 survey of 453 professional painters who were questioned about the paint<br />

product they last used. Zero VOC according to EPA Method 24. © 2016 Benjamin Moore & Co. Benjamin Moore, Green Promise,<br />

Paint like no other, Ultra Spec and the triangle “M” symbol are registered trademarks licensed to Benjamin Moore & Co.<br />

Circle 755

editorial<br />

3030 W. Salt Creek Lane, Suite 201<br />

Arlington Heights, IL 60005-5025<br />

847.391.1000 • Fax: 847.390.0408<br />

STAFF<br />

EDITORIAL DIRECTOR<br />

David Barista<br />

847.954.7929; dbarista@sgcmail.com<br />

EXECUTIVE EDITOR<br />

Robert Cassidy<br />

847.391.1040; rcassidy@sgcmail.com<br />

SENIOR EDITOR<br />

John Caulfield<br />

732.257.6319; jcaulfield@sgcmail.com<br />

ASSOCIATE EDITORS<br />

Michael Chamernik; mchamernik@sgcmail.com<br />

David Malone; dmalone@sgcmail.com<br />

CONTRIBUTING EDITORS<br />

Susan Bady, Peter Fabris, Mike Plotnick, Adam<br />

Sullivan, C.C. Sullivan<br />

DESIGNER<br />

Cathy LePenske<br />

WEB DESIGNER<br />

Agnes Smolen<br />

EDITORIAL ADVISORS<br />

David P. Callan, PE, CEM, LEED AP, HBDP<br />

Senior Vice President, McGuire Engineers, Inc.<br />

Patrick E. Duke<br />

Senior Vice President, CBRE Healthcare<br />

Carolyn Ferguson, FSMPS, CPSM<br />

President, WinMore Marketing Advisors<br />

Josh Flowers, AIA, LEED AP BD+C<br />

General Counsel, Hnedak Bobo Group<br />

Emily Grandstaff-Rice, AIA, LEED AP BD+C<br />

Senior Associate, Arrowstreet Inc.<br />

Arlen Solochek, FAIA<br />

Associate Vice Chancellor, Maricopa County CCD<br />

Philip Tobey, FAIA, FACHA<br />

Senior Vice President, SmithGroupJJR<br />

Peter Weingarten, AIA, LEED AP<br />

Director of the Architectural Practice, Gensler<br />

GROUP DIRECTOR - PRINCIPAL<br />

Tony Mancini<br />

610.688.5553; tmancini@sgcmail.com<br />

EVENTS MANAGER<br />

Judy Brociek<br />

847.954.7943; jbrociek@sgcmail.com<br />

DIRECTOR OF AUDIENCE DEVELOPMENT<br />

Doug Riemer<br />

For list rental information, contact Geffrey Gardner at<br />

845.201.5331; geffrey.gardner@reachmarketing.com<br />

CREATIVE SERVICES ASSISTANT MANAGER<br />

Holly Dryden<br />

MARKETING DIRECTOR<br />

Michael Porcaro<br />

SUBSCRIPTION INQUIRIES<br />

Circulation Department<br />

<strong>Building</strong> <strong>Design</strong>+<strong>Construction</strong><br />

3030 W. Salt Creek Lane, Suite 201<br />

Arlington Heights, IL 60005-5025<br />

CORPORATE<br />

Chairman Emeritus (1922-2003)<br />

H.S. Gillette<br />

Chairperson<br />

K.A. Gillette<br />

President/CEO<br />

E.S. Gillette<br />

Senior Vice Presidents<br />

Ann O’Neill, Rick Schwer<br />

Senior Vice President/CFO<br />

David Shreiner<br />

Vice President of Custom Media & Creative Services<br />

Diane Vojcanin<br />

For advertising contacts, see page 86.<br />

is the nation’s grand tech boom<br />

REALLY AN INNOVATION FUNK?<br />

In a world with self-driving cars, holographic gaming,<br />

drone-delivered pizza, AI computers, hoverboards<br />

(ones that actually hover), 24/7 connectivity to every<br />

corner of the world, heck, even one-hour grocery<br />

deliveries, it’s diffi cult to comprehend the thought that<br />

we’re in a downcycle of technological achievement.<br />

The stuff of science fi ction truly has become<br />

reality: we’re wearing watches that allow<br />

us to make video calls; we’re running<br />

our businesses and lives from robust, handheld<br />

computers; we’re using deep data and connectivity<br />

to reinvent business models; we’re powering<br />

our homes, offi ces, and cars with wind, solar,<br />

geothermal, and battery sources; we’re programming<br />

robots to clean our houses, assemble our<br />

products, construct our buildings, even cook<br />

our food; we’re conducting advanced surgical<br />

procedures remotely, and in a fraction of the time.<br />

The list goes on and on.<br />

But is all this stuff—the gadgets, the apps,<br />

the micro-computers, the entertainment and<br />

media—actually enriching the nation’s standard<br />

of living? Is it igniting the economy to benefi t<br />

the greater good? Does it make us happier and<br />

more fulfi lled as a nation?<br />

By and large, no, argues American economist<br />

and Northwestern University social sciences<br />

professor Robert J. Gordon, in his new book,<br />

“The Rise and Fall of American Growth: The U.S.<br />

Standard of Living Since the Civil War” (http://<br />

amzn.to/1qOPVr2).<br />

Gordon asserts that, despite popular belief,<br />

the country is not in a great age of technological<br />

and digital innovation. Actually, it’s quite the<br />

contrary—we’re in the midst of a tech innovation<br />

downturn, at least when compared to the last<br />

great innovation era: 1870 to 1970.<br />

During that time, writes Gordon, medical<br />

breakthroughs raised the average life expectancy<br />

from 45 to 72; transportation advanced from<br />

horse and buggy to car to plane (to spaceship!);<br />

communication progressed from paper to radio<br />

to television (email was invented two years later,<br />

in 1972). Homeownership skyrocketed (especially<br />

after WWII), and houses featured modern<br />

luxuries like electric lighting, indoor plumbing,<br />

and home appliances.<br />

Gordon contends that the century-long period<br />

following the Civil War is unlike anything we are<br />

ever going to see again. He posits that some<br />

inventions are more important than others, and<br />

that the post-Civil War era just happened to<br />

produce a multitude of game changers across<br />

nearly every major industry. The light bulb, internal-combustion<br />

engine, mason jar, condensed<br />

milk, refrigerator, elevator, anesthetics, X-ray,<br />

antibiotics, antiseptic surgery, waterworks, assembly<br />

line (and the 40-hour work week)—add<br />

them up and then consider your iPhone. Not so<br />

impressive, is it?<br />

In his recent review of Gordon’s book, BD+C<br />

Associate Editor David Malone suggests that<br />

Gordon’s modern tech slowdown could actually<br />

be the calm before the storm. The apps,<br />

the data, the gadgets, the evermore-powerful<br />

computers, the infi nitely connected world, the<br />

nanosciences—they’re in their infancy. The<br />

world’s brightest minds (human and synthetic;<br />

think IBM’s Watson) need time to invent, solve,<br />

ideate, collaborate, innovate, improve, perfect.<br />

I don’t know about you, but I choose to<br />

believe that we’re on the cusp of the next great<br />

era of innovation. The question remains: Will the<br />

results improve or diminish our quality of life?<br />

David Barista, Editorial Director<br />

dbarista@sgcmail.com<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 9

news<br />

BY JOHN CAULFIELD, SENIOR EDITOR<br />

NATION’S SCHOOL BUILDING NEEDS FACE<br />

$46 BILLION ANNUAL FUNDING SHORTFALL<br />

The nation faces a projected annual<br />

shortfall of $46 billion in school funding,<br />

according to “The State of Our<br />

Schools: America’s K-12 Facilities,” a new<br />

report by the Center for Green Schools at<br />

the U.S. Green <strong>Building</strong> Council (USGBC),<br />

the 21st Century School Fund, and the<br />

National Council on School Facilities.<br />

The report features in-depth, state-by-state<br />

analysis of investment in school infrastructure<br />

and a perspective on 20 years of school facility<br />

investment nationwide. It also makes recommendations<br />

for investments, innovations,<br />

and reforms to improve learning environments<br />

in all U.S. public schools.<br />

Currently, six states (Massachusetts,<br />

RSMEANS COSTS COMPARISONS: SPORTS FACILITIES<br />

ENCLOSED<br />

SWIMMING POOL<br />

RACQUETBALL<br />

COURT<br />

BOWLING<br />

ALLEY<br />

HOCKEY RINK/<br />

SOCCER<br />

’16 ’16 ’16 ’16<br />

Atlanta 229.05 163.25 149.62 159.98<br />

Baltimore 240.03 171.08 156.79 167.65<br />

Boston 302.08 215.31 197.32 210.99<br />

Chicago 303.36 216.22 198.16 211.88<br />

Cleveland 252.54 180.00 164.97 176.39<br />

Dallas 220.37 157.07 143.95 153.92<br />

Denver 236.71 168.71 154.62 165.33<br />

Detroit 263.52 187.82 172.14 184.06<br />

Houston 224.20 159.80 146.45 156.59<br />

Kansas City, Mo. 264.03 188.19 172.47 184.41<br />

Los Angeles 280.12 199.65 182.98 195.65<br />

Miami 221.90 158.16 144.95 154.99<br />

Minneapolis 281.40 200.56 183.81 196.54<br />

New Orleans 222.92 158.89 145.62 155.70<br />

New York City 335.02 238.78 218.84 234.00<br />

Philadelphia 294.93 210.21 192.65 205.99<br />

Phoenix 224.96 160.34 146.95 157.13<br />

Pittsburgh 262.76 187.28 171.64 183.52<br />

Portland, Ore. 259.18 184.73 169.30 181.03<br />

St. Louis 262.76 187.28 171.64 183.52<br />

San Diego 270.42 192.74 176.64 188.87<br />

San Francisco 317.91 226.59 207.67 222.05<br />

Seattle 264.29 188.37 172.64 184.59<br />

Washington, D.C. 249.22 177.63 162.80 174.07<br />

Winston-Salem, N.C. 222.41 158.52 145.28 155.34<br />

COSTS IN DOLLARS PER SQUARE FOOT FOR MORE DATA, VISIT RSMEANS AT WWW.RSMEANS.COM, OR CALL (800) 448-8182.<br />

Note to readers: In an effort to ensure that we are providing the most accurate and current data, RSMeans<br />

is changing the components of its models to keep them in line with industry standards. Therefore, displayed<br />

costs for the models should not be compared to RSMeans costs from previous years. Please call RSMeans<br />

with specifi c questions regarding the changes: (800) 448-8182.<br />

School districts should be spending $145 billion<br />

a year on buildings, but are $46 billion short.<br />

Wyoming, Connecticut, Ohio, Kentucky, and<br />

Hawaii) pay for all or nearly all of the capital<br />

construction costs for schools in their state;<br />

12 states (Idaho, Indiana, Louisiana, Michigan,<br />

Missouri, Nebraska, Nevada, Oklahoma,<br />

Oregon, South Dakota, Tennessee, and Wisconsin)<br />

provide no direct support to districts<br />

for capital construction responsibilities. In the<br />

remaining 32 states, the level of state support<br />

varies greatly, and the federal government<br />

contributes almost nothing to capital construction<br />

to help alleviate disparities.<br />

The report identifi es four key strategies for<br />

addressing the structural defi cits in the K–12<br />

public education infrastructure:<br />

• Understand public school facilities conditions<br />

and provide communities access to<br />

accurate data about school facilities.<br />

• Engage in education facilities planning<br />

using best practices from across the country<br />

and support local communities in proposing<br />

creative and practical plans to improve their<br />

public school facilities.<br />

• Support new public funding to provide<br />

what is needed to build and maintain adequate<br />

and equitable school facilities.<br />

• Leverage public and private resources to<br />

extend a community’s investments, utilizing<br />

a new generation of structures, funding<br />

streams, and partnerships.<br />

More at: www.BDCnetwork.com/<br />

K12schoolsUSGBC<br />

10 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

WHEN THE BEST WANT THE BEST<br />

TWO HOUR FIRE RESISTIVE CURTAIN WALL<br />

2 HOUR FIRE RESISTIVE GLASS<br />

INTERIOR/ELEVATOR ENCLOSURE<br />

WITH SUPERLITE II-XL 120<br />

IN GPX CURTAIN WALL FRAMING<br />

Architect:<br />

Sieger Suarez Architects<br />

General Contractor:<br />

Coastal <strong>Construction</strong> Group<br />

of South Florida Inc.<br />

Glazing Contractor:<br />

Continental Glass Systems<br />

RENDERING COURTESY OF METROSTUDIO.COM<br />

S I E G E R S U A R E Z A R C H I T E C T S<br />

60-STORY PORSCHE DESIGN TOWER<br />

TM<br />

Made in USA<br />

Circle 756

news<br />

MEDICAL OFFICES ARE BEST BET FOR<br />

HEALTH REALTY INVESTORS: CBRE<br />

Investors in healthcare buildings view multitenant<br />

medical offi ces as their best bet for<br />

return on investments whose fi nancing, to<br />

an increasing degree, leans toward cash<br />

rather than debt.<br />

Those are some of the fi ndings in a 15-page<br />

<strong>Design</strong>ing with CMU?<br />

NO WORRIES<br />

BlockFlash ® , the patented single-wythe CMU<br />

flashing system, is cleverly simple—collect<br />

all the water in the cells, then get rid of it.<br />

It’s simple to install too. Totally reliable by<br />

design, it simply works every time—spec<br />

BlockFlash and have no worries.<br />

report that CBRE’s U.S. Healthcare Capital<br />

Markets Group has released, based on input<br />

from 80 healthcare real estate investors.<br />

Nearly one-third (32%) of all respondents<br />

say they target transactions that fall between<br />

$20 million and $50 million. Another 31%<br />

say that their preferred transaction range is<br />

$10 million to $20 million. Nearly all of the<br />

respondents—96%—are most interested in<br />

medical offi ce buildings as the type of building<br />

that meets their acquisition criteria. The next<br />

preferred building type is ambulatory surgery<br />

centers (63%), wellness centers (41%), and<br />

assisted living facilities (39%).<br />

The total amount of equity that fi rms allocated<br />

for healthcare real estate investment<br />

this year, nearly $14.5 billion, was about 7%<br />

less than the $15.5 billion estimate from the<br />

2015 survey. But the 2016 number is still considerably<br />

higher than estimates in the years<br />

2011 through 2014, and is actually 132%<br />

of the total market transaction volume that<br />

traded in the healthcare sector in 2015.<br />

More at: www.BDCnetwork.com/HCoutlook16<br />

NASCENT WIRELESS<br />

SENSOR MARKET IS<br />

POISED TO ASCEND<br />

IN NEXT DECADE<br />

Over the next decade, revenue from wireless<br />

sensor sales worldwide for installation and<br />

use in commercial structures is expected<br />

to increase at a compound annual rate of<br />

16.5%, a projection that refl ects the growing<br />

demand for products that provide intelligent<br />

Call or email for samples: 800.664.6638 x509 •samples@mortarnet.com<br />

mortarnet.com<br />

($ Millions)<br />

$800<br />

$700<br />

$600<br />

$500<br />

$400<br />

$300<br />

$200<br />

$100<br />

0<br />

North America<br />

Europe<br />

Asia Pacific<br />

Latin America<br />

Middle East & Africa<br />

2016 2017 2018 2019 2020 2021 2022 2023 2024 2025<br />

A new report from Navigant Research foresees<br />

a steady climb in commercial demand for<br />

wireless sensors, as developers and their AEC<br />

partners seek better ways to make their buildings<br />

smarter and more interconnected.<br />

SOURCE: NAVIGANT RESEARCH<br />

Circle 757<br />

12 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

Circle 758

news<br />

BD+C CAPTURES TWO 2016<br />

JESSE H. NEAL AWARDS FOR<br />

EXCELLENCE IN JOURNALISM<br />

<strong>Building</strong> <strong>Design</strong>+<strong>Construction</strong> brought<br />

home two Jesse H. Neal Awards,<br />

considered the “Pulitzer Prize of the<br />

business press,” at the annual awards<br />

luncheon of Connectiv, the Business<br />

Information Association, a division of<br />

the Software & Information Industry Association<br />

(formerly ABM), on April 1.<br />

BD+C won in the Best Website category<br />

for its redesigned BDCnetwork.<br />

com and in the Best Range of Work by<br />

The BD+C team (l. to r.): John Caulfield, Senior<br />

Editor; Tony Mancini, Publisher, Group Director;<br />

David Barista, Editorial Director; Kevin Herda,<br />

Director of IT; and Robert Cassidy, Executive<br />

Editor. (Not pictured: Michael Chamernik and<br />

David Malone, Associate Editors)<br />

a Single Author category for articles by BD+C’s Senior Editor John Caulfi eld. BD+C also<br />

received two Neal Finalist honors, in the Best Technical Content category for its “<strong>Building</strong><br />

Technology Tools” series, and in the Best Instructional Content category for its “What<br />

Went Wrong? Diagnosing <strong>Building</strong> Envelope Distress” education course.<br />

More at: www.BDCnetwork.com/2016neals<br />

building solutions via the Internet of Things.<br />

A new report from market research fi rm<br />

Navigant, “Wireless Sensors for Commercial<br />

<strong>Building</strong>s,” estimates that global sensor<br />

sales will reach $188.2 million this year, and<br />

increase to $745.2 million by 2025.<br />

Sensors capture, communicate, and<br />

may even analyze energy and operational<br />

data, the report states. The resulting<br />

useful information will direct fundamental<br />

changes in operations that lead to energy<br />

effi ciency improvements with substantial<br />

cost savings.<br />

Asia-Pacifi c and European markets are<br />

expected to experience the highest growth;<br />

demand in North America will increase more<br />

modestly. Navigant does not see the Middle<br />

East, Africa, and Latin America as markets<br />

where there will be a high penetration of<br />

wireless sensors in the foreseeable future.<br />

More at: www.BDCnetwork.com/<br />

WirelessSensorsReport<br />

Start every job<br />

with ZipWall ® .<br />

DUST BARRIER SYSTEM 800-718-2255<br />

Sets up in just a few minutes<br />

No ladders, no tape, no damage<br />

See how easy it is at<br />

zipwall.com.<br />

Circle 759<br />

14 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

news<br />

CHICAGO TO<br />

INSTALL 500<br />

SENSORS VIA AN<br />

‘ARRAY OF THINGS’<br />

DATA PROJECT<br />

Chicago will install 50 location-based<br />

sensor devices around the city this<br />

summer, and 450 more by the end of<br />

2018. The so-called Array of Things<br />

project will track temperature, air quality,<br />

light, and traffi c data in an effort to<br />

improve urban life conditions, according<br />

to the Chicago Tribune.<br />

Sensors will be installed into streetlight<br />

traffi c signal poles in the downtown Loop<br />

and in a yet to be decided neighborhood.<br />

The devices will be concentrated in areas<br />

facing such problems as poor air quality<br />

and highly fl uctuating temperatures.<br />

The project, a collaboration of the<br />

University of Chicago, Argonne National<br />

Laboratory, and the School of the Art Institute<br />

of Chicago, received a $3.1 million<br />

grant from the National Science Foundation<br />

last September.<br />

Data from the project will be released<br />

to the public via Chicago’s Open Data<br />

platform a few months after the fi rst sensors<br />

are installed. All software, hardware,<br />

parts, and specifi cations will be published<br />

as open source.<br />

The Array of Things website says that<br />

the technology will serve as a “fi tness<br />

tracker” for Chicago, allowing residents to<br />

monitor exposure to air pollutants and fi nd<br />

the least congested travel routes.<br />

More at: www.BDCnetwork.com/ChicagoSensors<br />

real estate (CRE) and how these trends are<br />

likely to infl uence companies’ and investors’<br />

decisions in the near future.<br />

Drawing from its own research and other<br />

relevant data, JLL depicts an environment<br />

where technology and data intelligence will<br />

Make the Solid Choice<br />

for Efficiency<br />

Insulated Metal Panels Deliver<br />

• Highest R-value per inch<br />

• Reduced potential for air, vapor,<br />

or moisture leaks<br />

• Complete walls in one step<br />

• Easy installation for faster occupancy<br />

• Low maintenance, high durability<br />

transform organizations, where the primacy<br />

of user experience and workplace collaboration<br />

will be strategic imperatives, and where<br />

growth opportunities will expand well beyond<br />

the half-dozen or so metropolises that have<br />

dominated real estate development and<br />

CYBER ATTACKS,<br />

CO-WORKING<br />

ARE AMONG THE<br />

TOP TRENDS IN<br />

COMMERCIAL REAL<br />

ESTATE FOR 2016,<br />

SAYS JLL REPORT<br />

Commercial real estate services and<br />

investment manager JLL has identifi ed 10<br />

trends in a volatile world for commercial<br />

Insulated Metal Panels<br />

Single Element, Multiple Benefits<br />

Circle 760<br />

Learn more at<br />

insulatedmetalpanels.org<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 15

investment in the past.<br />

Here’s a breakdown of JLL’s white paper:<br />

• Threats. Any CRE strategies and policies need to account for an<br />

increasingly dangerous world with elevated geopolitical risk, security<br />

concerns, and uncertainty. Between October 2014 and October 2015,<br />

there was a 56% increase in politically motivated cyber attacks and a<br />

100% increase in criminal-targeted attacks, according to global risk<br />

assessor Control Risks.<br />

• Convergence. As CEOs demand higher performance, CREs<br />

have been integrating human resources and real estate. A poll of 277<br />

corporate-suite executives last October found that 75% expected to<br />

improve workplace productivity and 60% expected improvements in<br />

people and business productivity. More frequent interaction between<br />

company divisions should facilitate some of these gains.<br />

• Experience. More than three-quarters of respondents to JLL’s<br />

latest Global Corporate Real Estate Survey report that leadership has<br />

high hopes for enhancing workplace experience over the next three<br />

years. The physical environment will play a role here, as more companies<br />

make the connection between employee productivity and better<br />

lighting, ventilation, and temperature control.<br />

• Digital drive. By 2020, total mobile subscriptions could reach 9.2<br />

billion worldwide. The ubiquity of digital and third-platform technology<br />

will have a profound impact on real estate and its users.<br />

• Co-working. The number of co-working spaces worldwide grew<br />

to 7,800 in 2015, versus 3,400 in 2013. The number of people using<br />

co-working spaces could hit one million by 2018.<br />

More at: www.BDCnetwork.com/JLLcre16<br />

NEWS BRIEFS ----------------------------------------<br />

HERZOG & DE MEURON has released new renderings showing a<br />

light well in the center of a concave roof for the NATIONAL LIBRARY<br />

OF ISRAEL. The Israeli fi rm MANN SHINAR ARCHITECTS & PLAN-<br />

NERS contributed to the design. www.BDCnetwork.com/IsraelLibrary<br />

The City and Port of Long Beach, Calif., closed on the $520 million<br />

LONG BEACH CIVIC CENTER PROJECT, which calls for a new city<br />

hall, port HQ, main library, public park, and street improvements. ARUP<br />

served as a lead advisor and oversaw fi nancial, commercial, real estate,<br />

design, engineering, and cost consulting on the PUBLIC-PRIVATE<br />

PARTNERSHIP. www.BDCnetwork.com/LongBeachPPP<br />

<strong>Construction</strong> has begun on RUR ARCHITECTURE DPC’S TAIPEI<br />

POP MUSIC CENTER’S SOUTH SITE, a mixed-use center dedicated<br />

to the production and performance of Taiwanese pop music. Plans call<br />

for a 5,000-seat Main Hall, an outdoor performance area for 3,000, and<br />

three live houses for smaller shows. www.BDCnetwork.com/TaipeiPop<br />

Circle 761<br />

Chicago’s historic COOK COUNTY HOSPITAL may be up for redevelopment.<br />

The century-old Beaux Arts–inspired structure, which has<br />

been shuttered since 2002, will become a mixed-use development with<br />

a hotel, apartments, and shops. The CIVIC HEALTH DEVELOPMENT<br />

www.BDCnetwork.com

Premier Products. Premier Partners.<br />

Proven History.<br />

Main Image: INFOMART • Dallas, TX • 1985 | Inset Image: Maple Pine Hardwood Floors<br />

METAL COATINGS<br />

Traditionally for Metal. Now for Hardwood.<br />

For decades, architects have trusted DURANAR ® fluoropolymer<br />

coatings, expertly applied by members of the PPG CAP CERTIFIED<br />

APPLICATOR SM PROGRAM, to protect and beautify aluminum<br />

building components on landmark building projects. Now they can<br />

do the same with hardwood floors finished by the first PPG CAP<br />

program member certified to apply DURETHANE ® wood coatings.<br />

For the first time, architects can specify custom-colored, prefinished<br />

hardwood floors for office buildings, restaurants, hotels and retail<br />

stores with the same confidence they reserve for Duranar metal<br />

coatings applied by traditional PPG CAP program members.<br />

Whether your goal is to add warmth and color to a building’s<br />

interior or exterior, PPG can connect you with a certified<br />

applicator trained and audited to deliver the world-class customer<br />

service, industry-leading technical expertise and accelerated<br />

product delivery your project demands.<br />

To learn more, visit ppgideascapes.com or call 1-888-PPG-IDEA.<br />

Architectural Window<br />

Rutherford, NJ • (201) 939-2200<br />

architecturalwindow.com<br />

Astro Shapes<br />

Struthers, OH • (330) 755-1414<br />

astroshapes.com<br />

Durapaint Industries, Ltd.<br />

Scarborough, ON • (416) 754-3664<br />

durapaint.net<br />

Kawneer Co., Inc.<br />

Bloomsburg, PA • (570) 784-8000<br />

Cranberry Twp., PA • (724) 776-7000<br />

Lethbridge, AB • (403) 320-7755<br />

Springdale, AR • (479) 756-2740<br />

Visalia, CA • (559) 651-4000<br />

kawneer.com<br />

Keymark Corporation<br />

Fonda, NY • (518) 853-3421<br />

Lakeland, FL • (863) 858-5500<br />

keymarkcorp.com<br />

HARDWOOD COATINGS<br />

Sapa Extrusions Americas<br />

Gainesville, GA • (770) 355-1560<br />

Mississauga, ON • (905) 890-8821<br />

Pointe Claire, QC • (514) 697-5120<br />

Portland, OR • (503) 285-0404<br />

Yankton, SD • (605) 665-6063<br />

sapagroup.com<br />

Spectrum Metal Finishing, Inc.<br />

Youngstown, OH • (330) 758-8358<br />

spectrummetal.com<br />

Trojan Architectural Coaters<br />

Pompano Beach, FL • (954) 366-5319<br />

trojanpowder.com<br />

Tecnoglass S.A.<br />

Barranquilla, Colombia • 57-5-373-4000<br />

tecnoglass.com<br />

Windsor Metal Finishing, Inc.<br />

Kissimmee, FL • (407) 932-0008<br />

1stchoicewindsor.com<br />

YKK AP America Inc.<br />

Austell, GA • (678) 838-6000<br />

ykkap.com<br />

Somerset Hardwood Flooring<br />

Somerset, KY • (877) 404-9663<br />

somersetfl oors.com<br />

Duranar, Durathane and the PPG Logo are registered trademarks, PPG IdeaScapes is a trademark and The PPG CAP Certifi ed Applicator Program<br />

and design are servicemarks of PPG Industries Ohio, Inc.<br />

Circle 762

news<br />

GROUP is reported to be ready to invest<br />

$600 million in the project.<br />

www.BDCnetwork.com/CookCoHospital<br />

A new chair lets employees set their own<br />

climate controls. HYPERCHAIR, from Personal<br />

Comfort Systems, was developed by<br />

researchers at the CENTER FOR THE BUILT<br />

ENVIRONMENT AT UC BERKELEY. It uses<br />

heating tape that is woven into the fabric of the<br />

chair to warm the occupant.<br />

www.BDCnetwork.com/Hyperchair<br />

In April, ANSCHUTZ ENTERTAINMENT<br />

GROUP and MGM RESORTS INTERNA-<br />

TIONAL opened their 650,000-sf T-MOBILE<br />

ARENA, in Las Vegas. The $375 million<br />

sports/concert venue is seen as part of Sin<br />

City’s strategy to lure a professional sports<br />

team. www.BDCnetwork.com/T-MobileArena<br />

DREXEL UNIVERSITY’S $3.5 billion UNIVER-<br />

SITY CITY, on the eastern edge of Philadelphia<br />

next to the Schuylkill River, is being designed by<br />

SHoP Architects and West 8. BRANDYWINE<br />

REALTY TRUST shared plans for 700,000 sf of<br />

mixed-use buildings, residential spaces, offi ces,<br />

and education and research facilities.<br />

www.BDCnetwork.com/DrexelCity<br />

About one in 10 households in the U.S. rent<br />

space from a SELF-STORAGE FACILITY.<br />

Some 15 million sf of storage space was<br />

added nationwide last year. Another 500–600<br />

facilities with a total 30 MILLION SF OF<br />

SPACE should be completed in 2016. Their<br />

primary customers: women.<br />

www.BDCnetwork.com/Self-storage<br />

Germany’s INGENHOVEN ARCHITECTS has<br />

designed two towers, a lifestyle residence and<br />

an offi ce high-rise, for Tokyo’s Toranomon District.<br />

At 220 meters, the 122,000-sm Toranomon<br />

Hills Residential Tower will be Tokyo’s<br />

tallest residential structure. The 175,000-sm<br />

Toranomon Hills Business Tower will stand 185<br />

meters tall. The project is being led by Japanese<br />

developer MORI BUILDING.<br />

www.BDCnetwork.com/TokyoTwins<br />

A San Francisco low-income mixed-use<br />

complex, a LOS ANGELES HOMELESS VET-<br />

ERANS HOUSING FACILITY, and student<br />

residential buildings at UMass Amherst were<br />

among the winners in the AIA MULTIFAMILY<br />

AND SPECIALIZED HOUSING projects, part<br />

of the 2016 AIA Housing Awards.<br />

www.BDCnetwork.com/AIAHousingAwards<br />

CLARIFICATION<br />

The April 2015 AIA course, “Water Vapor<br />

Migration 101,” contained an error (page<br />

56). The correct text reads: “For typical interior<br />

environments in cold climates, water<br />

vapor fl ow is primarily from the interior to<br />

the exterior for most of the year.” Thanks<br />

to Stephen Werry for pointing this out. The<br />

editors regret the error.<br />

Now you can be as colorful with your grout color choices.<br />

Available in over 6000 grout colors.<br />

Watch a brief video<br />

on PERMACOLOR Select!<br />

LIFETIME *<br />

Warranty<br />

EQUIPPED WITH<br />

STONETECH ®<br />

SEALER<br />

TECHNOLOGY<br />

^<br />

Equipped with<br />

Anti-Microbial Technology<br />

With PERMACOLOR ® Select<br />

ANYCOLOR , we can match your<br />

grout to over 6000 colors<br />

available in the Benjamin Moore ®†<br />

and Sherwin-Williams ®† palettes.<br />

*<br />

See Data Sheet 230.99 for complete warranty information. ^When mixed with PERMACOLOR® Select Base. † Sherwin-Williams and Benjamin Moore have no involvement with this program.<br />

A-6158-0416 ©2016 LATICRETE International, Inc. All trademarks shown are the intellectual properties of their respective owners.<br />

Never needs sealing – equipped with<br />

STONETECH ® Sealer Technology<br />

Also available in 80 stocked colors, including all 40<br />

LATICRETE ® colors and the top selling competitor colors<br />

Vibrant consistent color<br />

www.laticrete.com l 1.800.243.4788<br />

Circle 763<br />

18 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

Circle 764

ON THE<br />

drawing board<br />

BY MICHAEL CHAMERNIK, ASSOCIATE EDITOR<br />

1<br />

2<br />

3<br />

1<br />

AQUARIUM<br />

OF THE PACIFIC UNVEILS<br />

A WHALE OF A PROJECT IN LONG BEACH<br />

The Aquarium of the Pacifi c’s new Pacifi c Visions wing in Long<br />

Beach, Calif., will have a façade made of 800 light-diffusing glass<br />

panels that changes colors throughout the day. The panels,<br />

which total 18,000 sf, also will act as a ventilated rainscreen. Best<br />

of all, when the light hits the aquarium wing’s smooth contours<br />

just right, it will look, as Shakespeare’s Polonius once said, “very<br />

like a whale.” EHDD designed the addition, which features a 300-<br />

seat theater with a 32x130-foot screen, curved in a 180-degree<br />

arc. The wing will have a spacious front plaza that doubles as<br />

a community gathering space, a 6,000-sf exhibit gallery with<br />

live animals and interactive displays, and an art gallery. The $53<br />

million development is the fi nal phase of the aquarium’s campus<br />

master plan.<br />

2<br />

WEST<br />

PALM BEACH’S ‘MUSEUM IN A GARDEN’<br />

WILL EMPHASIZE OUTDOOR GATHERING SPOTS<br />

<strong>Construction</strong> is moving along on an expansion to a museum that<br />

holds 7,000+ pieces of art, including works from Vincent van<br />

Gogh and Edgar Degas. Foster + Partners designed the new<br />

West Wing for the Norton Museum of Art, West Palm Beach,<br />

Fla. The fi rm calls the concept a “museum in a garden.” Outside<br />

the building, 20,000 sf of lawns and plantings will replace a<br />

parking lot; a 9,000-sf event lawn will be available for parties.<br />

Other renovations: 12,000 sf of new gallery space, a 210-seat<br />

auditorium, and a family gallery, which will have a 150-foot-long<br />

colonnade with large windows that look out onto the gardens.<br />

A 3,600-sf, 43-foot-tall great hall will serve as a gathering spot<br />

at the center of the building. The <strong>Building</strong> Team: CBT (executive<br />

architect), EDSA (landscape), and Gilbane <strong>Building</strong> Co. (GC).<br />

20 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

3 4<br />

3COMMUNAL SPACES DRIVE DESIGN OF<br />

HARVARD’S NEW CAMPUS CENTER<br />

The Richard A. and Susan F. Smith Campus Center at Harvard<br />

University will have common spaces galore. The university<br />

stresses open areas, believing that they help improve students’<br />

intellectual, cultural, and social experiences. The building, to be<br />

situated at the center of the campus, will have a multipurpose<br />

indoor gathering space with room for exhibitions, retail,<br />

food services, studying, and performances. New gardens,<br />

landscaping, and plazas are planned for the site. On the<br />

<strong>Building</strong> Team: Hopkins Architects (design architect), Bruner/<br />

Cott (executive architect), Simpson Gumpertz & Heger (SE),<br />

Michael Van Valkenburgh Associates (landscape design), and<br />

Faithful+Gould (PM).<br />

4<br />

HUNTSVILLE’S<br />

BOTANICAL GARDEN<br />

STARTS WORK ON $13M WELCOME CENTER<br />

The Huntsville (Ala.) Botanical Garden is adding a $13 million,<br />

30,000-sf Guest Welcome Center that is designed to resemble<br />

a traditional Southern-style home. Due to open next year, the<br />

center will consist of three rental facilities: a grand hall that can<br />

accommodate up to 350 guests, a more casual carriage house<br />

for 200 or so guests, and a glass conservatory for up to 40<br />

guests. It will include a 3,500-sf check-in area, as well as a café<br />

and gift shop. The <strong>Building</strong> Team: Matheny Goldmon (architect),<br />

4Site Inc. (CE), PEC Structural Engineering, and SSOE Group<br />

(MEP). Turner <strong>Construction</strong> Company provided preconstruction<br />

services.<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 21

It’s not just any yellow,<br />

it’s precisely the yellow you were looking for.<br />

Riverton Community Housing<br />

Devon Lundy of UrbanWorks Architecture, LLC<br />

Minneapolis, MN<br />

In addition to several thousand<br />

color options, Nichiha’s Architectural Wall Panels are also engineered to deliver<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Discover Nichiha’s quick clip installation, drained<br />

and back-ventilated rainscreen system<br />

nichiha.com 866.424.4421<br />

©2016 Nichiha USA, Inc.<br />

Circle 765

5<br />

Who are<br />

we to tell<br />

you what<br />

color to<br />

make your<br />

building?<br />

5<br />

SKYSCRAPER<br />

USES NOVEL STRUCTURAL SYSTEM<br />

TO SUSPEND OVER NEIGHBORING BUILDING<br />

In planning Salt Lake City’s newest tower, 111 Main, architect Skidmore, Owings &<br />

Merrill had to solve a natty problem: how to suspend a portion of the building over<br />

an adjacent structure. The 387-foot-tall building shares a contiguous parcel with the<br />

new George S. and Dolores Doré Eccles Theater, which overlaps on the lower four<br />

stories and basement level of the tower. SOM designed the penthouse roof level with<br />

a balanced two-way steel hat truss system that supports the tower’s 18 perimeter<br />

columns. The central reinforced concrete core walls provide the only connection of the<br />

tower to its foundation and resist all gravity loads, as well as wind and seismic vertical<br />

and lateral loads. Also on the <strong>Building</strong> Team: City Creek Reserve (developer) and<br />

Oakland <strong>Construction</strong> (GC).<br />

6<br />

EVENTS<br />

6<br />

CENTER AND ARENA ACCOMMODATES BOOM<br />

IN ENROLLMENT AT CALIFORNIA BAPTIST UNIVERSITY<br />

Enrollment at California Baptist University in Riverside has more than doubled in the<br />

past six years, to 8,540 students. The school needs more space, so it’s building<br />

a new events center and arena. The 153,000-sf venue will have 5,050 seats, with<br />

room to expand to 6,000+. The two-level multiuse facility will be the school’s largest<br />

indoor gathering space, and will host athletic events, orientations, commencement<br />

ceremonies, and chapel programs. The plan also includes locker rooms, athletics<br />

suites, and offi ces. SVA Architects and HOK designed the facility in the Mission Revival<br />

style that is prevalent on campus. The $73 million project is expected to be completed<br />

by April 2017. Sundt <strong>Construction</strong> is the GC.<br />

www.BDCuniversity.com<br />

So, tell us what<br />

color you want.<br />

Nichiha’s Color Xpressions<br />

system lets you transform<br />

virtually any standard color<br />

of paint into a fully-functioning<br />

rainscreen system. With<br />

Illumination Architectural Wall<br />

Panels and Color Xpressions,<br />

there’s no need to compromise<br />

on color or performance.<br />

Find your color and spec it<br />

at itsyourcolor.com<br />

Circle 766<br />

nichiha.com 866.424.4421<br />

©2016 Nichiha USA, Inc.

Outperform rigid board<br />

insulation on every level.<br />

Including price.<br />

Discover a better option than rigid foam board, with Icynene ProSeal spray foam<br />

insulation. From cost, performance, to design capabilities, it’s the superior choice.<br />

Find out more at icynene.com/whyproseal.<br />

The Evolution of Insulation<br />

icynene.com/whyproseal<br />

Odyssey Elementary School by VCBO Architecture<br />

Photographer: Scot Zimmerman<br />

Circle 767

19 TH ANNUAL<br />

BUILDING TEAM<br />

AWARDS<br />

Twelve building projects<br />

that represent the best in<br />

AEC team collaboration.<br />

Illuminated by daylight<br />

that floods through its<br />

oculus and reflector,<br />

the central atrium at the<br />

Chicago Public Library’s<br />

new Chinatown Branch<br />

functions as a lounge,<br />

exhibition, and prefunction<br />

space.<br />

PLATINUM<br />

26 Onondaga Lakeview Amphitheater<br />

30 Fulton Center<br />

GOLD<br />

34 Chicago Public Library,<br />

Chinatown Branch<br />

38 The Tower at PNC Plaza<br />

SILVER<br />

40 CHS Field<br />

42 LA MTA Division 13 Bus Operations<br />

& Maintenance Facility<br />

BRONZE<br />

44 Ravenswood Family Health Center<br />

48 275 Wyman Street<br />

50 New York City Police<br />

Training Academy<br />

52 John J. Hemmingson Center,<br />

Gonzaga University<br />

HONORABLE MENTION<br />

54 UCSD Medical Center Central Plant<br />

56 3737 Chestnut<br />

58 Meet the judges<br />

JON MILLER, HEDRICH BLESSING<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 25

The Onondaga Lakeview<br />

Amphitheater, near Syracuse,<br />

N.Y., seats 17,500. It<br />

is the first phase of a more<br />

extensive revitalization initiative<br />

that will benefit two<br />

nearby communities.<br />

a performing arts<br />

center extraordinaire<br />

REVIVES A ONCE-TOXIC LAKEFRONT SITE<br />

Early coordination, prefabrication, and judicious value engineering contributed<br />

to the accelerated completion of this Upstate New York design-build project.<br />

26 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

uilding<br />

team<br />

awards<br />

2016<br />

PLATINUM AWARD<br />

DAVID REVETTE/REVETTE STUDIO<br />

In September 2014, New York Governor<br />

Andrew Cuomo signed legislation<br />

that allowed for the construction of a<br />

new performing arts venue on Onondaga<br />

Lake, about fi ve miles northwest of<br />

Syracuse.<br />

One year later, on September 3, 2015,<br />

the Onondaga Lakeview Amphitheater, a<br />

gleaming, 74,000-sf outdoor event complex<br />

with a seating capacity of 17,500,<br />

held its fi rst performance, featuring country<br />

singer Miranda Lambert. This summer, the<br />

facility will host 25 concerts.<br />

The state-of-the-art amphitheater transformed<br />

an EPA-designated Superfund site<br />

into a destination that honors its surroundings<br />

and encourages a celebration of arts<br />

and culture. The facility was the fi rst step<br />

in a larger community revitalization initiative<br />

along the lake’s western shore, involving<br />

the village of Solvay and the town of<br />

Geddes. It’s the only vertical design-build<br />

contract that the Empire State has let go<br />

forward.<br />

With an accelerated construction period,<br />

early and constant <strong>Building</strong> Team collaboration<br />

and cooperation were essential<br />

for the on-time and on-budget completion<br />

of this project. That collaboration began<br />

even before the county awarded the<br />

contract, with the structural design team<br />

working at risk to deliver the steel mill<br />

order only eight days after the contract<br />

was signed.<br />

Project planning and early identifi cation<br />

of subcontractors were critical to the success<br />

of this project. BIM played a sem inal<br />

role in delivering accurate documents on<br />

time. The integration of structural analysis<br />

software (ETABS) and modeling software<br />

(Revit Structure) quantitatively reduced the<br />

drawing production time, while increasing<br />

the accuracy of the information.<br />

“The <strong>Building</strong> Team did a terrifi c job of<br />

melding with a stunning landscape, but<br />

not overpowering it,” said awards judge<br />

Beau Sanders, PE, SE, Associate and<br />

Project Manager with engineering fi rm<br />

Graef. “It’s apparent that they thought<br />

through all the details, from design to<br />

construction. It’s a beautiful project that is<br />

not just for concertgoers, but for the whole<br />

community to enjoy and appreciate.”<br />

BLENDING IN WITH THE<br />

NATURAL LANDSCAPE<br />

The site consists of capped industrial<br />

waste. Any attempt to remove it could<br />

have resulted in further environmental<br />

damage. To avoid this, the design minimized<br />

the need for signifi cant cut and fi ll.<br />

Gilbane <strong>Building</strong> Company, the general<br />

contractor, mandated 40-hour Hazardous<br />

Waste Operations and Emergency<br />

Response training for anyone who would<br />

be working in potential areas of contamination.<br />

Gilbane also calibrated on a daily<br />

basis air-monitoring workstations that<br />

tracked contaminants on site or dissipating<br />

outside the work perimeter.<br />

Over 80,000 cubic yards of existing<br />

industrial waste were excavated and relocated<br />

to an onsite staging area. Another<br />

130,000 cubic yards of infi ll were brought<br />

in. More than 230 steel piles were driven<br />

to support the amphitheater’s back-ofhouse<br />

and pavilion structures.<br />

To deliver power, water, and other<br />

services to the facility, Gilbane drilled horizontally<br />

underneath Interstate 690 without<br />

needing to close down any lanes.<br />

The building’s design and orientation<br />

take advantage of the natural land<br />

contours and lake views. So integrated is<br />

the building’s design with its environment<br />

that a bicycle path which circles the lake<br />

passes directly through the pavilion, underscoring<br />

the site’s function as a county<br />

park. The covered pavilion’s fascia, when<br />

backlit, correlates to the natural light at<br />

dusk on the lake waves.<br />

The pavilion façade has 198 steelsupported,<br />

20-foot-high mesh panels that,<br />

when illuminated, play off the natural landscape<br />

beyond the amphitheater’s lawn.<br />

The fascia allows the transmission of<br />

highly amplifi ed sound from speakers at<br />

the stage and from behind the mesh to<br />

reach patrons with clarity. The rear lawn<br />

loudspeakers—12,500 of the amphitheater’s<br />

seating capacity is on an 80,000-sf<br />

lawn—are positioned directly behind the<br />

unobtrusive open mesh system, which is<br />

not only designed for sound integrity but<br />

also to provide a clean look at the rear<br />

skirt of the shed roof.<br />

Westlake Reed Leskosky’s in-house<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 27

uilding<br />

team<br />

awards<br />

2016<br />

PLATINUM AWARD<br />

The performing arts<br />

center was designed to<br />

blend in with its surroundings.<br />

A bicycle path that<br />

encircles the nearby lake<br />

runs through the facility.<br />

The backlit fascia is meant<br />

to match the natural light<br />

at dusk. Illuminated panels<br />

mimic the local landscape.<br />

DAVID REVETTE/REVETTE STUDIO<br />

theatrical and A/V specialists conducted<br />

thorough reviews of the amphitheater’s<br />

audiovisual requirements throughout the<br />

design and construction stages. Acoustical<br />

consultant Jaffe Holden assisted on the<br />

sound parameters of the design.<br />

The covered area of<br />

the amphitheater is<br />

supported by eight<br />

trusses (each weighing<br />

84,000 pounds)<br />

with four unique end<br />

conditions to achieve<br />

a maximum span of<br />

190 feet. The covered<br />

area is designed to<br />

provide patrons with<br />

unobstructed views of<br />

the lake. Acoustically<br />

transparent fascia<br />

allows sound from<br />

the stage to reach the<br />

audience on the lawn<br />

with clarity.<br />

VALUE ENGINEERING<br />

BEATS THE BUDGET LIMITS<br />

The amphitheater’s original program was<br />

valued at over $80 million, but the taxpayerfunded<br />

contract was less than $50 million.<br />

Smart engineering and construction were<br />

imperative to meet the county’s goals for<br />

the building.<br />

The signature feature of the amphitheater<br />

is the pavilion canopy, which covers more<br />

than 5,000 seats and provides unobstructed<br />

views of Lake Onondaga. The design<br />

called for maintaining bolted connections in<br />

the fi eld, which allowed for swift erection to<br />

meet the project’s schedule.<br />

The pavilion’s roof design utilizes eight<br />

trusses with four unique end conditions;<br />

this system achieves a maximum span of<br />

190 feet. Each truss weighs over 84,000<br />

pounds and is supported by the steel at the<br />

stage and columns infi lled with 10,000-psi<br />

concrete. Ninety percent of the trusses are<br />

identical in their confi guration.<br />

Gilbane prefabricated the trusses off site.<br />

They arrived at the site in no more than<br />

three sections and were set in movable<br />

cradles for fi nal connection detailing. Completed<br />

trusses were erected in one pick,<br />

using a pair of cranes in tandem.<br />

Systems and spaces were shifted to<br />

save money. Relocating the fourth-fl oor<br />

Event Center to a lower level provides<br />

panoramic views of the lake and eliminated<br />

the need for two elevators. The<br />

third-fl oor mechanical room was moved as<br />

well, allowing the pavilion to be reduced in<br />

size from four stories to two, which saved<br />

considerably on costs.<br />

An average of 230 tradespeople were<br />

on site every day during construction. The<br />

project exceeded 200,000 total workerhours<br />

without a single recordable or losttime<br />

incident.<br />

—John Caulfi eld<br />

PROJECT SUMMARY<br />

PLATINUM AWARD<br />

Onondaga Lakeview Amphitheater<br />

Geddes, N.Y.<br />

BUILDING TEAM<br />

Submitting firm: Gilbane <strong>Building</strong> Company (GC);<br />

Westlake Reed Leskosky (lead designer, executive<br />

architect, interior design, SE/MEP engineer)<br />

Owner: Onondaga County, N.Y.<br />

Architect: C&S Companies<br />

Structural: QPK <strong>Design</strong><br />

Site/civil: Savin Engineers<br />

Acoustics: Jaffe Holden<br />

GENERAL INFORMATION<br />

Project size: 74,000 sf<br />

<strong>Construction</strong> cost: $49.5 million<br />

<strong>Construction</strong> period: January 2015 to August 2015<br />

Delivery method: <strong>Design</strong>-build<br />

28 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

FOCUSED<br />

ON PERFORMANCE<br />

Grace <strong>Construction</strong> Products, the brand you know and trust,<br />

has a new name — GCP Applied Technologies.<br />

Our history of product performance is taking us into the future. A<br />

leader in the construction industry for generations, our focus on<br />

product performance helps you build it right the first time with<br />

products like Preprufe ® , Bituthene ® and Perm-A-Barrier ® .<br />

Our Preprufe SCS ® is the only system specifically<br />

engineered for waterproofing shotcrete.<br />

Another way GCP Applied Technologies is leading<br />

the way in the construction industry.<br />

You build a more beautiful world.<br />

We help you protect it.<br />

gcpat.com/performance<br />

Learn more about GCP Applied Technologies’ history<br />

of performance & innovation — visit us online.<br />

PICTURED:<br />

Zakim Bridge, Boston, USA<br />

The visual piedmont of Boston’s multi-billion dollar<br />

“Big Dig”, this is the widest asymmetrical cable-stayed<br />

bridge in the world and the first in the United States.<br />

THE BRAND YOU KNOW AND TRUST HAS A NEW NAME<br />

©2016 GCP Applied Technologies Inc.<br />

Circle 768

The interior of Fulton Center is constructed<br />

of architecturally exposed structural steel,<br />

glass storefronts, stainless steel panels,<br />

GFRC column covers and ceilings, granite<br />

flooring, and a decorative cable net structure<br />

in the oculus. Spiral stairs, 15 ADAcompliant<br />

elevators, and 10 escalators<br />

convey 300,000 passengers a day between<br />

nine train lines. A 350-foot tunnel connects<br />

to train lines at the World Trade Center.<br />

© HALLIE TSAI / GRIMSHAW<br />

NYC subway station<br />

LIGHTS THE WAY FOR 300,000 RIDERS A DAY<br />

Fulton Center, which handles 85% of the riders coming to Lower Manhattan, is like<br />

no other station in the city’s vast underground transit web—and that’s a good thing.<br />

30 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

uilding<br />

team<br />

awards<br />

2016<br />

PLATINUM AWARD<br />

JON ORTNER / ORTNER PHOTOGRAPHY<br />

The 53-foot-diameter oculus looms over<br />

the grand atrium. Suspended under tension<br />

within the conical atrium is the “Sky<br />

Reflector-Net,” by James Carpenter <strong>Design</strong><br />

Associates, Grimshaw Architects, and<br />

Arup. The artwork is composed of 112 tensioned<br />

cables, 224 high-strength rods, and<br />

nearly 10,000 stainless steel components;<br />

952 aluminum panels distribute sunlight<br />

down to the lowest levels of the station.<br />

The Metropolitan Transit Authority’s<br />

new Fulton Center transit station<br />

must seem like a miracle to the<br />

300,000 subway riders who trod<br />

its polished granite fl oors every workday.<br />

Instead of the usual stultifying dankness of<br />

the city’s 421 other subway stops, Fulton<br />

Center offers even the most jaded New<br />

Yorker that rarest of gifts: sunlight, glorious<br />

sunlight! Thanks to a 120-foot-high oculus,<br />

the station overfl ows with natural light during<br />

the day; at night, weather permitting,<br />

you can look up and catch a glimpse of the<br />

galaxies. What a treat!<br />

This lovely bijou—the MTA calls it the<br />

“Jewel of Lower Manhattan”—did come at<br />

a price: $1.4 billion, not to mention more<br />

than a decade of planning, design, and<br />

construction. But<br />

that’s chicken feed<br />

compared to the $15<br />

billion for the World<br />

Trade Center PATH<br />

station, which opened<br />

March 3 after nearly a<br />

dozen years of construction. Eat your heart<br />

out, Señor Calatrava!<br />

The centerpiece of the station is the oculus.<br />

Not only does it fl ood the transit hub<br />

with daylight, the frustum-shaped dome<br />

also acts as a reservoir for the heat that<br />

rises from the subway lines; this reduces<br />

the load on the air-conditioning system.<br />

(The project earned LEED Silver status.)<br />

Steel cables descending from the skylight<br />

are adorned with 952 diamond-shaped<br />

‘When public investment yields such magnifi cent<br />

results, the rewards reverberate for generations.’<br />

—Peter Ousley, BTA Awards Juror<br />

aluminum panels. This giant art installation<br />

refl ects daylight downward and through the<br />

building. Behind the netting are three levels<br />

of retail space, totaling 66,000 sf.<br />

To detail and construct the oculus, the<br />

<strong>Building</strong> Team—led by Plaza Schiavone<br />

Joint Venture (CM), Grimshaw Architects,<br />

and Arup (SE/MEP)—created 3D models of<br />

the exterior stainless steel skin, developed<br />

a panelized pattern that mimicked the fi nal<br />

geometry of the dome, and incorporated the<br />

www.BDCuniversity.com BUILDING DESIGN+CONSTRUCTION MAY 2016 31

uilding<br />

team<br />

awards<br />

2016<br />

PLATINUM AWARD<br />

© JAMES EWING / OTTO<br />

JON ORTNER / ORTNER PHOTOGRAPHY<br />

© JAMES EWING / OTTO<br />

Fulton Center (left) is the city’s only transit hub with all-digital signage—60 screens.<br />

A view up to the oculus from the main floor (above left). The Corbin <strong>Building</strong><br />

(above), a 125-year-old brownstone landmark that abuts the site, was restored.<br />

‘I like the way Fulton Center pulls people into the<br />

subway system in a festive and welcoming way.’<br />

—Gary B. Keclik, BTA Awards Juror<br />

© JAMES EWING / OTTO<br />

panels, the structural supports, and the internal<br />

and external catwalks into the design.<br />

The panels were then prefabricated off site.<br />

BUILDING TEAM FOCUSES<br />

ON QUALITY AND SAFETY<br />

Maintaining the highest level of quality was<br />

central to the project. Subcontractors were<br />

given performance-based specifi cations<br />

that demanded a mockup for every critical<br />

aspect of the work. The construction<br />

manager’s Quality Control Team required<br />

each discipline to develop a “quality work<br />

plan” that included a rigorous inspection<br />

schedule. The team performed quality<br />

audits in Asia, Europe, and the U.S. Pacifi c<br />

Northwest to validate manufacturers’ quality<br />

programs and assure that materials met<br />

pre-established quality standards.<br />

The 300,000 daily<br />

riders who use the nine<br />

subway lines that feed<br />

into Fulton Center<br />

represent 85% of all downtown subway<br />

users. Keeping them safe during construction<br />

was of paramount importance to the<br />

<strong>Building</strong> Team. Plaza Schiavone brought in<br />

a full-time safety site coordinator (and sometimes<br />

two) to oversee a comprehensive<br />

safety plan. The steel erector had to provide<br />

fall protection at six feet. All trades were<br />

required to obtain a ladder permit on a daily<br />

basis to avoid any hazards in the work area.<br />

After 966,353 worker-hours, the lost-time<br />

accident rate on the project was 2.25.<br />

Fulton Center represents “a shift in the<br />

perception of the mass transit system<br />

and support facilities, while adding an<br />

attractive and inviting design to the urban<br />

streetscape,” said awards judge Gary<br />

B. Keclik, AIA, CSI, LEED AP, Green<br />

Globes Assessor, Keclik Associates Ltd.<br />

“It provides a welcoming way to make the<br />

subway experience more memorable for<br />

visitors and riders that’s vastly different<br />

from the traditional walk down steps into a<br />

dark tunnel.”<br />

—Robert Cassidy<br />

PROJECT SUMMARY<br />

PLATINUM AWARD<br />

Fulton Center<br />

New York, N.Y.<br />

BUILDING TEAM<br />

Submitting firm: Plaza <strong>Construction</strong> (CM)<br />

Owner: Metropolitan Transit Authority<br />

Architect: Grimshaw Architects<br />

Structural/MEP: Arup<br />

Electrical: Woodward Engineering Inc.<br />

GC: Plaza Schiavone Joint Venture<br />

GENERAL INFORMATION<br />

Project size: 120,000 sf<br />

<strong>Construction</strong> cost: $1.4 billion<br />

<strong>Construction</strong> period: 2004 (first award) to<br />

January 2015<br />

Delivery method: <strong>Construction</strong> manager<br />

32 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

GO AHEAD, THROW US A CURVE.<br />

TILTED RADIUS WALL<br />

CUSTOM ANGLED HORIZONTALS<br />

COMPLEX MITERED FRAMING<br />

WINDOWS • STOREFRONTS • CURTAIN WALLS • ENTRANCES<br />

Extremely complex project. Extra-tight timeline. Enter EFCO.<br />

For this defense contractor’s state-of-the-art office building, we used 3D<br />

software technology to design the framing system and to determine the<br />

size, radius and angle of the building’s curved glass. And we created<br />

custom angled horizontals, allowing the exterior covers to remain parallel<br />

to the ground. The result? A building delivered on time. On budget. And<br />

precisely on target with the architect’s design intent. Mission accomplished.<br />

BAE Systems • Sterling Heights, MI • Architect: Smith Group<br />

© 2016 EFCO Corporation<br />

Circle 769<br />

COMMERCIAL<br />

SOLUTIONS<br />

SEE WHAT WE CAN DO FOR YOU.<br />

pecsBDC.com • 800.591.7777<br />

Visit us at the 2016 AIA National Convention,<br />

Booth 4101 and 42011LL.

uilding<br />

team<br />

awards<br />

2016<br />

GOLD AWARD<br />

Vertical fins provide<br />

essential shading for the<br />

pebble-shaped library,<br />

which is wrapped in glass<br />

curtain wall to maximize<br />

views and natural light.<br />

JON MILLER, HEDRICH BLESSING<br />

chinatown library<br />

UNITES AND SERVES TWO EMERGING<br />

CHICAGO NEIGHBORHOODS<br />

One of Chicago’s most signifi -<br />

cant architectural additions<br />

in 2015 was not a booming<br />

high-rise at the center of<br />

the Loop or a grand new park along the<br />

lakefront. It was a small, pebble-shaped,<br />

glass-and-steel library that serves as the<br />

new beating heart of two neighborhoods<br />

on the city’s South Side.<br />

The 16,000-sf Chinatown Branch<br />

Library is strategically placed at the nexus<br />

of Chicago’s historic southern and emerging<br />

northern Chinatown neighborhoods—<br />

the intersection of Archer Avenue and<br />

Wentworth Avenue—with the<br />

goal of uniting the communities<br />

and serving as a catalyst<br />

for the developing area. It<br />

provides much needed public<br />

spaces—indoor and out—for<br />

the neighborhoods, and<br />

makes a bold architectural<br />

statement in an area that is<br />

rich in tradition.<br />

The library’s ovate form makes the<br />

most of the prominent, yet oddly shaped<br />

site. It adheres to Feng Shui principles by<br />

matching the existing alignments of the<br />

‘This is a beautiful jewel, built by utilizing<br />

tools and building systems readily<br />

available to the industry.’<br />

—Bill Kline, BTA Awards Juror<br />

adjacent streets without creating aggressive<br />

corners, and is designed and sited to<br />

anticipate a future realignment of Wentworth<br />

Avenue that would encroach onto<br />

the site.<br />

To reinforce the concept of the library<br />

34 MAY 2016 BUILDING DESIGN+CONSTRUCTION www.BDCnetwork.com

Rain or shine,<br />

STPE technology performs.<br />

DuPont Tyvek ® Fluid Applied Weather Barrier with silyl-terminated<br />

polyether (STPE) technology offers the perfect combination of building<br />

and material science. Unlike many conventional water-based acrylic weather<br />

barriers, our high-solids formulation won’t wash off. Plus, it features<br />

exceptional elongation and recovery, no shrinkage or cracking during curing<br />

and the ideal perm rating for dependable long-term performance.<br />

Tough. Tested. Proven.<br />

That’s Tyvek ® Fluid Applied Weather Barrier—only from DuPont.<br />

Read the case studies at fluidapplied.tyvek.com<br />

FOR<br />

GREATER<br />

GOOD TM<br />

Copyright © 2016 DuPont. All rights reserved. The DuPont Oval Logo, DuPont , For Greater Good and Tyvek ® are registered trademarks or trademarks of E.I. du Pont de Nemours and Company or its affiliates.<br />

Circle 790

uilding<br />

team<br />

awards<br />

2016<br />

GOLD AWARD<br />

Furnishings and book storage, including<br />

eye-height shelving, are arranged to<br />

accommodate multiple uses, informal<br />

collaborative areas, and reading options.<br />

JON MILLER, HEDRICH BLESSING<br />

JON MILLER, HEDRICH BLESSING<br />

The interior spaces are situated around the<br />

library’s central atrium, which functions as a<br />

lounge, exhibition, and pre-function space.<br />

as a civic, educational, and social hub, the<br />

<strong>Building</strong> Team wrapped the structure in an<br />

ultra-transparent glass curtain wall, which<br />

extends the full height of the two-story<br />

structure. With minimal interior walls, the<br />

library offers patrons panoramic views of<br />

the surrounding neighborhood. Likewise,<br />

passersby can see deep into the fi rst fl oor<br />

of the library, especially at night, when the<br />

building glows like a beacon.<br />

The interior spaces are situated around<br />

the library’s central atrium, which functions<br />

as a lounge, exhibition, and pre-function<br />

space, and features a curved staircase and<br />

a single skylight oculus and refl ector above.<br />

Directly behind the staircase is a glasswalled,<br />

multipurpose community meeting<br />

room that is used for lectures, tutoring,<br />

quiet reading, lounge space, musical<br />

rehearsal, and special events. Acoustical<br />